What Is a Drayage in the Context of Trucking

What is drayage in trucking?

Drayage, in the context of trucking and logistics, refers to the transportation of goods over a short distance, often within the same metropolitan area or between a seaport/rail ramp and an inland destination. This specialized trucking service plays a crucial role in the supply chain by facilitating the movement of cargo containers between different modes of transportation, such as ships, trains, and trucks.

Characteristics of Drayage Trucking:

– Short-haul trips, usually less than 100 miles

– Focuses on the first and last mile of the supply chain

– Involves the pickup and delivery of intermodal containers

– Requires specialized equipment, such as chassis and container trailers

Drayage trucking companies, also known as drayage carriers or intermodal carriers, specialize in providing these short-distance transportation services. They work closely with shipping lines, freight forwarders, and intermodal marketing companies (IMCs) to ensure the smooth flow of cargo between different transportation nodes.

How does drayage fit into the overall supply chain?

Drayage plays a critical role in the overall supply chain by bridging the gap between different modes of transportation and facilitating the efficient movement of goods from origin to destination. It serves as a vital link in the intermodal transportation network, connecting seaports, rail terminals, and inland distribution centers.

The Role of Drayage in the Supply Chain:

1. Port Drayage: Transporting containers between seaports and nearby rail terminals, warehouses, or distribution centers.

2. Rail Drayage: Moving containers between rail terminals and local warehouses or distribution centers.

3. Cross-Docking: Transferring cargo from one mode of transportation to another, such as from a ship to a truck or from a truck to a train.

4. Last-Mile Delivery: Delivering containers to their final destination, such as a retail store or a manufacturing facility.

By providing these essential services, drayage helps to streamline the supply chain, reduce transit times, and minimize the risk of delays or disruptions. It also enables shippers to take advantage of the benefits of intermodal transportation, such as cost savings, reduced environmental impact, and increased flexibility.

| Supply Chain Stage | Drayage Role |

|---|---|

| Port Operations | Moving containers from ships to rail or truck terminals |

| Rail Transportation | Transferring containers between rail terminals and local warehouses |

| Warehousing & Distribution | Delivering containers to distribution centers or cross-docking facilities |

| Last-Mile Delivery | Transporting containers to final destinations, such as retail stores or factories |

What are the different types of drayage services?

Drayage services can be categorized based on the specific transportation needs and the locations involved. Understanding the different types of drayage services is essential for shippers and logistics professionals to optimize their supply chain operations.

Types of Drayage Services:

1. Intra-Carrier Drayage: This type of drayage involves the movement of containers between different terminals or facilities operated by the same carrier, such as a shipping line or a rail company.

2. Inter-Carrier Drayage: Inter-carrier drayage refers to the transportation of containers between terminals or facilities operated by different carriers, such as moving a container from a ship to a rail terminal operated by another company.

3. Door-to-Door Drayage: This service involves the pickup of a container from a shipper’s location and its delivery to the final destination, such as a consignee’s warehouse or a retail store.

4. Expedited Drayage: Expedited drayage services are designed for time-sensitive shipments that require faster transit times and prioritized handling.

5. Hazardous Materials Drayage: This specialized drayage service involves the transportation of containers carrying hazardous materials, which requires compliance with strict regulations and safety protocols.

6. Overweight/Oversized Drayage: Drayage carriers that offer this service are equipped to handle containers that exceed standard weight or size limits, which may require special permits and routing.

Factors to Consider When Choosing a Drayage Service:

– Proximity to ports, rail terminals, and key distribution centers

– Fleet size and availability of specialized equipment

– Experience and expertise in handling specific types of cargo

– Compliance with safety and security regulations

– Technology and tracking capabilities

– Pricing and contract terms

By selecting the appropriate type of drayage service and partnering with experienced drayage carriers, shippers can optimize their supply chain efficiency, reduce costs, and improve customer satisfaction.

What equipment is used in drayage operations?

Drayage operations rely on specialized equipment to efficiently transport cargo containers between different modes of transportation and locations. The type of equipment used depends on factors such as the size and weight of the containers, the distance to be traveled, and the specific requirements of the cargo.

Essential Equipment in Drayage Operations:

1. Chassis: A chassis is a wheeled steel frame designed to securely hold and transport intermodal containers. Drayage carriers use chassis to move containers over the road between ports, rail terminals, warehouses, and other locations.

2. Tractors: Drayage tractors, also known as yard trucks or terminal tractors, are specialized vehicles used to move chassis and containers within port or terminal facilities. These tractors are designed for short-distance, low-speed operations and feature a fifth-wheel coupling for easy attachment to chassis.

3. Container Trailers: Container trailers, also called container chassis, are specifically designed to carry intermodal containers over longer distances on highways. These trailers have twist locks to secure the containers in place during transportation.

4. Genset: A genset, or generator set, is a portable power unit attached to a chassis or trailer to provide electrical power to refrigerated containers (reefers) during transport. This ensures that temperature-sensitive cargo remains at the required temperature throughout the drayage process.

5. Reach Stackers: Reach stackers are versatile lifting vehicles used in port and terminal operations to handle and stack containers. They can be used to load and unload containers from chassis, stack containers in storage areas, and transfer containers between different modes of transportation.

| Equipment | Purpose |

|---|---|

| Chassis | Transporting containers over the road |

| Tractors | Moving chassis and containers within port or terminal facilities |

| Container Trailers | Carrying containers over longer distances on highways |

| Genset | Providing power to refrigerated containers during transport |

| Reach Stackers | Handling and stacking containers in port and terminal operations |

Drayage carriers invest in modern, well-maintained equipment to ensure the safe and efficient transportation of cargo containers. They also train their drivers and operators to handle this specialized equipment effectively, adhering to safety regulations and industry best practices.

What challenges do drayage trucking companies face?

Drayage trucking companies play a vital role in the supply chain, but they also face numerous challenges that can impact their operations, profitability, and overall efficiency. Understanding these challenges is crucial for drayage carriers to develop strategies to overcome them and for shippers to appreciate the complexities involved in drayage services.

Key Challenges Faced by Drayage Trucking Companies:

1. Congestion and Delays at Ports: Port congestion, caused by factors such as increased cargo volumes, limited infrastructure, and inefficient processes, can lead to significant delays for drayage carriers. These delays result in longer wait times, reduced productivity, and increased costs.

2. Driver Shortage: The trucking industry, including drayage carriers, faces a chronic shortage of qualified drivers. Factors such as an aging workforce, high turnover rates, and a lack of interest among younger generations contribute to this challenge, making it difficult for drayage companies to maintain adequate staffing levels.

3. Regulatory Compliance: Drayage carriers must comply with a wide range of regulations, including safety standards, environmental regulations, and hours-of-service rules. Keeping up with changing regulations and ensuring compliance can be time-consuming and costly for drayage companies.

4. Equipment Availability and Maintenance: Drayage operations require specialized equipment, such as chassis and container trailers. The availability of this equipment can be limited, especially during peak seasons, leading to operational bottlenecks. Additionally, maintaining and repairing this equipment is costly and time-consuming.

5. Fluctuating Fuel Costs: Fuel is a significant expense for drayage carriers, and fluctuations in fuel prices can have a major impact on their operating costs and profitability. Drayage companies must develop strategies to manage fuel costs, such as implementing fuel surcharges or investing in more fuel-efficient vehicles.

6. Technology Adoption: Keeping up with the latest technology trends, such as transportation management systems (TMS), real-time tracking, and electronic logging devices (ELDs), can be challenging for drayage carriers. Investing in and implementing these technologies requires significant financial resources and staff training.

Overcoming Challenges in Drayage Trucking:

– Collaborating with ports and other stakeholders to address congestion and improve efficiency

– Implementing driver retention and recruitment programs to mitigate the driver shortage

– Staying informed about regulatory changes and developing compliance strategies

– Optimizing equipment utilization and maintenance processes

– Implementing fuel cost management strategies and exploring alternative fuel options

– Investing in technology and training to improve operational efficiency and customer service

By addressing these challenges proactively, drayage trucking companies can enhance their operations, reduce costs, and provide better service to their customers.

How is technology transforming drayage logistics?

Technology is revolutionizing the drayage logistics industry, enabling carriers to streamline operations, improve efficiency, and enhance customer service. By adopting cutting-edge technologies, drayage companies can overcome many of the challenges they face and position themselves for success in an increasingly competitive market.

Key Technologies Transforming Drayage Logistics:

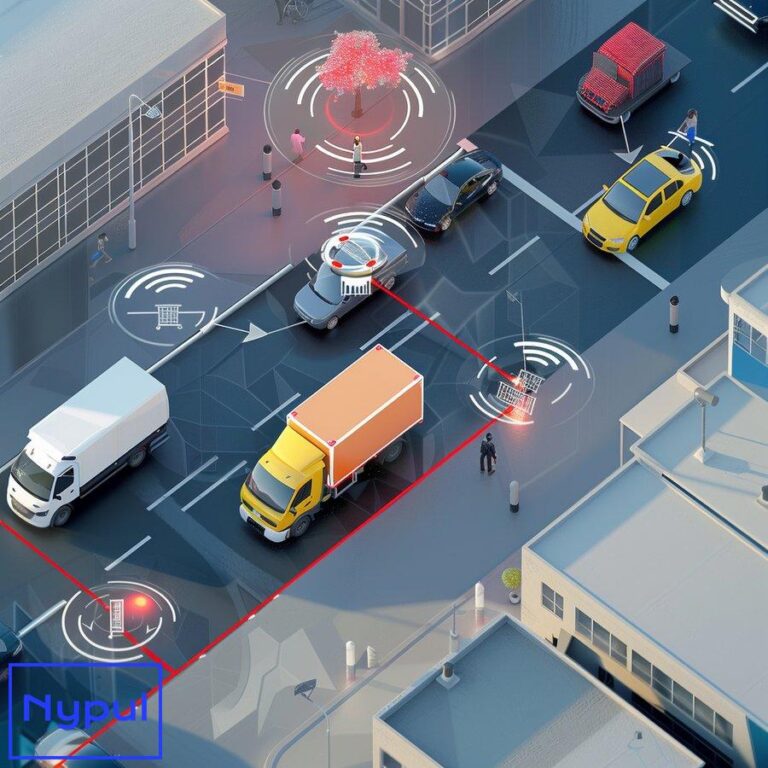

1. Transportation Management Systems (TMS): TMS software helps drayage carriers optimize route planning, dispatch operations, and resource utilization. These systems provide real-time visibility into shipment status, enabling better decision-making and improved communication with customers.

2. Real-Time Tracking and Visibility: GPS-based tracking systems and Internet of Things (IoT) devices allow drayage companies to monitor the location and status of their vehicles and cargo in real-time. This visibility helps carriers improve on-time delivery performance, reduce delays, and provide accurate ETAs to customers.

3. Electronic Logging Devices (ELDs): ELDs automatically record driver hours of service (HOS), ensuring compliance with regulations and reducing the administrative burden on drivers and dispatchers. These devices also provide valuable data insights that can be used to optimize driver performance and improve safety.

4. Automation and Robotics: Automated container handling equipment, such as automated guided vehicles (AGVs) and robotic cranes, are being deployed in ports and terminals to improve efficiency and reduce labor costs. These technologies can help drayage carriers reduce wait times and improve turnaround times at facilities.

5. Blockchain and Smart Contracts: Blockchain technology has the potential to revolutionize drayage logistics by enabling secure, transparent, and tamper-proof transactions between parties. Smart contracts can automate payment processes, reduce paperwork, and improve trust among stakeholders in the drayage ecosystem.

6. Data Analytics and Artificial Intelligence: Drayage companies can leverage data analytics and AI-powered tools to gain insights into their operations, predict demand patterns, and optimize decision-making. These technologies can help carriers identify bottlenecks, reduce costs, and improve customer service.

Benefits of Technology Adoption in Drayage Logistics:

– Improved operational efficiency and productivity

– Enhanced visibility and real-time tracking of shipments

– Reduced manual processes and paperwork

– Improved compliance with regulations and safety standards

– Better decision-making through data-driven insights

– Enhanced customer service and communication

| Technology | Benefits |

|---|---|

| Transportation Management Systems (TMS) | Optimized route planning, dispatch operations, and resource utilization |

| Real-Time Tracking and Visibility | Improved on-time delivery performance, reduced delays, and accurate ETAs |

| Electronic Logging Devices (ELDs) | Ensured compliance with regulations and reduced administrative burden |

| Automation and Robotics | Improved efficiency and reduced labor costs in ports and terminals |

| Blockchain and Smart Contracts | Secure, transparent, and tamper-proof transactions between parties |

| Data Analytics and Artificial Intelligence | Insights into operations, demand prediction, and optimized decision-making |

By embracing these technologies, drayage logistics companies can position themselves for success in the digital age, improving their competitiveness and delivering greater value to their customers.

What factors influence drayage costs and pricing?

Drayage costs and pricing are influenced by a variety of factors, ranging from operational expenses to market conditions. Understanding these factors is crucial for shippers to make informed decisions when selecting drayage services and for carriers to develop competitive pricing strategies.

Key Factors Influencing Drayage Costs and Pricing:

1. Distance and Location: The distance between the pickup and delivery points, as well as the specific locations involved (e.g., ports, rail terminals, or distribution centers), can significantly impact drayage costs. Longer distances and more congested areas typically result in higher prices.

2. Fuel Costs: Fuel is a major expense for drayage carriers, and fluctuations in fuel prices directly affect drayage costs. Carriers often implement fuel surcharges to mitigate the impact of rising fuel prices on their operations.

3. Labor Costs: Driver wages, benefits, and other labor-related expenses are significant components of drayage costs. The ongoing driver shortage and the need to attract and retain qualified drivers put upward pressure on labor costs, which can translate into higher drayage prices.

4. Equipment Costs: The cost of purchasing, leasing, and maintaining specialized drayage equipment, such as chassis and container trailers, is another important factor in determining drayage prices. Carriers must recover these costs through their pricing models.

5. Market Demand and Capacity: The balance between market demand for drayage services and the available capacity of drayage carriers can influence pricing. During peak seasons or periods of high demand, prices may increase due to capacity constraints and the need to prioritize shipments.

6. Regulatory Compliance: Compliance with safety regulations, environmental standards, and other legal requirements can add to drayage costs. Carriers must invest in training, technology, and processes to ensure compliance, and these costs are often reflected in their pricing.

7. Accessorial Charges: Additional services or requirements, such as detention time, layover fees, or hazardous material handling, can result in accessorial charges that increase the overall cost of drayage services.

Strategies for Managing Drayage Costs:

– Optimize route planning and reduce empty miles

– Implement fuel efficiency measures and explore alternative fuel options

– Invest in driver retention and recruitment programs to control labor costs

– Maximize equipment utilization and implement preventive maintenance practices

– Collaborate with partners to balance demand and capacity

– Stay informed about regulatory changes and develop cost-effective compliance strategies

– Negotiate favorable contract terms and explore opportunities for cost savings

| Factor | Impact on Drayage Costs |

|---|---|

| Distance and Location | Longer distances and congested areas increase costs |

| Fuel Costs | Fluctuations in fuel prices directly affect drayage costs |

| Labor Costs | Driver wages and benefits are significant components of costs |

| Equipment Costs | Purchasing, leasing, and maintaining equipment adds to costs |

| Market Demand and Capacity | High demand and capacity constraints can increase prices |

| Regulatory Compliance | Compliance with regulations adds to costs |

| Accessorial Charges | Additional services or requirements result in extra charges |

By understanding the factors that influence drayage costs and implementing effective cost management strategies, shippers and carriers can optimize their operations and maintain competitive pricing in the market.