What Is a Drayage Partner

What is drayage and why is it crucial in logistics?

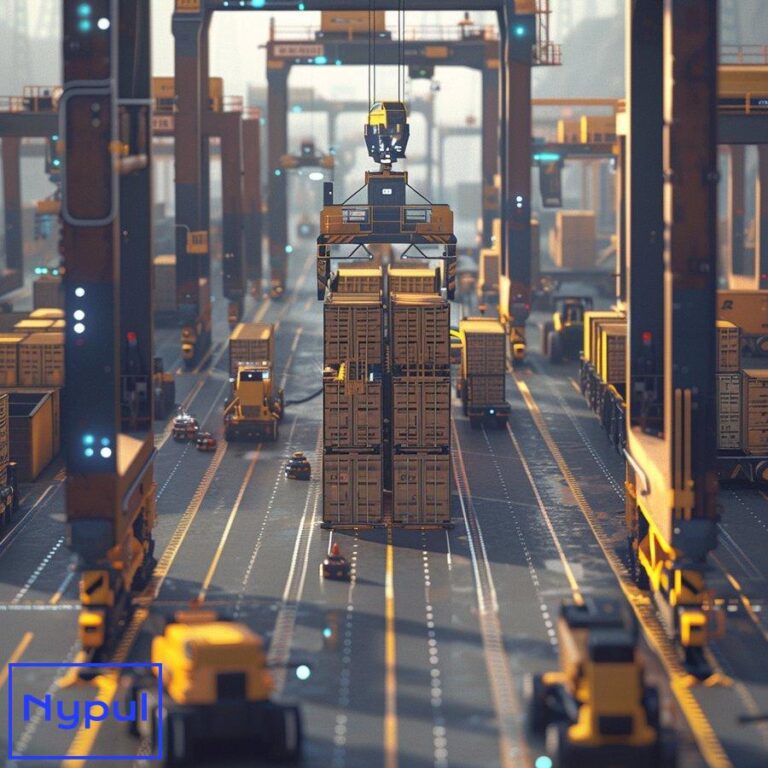

Drayage refers to the short-distance transportation of shipping containers and cargo, typically within a single metropolitan area. This critical link in the supply chain involves moving freight from ports or rail terminals to warehouses, distribution centers, or other nearby destinations.

While seemingly simple, drayage plays an outsized role in the efficiency and reliability of global logistics networks. Without smooth drayage operations, cargo can become bottlenecked at ports and rail yards, causing costly delays that ripple throughout supply chains.

The importance of drayage stems from its position as the “first mile” or “last mile” in intermodal freight transport. Drayage trucks bridge the gap between long-distance shipping modes like ocean vessels or freight trains and local distribution networks. This allows containerized cargo to flow seamlessly from global trade routes to regional supply chains.

Some key reasons drayage is crucial for logistics:

Port congestion mitigation

Efficient drayage operations keep containers moving out of crowded ports, preventing backlogs that can paralyze maritime trade. Quick container turnover at ports is essential for overall supply chain fluidity.

Intermodal connectivity

Drayage enables freight to transition between transportation modes, connecting ocean, rail, and trucking networks. This intermodal flexibility is the backbone of modern global trade.

Just-in-time inventory

Many businesses rely on precisely timed deliveries to minimize warehousing costs. Reliable drayage is critical for maintaining lean, just-in-time inventory systems.

Cost control

Drayage typically represents a small portion of overall shipping costs. However, drayage delays or inefficiencies can trigger expensive demurrage and detention fees at ports and rail yards.

Supply chain visibility

Short-distance drayage moves are often the most opaque part of long-distance freight journeys. Effective drayage provides crucial visibility into the first and last segments of shipments.

To illustrate the pivotal role of drayage, consider this simplified breakdown of a typical intermodal freight journey:

| Stage | Transportation Mode | Distance | Time |

|---|---|---|---|

| Origin to Port | Truck (Drayage) | 50 miles | 2 hours |

| Ocean Shipping | Container Vessel | 6,000 miles | 14 days |

| Port to Rail Terminal | Truck (Drayage) | 30 miles | 1 hour |

| Rail Transport | Freight Train | 2,000 miles | 3 days |

| Rail to Warehouse | Truck (Drayage) | 40 miles | 1.5 hours |

In this example, drayage accounts for only 120 out of 8,120 total miles traveled. Yet these short truck moves are essential for connecting the long-distance ocean and rail segments. Any drayage delays could derail the entire 17-day journey.

The strategic importance of drayage has grown in recent years due to several factors:

E-commerce growth

The rise of online retail has increased pressure for rapid, reliable deliveries. This puts greater emphasis on efficient drayage to and from urban distribution centers.

Port congestion

Major ports have struggled with unprecedented congestion, particularly since 2020. Streamlined drayage is crucial for alleviating port bottlenecks.

Intermodal expansion

Shippers are increasingly using intermodal transport to optimize costs and reduce emissions. This trend amplifies the need for seamless drayage connections.

Supply chain visibility

There is growing demand for end-to-end shipment tracking. Drayage often represents a visibility gap that logistics providers are working to close.

Environmental concerns

Many ports face pressure to reduce emissions from idling trucks. Efficient drayage operations can minimize truck queues and dwell times at marine terminals.

Understanding the critical nature of drayage is essential for anyone involved in logistics and supply chain management. While it may seem like a simple trucking service, drayage is the glue that holds intermodal freight networks together. Optimizing drayage operations can yield outsized benefits for overall supply chain performance.

Who are drayage partners and what do they do?

Drayage partners are specialized logistics providers that focus on short-distance freight transportation, primarily involving shipping containers and intermodal cargo. These companies bridge the crucial gap between long-haul transportation modes and local distribution networks.

The core function of drayage partners is to move containers and other freight over short distances, typically within a single metropolitan area. This often involves transporting cargo between:

Seaports and rail terminals

Drayage partners shuttle containers between marine terminals and nearby intermodal rail yards, enabling seamless sea-to-rail connections.

Ports and warehouses

Many drayage moves involve taking imported containers from ports to local distribution centers or warehouses.

Rail terminals and distribution centers

For rail shipments, drayage partners handle the final leg from rail yards to nearby warehouses or manufacturing facilities.

Transload facilities

Drayage companies often move freight to and from transload warehouses, where goods are transferred between international and domestic containers.

While the core service of drayage partners is short-distance trucking, many offer a range of additional logistics services to support intermodal freight movement:

Container storage

Drayage partners frequently provide short-term storage for containers at their own yards, helping to alleviate congestion at ports and rail terminals.

Customs coordination

Many drayage companies assist with customs clearance processes, leveraging their expertise in port and border regulations.

Freight station operations

Some drayage partners operate container freight stations, where they consolidate or deconsolidate shipments.

Chassis provision

Drayage companies often maintain their own fleet of chassis (the wheeled frames for hauling containers), ensuring equipment availability.

Technology integration

Leading drayage partners offer sophisticated tracking and visibility solutions to keep shippers informed about container movements.

Warehousing services

Many drayage providers have expanded into warehousing, offering integrated container drayage and distribution services.

The role of drayage partners has evolved significantly in recent years. Once viewed simply as local trucking providers, many have transformed into comprehensive intermodal logistics specialists. This evolution has been driven by:

Supply chain complexity

Global trade networks have become increasingly intricate, requiring drayage partners to offer more sophisticated services.

Technology adoption

The logistics industry’s digital transformation has pushed drayage companies to invest heavily in software and tracking systems.

Capacity constraints

Persistent shortages of drivers and equipment have led drayage partners to focus on efficiency and asset utilization.

Regulatory changes

Stricter environmental and safety regulations have compelled drayage providers to modernize their fleets and operations.

To illustrate the diverse services offered by modern drayage partners, consider this comparison of traditional and expanded service models:

| Service Area | Traditional Drayage Model | Expanded Drayage Partner Model |

|---|---|---|

| Core Transportation | Local container trucking | Intermodal drayage, transloading, LTL consolidation |

| Equipment | Trucks and basic chassis | Diverse chassis fleet, specialized trailers, yard tractors |

| Facilities | Small truck yard | Container yard, cross-dock warehouse, CFS facility |

| Technology | Basic dispatch system | TMS integration, real-time tracking, predictive analytics |

| Customs & Compliance | Limited involvement | Full customs brokerage, compliance consulting |

| Value-Added Services | Minimal offerings | Warehousing, distribution, kitting, reverse logistics |

This expanded service model allows drayage partners to position themselves as integral players in the broader logistics ecosystem. By offering a comprehensive suite of intermodal services, these companies can provide more value to shippers and better optimize the flow of freight through complex supply chains.

The importance of choosing the right drayage partner cannot be overstated. These companies play a pivotal role in determining the efficiency, reliability, and cost-effectiveness of intermodal shipping operations. A strong drayage partner can:

Minimize port congestion

Efficient drayage operations keep containers flowing smoothly through marine terminals, reducing costly bottlenecks.

Improve transit times

Optimized drayage routing and scheduling can significantly reduce overall shipment durations.

Enhance visibility

Advanced drayage partners provide real-time tracking and proactive alerts, closing visibility gaps in intermodal shipments.

Reduce costs

Effective drayage management can minimize accessorial charges like demurrage and detention fees.

Increase flexibility

Drayage partners with diverse service offerings can quickly adapt to changing shipping needs and market conditions.

Ensure compliance

Experienced drayage providers navigate complex port regulations and customs requirements, minimizing delays and penalties.

As global supply chains continue to evolve, the role of drayage partners will likely expand further. These companies are well-positioned to serve as key nodes in increasingly digital and interconnected logistics networks. Shippers and logistics providers who develop strong relationships with capable drayage partners will be better equipped to navigate the challenges of modern freight transportation.

How do drayage partners differ from general carriers?

Drayage partners and general carriers both play crucial roles in the transportation industry, but they differ significantly in their focus, operations, and expertise. Understanding these distinctions is essential for shippers and logistics professionals seeking to optimize their supply chains.

Operational focus

Drayage partners specialize in short-distance, high-frequency moves, typically within a single metropolitan area. Their operations revolve around ports, rail terminals, and nearby distribution centers. General carriers, on the other hand, often focus on longer-haul transportation, covering regional or national routes.

Equipment specialization

Drayage companies maintain fleets specifically designed for container handling. This includes specialized tractors, a variety of chassis types, and equipment for efficient port and rail yard operations. General carriers usually operate a more diverse fleet suited for various types of freight and longer distances.

Regulatory expertise

Drayage partners possess in-depth knowledge of port regulations, customs procedures, and local transportation rules. This expertise is crucial for navigating the complex regulatory environment of international trade entry points. General carriers typically have broader regulatory knowledge covering interstate commerce and general transportation laws.

Service integration

Many drayage partners offer integrated services closely tied to port and intermodal operations, such as container storage, transloading, and customs coordination. General carriers more commonly focus on point-to-point transportation, with fewer ancillary services directly related to international trade.

Technology systems

Drayage partners often utilize specialized software for port scheduling, container tracking, and intermodal coordination. Their systems are designed to interface with port and terminal operating systems. General carriers typically use more generalized transportation management systems focused on route optimization and load planning.

Pricing models

Drayage services are often priced based on complex factors including port congestion, equipment availability, and specific terminal requirements. General carrier pricing usually follows more standardized models based primarily on distance, weight, and service level.

Network structure

Drayage partners build dense networks within specific port and rail hub regions, optimizing for local efficiency. General carriers develop broader networks designed for long-distance coverage and interstate connectivity.

Capacity management

Drayage operations require nimble capacity management to handle fluctuating port volumes and potential congestion. General carriers often focus on more stable, predictable capacity allocation across their networks.

To further illustrate these differences, consider the following comparison table:

| Aspect | Drayage Partners | General Carriers |

|---|---|---|

| Typical move distance | 0-100 miles | 100+ miles |

| Primary customers | Importers, exporters, intermodal shippers | Diverse shippers across industries |

| Key operational locations | Ports, rail yards, nearby DCs | Terminals, DCs, manufacturing facilities |

| Equipment focus | Container chassis, yard tractors | Dry vans, reefers, flatbeds |

| Regulatory specialization | Customs, port rules, container regulations | DOT regulations, interstate commerce laws |

| Technology integration | Port community systems, terminal interfaces | Load boards, ELD systems |

| Pricing complexity | High (port fees, congestion factors) | Moderate (standardized rate structures) |

| Service speed | Rapid turnaround (often same-day) | Longer transit times (days to weeks) |

| Network density | High in port/rail regions | Broader geographic coverage |

| Intermodal expertise | Core competency | Often a secondary service |

These distinctions highlight why shippers often need both drayage partners and general carriers to create comprehensive logistics solutions. Drayage partners excel in the specialized world of port and intermodal operations, while general carriers provide the long-distance transportation backbone.

Operational agility

Drayage partners must be highly adaptable to handle the dynamic nature of port and rail terminal operations. They need to quickly adjust to vessel delays, terminal congestion, and last-minute changes in container availability. This requires sophisticated dispatching systems and flexible driver scheduling.

General carriers typically operate with more predictable schedules and longer planning horizons. While they certainly face operational challenges, the day-to-day volatility is usually less extreme than in drayage operations.

Driver skills and training

Drayage drivers require specialized skills for navigating busy port environments, operating various types of container handling equipment, and efficiently managing short-haul, high-frequency moves. They must also be well-versed in port security protocols and documentation requirements.

Drivers for general carriers focus more on long-haul driving skills, hours-of-service management, and interstate navigation. While still demanding, these roles typically involve less frequent loading/unloading and fewer interactions with terminal personnel.

Customer relationships

Drayage partners often develop deep, localized relationships with specific shippers, freight forwarders, and terminal operators in their port regions. These relationships are crucial for navigating the complexities of port operations and securing preferential treatment during congested periods.

General carriers usually maintain broader customer bases spread across larger geographic areas. While strong relationships are still important, the intense local focus of drayage operations is less common.

Environmental considerations

Drayage operations face increasing scrutiny regarding environmental impact, particularly in densely populated port areas. Many drayage partners are at the forefront of adopting clean truck technologies and participating in port sustainability initiatives.

General carriers also face environmental pressures, but the focus is often more on long-haul efficiency and overall fleet emissions rather than the acute local air quality concerns prevalent in port regions.

Asset utilization patterns

Drayage partners strive for high-frequency asset utilization, often completing multiple trips per day with the same truck and driver. This requires precise scheduling and close coordination with terminal operators.

General carriers typically aim for high asset utilization through longer trips and minimized empty miles. Their focus is more on optimizing routes and balancing network flows over larger geographic areas.

Scalability challenges

Scaling drayage operations often requires navigating constrained port and terminal environments with limited capacity for additional trucks. Growth may depend on securing more favorable terminal access or expanding into new port regions.

General carriers can often scale more linearly by adding trucks and drivers to cover new lanes or expand service areas, without the same level of geographic constraint.

Understanding these nuanced differences between drayage partners and general carriers is crucial for effective supply chain management. Many sophisticated logistics operations leverage the strengths of both types of providers, using drayage partners for specialized port and rail terminal operations while relying on general carriers for longer-haul transportation needs.

As supply chains become increasingly complex and interconnected, the lines between drayage and general carriers may blur somewhat. Some larger transportation companies now offer both specialized drayage services and general carrying capabilities. However, the core distinctions in operational focus and expertise are likely to remain significant for the foreseeable future.

What benefits does working with a drayage partner offer?

Collaborating with a specialized drayage partner can yield numerous advantages for shippers, freight forwarders, and other logistics stakeholders. These benefits stem from the drayage partner’s focused expertise, local knowledge, and tailored services designed to optimize the critical first and last miles of intermodal shipments.

Enhanced port and terminal efficiency

![]()

Drayage partners possess intimate knowledge of port and rail terminal operations, including:

Gate procedures

Experienced drayage providers understand the intricacies of terminal entry and exit processes, minimizing delays and documentation errors.

Terminal layouts

Familiarity with specific terminal configurations allows for more efficient container pickup and drop-off routing.

Equipment availability

Drayage partners often have real-time insight into chassis and container availability, reducing wasted trips and improving asset utilization.

This specialized knowledge translates into faster turn times, reduced congestion, and lower risk of demurrage and detention charges.

Improved intermodal connectivity

Drayage is the crucial link in intermodal transportation chains. Effective drayage partners excel at:

Mode synchronization

Coordinating container movements to align with vessel arrivals, train schedules, and warehouse receiving windows.

Equipment matching

Ensuring the right chassis and truck combinations are available for specific container types and weights.

Cross-docking and transloading

Facilitating smooth transfers between international and domestic containers or trailers.

By optimizing these connections, drayage partners help reduce overall transit times and improve the reliability of intermodal shipments.

Cost reduction and control

While drayage itself represents a relatively small portion of total freight costs, it can significantly impact overall## What benefits does working with a drayage partner offer? (continued)

While drayage itself represents a relatively small portion of total freight costs, it can significantly impact overall shipping economics. Drayage partners can help reduce costs through:

Demurrage and detention avoidance

Minimizing the risk of costly fees for late container returns or exceeding free time at ports and terminals.

Chassis optimization

Providing or arranging for chassis to avoid expensive leasing or per-diem charges.

Fuel efficiency

Optimizing routing and equipment to minimize empty miles and reduce fuel consumption.

Accessorial fee management

Negotiating favorable rates for port-specific charges and accessorials.

Proactive cost control

Providing transparency and control over drayage spend through reporting and analytics.

Improved visibility and tracking

Drayage operations have historically been a visibility gap in intermodal supply chains. Leading drayage partners now offer:

Real-time tracking

Providing container status updates and estimated arrival times through web portals and mobile apps.

Exception management

Proactively alerting shippers to delays, chassis issues, or other potential problems.

Customized reporting

Delivering detailed performance metrics and analytics tailored to each customer’s needs.

Seamless integration

Interfacing with shippers’ transportation management systems and port community systems for streamlined data exchange.

This enhanced visibility enables shippers to make more informed decisions, proactively manage exceptions, and provide better customer service.

Regulatory compliance and risk mitigation

Navigating the complex regulatory landscape of ports and international trade is a core competency of drayage partners. They can help mitigate compliance risks by:

Customs clearance

Assisting with customs documentation and clearance processes to avoid delays and penalties.

Safety regulations

Ensuring compliance with DOT safety rules, port security requirements, and other relevant regulations.

Environmental standards

Meeting clean truck programs, emissions regulations, and other sustainability initiatives at ports.

Cargo liability

Providing cargo liability insurance coverage and expertise in handling claims.

Scalability and flexibility

Drayage partners can help shippers scale their operations and adapt to changing market conditions. Key advantages include:

Capacity on demand

Providing additional capacity during peak seasons or unexpected surges in volume.

Geographic expansion

Enabling entry into new port markets or trade lanes through established local relationships and infrastructure.

Agile response

Quickly adjusting to port disruptions, chassis shortages, or other supply chain challenges.

Seasonal adjustments

Scaling up or down in response to cyclical volume fluctuations.

Innovative solutions

Collaborating on new service offerings or technology implementations to drive continuous improvement.

Sustainability and environmental stewardship

As sustainability becomes an increasingly critical priority for supply chains, drayage partners are well-positioned to drive progress. Advantages include:

Clean truck adoption

Investing in alternative fuel vehicles, electric trucks, and other emissions-reducing technologies.

Idle reduction

Optimizing routing and terminal operations to minimize truck idling and fuel consumption.

Chassis electrification

Deploying electric and hybrid yard tractors for container handling.

Intermodal optimization

Shifting freight from truck to rail or short-sea shipping where feasible to reduce emissions.

Sustainability reporting

Providing data and analytics to help shippers measure and report on their transportation-related sustainability metrics.

By partnering with drayage providers committed to environmental stewardship, shippers can enhance their own sustainability efforts and reduce their carbon footprint.

In summary, working with a specialized drayage partner offers a range of strategic and operational benefits that can significantly improve the performance, cost-effectiveness, and sustainability of intermodal supply chains. As global trade continues to evolve, the value of these partnerships will only grow more apparent.

Which key services do drayage partners provide?

Drayage partners offer a diverse array of services tailored to the unique needs of intermodal freight transportation. While core container trucking remains the foundation, leading drayage providers have expanded their capabilities to deliver comprehensive logistics solutions. Key services include:

![]()

Container Drayage

- Port and rail terminal drayage

- Transporting containers between marine terminals and nearby rail yards

- Delivering import containers from ports to nearby warehouses or distribution centers

-

Picking up export containers from shippers and delivering them to ports

-

Chassis provisioning

- Providing or arranging for chassis to haul containers

-

Maintaining a diverse fleet of chassis types to match specific container requirements

-

Chassis management

- Tracking chassis utilization and availability

-

Optimizing chassis pools to minimize per-diem costs and delays

-

Expedited services

- Offering priority or guaranteed drayage services for time-sensitive freight

- Providing rapid response to unexpected container availability or port disruptions

Intermodal Services

- Transloading and cross-docking

- Transferring cargo between international and domestic containers or trailers

-

Operating cross-dock facilities for efficient transload operations

-

Intermodal container storage

- Providing short-term storage for import and export containers

-

Staging containers for upcoming vessel or rail moves

-

Intermodal equipment leasing

- Offering long-term leases on intermodal containers and chassis

-

Providing a flexible alternative to outright equipment ownership

-

Intermodal freight forwarding

- Arranging comprehensive intermodal transportation services

- Coordinating ocean, rail, and drayage moves as a single service

Value-Added Services

- Warehousing and distribution

- Operating warehouses and distribution centers for import and export cargo

-

Providing value-added services like kitting, labeling, and reverse logistics

-

Customs brokerage

- Assisting with customs clearance and documentation

-

Advising on tariffs, trade regulations, and compliance requirements

-

Cargo insurance

- Offering cargo liability coverage for intermodal shipments

-

Handling claims and providing risk management expertise

-

Sustainability initiatives

- Investing in clean truck technologies like alternative fuels and electrification

-

Participating in port-led sustainability programs and emissions reduction efforts

-

Technology solutions

- Providing real-time container tracking and visibility

- Offering web portals and mobile apps for shipment management

-

Integrating with shippers’ transportation management systems

-

Dedicated contract carriage

- Providing exclusive use of drayage assets and drivers for high-volume shippers

- Customizing operations to meet specific service level requirements

The range and sophistication of these services illustrate how drayage partners have evolved from basic trucking providers into comprehensive intermodal logistics specialists. By offering a one-stop shop for container transportation and value-added services, leading drayage companies can help shippers optimize their supply chains and gain a competitive edge in global trade.

How can you choose the right drayage partner for your needs?

Selecting the right drayage partner is a critical decision that can significantly impact the efficiency, cost-effectiveness, and reliability of intermodal freight operations. With so many drayage providers to choose from, it’s essential to have a clear understanding of your specific requirements and the key factors to consider. Here are some steps to help guide your selection process:

Define your needs

Start by clearly defining your drayage requirements, including:

- Geographic coverage

- Which ports, rail terminals, and markets do you need drayage services for?

-

Are you looking for a local provider or a national network?

-

Service requirements

- What level of service do you need (e.g., expedited, guaranteed)?

-

Do you require any specialized equipment or value-added services?

-

Technology capabilities

- What level of visibility and tracking do you need?

-

Are integrations with your TMS or other systems required?

-

Sustainability goals

- Do you have specific emissions reduction targets or clean truck requirements?

-

Are you looking for a partner committed to environmental stewardship?

-

Pricing and cost control

- What is your budget for drayage services?

- Are you seeking the lowest cost or the best overall value?

Clearly articulating your needs will help you identify the right drayage partners to evaluate.

Evaluate potential partners

Once you’ve defined your requirements, research and evaluate potential drayage partners based on factors like:

- Service area coverage

- Fleet size and equipment capabilities

- Technology and visibility solutions

- Sustainability initiatives and clean truck adoption

- Financial stability and credit rating

- Safety record and compliance history

- Customer references and case studies

- Pricing and accessorial fee structures

Narrow your list to 3-5 top contenders based on how well they align with your needs and priorities.

Conduct a thorough assessment

For your top drayage partner candidates, conduct a more in-depth assessment, including:

- On-site visits and facility tours

- Interviews with key personnel

- Detailed pricing and contract reviews

- Assessments of technology capabilities and integrations

- Discussions of sustainability initiatives and emissions reduction plans

- Comprehensive reference checks with current customers

This deeper dive will help you uncover any potential red flags and gain confidence in your final selection.

Negotiate and finalize the partnership

Once you’ve identified your preferred drayage partner, negotiate the contract terms and finalize the partnership. Key considerations include:

- Pricing and rate structures

- Service level agreements and KPIs

- Liability and insurance requirements

- Dispute resolution processes

- Termination clauses and exit strategies

Involve your legal counsel to ensure the contract protects your interests and aligns with your business objectives.

Establish a strong working relationship

Building a successful drayage partnership requires ongoing communication, collaboration, and continuous improvement. Some best practices include:

- Designating key points of contact on both sides

- Holding regular performance reviews and feedback sessions

- Collaborating on process improvements and innovation

- Providing timely feedback on service issues or concerns

- Celebrating successes and recognizing outstanding performance

By investing in the partnership, you’ll be better positioned to weather challenges, adapt to changing market conditions, and drive long-term value.

Choosing the right drayage partner is a critical decision that can yield significant benefits for your intermodal freight operations. By following these steps and prioritizing factors like service quality, technology capabilities, sustainability, and overall value, you can identify a drayage provider that will be a true strategic partner in your supply chain success.

What challenges do drayage operations face?

Drayage operations face a unique set of challenges stemming from their position at the intersection of global trade, local transportation, and complex supply chain dynamics. Understanding these challenges is crucial for shippers, logistics providers, and drayage partners themselves to develop effective strategies for overcoming obstacles and optimizing performance. Key challenges include:

Port and terminal congestion

Ports and rail terminals are the epicenters of drayage activity, but they are also prone to chronic congestion that can wreak havoc on drayage operations. Factors contributing to port congestion include:

- Vessel bunching and surges in container volumes

- Chassis shortages and equipment imbalances

- Inefficient terminal layouts and gate processes

- Truck queues and excessive dwell times

- Labor shortages and work stoppages

Congestion leads to delays, unpredictable turn times, and increased costs for drayage providers and their customers. Mitigating port congestion requires collaboration among terminals, ocean carriers, chassis providers, and drayage partners to optimize processes and infrastructure.

Driver shortages and high turnover

Drayage operations rely on a skilled, dedicated workforce of truck drivers. However, the drayage industry faces persistent challenges in recruiting and retaining qualified drivers due to:

- Demanding work schedules and long hours

- Congestion-related delays and unpaid wait times

- Lack of driver amenities and rest areas at ports

- Relatively low pay compared to long-haul trucking

- High costs of obtaining commercial driver’s licenses

Driver shortages lead to capacity constraints, service delays, and rising labor costs. Drayage providers are working to address these challenges through improved driver compensation, better working conditions, and more efficient scheduling practices. However, the driver shortage remains a significant obstacle to consistent, reliable drayage operations.

Chassis shortages and mismatches

Chassis are the wheeled frames used to haul containers, and their availability is critical for drayage operations. However, the chassis market faces chronic shortages and mismatches due to:

- Chassis pools that are too small to handle peak volumes

- Chassis being tied up in long-term leases or per-diem arrangements

- Chassis being stranded at off-dock locations

- Chassis being incompatible with specific container types or weights

Chassis shortages lead to delays, extra fees, and inefficient drayage moves. Drayage providers are working to address these challenges by investing in larger chassis fleets, optimizing chassis utilization, and collaborating with ocean carriers and terminals to improve chassis availability and compatibility.

Regulatory complexity and compliance

Drayage operations must navigate a complex web of regulations at the federal, state, and local levels, including:

- DOT safety regulations and driver qualification requirements

- Port security and access control measures

- Environmental regulations and clean truck programs

- Customs clearance and documentation requirements

- Zoning and permitting rules for drayage facilities

Compliance failures can lead to fines, penalties, and service disruptions. Drayage providers must stay current on regulatory changes, invest in compliance systems, and work closely with port authorities and government agencies to ensure smooth operations.

Technology integration challenges

Drayage operations are becoming increasingly dependent on technology for visibility, efficiency, and compliance. However, integrating disparate systems and data sources remains a significant challenge, including:

- Connecting drayage management systems with port community systems

- Integrating real-time tracking data with shippers’ transportation management systems

- Automating data exchange between drayage providers, terminals, and ocean carriers

- Implementing electronic logging devices (ELDs) and other compliance technologies

Lack of system integration leads to data silos, manual workarounds, and reduced visibility. Drayage providers are investing in API-based integration capabilities and collaborating with technology partners to develop more seamless solutions.

Sustainability pressures

As concerns about climate change and local air quality grow, drayage operations face increasing pressure to reduce emissions and adopt sustainable practices, including:

- Transitioning to alternative fuel and electric vehicles

- Minimizing truck idling and optimizing routing

- Participating in port-led sustainability initiatives

- Providing data and analytics to measure environmental impact

Meeting sustainability goals requires significant capital investments, operational changes, and collaboration with ports, terminals, and shippers. Drayage providers that embrace sustainability can gain a competitive advantage, but the transition poses challenges in terms of cost, infrastructure, and technology adoption.

Overcoming these challenges requires a multi-faceted approach involving process improvements, technology adoption, regulatory compliance, and collaborative partnerships. Drayage providers, shippers, and logistics stakeholders must work together to develop innovative solutions that enhance efficiency, reliability, and sustainability in the face of these complex challenges.

How do successful drayage partnerships operate in practice?

Successful drayage partnerships are built on a foundation of trust, communication, and a shared commitment to operational excellence. By aligning their goals, processes, and technologies, drayage partners and their customers can create a synergistic relationship that drives continuous improvement and value creation. Here’s a look at how successful drayage partnerships operate in practice:

Aligned goals and KPIs

Effective drayage partnerships begin with a clear understanding of each party’s goals and expectations. Drayage partners and their customers should collaborate to define key performance indicators (KPIs) that align with shared objectives, such as:

- On-time performance

- Turn time at ports and terminals

- Chassis utilization and availability

- Shipment visibility and exception management

- Cost control and accessorial fee management

- Sustainability metrics like emissions reduction

By aligning on KPIs, partners can track progress, identify areas for improvement, and celebrate successes together.

Proactive communication and collaboration

Successful drayage partnerships thrive on proactive communication and collaboration at all levels of the organizations. This includes:

- Designating dedicated points of contact

- Holding regular performance review meetings

- Collaborating on process improvements and innovation

- Sharing data and insights to drive decision-making

- Providing timely feedback on service issues or concerns

By fostering a culture of open communication and collaboration, partners can quickly resolve problems, adapt to changing conditions, and identify opportunities for optimization.

Integrated technology and data sharing

Leading drayage partnerships leverage technology and data to drive efficiency, visibility, and continuous improvement. This includes:

- Integrating drayage management systems with port community systems and TMS platforms

- Implementing real-time tracking and exception management capabilities

-

**### Integrated technology and data sharing (continued)

-

Utilizing predictive analytics to forecast demand and optimize resource allocation

- Sharing performance data and insights to drive joint decision-making

- Implementing electronic logging devices (ELDs) and automated compliance systems

By integrating technology and sharing data, partners can enhance visibility into the drayage process, streamline operations, and proactively address potential issues before they escalate.

Continuous improvement and innovation

Successful drayage partnerships prioritize continuous improvement and innovation to stay competitive in a rapidly evolving logistics landscape. This involves:

- Regularly reviewing performance metrics and KPIs

- Conducting root cause analyses to identify and address performance gaps

- Collaborating on process improvements and best practices

- Exploring new technologies and solutions to enhance efficiency

- Encouraging a culture of innovation within both organizations

By fostering an environment of continuous improvement, partners can adapt to changing market conditions, enhance service levels, and drive operational efficiencies.

Flexibility and responsiveness

The dynamic nature of logistics requires drayage partners to be flexible and responsive to changing circumstances. Successful partnerships embrace:

- Agile scheduling and resource allocation to accommodate fluctuations in volume

- Rapid response to unexpected disruptions, such as port congestion or chassis shortages

- Collaboration on contingency plans to mitigate risks and maintain service levels

- Open lines of communication to facilitate quick decision-making

This flexibility allows partners to navigate challenges effectively and maintain high service levels, even in the face of uncertainty.

Focus on sustainability

As sustainability becomes an increasingly important priority for supply chains, successful drayage partnerships incorporate sustainable practices into their operations. This includes:

- Investing in clean truck technologies and alternative fuels

- Implementing strategies to reduce idling and optimize routing

- Participating in port-led sustainability initiatives and emissions reduction programs

- Providing data and analytics to track and report on sustainability metrics

By prioritizing sustainability, partners can enhance their competitive advantage and contribute to broader environmental goals.

Building strong relationships

At the heart of successful drayage partnerships is a commitment to building strong, trusting relationships. This involves:

- Investing time and resources into relationship-building activities

- Celebrating successes and recognizing outstanding performance

- Encouraging open dialogue and constructive feedback

- Fostering a sense of shared purpose and collaboration

Strong relationships enable partners to work together effectively, navigate challenges, and achieve mutual success.

In summary, successful drayage partnerships operate through aligned goals, proactive communication, integrated technology, continuous improvement, flexibility, sustainability, and strong relationships. By focusing on these key elements, drayage partners and their customers can create a collaborative environment that drives operational excellence and enhances supply chain performance. As the logistics landscape continues to evolve, these partnerships will be essential for navigating the complexities of modern freight transportation.