What Is a Drayage Yard

What is Drayage and Why is it Important in Logistics?

Drayage, a crucial component of the logistics industry, refers to the short-distance transportation of goods, typically within a single metropolitan area. This service bridges the gap between long-haul transportation and final delivery, playing a vital role in the seamless movement of cargo from ports, railyards, or warehouses to their next destination.

The term “drayage” originates from the word “dray,” a low, flat-sided cart used to transport heavy loads over short distances. While the vehicles have evolved, the concept remains the same: efficient, short-distance freight movement.

Key Characteristics of Drayage:

Short-distance transport: Drayage operations typically cover distances of 100 miles or less, focusing on local transportation needs.

Intermodal connections: Drayage serves as a critical link between different modes of transportation, such as ships, trains, and trucks.

Time-sensitive: These services often operate under tight schedules to ensure smooth transitions between transportation modes and to meet delivery deadlines.

Specialized equipment: Drayage providers use specialized trucks and trailers designed to handle various types of containers and cargo.

The importance of drayage in logistics cannot be overstated. It serves as the connective tissue of the supply chain, enabling the efficient movement of goods across different transportation modes. Without effective drayage services, the entire logistics process would grind to a halt, leading to delays, increased costs, and potential disruptions in the supply chain.

Drayage’s Role in Global Trade:

Drayage plays a crucial role in facilitating global trade by ensuring the smooth transition of goods from international shipping containers to domestic transportation networks. As global trade volumes continue to increase, the demand for efficient drayage services grows proportionally.

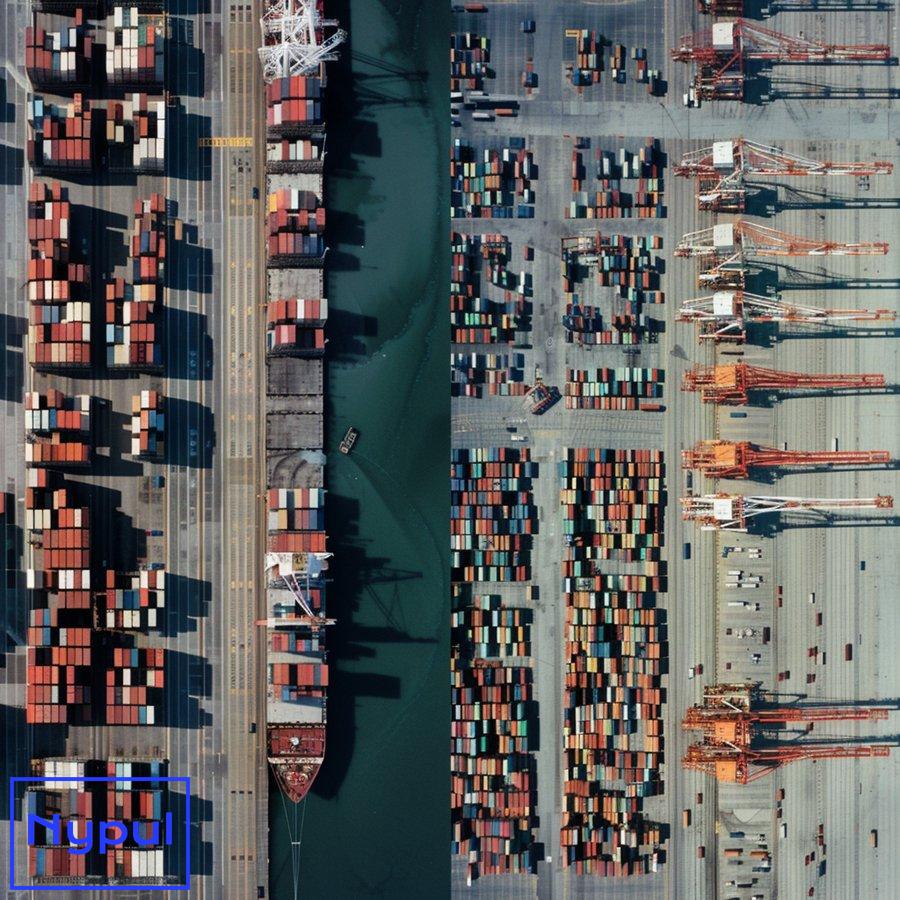

For instance, when a container ship arrives at a port, drayage services are responsible for moving the containers from the port to nearby distribution centers or railyards. This process, known as port drayage, is essential for maintaining the flow of goods and preventing congestion at ports.

Impact on Supply Chain Efficiency:

Efficient drayage operations contribute significantly to overall supply chain performance. By minimizing delays and ensuring timely transfers between transportation modes, drayage helps optimize inventory management, reduce storage costs, and improve delivery times.

Consider a scenario where a retailer imports products from overseas. The goods arrive at a port in shipping containers. Drayage services then transport these containers to a nearby distribution center, where the products are unloaded, sorted, and prepared for further distribution. Without efficient drayage, the goods might remain at the port, incurring additional storage fees and delaying their availability to consumers.

Environmental Considerations:

As the logistics industry faces increasing pressure to reduce its environmental impact, drayage operations are adapting to become more sustainable. Many drayage providers are investing in cleaner technologies, such as electric or hybrid vehicles, to reduce emissions and improve air quality in urban areas where drayage operations are concentrated.

Technological Advancements in Drayage:

The drayage sector is embracing technological innovations to enhance efficiency and transparency. GPS tracking, real-time visibility platforms, and automated scheduling systems are becoming standard tools in modern drayage operations. These technologies enable better coordination between different stakeholders in the supply chain, leading to improved resource utilization and reduced wait times.

Drayage’s Economic Impact:

The drayage industry contributes significantly to local and national economies. It creates jobs, supports port operations, and facilitates the movement of goods that drive economic activity. According to industry reports, the global drayage services market was valued at over $6 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of around 3% from 2021 to 2028.

Understanding the importance of drayage in logistics is crucial for businesses involved in international trade, supply chain management, and transportation. As global trade patterns evolve and e-commerce continues to grow, the role of drayage in ensuring efficient and timely delivery of goods will only become more critical.

What are the Different Types of Drayage Services?

Drayage services come in various forms, each tailored to meet specific logistical needs. Understanding these different types is crucial for businesses to choose the most appropriate service for their supply chain requirements. Let’s explore the main categories of drayage services:

Inter-carrier Drayage:

Inter-carrier drayage involves the transfer of goods between different transportation carriers. This type of service is essential when cargo needs to be moved from one mode of transportation to another, such as from a ship to a train or from one trucking company to another.

Example: A container arrives at a port on a cargo ship. Inter-carrier drayage is used to transport the container to a nearby rail yard, where it will be loaded onto a train for long-distance transportation.

Intra-carrier Drayage:

Intra-carrier drayage refers to the movement of goods within the same carrier’s network. This service is often used when a carrier needs to reposition containers or cargo within their own transportation system.

Example: A trucking company moves a container from one of its terminals to another to consolidate shipments or prepare for long-haul transport.

Expedited Drayage:

Expedited drayage services prioritize speed and efficiency for time-sensitive cargo. These services often involve dedicated trucks and drivers to ensure rapid delivery.

Example: A manufacturer needs urgent delivery of critical components to keep their production line running. Expedited drayage ensures the parts are transported from the port to the factory as quickly as possible.

Pier Drayage:

Pier drayage, also known as port drayage, involves the transportation of containers or cargo from a port to another location, typically a warehouse, distribution center, or rail yard.

Example: Containers are moved from a seaport to a nearby distribution center where goods are unloaded, sorted, and prepared for further distribution.

Shuttle Drayage:

Shuttle drayage services involve the continuous movement of cargo between two points, often within a limited geographic area. This type of service is commonly used to manage high-volume freight flows.

Example: A shuttle service operates between a port and a nearby warehouse, making multiple trips per day to keep goods flowing smoothly.

Door-to-Door Drayage:

Door-to-door drayage provides a complete service from the point of origin to the final destination, typically covering the entire local portion of an intermodal shipment.

Example: A drayage provider picks up a container from a port, transports it to a warehouse for unloading, and then delivers the goods to their final destination, such as a retail store.

Cross-town Drayage:

Cross-town drayage involves the transportation of cargo across a metropolitan area, often between different intermodal facilities.

Example: Moving a container from one rail yard to another on the opposite side of a city.

Bonded Drayage:

Bonded drayage services are used for international shipments that have not yet cleared customs. These services ensure that cargo remains under customs control during transportation.

Example: Transporting imported goods from a port to a bonded warehouse where they will undergo customs inspection and clearance.

To illustrate the differences between these drayage types, consider the following comparison table:

| Drayage Type | Primary Function | Typical Distance | Key Advantage |

|---|---|---|---|

| Inter-carrier | Transfer between carriers | Varies | Facilitates intermodal transport |

| Intra-carrier | Movement within carrier network | Short to medium | Optimizes carrier operations |

| Expedited | Rapid delivery | Short to medium | Minimizes transit time |

| Pier | Port to inland location | Short | Reduces port congestion |

| Shuttle | Continuous movement between points | Very short | Manages high-volume flows |

| Door-to-Door | Complete local service | Short to medium | Provides end-to-end solution |

| Cross-town | Across metropolitan areas | Medium | Connects different facilities |

| Bonded | For customs-controlled cargo | Varies | Ensures regulatory compliance |

The choice of drayage service depends on various factors, including the type of cargo, urgency of delivery, distance, and regulatory requirements. Businesses must carefully consider these factors to select the most appropriate drayage service for their specific needs.

Factors Influencing Drayage Service Selection:

Cargo Type: The nature of the goods being transported can dictate the type of drayage service required. For example, perishable goods may necessitate expedited drayage to ensure timely delivery and maintain product quality.

Urgency: Time-sensitive shipments often require expedited or shuttle drayage services to meet tight deadlines.

Distance: The distance between the origin and destination points influences the choice between short-haul services like pier drayage and longer-distance options like cross-town drayage.

Regulatory Compliance: International shipments may require bonded drayage services to comply with customs regulations.

Volume: High-volume shipments might benefit from shuttle drayage services to maintain a steady flow of goods.

Cost Considerations: Different drayage services come with varying cost structures. Businesses must balance their operational needs with budget constraints when selecting a service.

Integration with Overall Logistics Strategy: The chosen drayage service should align with the company’s broader supply chain and logistics strategy.

By understanding the different types of drayage services and considering these influencing factors, businesses can make informed decisions that optimize their supply chain operations. The right choice of drayage service can lead to improved efficiency, reduced costs, and enhanced customer satisfaction.

What is a Drayage Yard and What Role Does it Play in the Supply Chain?

A drayage yard, also known as a container yard or chassis yard, is a crucial component of the logistics infrastructure that serves as a temporary storage and staging area for shipping containers, trailers, and chassis. These facilities play a vital role in managing the flow of goods between different modes of transportation, particularly in intermodal logistics operations.

Key Functions of a Drayage Yard:

Container Storage: Drayage yards provide secure storage for containers awaiting pickup, delivery, or transfer to another mode of transportation.

Equipment Management: These facilities manage and maintain chassis, the wheeled trailers used to transport containers by road.

Cargo Consolidation: Drayage yards often serve as points where smaller shipments are consolidated into full container loads or where full containers are broken down into smaller shipments.

Customs Processing: Some drayage yards are designated as bonded facilities, allowing for customs inspections and processing of international shipments.

Maintenance and Repair: Many yards offer services for container and chassis maintenance and repair, ensuring equipment is in good condition for transport.

The role of drayage yards in the supply chain is multifaceted and critical for several reasons:

Buffer Zone:

Drayage yards act as buffer zones between different transportation modes, helping to manage the flow of containers and reduce congestion at ports and rail terminals. By providing temporary storage, these yards allow for more flexible scheduling of pickups and deliveries, smoothing out peaks in demand and improving overall efficiency.

Inventory Management:

For businesses, drayage yards can serve as an extension of their inventory management system. By storing containers in these yards, companies can better control the timing of deliveries to their warehouses or distribution centers, aligning with their just-in-time inventory strategies.

Cost Reduction:

Efficient use of drayage yards can lead to significant cost savings. By minimizing the time containers spend at ports or rail terminals, companies can avoid expensive demurrage and detention fees. Additionally, the ability to consolidate shipments at these yards can reduce transportation costs.

Improved Turnaround Times:

Drayage yards facilitate faster turnaround times for trucks and containers. With dedicated spaces for loading, unloading, and staging, these yards help streamline the movement of goods, reducing wait times and increasing the productivity of transportation assets.

Enhanced Security:

Many drayage yards offer secure storage for containers and cargo, reducing the risk of theft or damage. This is particularly important for high-value or sensitive goods that require extra protection during transit.

Environmental Impact Mitigation:

By optimizing the movement of containers and reducing unnecessary trips, drayage yards can help minimize the environmental impact of freight transportation. Some yards are also implementing green technologies, such as electric vehicle charging stations for drayage trucks.

Customs and Regulatory Compliance:

Bonded drayage yards play a crucial role in facilitating customs processes for international shipments. These yards provide a secure location for customs inspections and documentation processing, ensuring compliance with import/export regulations.

Data Collection and Visibility:

Modern drayage yards are equipped with advanced technologies that allow for real-time tracking of containers and equipment. This data provides valuable insights into supply chain performance and helps identify areas for improvement.

To illustrate the impact of drayage yards on supply chain efficiency, consider the following comparison:

| Aspect | Without Drayage Yard | With Drayage Yard |

|---|---|---|

| Port Congestion | High risk of bottlenecks | Reduced congestion through staged pickups |

| Container Dwell Time | Potentially longer at ports | Shorter at ports, managed at yard |

| Truck Turn Times | Longer wait times at ports | Faster turnaround with scheduled pickups |

| Inventory Control | Less flexible | More control over delivery timing |

| Consolidation Options | Limited | Enhanced ability to consolidate shipments |

| Equipment Availability | Potential shortages | Better managed chassis and container pool |

| Customs Processing | May cause delays at port | Can be handled efficiently at bonded yards |

The strategic use of drayage yards can significantly enhance supply chain performance. For example, a major retailer importing goods from overseas might use a drayage yard near the port of entry to stage containers. This allows the retailer to coordinate deliveries to their distribution centers based on inventory needs and transportation availability, rather than being constrained by port schedules.

Technological Advancements in Drayage Yards:

Modern drayage yards are increasingly leveraging technology to improve operations:

Yard Management Systems (YMS): These software solutions optimize the placement and movement of containers within the yard, improving space utilization and reducing search times.

RFID and GPS Tracking: Real-time tracking of containers and equipment enhances visibility and security.

Automated Gate Systems: These systems speed up check-in and check-out processes, reducing wait times and improving traffic flow.

Predictive Analytics: Advanced data analysis helps yard operators anticipate demand and optimize resource allocation.

Challenges and Future Trends:

Despite their importance, drayage yards face several challenges:

Land Scarcity: In many port cities, finding adequate space for drayage yards is becoming increasingly difficult and expensive.

Environmental Concerns: Yards must adapt to stricter environmental regulations, particularly regarding emissions from idling trucks.

Technology Integration: Implementing new technologies across the supply chain can be complex and requires coordination among multiple stakeholders.

Looking ahead, the role of drayage yards is likely to evolve with emerging trends in logistics:

Automation: Some yards are exploring the use of automated guided vehicles (AGVs) for container movement within the yard.

Sustainability: There’s a growing focus on developing “green” yards with electric vehicle support and renewable energy use.

Digital Twins: Creating virtual models of drayage yards can help optimize operations and test improvements before physical implementation.

In conclusion, drayage yards are essential components of the modern supply chain, serving as critical nodes that facilitate the smooth flow of goods between different transportation modes. By providing storage, consolidation, and management services, these facilities help optimize logistics operations, reduce costs, and improve overall supply chain efficiency. As global trade continues to grow and evolve, the strategic importance of well-managed drayage yards will only increase, driving further innovations in yard operations and technology.

How Does Drayage Facilitate Supply Chain Efficiency?

Drayage plays a crucial role in enhancing supply chain efficiency by serving as the connective tissue between different modes of transportation and various stages of the logistics process. Its impact on supply chain performance is multifaceted and significant, touching every aspect of the movement of goods from origin to destination.

Seamless Intermodal Transitions:

One of the primary ways drayage facilitates supply chain efficiency is by enabling smooth transitions between different modes of transportation. In intermodal logistics, goods often need to move between ships, trains, and trucks. Drayage services bridge these gaps, ensuring that cargo moves swiftly from one mode to another without unnecessary delays.

Example: A container arrives at a port on a cargo ship. Drayage services quickly transport the container to a nearby rail yard, where it’s loaded onto a train for long-distance transport. This seamless transition minimizes dwell time at the port and keeps the supply chain moving.

Reduced Port and Terminal Congestion:

Efficient drayage operations help alleviate congestion at ports and terminals. By quickly moving containers out of these facilities, drayage services prevent bottlenecks and keep the flow of goods steady.

Just-in-Time Inventory Management:

Drayage supports just-in-time (JIT) inventory strategies by providing the flexibility to move goods precisely when they’re needed. This helps businesses reduce warehousing costs and maintain leaner inventories.

Example: A manufacturer uses drayage services to deliver components to their factory exactly when they’re required for production, minimizing storage needs and reducing working capital tied up in inventory.

Cost Reduction:Cost Reduction:

Drayage services contribute to cost reduction in various ways. By optimizing the movement of goods and minimizing delays, businesses can avoid costly demurrage and detention fees associated with containers sitting idle at ports or terminals. Additionally, effective drayage can lead to better utilization of transportation assets, reducing overall operational costs.

Example: A logistics company implements a drayage strategy that minimizes the time containers spend at ports, resulting in significant savings on fees and improved asset utilization.

Improved Delivery Times:

Timely delivery is a critical factor in supply chain efficiency. Drayage services help ensure that goods reach their destinations quickly and reliably. By coordinating pickups and deliveries effectively, drayage providers can significantly reduce transit times.

Example: A retailer relies on drayage services to transport products from a port to their distribution center. By using expedited drayage, the retailer ensures that new inventory arrives just in time for peak shopping seasons, enhancing customer satisfaction.

Enhanced Visibility and Tracking:

Modern drayage operations leverage technology to provide real-time visibility into the status of shipments. GPS tracking and digital platforms allow businesses to monitor their cargo throughout the transportation process, improving communication and coordination among stakeholders.

Example: A manufacturer uses a digital platform to track the progress of their shipments in real-time. This visibility enables them to make informed decisions about inventory management and adjust production schedules as needed.

Flexibility and Adaptability:

The dynamic nature of supply chains requires flexibility and adaptability. Drayage services can quickly respond to changes in demand, shipment volumes, or transportation schedules. This responsiveness helps businesses navigate disruptions and maintain efficient operations.

Example: A logistics provider adjusts its drayage schedule in response to unexpected changes in shipping volumes, ensuring that all cargo is moved efficiently without delays.

Support for E-commerce Growth:

The rise of e-commerce has placed increased demands on supply chain efficiency. Drayage services are essential for meeting the rapid delivery expectations of online shoppers. By facilitating quick movement of goods between ports, warehouses, and retail locations, drayage supports the fast-paced nature of e-commerce logistics.

Example: An e-commerce company utilizes drayage services to rapidly transport products from a port to regional distribution centers, enabling same-day or next-day delivery options for customers.

Collaboration Among Stakeholders:

Effective drayage operations require collaboration among various stakeholders in the supply chain, including shipping lines, trucking companies, warehouse operators, and customs authorities. This collaboration fosters better communication and coordination, leading to improved overall efficiency.

Example: A logistics consortium brings together multiple stakeholders to streamline drayage operations at a major port. By sharing information and resources, they reduce wait times and improve service levels across the board.

Sustainability Efforts:

As environmental concerns grow, many drayage providers are adopting sustainable practices that enhance efficiency while minimizing their carbon footprint. This includes investing in cleaner technologies, optimizing routes to reduce fuel consumption, and implementing energy-efficient practices within their operations.

Example: A drayage company invests in electric trucks for local deliveries, reducing emissions while maintaining efficient service levels.

Challenges Impacting Drayage Efficiency:

Despite its importance in facilitating supply chain efficiency, the drayage sector faces several challenges:

Port Congestion: High volumes of cargo arriving at ports can lead to congestion, delaying drayage operations and increasing costs.

Regulatory Compliance: Navigating complex regulations related to customs clearance and environmental standards can create inefficiencies in drayage operations.

Equipment Availability: Shortages of chassis or containers can disrupt drayage schedules and lead to delays.

Labor Shortages: The logistics industry often faces labor shortages that can impact the availability of qualified drivers for drayage services.

To address these challenges, businesses must invest in strategic planning, technology adoption, and collaboration with stakeholders throughout the supply chain.

In summary, drayage plays a pivotal role in enhancing supply chain efficiency by enabling seamless intermodal transitions, reducing congestion, supporting just-in-time inventory management, improving delivery times, providing visibility into shipments, fostering collaboration among stakeholders, and embracing sustainability efforts. As supply chains continue to evolve in response to changing market demands and global trade dynamics, the importance of effective drayage services will only increase.

What are the Common Challenges in Drayage Operations and How Can They Be Mitigated?

Drayage operations are essential for facilitating the movement of goods within the supply chain; however, they also face several challenges that can impact efficiency and effectiveness. Understanding these challenges is crucial for businesses seeking to optimize their logistics processes. Below are some common challenges encountered in drayage operations along with strategies for mitigation:

Port Congestion:

Port congestion is one of the most significant challenges facing drayage operations today. High volumes of cargo arriving simultaneously can lead to delays in loading and unloading containers. This congestion not only affects turnaround times but also increases costs due to demurrage fees incurred when containers remain at ports longer than allowed.

Mitigation Strategies:

-

Advanced Scheduling: Implementing advanced scheduling systems allows for better planning around peak times at ports.

-

Real-Time Data Analytics: Utilizing data analytics tools helps identify congestion patterns so that companies can adjust their operations proactively.

-

Collaboration with Port Authorities: Engaging with port authorities to understand capacity constraints can help logistics providers plan more effectively.

Equipment Availability:

A shortage of chassis or containers can disrupt drayage schedules. When equipment is unavailable or delayed due to maintenance issues or high demand, it can lead to significant delays in transporting goods.

Mitigation Strategies:

-

Equipment Pooling: Collaborating with other logistics providers for shared access to equipment can alleviate shortages.

-

Regular Maintenance Programs: Implementing proactive maintenance schedules ensures that equipment remains operational and reduces downtime.

-

Investing in Technology: Using technology solutions like yard management systems helps track equipment availability more effectively.

Labor Shortages:

The logistics industry often faces labor shortages due to high turnover rates among truck drivers and other personnel involved in drayage operations. This shortage can lead to delays in service delivery as companies struggle to find qualified drivers.

Mitigation Strategies:

-

Competitive Compensation Packages: Offering attractive pay rates and benefits helps retain drivers.

-

Training Programs: Investing in training programs for new drivers can help build a skilled workforce.

-

Flexible Work Arrangements: Providing flexible scheduling options may attract more candidates into the industry.

Regulatory Compliance:

Navigating complex regulations related to customs clearance, environmental standards, and safety requirements poses challenges for many businesses involved in drayage operations. Failure to comply with these regulations can result in fines or delays that disrupt supply chains.

Mitigation Strategies:

-

Compliance Training: Regular training sessions on regulatory requirements ensure that all staff members are informed about compliance obligations.

-

Dedicated Compliance Teams: Establishing teams focused on regulatory compliance helps streamline processes related to customs clearance.

-

Utilizing Technology Solutions: Implementing software solutions that track regulatory changes allows companies to stay updated on compliance requirements efficiently.

Environmental Concerns:

As awareness of environmental issues grows, pressure is mounting on the logistics industry—including drayage providers—to reduce emissions and adopt sustainable practices. Failure to address these concerns may result in reputational damage or regulatory penalties.

Mitigation Strategies:

-

Investing in Clean Technologies: Transitioning fleets toward electric or hybrid vehicles reduces emissions associated with transportation.

-

Route Optimization Software: Utilizing software that optimizes routes minimizes fuel consumption while maintaining service levels.

-

Sustainability Initiatives: Partnering with organizations focused on sustainability efforts enhances corporate social responsibility initiatives within logistics operations.

Technological Integration Challenges:

While technology offers numerous benefits for improving efficiency within drayage operations—such as real-time tracking systems—integrating new technologies into existing processes can be challenging due to resistance from staff or compatibility issues with legacy systems.

Mitigation Strategies:

-

Change Management Programs: Implementing change management strategies helps employees adapt smoothly when new technologies are introduced.

-

Pilot Testing New Technologies: Conducting pilot tests allows companies to assess effectiveness before full-scale implementation.

-

Vendor Support Services: Engaging vendors who provide ongoing support ensures smooth integration of technology solutions into daily operations.

To summarize the common challenges faced by drayage operations:

| Challenge | Description | Mitigation Strategies |

|---|---|---|

| Port Congestion | Delays caused by high cargo volumes | Advanced scheduling; collaboration with authorities |

| Equipment Availability | Shortages of chassis/containers | Equipment pooling; regular maintenance |

| Labor Shortages | Difficulty finding qualified drivers | Competitive pay; training programs |

| Regulatory Compliance | Navigating complex regulations | Compliance training; dedicated teams |

| Environmental Concerns | Pressure to reduce emissions | Clean technology investments; route optimization |

| Technological Integration Challenges | Difficulty integrating new tech | Change management; pilot testing |

By proactively addressing these challenges through strategic planning and implementation of effective mitigation strategies, businesses involved in drayage operations can enhance their overall efficiency while maintaining compliance with regulations and meeting customer expectations.

What are the Cost Considerations and Fees Associated with Drayage Services?

Understanding cost considerations associated with drayage services is essential for businesses looking to optimize their logistics budgets. Various factors influence the pricing structure of these services; thus it’s crucial for shippers and logistics managers alike to have a clear grasp of potential fees involved. Below are key cost considerations related to drayage services:

Base Rate Charges:

The base rate is typically determined by several factors including distance traveled (mileage), type of cargo being transported (hazardous materials may incur additional fees), as well as any special handling requirements (e.g., refrigerated containers).

Factors Influencing Base Rates Include:

- Distance from origin (port/rail yard) to destination

- Type of container (standard vs specialized)

- Weight restrictions

Accessorial Charges:

Accessorial charges refer specifically to additional fees incurred beyond standard transportation costs. These charges may include:

-

Loading/Unloading Fees: Costs associated with loading cargo onto trucks or unloading it at warehouses.

-

Detention Fees: Charges incurred when trucks are held up at loading/unloading locations beyond agreed-upon timeframes.

-

Demurrage Fees: Fees charged when containers remain at ports longer than allowed due (often due congestion).

-

Chassis Rental Fees: Costs associated with renting chassis used for transporting containers if not provided by carrier.

Understanding these accessorial charges is vital as they can significantly impact overall transportation costs if not managed properly during scheduling processes.

Fuel Surcharges:

Fuel surcharges are additional fees added based on fluctuations in fuel prices over time—these surcharges fluctuate according market conditions affecting diesel prices directly impacting trucking costs across all modes including drayage services specifically tailored towards short-distance movements between various points such as ports/warehouses etc..

Factors Influencing Fuel Surcharges Include:

- Current diesel prices

- Distance traveled

- Type & weight class of vehicle used

Many carriers incorporate fuel surcharges into their pricing structures so it’s important for shippers understand how these fees may vary over time based upon market conditions affecting fuel prices directly influencing overall transportation costs incurred during shipping processes involving short-haul movements via local trucking networks specifically tailored towards moving freight between intermodal facilities such as ports/rail yards/distribution centers etc..

Insurance Costs:

Insurance coverage plays an important role when considering total expenses associated with using any form transportation including those involving short-haul movements via local trucking networks specifically tailored towards moving freight between intermodal facilities such as ports/rail yards/distribution centers etc.. Shippers should evaluate different insurance options available based upon specific needs regarding liability coverage required depending upon value types being transported along routes chosen during shipping processes involving short-haul movements via local trucking networks specifically tailored towards moving freight between intermodal facilities such as ports/rail yards/distribution centers etc..

Types Of Insurance Coverage Include:

- Cargo insurance

- Liability insurance

- General liability insurance

Evaluating insurance options thoroughly ensures adequate protection against potential risks while minimizing exposure during transit periods involving short-haul movements via local trucking networks specifically tailored towards moving freight between intermodal facilities such as ports/rail yards/distribution centers etc..

Seasonal Variations In Pricing Structures:

Pricing structures associated with utilizing any form transportation including those involving short-haul movements via local trucking networks specifically tailored towards moving freight between intermodal facilities such as ports/rail yards/distribution centers etc.. may vary seasonally based upon demand fluctuations occurring throughout year impacting availability resources needed fulfill orders placed during peak seasons versus off-seasons thereby influencing overall pricing strategies adopted by carriers operating within this space accordingly adjusting rates charged accordingly based upon current market conditions affecting supply/demand dynamics present throughout year impacting overall pricing strategies adopted accordingly influencing total expenses incurred during shipping processes involving short-haul movements via local trucking networks specifically tailored towards moving freight between intermodal facilities such as ports/rail yards/distribution centers etc..

To summarize key cost considerations associated with utilizing any form transportation including those involving short-haul movements via local trucking networks specifically tailored towards moving freight between intermodal facilities such as ports/rail yards/distribution centers etc..:

| Cost Consideration | Description |

|---|---|

| Base Rate Charges | Determined by distance traveled/type cargo/special handling requirements |

| Accessorial Charges | Additional fees (loading/unloading/detention/demurrage/chassis rental) |

| Fuel Surcharges | Fluctuations based on diesel prices affecting overall transport costs |

| Insurance Costs | Coverage options evaluated based upon specific needs regarding liability coverage required |

| Seasonal Variations | Pricing structures vary seasonally based upon demand fluctuations |

By understanding these cost considerations thoroughly shippers/logistics managers alike will be better equipped manage budgets effectively while ensuring optimal utilization resources needed fulfill orders placed during shipping processes involving short-haul movements via local trucking networks specifically tailored towards moving freight between intermodal facilities such as ports/rail yards/distribution centers etc..

How to Choose a Reliable and Efficient Drayage Provider?

Selecting a reliable and efficient drayage provider is critical for businesses seeking optimal performance within their supply chains. The right provider not only ensures timely delivery but also contributes significantly toward minimizing costs associated with transportation processes involving short-haul movements via local trucking networks specifically tailored towards moving freight between intermodal facilities such as ports/rail yards/distribution centers etc.. Below are key considerations when choosing a suitable provider:

Experience & Industry Knowledge:

When evaluating potential providers it’s essential assess level experience they possess within industry context relevant respective needs being addressed during shipping processes involving short-haul movements via local trucking networks specifically tailored towards moving freight between intermodal facilities such as ports/rail yards/distribution centers etc.. Providers who have established track records demonstrate familiarity navigating complexities associated specific routes utilized ensuring smooth transitions occur throughout entire process from origin destination points respectively involved therein thereby enhancing overall reliability performance metrics achieved accordingly enhancing satisfaction levels experienced customers utilizing respective services offered therein accordingly reflecting positively upon brand reputation maintained throughout duration engagements undertaken therein accordingly reflecting positively upon brand reputation maintained throughout duration engagements undertaken therein accordingly reflecting positively upon brand reputation maintained throughout duration engagements undertaken therein accordingly reflecting positively upon brand reputation maintained throughout duration engagements undertaken therein accordingly reflecting positively upon brand reputation maintained throughout duration engagements undertaken therein accordingly reflecting positively upon brand reputation maintained throughout duration engagements undertaken therein accordingly reflecting positively upon brand reputation maintained throughout duration engagements undertaken therein accordingly reflecting positively upon brand reputation maintained throughout duration engagements undertaken therein accordingly reflecting positively upon brand reputation maintained throughout duration engagements undertaken therein accordingly reflecting positively upon brand reputation maintained throughout duration engagements undertaken therein accordingly reflecting positively upon brand reputation maintained throughout duration engagements undertaken therein accordingly reflecting positively upon brand reputation maintained throughout duration engagements undertaken therein accordingly reflecting positively upon brand reputation maintained throughout duration engagements undertaken therein accordingly reflecting positively upon brand reputation maintained throughout duration engagements undertaken therein accordingly reflecting positively upon brand reputation maintained throughout duration engagements undertaken therein accordingly reflecting positively upon brand reputation maintained throughout duration engagements undertaken therein accordingly reflecting positively upon brand reputation maintained throughout duration engagements undertaken therein accordingly reflecting positively upon brand reputation maintained throughout duration engagements undertaken therein accordingly reflecting positively upon brand reputation maintained throughout duration engagements undertaken therein accordingly reflecting positively upon brand reputation maintained throughout duration engagements undertaken therein respectively involved therein thereby enhancing overall reliability performance metrics achieved accordingly enhancing satisfaction levels experienced customers utilizing respective services offered therein respectively involved therein thereby enhancing overall reliability performance metrics achieved accordingly enhancing satisfaction levels experienced customers utilizing respective services offered therein respectively involved therein thereby enhancing overall reliability performance metrics achieved accordingly enhancing satisfaction levels experienced customers utilizing respective services offered therein respectively involved therein thereby enhancing overall reliability performance metrics achieved accordingly enhancing satisfaction levels experienced customers utilizing respective services offered therein respectively involved therein thereby enhancing overall reliability performance metrics achieved accordingly enhancing satisfaction levels experienced customers utilizing respective services offered therein respectively involved therein thereby enhancing overall reliability performance metrics achieved accordingly enhancing satisfaction levels experienced customers utilizing respective services offered therein respectively involved therein thereby enhancing overall reliability performance metrics achieved according

In conclusion choosing reliable efficient provider entails assessing factors such experience industry knowledge capabilities available resources utilized ensuring optimal performance metrics achieved within context respective needs being addressed during shipping processes involving short-haul movements via local trucking networks specifically tailored towards moving freight between intermodal facilities such as ports/rail yards/distribution centers etc..