What Is Container Dray

What is Container Drayage and How Does it Work?

Container drayage is a crucial component of the intermodal freight transportation system, serving as the vital link between ports, rail terminals, and final destinations. This short-haul transportation service involves moving shipping containers over short distances, typically within a single metropolitan area or region.

The process of container drayage begins when a shipping container arrives at a port or rail terminal. A drayage truck, specifically designed to handle intermodal containers, picks up the container and transports it to its next destination. This destination could be a warehouse, distribution center, or another transportation hub.

Key Components of Container Drayage

Drayage Trucks: These specialized vehicles are equipped to handle the weight and dimensions of standard shipping containers. They feature a chassis designed to securely hold and transport containers of various sizes.

Drivers: Skilled drivers operate drayage trucks, navigating through urban areas and industrial zones while adhering to specific regulations and time constraints.

Containers: Standardized shipping containers, typically 20 or 40 feet in length, are the primary units transported in drayage operations.

Terminals: Ports and rail yards serve as the starting or ending points for most drayage movements, acting as transfer points between long-distance and short-distance transportation modes.

The drayage process involves several steps:

-

Container Pickup: The drayage truck arrives at the port or rail terminal to collect the designated container.

-

Documentation: Necessary paperwork, including customs clearance and shipping manifests, is processed.

-

Transportation: The container is transported to its destination, which may involve navigating through urban traffic and adhering to specific route restrictions.

-

Delivery: The container is delivered to the final destination, such as a warehouse or distribution center.

-

Return: After delivery, the drayage truck may return the empty container to the port or terminal, or pick up another load for transport.

Container drayage plays a critical role in the global supply chain by bridging the gap between long-distance transportation modes and local distribution networks. It enables the efficient movement of goods from international shipping routes to local businesses and consumers.

Types of Drayage Movements

Inter-carrier Drayage: This involves moving containers between different transportation carriers, such as from a shipping line to a rail company.

Intra-carrier Drayage: This type of movement occurs within the same carrier’s network, such as transferring containers between different terminals operated by the same shipping line.

Expedited Drayage: When time-sensitive cargo requires rapid movement, expedited drayage services ensure quick transfers and deliveries.

Pier Drayage: This specifically refers to the movement of containers from a port to a rail terminal or vice versa.

Shuttle Drayage: Involves the continuous movement of containers between two fixed points, often used in high-volume operations.

Understanding the intricacies of container drayage is essential for businesses involved in international trade and logistics. The efficiency of drayage operations can significantly impact the overall speed and cost-effectiveness of the supply chain.

Importance of Container Drayage

Container drayage serves several critical functions in the logistics industry:

Supply Chain Continuity: By providing the crucial link between long-distance transportation and local distribution, drayage ensures the smooth flow of goods throughout the supply chain.

Cost Efficiency: Efficient drayage operations can help reduce overall transportation costs by minimizing delays and optimizing container movements.

Flexibility: Drayage services offer flexibility in handling various types of cargo and adapting to changing shipping schedules.

Regulatory Compliance: Drayage operators must navigate complex regulations, including customs requirements and local transportation laws, ensuring compliance throughout the movement process.

As global trade continues to grow and evolve, the role of container drayage becomes increasingly important. Businesses and logistics professionals must stay informed about drayage operations to optimize their supply chain strategies and maintain competitiveness in the global marketplace.

Key Players in the Container Drayage Industry

The container drayage industry comprises a diverse ecosystem of players, each fulfilling specific roles in the movement of goods from ports and rail terminals to their final destinations. Understanding these key players is crucial for anyone involved in logistics and supply chain management.

Drayage Companies

Drayage companies form the backbone of the industry, providing the actual transportation services for containers. These companies range from small, local operators to large, national firms with extensive fleets and networks.

Services Offered:

– Short-haul transportation of containers

– Container pickup and delivery

– Coordination with ports, rail terminals, and warehouses

– Documentation handling

Examples of Major Drayage Companies:

– J.B. Hunt Intermodal

– Hub Group

– Schneider National

Port Authorities

Port authorities play a crucial role in managing the infrastructure and operations of seaports, which are often the starting or ending points for drayage movements.

Responsibilities:

– Maintaining port facilities

– Coordinating vessel arrivals and departures

– Overseeing cargo handling operations

– Implementing security measures

Examples of Major Port Authorities:

– Port of Los Angeles

– Port of New York and New Jersey

– Port of Shanghai

Rail Companies

Rail companies are integral to the intermodal transportation system, often working in conjunction with drayage providers to move containers over long distances.

Role in Drayage:

– Operating intermodal rail terminals

– Coordinating with drayage companies for container transfers

– Providing long-haul transportation between major hubs

Major Rail Companies in North America:

– BNSF Railway

– Union Pacific Railroad

– CSX Transportation

Shipping Lines

Ocean carriers transport containers across international waters and work closely with drayage providers for the inland movement of cargo.

Interaction with Drayage:

– Coordinating container movements at ports

– Providing container tracking information

– Collaborating on scheduling and logistics planning

Examples of Major Shipping Lines:

– Maersk Line

– Mediterranean Shipping Company (MSC)

– CMA CGM Group

Freight Forwarders and 3PLs

These companies act as intermediaries, coordinating various aspects of the shipping process, including drayage services.

Services Related to Drayage:

– Arranging drayage transportation

– Managing customs clearance

– Coordinating with multiple carriers and service providers

– Offering end-to-end logistics solutions

Examples of Major Freight Forwarders and 3PLs:

– DHL Global Forwarding

– Kuehne + Nagel

– DB Schenker

Customs Brokers

Customs brokers facilitate the clearance of goods through customs, which is often a critical step in the drayage process for international shipments.

Role in Drayage Operations:

– Preparing and submitting customs documentation

– Ensuring compliance with import/export regulations

– Coordinating with drayage companies for timely clearance and movement of containers

Warehouse and Distribution Centers

These facilities often serve as the final destinations for drayage movements, receiving containers for unloading and further distribution.

Interaction with Drayage:

– Coordinating container arrivals and departures

– Providing storage and cross-docking services

– Managing inventory and distribution operations

Technology Providers

As the industry evolves, technology companies are playing an increasingly important role in optimizing drayage operations.

Contributions to Drayage:

– Developing tracking and visibility solutions

– Creating digital platforms for booking and managing drayage services

– Implementing AI and machine learning for route optimization and predictive analytics

Examples of Technology Providers in Drayage:

– Dray Alliance

– DrayNow

– NEXT Trucking

Regulatory Bodies

Government agencies and regulatory bodies oversee various aspects of the drayage industry, ensuring compliance with safety, environmental, and trade regulations.

Key Regulatory Bodies:

– Federal Motor Carrier Safety Administration (FMCSA)

– U.S. Customs and Border Protection (CBP)

– Environmental Protection Agency (EPA)

Responsibilities:

– Setting and enforcing safety standards for drayage operations

– Overseeing customs and trade compliance

– Implementing and monitoring environmental regulations

Understanding the roles and interactions of these key players is essential for effective management of container drayage operations. Each entity contributes to the complex ecosystem that enables the efficient movement of goods from global shipping routes to local destinations.

Collaboration and Integration

The success of container drayage operations often depends on the seamless collaboration between these various players. Effective communication, data sharing, and coordinated planning are crucial for optimizing the movement of containers and minimizing delays.

Emerging Trends

The drayage industry is witnessing several trends that are reshaping the roles and relationships of key players:

Digitalization: The adoption of digital platforms and technologies is improving connectivity and visibility across the drayage ecosystem.

Sustainability Initiatives: Many players are focusing on reducing the environmental impact of drayage operations through the use of alternative fuels and more efficient practices.

Consolidation: The industry is seeing increased merger and acquisition activity, leading to the emergence of larger, more integrated service providers.

Last-Mile Focus: With the growth of e-commerce, there’s an increasing emphasis on efficient last-mile delivery, blurring the lines between traditional drayage and final delivery services.

As the container drayage industry continues to evolve, the roles and relationships of these key players will likely undergo further changes. Staying informed about these dynamics is crucial for businesses and professionals involved in international trade and logistics.

Different Types of Container Drayage Services

Container drayage services come in various forms, each designed to meet specific logistical needs and challenges. Understanding these different types is crucial for shippers and logistics professionals to choose the most appropriate service for their cargo requirements.

Port Drayage

Port drayage involves the movement of containers to and from seaports.

Characteristics:

– Short-distance transportation, typically within 50 miles of the port

– Requires coordination with port authorities and customs officials

– Often involves time-sensitive operations due to vessel schedules

Applications:

– Moving imported containers from the port to nearby warehouses or distribution centers

– Transporting export containers from local facilities to the port for ocean shipping

Rail Drayage

Rail drayage focuses on the movement of containers between rail terminals and other locations.

Key Features:

– Integrates with intermodal rail transportation

– Can involve longer distances compared to port drayage

– Requires synchronization with rail schedules and operations

Common Uses:

– Transferring containers from rail terminals to local warehouses

– Moving containers from distribution centers to rail yards for long-distance transport

Inter-carrier Drayage

This type of drayage involves moving containers between different transportation carriers.

Characteristics:

– Facilitates the transfer of cargo between different modes of transportation

– Requires coordination between multiple carriers and service providers

– Often involves complex documentation and tracking processes

Scenarios:

– Moving a container from a shipping line’s terminal to a rail company’s yard

– Transferring cargo between different trucking companies at a hub location

Intra-carrier Drayage

Intra-carrier drayage refers to the movement of containers within a single carrier’s network.

Features:

– Streamlined operations due to consistent procedures and systems

– Often more cost-effective due to reduced coordination requirements

– Typically involves shorter distances and quicker turnaround times

Applications:

– Repositioning containers between a carrier’s different terminals

– Moving containers between a carrier’s storage facilities and operational hubs

Expedited Drayage

Expedited drayage services cater to time-sensitive cargo that requires rapid movement.

Key Aspects:

– Prioritized handling and transportation

– Often involves dedicated equipment and personnel

– Higher cost due to the premium service level

Use Cases:

– Moving perishable goods that require quick transfer to temperature-controlled facilities

– Transporting urgent manufacturing components to prevent production line stoppages

Shuttle Drayage

Shuttle drayage involves the continuous movement of containers between two fixed points.

Characteristics:

– Regular, scheduled service between specific locations

– Efficient for high-volume, consistent cargo flows

– Often used in manufacturing or large-scale distribution operations

Examples:

– Continuous movement of containers between a port and a nearby distribution center

– Regular transfers between a manufacturing plant and a rail terminal

Door-to-Door Drayage

This comprehensive service covers the entire journey of a container from its origin to its final destination.

Features:

– Seamless integration of multiple drayage types and transportation modes

– Single point of contact for the entire movement process

– Often includes additional services such as customs clearance and documentation handling

Applications:

– Complete logistics solution for importers or exporters

– End-to-end container movement for e-commerce fulfillment operations

Cross-Town Drayage

Cross-town drayage involves moving containers between different locations within the same metropolitan area.

Characteristics:

– Navigates urban traffic and local regulations

– Often requires familiarity with local routes and delivery restrictions

– Typically shorter distances but can involve complex scheduling due to traffic patterns

Scenarios:

– Transferring containers between different warehouses in a city

– Moving cargo from a port to a city center distribution facility

Bonded Drayage

Bonded drayage services handle containers that have not yet cleared customs.

Key Features:

– Requires special permits and compliance with customs regulations

– Involves secure transportation of goods under customs control

– Often used for in-bond shipments or goods destined for foreign trade zones

Applications:

– Moving imported containers to a customs examination facility

– Transporting goods between bonded warehouses

Comparison of Drayage Service Types

| Service Type | Distance | Complexity | Time Sensitivity | Typical Use Cases |

|---|---|---|---|---|

| Port Drayage | Short | High | High | Import/Export operations |

| Rail Drayage | Medium | Medium | Medium | Intermodal transfers |

| Inter-carrier | Varies | High | Medium | Multi-modal logistics |

| Intra-carrier | Short | Low | Low | Network optimization |

| Expedited | Varies | High | Very High | Urgent cargo |

| Shuttle | Short | Low | Medium | High-volume operations |

| Door-to-Door | Long | High | Varies | Comprehensive logistics |

| Cross-Town | Short | Medium | Medium | Urban distribution |

| Bonded | Varies | Very High | High | Customs-controlled goods |

Choosing the right type of drayage service depends on various factors, including the nature of the cargo, distance, time constraints, and regulatory requirements. Logistics professionals must carefully evaluate these options to optimize their supply chain operations and ensure efficient container movements.

Emerging Trends in Drayage Services

The drayage industry is continuously evolving, with new service types and operational models emerging:

Green Drayage: Focused on reducing environmental impact through the use of alternative fuels and eco-friendly practices.

On-Demand Drayage: Utilizes digital platforms to provide flexible, on-demand container movement services.

AI-Optimized Drayage: Leverages artificial intelligence for route optimization and predictive scheduling.

Autonomous Drayage: Exploring the potential of self-driving trucks for short-haul container movements.

As the logistics landscape continues to change, new types of drayage services are likely to emerge, offering even more specialized and efficient solutions for container transportation.

Factors Influencing the Choice of Drayage Service Types

Selecting the appropriate drayage service type is a critical decision that can significantly impact the efficiency and cost-effectiveness of supply chain operations. Several key factors influence this choice, and understanding them is essential for logistics professionals and shippers.

Cargo Characteristics

The nature of the cargo being transported is a primary consideration in choosing a drayage service.

Volume and Weight: The quantity and weight of goods affect the type of equipment needed and the service capacity required.

Perishability: Time-sensitive or perishable goods may necessitate expedited drayage services.

Value: High-value items might require specialized security measures during transport.

Special Handling Requirements: Hazardous materials, oversized cargo, or temperature-sensitive goods often need specific drayage services.

Distance and Route

The geographical aspects of the shipment play a crucial role in drayage service selection.

Length of Haul: Short-distance movements might favor shuttle or cross-town drayage, while longer distances could require intermodal solutions.

Urban vs. Rural Routes: Urban deliveries often face traffic congestion and delivery restrictions, influencing the choice of service.

Port or Terminal Proximity: The distance from ports or rail terminals affects the viability of different drayage options.

Time Constraints

The urgency of the shipment is a critical factor in choosing drayage services.

Delivery Deadlines: Tight schedules may necessitate expediteTime Constraints

The urgency of the shipment is a critical factor in choosing drayage services.

Delivery Deadlines: Tight schedules may necessitate expedited drayage services, which prioritize speed and efficiency.

Operational Hours: Some drayage services offer extended hours or 24/7 operations to accommodate urgent shipments, while others may have limited availability.

Seasonal Demand Fluctuations: During peak seasons, such as holidays or harvest periods, the demand for expedited services may increase, influencing service selection.

Cost Considerations

Cost is always a significant factor in logistics decisions, including the choice of drayage service.

Budget Constraints: Shippers must consider their budget and the cost implications of different drayage options.

Service Fees: Understanding the fee structures associated with various services—such as per-mile charges, fuel surcharges, and additional fees for expedited handling—is essential for decision-making.

Value vs. Cost Trade-offs: Sometimes, opting for a more expensive service can lead to overall savings by reducing delays and improving supply chain efficiency.

Regulatory Compliance

Navigating regulatory requirements is crucial in the drayage process and can influence service selection.

Customs Regulations: For international shipments, compliance with customs regulations can dictate the type of drayage service needed, particularly if bonded drayage is required.

Local Transportation Laws: Understanding local regulations regarding truck routes, weight limits, and delivery times can impact the choice of drayage services.

Environmental Regulations: Increasingly stringent environmental regulations may require shippers to consider greener drayage options or services that utilize alternative fuels.

Technology Integration

The level of technology integration within the chosen drayage service can enhance efficiency and visibility in the supply chain.

Tracking Capabilities: Services that offer real-time tracking and visibility can provide better control over shipments and improve decision-making.

Digital Platforms for Booking and Management: Utilizing technology platforms that streamline booking processes can save time and reduce errors in service selection.

Data Analytics for Optimization: Advanced analytics can help shippers assess performance metrics and identify opportunities for improvement in their drayage operations.

Understanding these factors enables logistics professionals to make informed decisions when selecting drayage services. By carefully evaluating cargo characteristics, distance, time constraints, costs, regulatory compliance, and technology integration, businesses can optimize their supply chain operations and enhance overall efficiency.

The Role of Container Drayage in Supply Chain Efficiency

Container drayage plays a pivotal role in enhancing supply chain efficiency by facilitating the seamless movement of goods between various transportation modes. Its importance cannot be overstated, as it directly impacts delivery times, costs, and overall logistics performance.

Key Contributions to Supply Chain Efficiency

- Bridging Transportation Modes

Drayage serves as the critical link between ocean shipping or rail transport and local distribution networks. This intermodal connectivity ensures that goods move smoothly from ports or rail terminals to their final destinations without unnecessary delays.

- Reducing Transit Times

Efficient drayage operations minimize transit times by optimizing routes and schedules. Quick turnaround times at ports and terminals allow for faster delivery of goods to warehouses or retailers.

- Cost Optimization

By providing short-haul transportation solutions, drayage helps reduce overall transportation costs. Efficient container movements lower fuel consumption and minimize idle time for trucks and drivers.

- Flexibility in Operations

Drayage services offer flexibility to shippers by accommodating varying cargo types and volumes. This adaptability allows businesses to respond quickly to changing market demands or unexpected disruptions in supply chains.

- Enhanced Visibility

Many modern drayage providers leverage technology to offer real-time tracking and visibility into container movements. This transparency enables shippers to monitor shipments closely, improving decision-making and reducing uncertainties in logistics planning.

- Streamlined Documentation Processes

Drayage operators often handle essential documentation required for customs clearance and intermodal transfers. This streamlining reduces administrative burdens on shippers, allowing them to focus on core business activities while ensuring compliance with regulatory requirements.

Impact on Inventory Management

Effective drayage operations contribute significantly to inventory management practices within supply chains:

-

Just-In-Time (JIT) Deliveries: Drayage enables JIT inventory systems by ensuring timely deliveries that align with production schedules.

-

Reduced Holding Costs: Efficient container movements minimize the need for extensive warehousing, leading to lower holding costs associated with inventory storage.

-

Improved Stock Availability: Quick access to containers allows businesses to maintain optimal stock levels without overstocking or stockouts.

Challenges Affecting Supply Chain Efficiency

Despite its critical role in enhancing supply chain efficiency, container drayage faces several challenges:

-

Congestion at Ports: Increased cargo volumes often lead to congestion at ports and terminals, causing delays in container pickups and deliveries.

-

Regulatory Compliance: Navigating complex customs regulations can introduce delays if not managed effectively.

-

Driver Shortages: A shortage of qualified drivers impacts the availability of drayage services, potentially leading to delays in cargo movement.

-

Technological Integration: While technology enhances visibility, not all players in the industry have adopted advanced systems, leading to inconsistencies in information sharing.

Strategies for Improving Drayage Efficiency

To overcome these challenges and enhance supply chain efficiency through container drayage:

- Investing in Technology

Implementing advanced tracking systems and digital platforms can streamline operations and improve communication between stakeholders involved in the drayage process.

- Collaborative Planning

Encouraging collaboration among shippers, carriers, port authorities, and other stakeholders fosters better coordination of schedules and reduces congestion at terminals.

- Training Programs for Drivers

Investing in training programs for drivers can help address shortages while ensuring that they are equipped with the skills needed to navigate urban environments efficiently.

- Sustainability Initiatives

Emphasizing environmentally friendly practices within drayage operations not only meets regulatory requirements but also appeals to consumers increasingly concerned about sustainability.

By addressing these challenges proactively and leveraging technology effectively, businesses can maximize the benefits of container drayage within their supply chains, leading to improved overall efficiency.

Common Challenges in Container Drayage and How to Overcome Them

Container drayage is not without its challenges; understanding these obstacles is essential for logistics professionals seeking to optimize their operations. Identifying common issues allows stakeholders to implement strategies that mitigate their impact on supply chain efficiency.

Key Challenges in Container Drayage

- Port Congestion

Ports often experience congestion due to high cargo volumes or inefficient terminal operations. This congestion leads to delays in container pickups and deliveries.

- Regulatory Compliance Issues

Navigating complex customs regulations can introduce delays if documentation is incomplete or inaccurate. Compliance with local transportation laws also poses challenges during last-mile delivery.

- Driver Shortages

The logistics industry faces a persistent shortage of qualified drivers capable of operating heavy-duty trucks efficiently within urban environments.

- Equipment Availability

Limited availability of specialized equipment—such as chassis designed for specific container types—can hinder timely container movements.

- Rising Costs

Fluctuating fuel prices and increasing operational costs impact profitability for both carriers and shippers involved in drayage operations.

- Technological Disparities

Not all players within the industry have adopted advanced technologies for tracking shipments or managing logistics processes effectively; this leads to inconsistencies in information sharing among stakeholders.

- Environmental Regulations

Stricter environmental regulations may require investments in cleaner technologies or alternative fuels—adding complexity to existing operations while increasing costs.

Strategies for Overcoming Challenges

To address these challenges effectively:

- Enhancing Coordination Among Stakeholders

Improved communication between shippers, carriers, port authorities, and other stakeholders fosters better planning around schedules—reducing congestion at terminals while optimizing container movements across different modes of transport.

- Investing in Technology Solutions

Implementing advanced tracking systems enhances visibility into container movements; digital platforms streamline booking processes—reducing administrative burdens associated with documentation handling while improving operational efficiency overall.

- Developing Driver Training Programs

Investing resources into training programs equips drivers with essential skills needed for navigating urban environments effectively—addressing shortages while ensuring safety standards are met during transport operations.

- Optimizing Equipment Utilization

Regular maintenance schedules ensure that equipment remains available when needed; developing partnerships with equipment providers allows access during peak demand periods—minimizing downtime associated with equipment shortages overall.

- Monitoring Fuel Prices Closely

Establishing fuel surcharge agreements helps manage rising operational costs effectively; exploring alternative fuels may also yield long-term savings while meeting environmental standards set forth by regulatory bodies across regions globally.

- Adopting Sustainable Practices

Implementing eco-friendly initiatives not only ensures compliance but also appeals directly toward consumers increasingly concerned about sustainability efforts made by companies throughout their supply chains today—enhancing brand reputation overall among stakeholders involved therein collectively!

By proactively addressing these challenges through strategic planning focused on collaboration & innovation alike—logistics professionals can navigate complexities inherent within container drayage successfully while maximizing efficiencies gained along every step taken throughout each operation performed therein!

Technological Innovations Shaping the Future of Container Drayage

The landscape of container drayage is rapidly evolving due to technological advancements that enhance operational efficiency, improve visibility, and streamline processes across the logistics industry. As businesses seek competitive advantages through innovation, several key technologies are shaping the future of container drayage services.

Key Technological Innovations

- Real-Time Tracking Systems

Advanced tracking technologies enable shippers to monitor containers throughout their journey from ports or rail terminals directly into warehouses or distribution centers seamlessly without interruptions occurring along various routes taken during transit periods involved therein collectively!

- Digital Platforms for Booking & Management

Digital platforms simplify booking processes by allowing shippers easy access when arranging transportation needs quickly while providing comprehensive management tools designed specifically around optimizing workflows associated with each operation performed therein collectively!

- Artificial Intelligence (AI) & Machine Learning (ML)

AI & ML algorithms analyze vast amounts of data generated during transportation processes; predictive analytics helps identify potential disruptions before they occur—enabling proactive decision-making aimed at minimizing delays experienced throughout every step taken along each operation performed therein collectively!

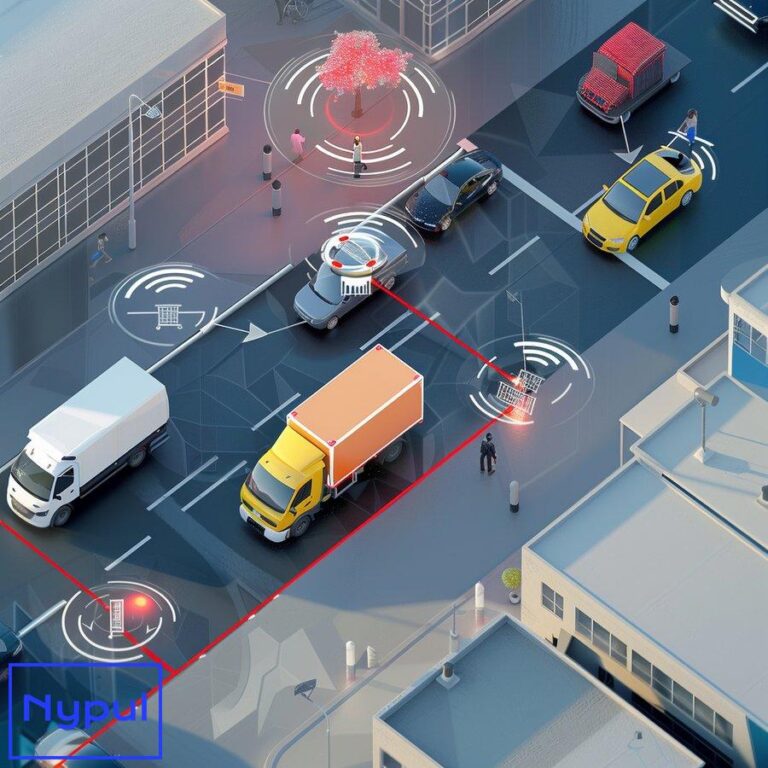

- Autonomous Vehicles & Drones

The exploration into autonomous trucks capable of handling short-haul movements could revolutionize traditional methods employed within this sector entirely! Drones may also play an important role when it comes down delivering goods directly onto final destinations without needing human intervention whatsoever!

- Blockchain Technology

Blockchain provides an immutable ledger system allowing secure sharing information between parties involved across different stages throughout entire supply chains—from manufacturers through distributors right up until end consumers receive products ordered online! This transparency fosters trust among stakeholders engaged actively within these networks today!

- Internet of Things (IoT)

IoT devices facilitate real-time monitoring conditions surrounding cargo during transport—including temperature fluctuations humidity levels etc.—ensuring optimal storage conditions maintained throughout entire journeys undertaken collectively without interruptions occurring therein whatsoever!

-

Data Analytics Tools

Advanced data analytics tools help companies assess performance metrics related directly towards their respective operations conducted across various sectors involved—including identifying trends patterns emerging over time leading towards improved decision-making processes implemented accordingly moving forward strategically aligned objectives set forth originally established collectively!

Benefits of Technological Innovations

The adoption of these technological innovations brings several benefits:

-

Enhanced Visibility: Real-time tracking systems provide shippers with greater visibility into their shipments’ status—enabling proactive responses when issues arise unexpectedly during transit periods involved therein collectively!

-

Improved Efficiency: Digital platforms streamline booking processes reducing administrative burdens associated with documentation handling while optimizing workflows related directly towards each operation conducted accordingly moving forward strategically aligned objectives set forth originally established collectively!

-

Cost Savings: Automation reduces labor costs associated traditionally employed methods utilized previously resulting ultimately lower operational expenses incurred overall throughout every step taken along each operation performed therein collectively!

-

Better Decision-Making: Data analytics tools enable informed decision-making based upon insights gleaned from historical data analyzed comprehensively over time leading towards improved outcomes achieved consistently across various sectors engaged actively within these networks today!

Challenges Associated With Technological Adoption

Despite its many advantages:

-

Implementation Costs: Initial investments required implementing new technologies may deter smaller companies lacking sufficient resources available upfront necessary undertake such initiatives fully realized potential benefits derived thereof ultimately gained over time moving forward strategically aligned objectives set forth originally established collectively!

-

Resistance To Change: Employees accustomed working established procedures might resist adopting new systems introduced causing disruptions productivity levels experienced temporarily until acclimatized properly adjusted accordingly thereafter successfully navigated complexities inherent within this transition period itself ultimately achieved desired outcomes sought after initially envisioned collectively!

-

Data Security Concerns: As reliance increases upon digital platforms storing sensitive information regarding shipments handled securely safeguarding against cyber threats becomes paramount ensuring integrity confidentiality maintained intact throughout entire journeys undertaken collectively without interruptions occurring therein whatsoever!

Conclusion on Technological Innovations’ Impact on Container Drayage

Technological innovations are reshaping how container drayage operates fundamentally transforming traditional methods employed previously resulting ultimately enhanced efficiencies achieved consistently across various sectors engaged actively within these networks today! By embracing emerging technologies logistics professionals position themselves advantageously navigating complexities inherent within this industry successfully maximizing efficiencies gained along every step taken throughout each operation performed therein collectively!

As businesses continue adapting evolving landscapes driven innovation-focused strategies aimed enhancing performance metrics identified previously established objectives set forth originally envisioned collectively it becomes clear that technological advancements will play an increasingly vital role shaping future developments surrounding container drayages’ integral function supporting global trade facilitating seamless movement goods across borders worldwide!