What Is Drayage and Intermodal

How does intermodal transportation work?

Intermodal transportation is a logistics strategy that involves using multiple modes of transport to move goods from origin to destination. This method leverages the strengths of various transportation modes—such as trucks, trains, ships, and planes—allowing for efficient and cost-effective shipping solutions.

The Process of Intermodal Transportation

-

Origin Pickup: The process begins with a truck picking up cargo from the shipper’s location. This truck transports the cargo to a nearby intermodal facility or terminal.

-

Loading into Containers: At the terminal, the cargo is loaded into standardized intermodal containers. These containers are designed for easy transfer between different modes of transport without unloading and reloading the cargo itself.

-

Rail Transport: Once loaded, the container is transferred onto a train for long-distance transport. Rail is often more economical for moving large volumes of cargo over land compared to trucking.

-

Transfer to Truck: Upon reaching the destination terminal, the container is unloaded from the train and placed back onto a truck for final delivery to the consignee.

-

Final Delivery: The truck delivers the container to its final destination, completing the intermodal journey.

Benefits of Intermodal Transportation

-

Cost Efficiency: By combining different transportation modes, shippers can reduce costs associated with fuel and labor.

-

Environmental Impact: Rail transport typically has a lower carbon footprint compared to trucking alone, making intermodal options more sustainable.

-

Flexibility: Intermodal transportation allows shippers to adapt their logistics strategies based on cargo type, distance, and delivery timelines.

-

Reduced Transit Times: Utilizing rail for long distances can lead to faster overall transit times compared to relying solely on trucks.

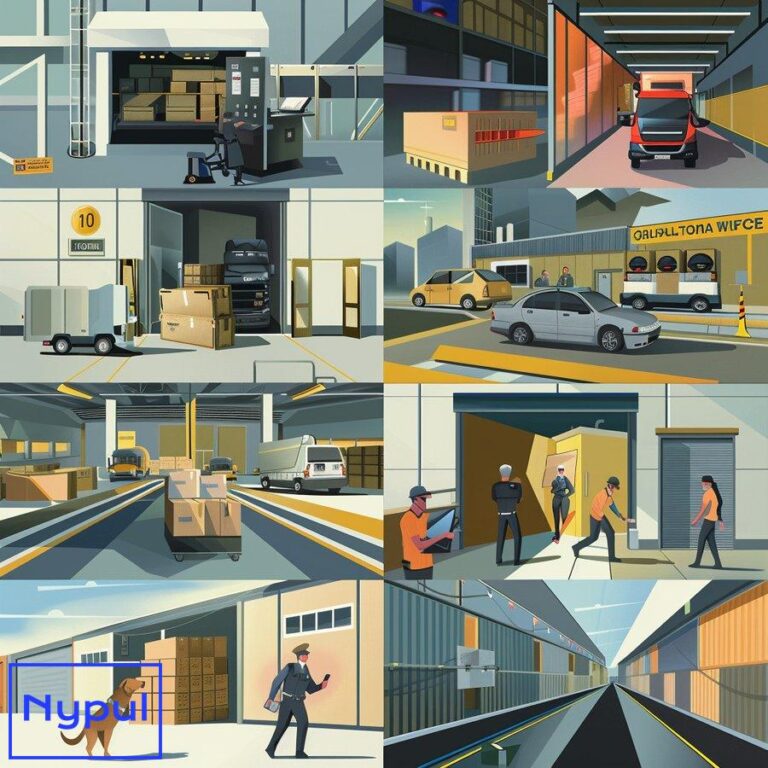

What are the key components of drayage operations?

Drayage operations play a crucial role in the intermodal transportation process by providing short-distance transport services between ports, rail terminals, and distribution centers. Understanding these key components is essential for optimizing logistics efficiency.

Key Components of Drayage Operations

-

Drayage Trucks: Specialized trucks designed for transporting containers over short distances. These vehicles are often equipped with hydraulic systems to facilitate loading and unloading.

-

Intermodal Terminals: Facilities where containers are transferred between different modes of transport. These terminals serve as critical hubs in the drayage process.

-

Container Handling Equipment: Equipment such as cranes and forklifts used at terminals to load and unload containers from trucks and trains.

-

Drivers: Skilled professionals who operate drayage trucks. Their expertise is vital for navigating busy port areas and ensuring timely deliveries.

-

Regulatory Compliance: Adherence to local, state, and federal regulations governing transportation safety, emissions standards, and driver qualifications.

Drayage Operations Workflow

-

Pickup Request: Shippers request drayage services through logistics providers or freight brokers.

-

Container Pickup: The drayage truck picks up the container from a port or rail terminal.

-

Transport to Destination: The truck transports the container to a designated location, such as a warehouse or distribution center.

-

Container Drop-off: The container is delivered and unloaded at its final destination.

-

Return Trip: The drayage truck returns to the terminal for another load or empty container pickup.

How do drayage and intermodal transportation interact?

The interaction between drayage and intermodal transportation is fundamental in creating an efficient supply chain. Drayage serves as a vital link that facilitates the seamless transfer of goods between different modes of transport.

Synergy Between Drayage and Intermodal Transportation

-

Integration of Services: Drayage acts as an essential service that connects ocean shipping or rail transport with local delivery networks. This integration ensures that goods move smoothly from one mode to another without delays.

-

Container Management: Efficient drayage operations help manage container flows at intermodal terminals, reducing congestion and improving turnaround times for trucks and trains alike.

-

Cost Optimization: By utilizing drayage services within an intermodal framework, shippers can optimize their logistics costs by minimizing empty miles traveled by trucks and maximizing container utilization across different transport modes.

Challenges in Interaction

-

Coordination Issues: Poor communication between drayage providers and intermodal carriers can lead to delays in loading/unloading schedules.

-

Capacity Constraints: Limited availability of drayage trucks during peak seasons can hinder timely transfers between transport modes.

-

Regulatory Compliance: Navigating complex regulations across different jurisdictions can complicate operations, requiring careful management by logistics providers.

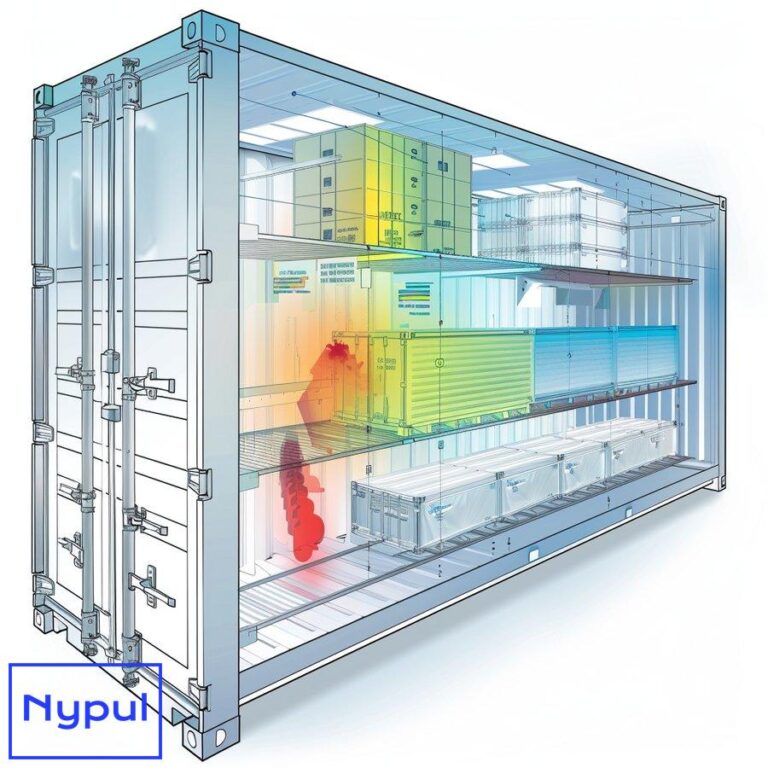

What equipment is essential for drayage and intermodal logistics?

The efficiency of drayage and intermodal logistics relies heavily on specialized equipment designed for handling containers during transit. Understanding this equipment helps stakeholders optimize their operations effectively.

Essential Equipment for Drayage Operations

- Drayage Trucks:

- Equipped with hydraulic lifts for easy loading/unloading.

-

Designed for maneuverability in tight port environments.

-

Chassis:

- A wheeled frame that supports containers during road transport.

-

Must be compatible with various container sizes (20′, 40′, etc.).

-

Container Handling Equipment:

- Cranes: Used at ports and terminals to lift containers onto trucks or trains.

-

Forklifts: Essential for moving containers within terminal yards.

-

Intermodal Containers:

- Standardized containers (ISO containers) that facilitate easy transfer across different transport modes.

- Available in various sizes (20′, 40′, etc.) depending on cargo requirements.

Essential Equipment for Intermodal Transport

- Railcars:

- Specialized cars designed to carry intermodal containers securely.

-

Equipped with locking mechanisms that ensure stability during transit.

-

Shipping Vessels:

-

Container ships designed specifically for transporting large volumes of intermodal containers across oceans.

-

Tracking Systems:

- GPS-enabled devices that allow real-time monitoring of container locations throughout transit.

| Equipment Type | Purpose | Key Features |

|---|---|---|

| Drayage Trucks | Short-distance transport | Hydraulic lifts, maneuverability |

| Chassis | Supports containers during road transport | Compatibility with various sizes |

| Cranes | Lifts containers at ports/terminals | High lifting capacity |

| Forklifts | Moves containers within terminals | Versatile operation |

| Railcars | Carries intermodal containers | Locking mechanisms |

| Shipping Vessels | Transports containers across oceans | Designed for large volumes |

| Tracking Systems | Monitors container locations | Real-time GPS tracking |

What challenges do drayage and intermodal operations face?

Despite their advantages, drayage and intermodal operations encounter several challenges that can impact efficiency, cost-effectiveness, and service quality. Identifying these challenges is essential for developing effective solutions.

Common Challenges in Drayage Operations

-

Congestion at Ports: High traffic volumes can lead to delays in loading/unloading operations, impacting overall transit times.

-

Driver Shortages: A lack of qualified drivers can result in increased operational costs and delays in service delivery.

-

Regulatory Compliance Issues: Navigating complex regulations related to safety standards, emissions controls, and labor laws can complicate operations.

Challenges in Intermodal Transportation

-

Coordination Difficulties: Ensuring seamless communication between multiple carriers can be challenging, leading to potential delays in shipments.

-

Infrastructure Limitations: Aging infrastructure at ports and rail terminals may hinder efficient loading/unloading processes.

-

Capacity Constraints: Fluctuations in demand can lead to capacity shortages in both trucking and rail services during peak seasons.

Addressing Challenges

To mitigate these challenges:

-

Implementing advanced scheduling systems can improve coordination among carriers.

-

Investing in driver training programs may help alleviate driver shortages by attracting new talent into the industry.

-

Advocating for infrastructure improvements at key transportation hubs can enhance overall operational efficiency.

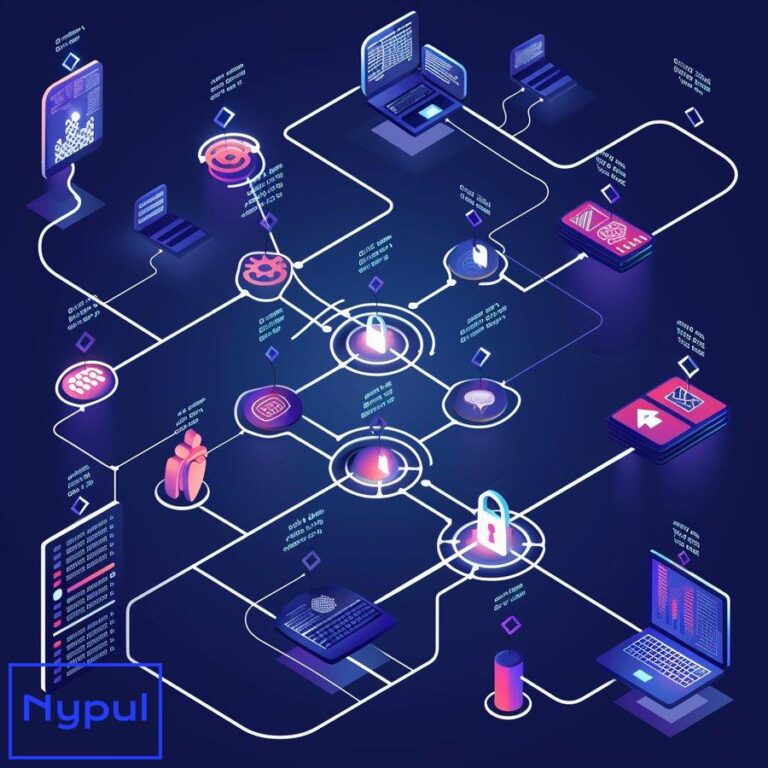

How does technology enhance drayage and intermodal efficiency?

Technology plays a pivotal role in enhancing the efficiency of drayage and intermodal operations by streamlining processes, improving visibility, and facilitating better decision-making among stakeholders.

Technological Innovations in Drayage Operations

- Real-Time Tracking Systems:

- GPS-enabled devices allow shippers to monitor container locations throughout transit.

-

Provides visibility into potential delays or disruptions along the supply chain.

-

Automated Scheduling Software:

- Optimizes routing decisions based on real-time traffic data.

-

Reduces idle time by efficiently allocating resources based on demand patterns.

-

Electronic Data Interchange (EDI):

- Facilitates seamless communication between shippers, carriers, and terminals.

- Streamlines documentation processes such as bills of lading and customs declarations.

Technological Innovations in Intermodal Transportation

- Blockchain Technology:

-

Enhances transparency by providing an immutable record of transactions across multiple parties involved in shipping.

-

Artificial Intelligence (AI):

-

Analyzes historical data to predict demand fluctuations, enabling better capacity planning among carriers.

-

Mobile Applications:

- Provides shippers with access to real-time information regarding shipment status via smartphones or tablets.

Impact on Efficiency

The adoption of these technologies leads to:

-

Improved operational transparency through real-time visibility into shipments.

-

Enhanced decision-making capabilities based on data-driven insights regarding demand patterns.

-

Reduced administrative burdens associated with paperwork through automated processes.

What factors influence drayage and intermodal shipping costs?

Understanding the factors that influence shipping costs is crucial for shippers looking to optimize their logistics budgets while maintaining service quality. Several elements contribute significantly to these costs within both drayage operations and broader intermodal transportation frameworks.

Factors Influencing Drayage Costs

-

Distance Traveled: Longer distances generally incur higher fuel expenses; thus affecting overall cost structures significantly.

-

Fuel Prices: Fluctuations in fuel prices directly impact operating expenses associated with trucking services.

-

Labor Costs: Wages paid to drivers play a significant role; higher wages may lead directly toward increased pricing structures.

-

Equipment Availability: Limited availability of chassis or trucks during peak seasons may drive up rental rates.

-

Port Fees & Tariffs: Charges imposed by port authorities or customs fees can add additional layers onto total expenses incurred.

Factors Influencing Intermodal Shipping Costs

-

Mode Selection: The choice between rail versus trucking influences overall pricing; rail tends toward lower costs over long distances while trucking offers flexibility.

-

Container Utilization Rates: Higher utilization rates reduce per-unit costs; inefficient use leads toward inflated pricing structures.

-

Seasonal Demand Fluctuations: Increased demand during peak seasons often leads toward elevated pricing due primarily toward capacity constraints.

-

Infrastructure Costs: Investments made into upgrading facilities impact overall operational expenses; outdated infrastructure may lead toward inefficiencies resulting ultimately toward higher costs incurred.

-

Regulatory Compliance Expenses: Adhering strictly toward regulations concerning safety standards adds additional layers onto total expenses incurred throughout shipping processes.

How can shippers choose the right drayage and intermodal partners?

Selecting appropriate partners within both drayage operations as well as broader intermodal frameworks requires careful consideration; doing so ensures optimal performance while maintaining cost-effectiveness throughout logistics processes undertaken by shippers involved within these industries today!

Criteria for Selecting Drayage Partners

-

Experience & Reputation: Look for providers with proven track records; reviews from other clients provide insights regarding reliability levels exhibited consistently over time.

-

Service Coverage Areas: Ensure chosen partners operate within necessary geographic regions relevant toward specific needs outlined beforehand by shippers involved directly within these transactions undertaken here today!

-

Technology Integration Capabilities: Evaluate whether potential partners utilize modern technologies enhancing operational efficiencies; systems facilitating real-time tracking offer significant advantages when managing shipments effectively!

-

Cost Structure Transparency: Seek out partners willing openly discuss pricing structures upfront; clarity surrounding fees associated ensures no hidden surprises arise later down road ahead!

-

Regulatory Compliance Knowledge Base: Verify partner familiarity concerning regulations governing industry standards; compliance issues could result costly fines impacting overall profitability margins realized ultimately thereafter!

Criteria for Selecting Intermodal Partners

-

Network Coverage & Connectivity Options Available Across Modes Chosen Here Today!

-

Flexibility Regarding Capacity Management Strategies Employed During Peak Seasons!

-

Customer Service Quality Standards Maintained Throughout Engagements Undertaken Here Today!

-

Innovative Solutions Offered Addressing Unique Challenges Faced By Shippers Engaged Within This Industry!

-

Sustainability Initiatives Implemented Aimed Toward Reducing Environmental Impacts Associated With Logistics Operations Undertaken Here Today!

By carefully evaluating these criteria when selecting both types of partners mentioned above here today will enable shippers achieve optimal performance while minimizing costs incurred throughout entire logistics processes undertaken collectively together moving forward ahead!