What Is Drayage in International Trade

Why is drayage crucial for global supply chains?

Drayage forms a critical link in global supply chains, connecting ports, rail yards, and distribution centers to enable the seamless flow of goods across international borders. As the first and last mile of intermodal freight transportation, drayage bridges the gap between long-distance shipping and local delivery.

The importance of drayage in global trade stems from its role in:

Facilitating modal transfers

Drayage allows cargo to transition between different transportation modes like ships, trains, and trucks. Without efficient drayage, containers would pile up at ports and rail terminals, causing costly delays and disruptions.

Enabling just-in-time logistics

By providing flexible, short-distance transportation, drayage supports lean inventory practices and just-in-time manufacturing. Companies can quickly move goods from ports to nearby warehouses or production facilities as needed.

Reducing congestion at ports

Prompt drayage operations prevent bottlenecks at busy seaports by swiftly moving containers out of terminal yards. This improves overall port productivity and capacity.

Supporting e-commerce fulfillment

As online retail grows, drayage plays a key role in transporting imported goods from ports to regional distribution centers for rapid order fulfillment and delivery.

Enhancing supply chain visibility

Modern drayage providers offer real-time tracking and status updates, giving shippers greater visibility into the movement of their cargo during a critical phase of transport.

Optimizing container utilization

Efficient drayage allows for faster turnaround of shipping containers, maximizing their productive use and reducing equipment shortages.

The strategic value of drayage becomes evident when examining its impact on key supply chain metrics:

| Metric | Impact of Efficient Drayage |

|---|---|

| Lead times | Reduced by 1-3 days on average |

| Inventory costs | Lowered by 5-10% through improved JIT capabilities |

| Port congestion | Decreased by 15-25% with faster container movements |

| Container dwell times | Cut by 30-50% at terminals |

| Supply chain visibility | Enhanced with real-time tracking and status updates |

As global trade volumes continue to grow, the strategic importance of drayage in supply chains is only expected to increase. Companies that optimize their drayage operations gain a competitive edge through improved efficiency, reduced costs, and enhanced customer service.

What are the different types of drayage services in international commerce?

In international commerce, drayage services come in various forms to meet the diverse needs of shippers and logistics providers. Understanding these different types helps businesses choose the most appropriate drayage solution for their specific requirements.

Inter-carrier drayage

This involves moving cargo between different transportation carriers. For example, transferring a container from a shipping line to a rail company at a port. Inter-carrier drayage ensures smooth transitions between modes of transport in intermodal shipping.

Intra-carrier drayage

This type of drayage occurs when cargo is moved between facilities owned by the same carrier. It might involve relocating containers between different terminals or depots operated by a single shipping line or logistics provider.

Expedited drayage

When time is of the essence, expedited drayage provides rapid transportation of urgent shipments. This service often involves dedicated trucks and priority handling to ensure the fastest possible delivery.

Pier drayage

Specifically focused on moving containers to and from port facilities, pier drayage is crucial for import and export operations. It connects seaports with inland transportation networks.

Shuttle drayage

This service involves short, repetitive movements between two nearby locations, such as between a port and a nearby warehouse or distribution center. Shuttle drayage optimizes the flow of goods in high-volume corridors.

Door-to-door drayage

A comprehensive service that handles the entire journey from the origin point (e.g., a factory) to the final destination (e.g., a retail store). This end-to-end solution simplifies logistics management for shippers.

Cross-town drayage

Involves moving cargo across a metropolitan area, often between different terminals or logistics hubs. This service is vital for efficient urban freight distribution.

Bonded drayage

Used for transporting goods that have not yet cleared customs. Bonded drayage providers are authorized to move cargo under customs bond, ensuring compliance with import regulations.

The choice of drayage service depends on various factors:

Cargo type

Different drayage services are suited for various types of cargo, from standard containers to oversized or specialized freight.

Distance

The length of the haul influences the type of drayage service required, ranging from short pier drayage to longer cross-town movements.

Time sensitivity

Urgent shipments may require expedited drayage services to meet tight deadlines.

Customs status

Goods that have not cleared customs require bonded drayage services to ensure regulatory compliance.

Volume and frequency

High-volume, regular shipments might benefit from dedicated shuttle drayage services.

To illustrate the application of different drayage types, consider the following scenarios:

| Scenario | Drayage Type | Benefit |

|---|---|---|

| Urgent medical supplies arriving at a port | Expedited drayage | Rapid delivery to hospitals |

| Regular container flows between port and nearby DC | Shuttle drayage | Optimized, high-frequency movements |

| Imported goods awaiting customs clearance | Bonded drayage | Compliant movement of uncleared cargo |

| Container transfer from ship to rail | Inter-carrier drayage | Seamless intermodal connectivity |

| Moving containers between terminals of same shipping line | Intra-carrier drayage | Efficient fleet and equipment management |

By understanding and leveraging these various drayage services, businesses can create more efficient, flexible, and responsive supply chains in international commerce. The right drayage strategy can lead to significant improvements in transit times, cost-effectiveness, and overall logistics performance.

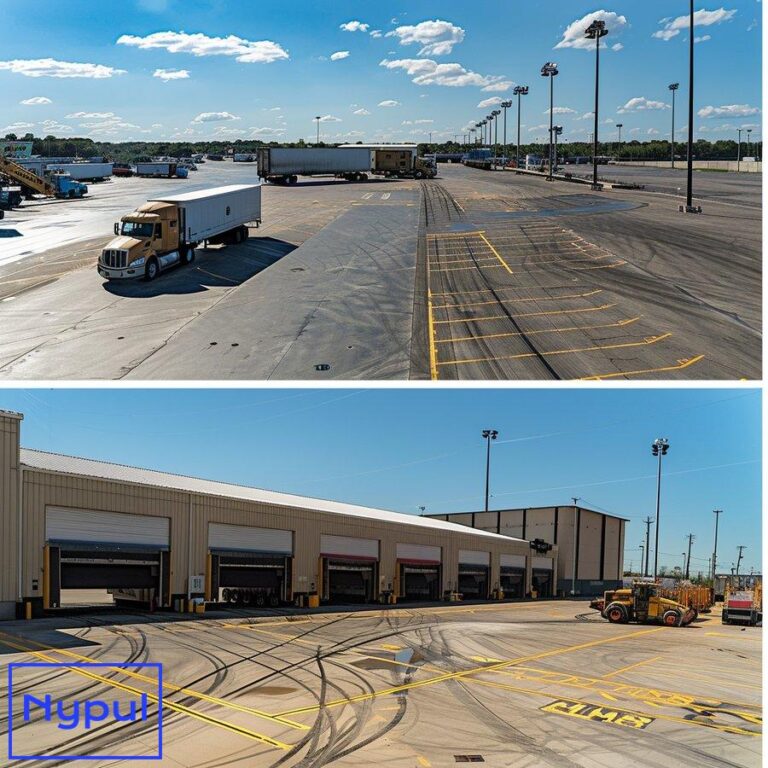

How do drayage operations work in practice?

Drayage operations involve a series of coordinated steps to move cargo efficiently over short distances, typically within a metropolitan area. Understanding this process is crucial for businesses engaged in international trade to optimize their supply chain operations.

Pre-arrival planning

Before a ship docks or a train arrives, drayage providers receive advance notifications about incoming cargo. This information includes details such as container numbers, cargo types, and expected arrival times. Drayage companies use this data to plan their operations, allocate resources, and schedule pickups.

Terminal procedures

Once the cargo arrives at the port or rail terminal, several steps occur:

Container discharge

Containers are unloaded from the vessel or train using specialized equipment like gantry cranes.

Customs clearance

For international shipments, customs officials may inspect the cargo and process necessary documentation.

Container release

After clearance, the terminal releases the container for pickup by the drayage provider.

Drayage pickup

The drayage process begins in earnest when the truck arrives at the terminal:

Driver check-in

The drayage truck driver presents credentials and pickup information at the terminal gate.

Container location

Terminal staff direct the driver to the specific location of the container within the yard.

Container loading

Using terminal equipment or the truck’s own capabilities, the container is loaded onto the drayage vehicle.

Transportation

The core of drayage operations involves the actual movement of the container:

Route planning

Drivers follow optimized routes to navigate urban traffic and reach the destination efficiently.

Real-time tracking

Many drayage providers offer GPS tracking, allowing customers to monitor their cargo’s progress.

Delivery and unloading

Upon reaching the destination (e.g., a warehouse or distribution center), the container is unloaded:

Arrival notification

The driver alerts the receiving facility of their arrival.

Container placement

The container is positioned for unloading, either by removing it from the truck or placing the entire trailer for live unloading.

Documentation

Necessary paperwork is completed to confirm delivery and transfer responsibility for the cargo.

Empty container management

After unloading, the empty container must be handled:

Return to terminal

Empty containers are often returned to the port or rail terminal for reuse.

Repositioning

Sometimes, empty containers are moved to other locations where they are needed for export loads.

Equipment maintenance

Drayage providers must maintain their fleet and equipment:

Truck servicing

Regular maintenance ensures vehicles are road-worthy and efficient.

Chassis management

Proper inventory and maintenance of container chassis is crucial for smooth operations.

To illustrate the efficiency of well-executed drayage operations, consider the following performance metrics:

| Operational Step | Average Time | Potential Improvement with Optimization |

|---|---|---|

| Terminal pickup | 60-90 minutes | 30-45 minutes with pre-arrival planning |

| Urban transport (20 miles) | 45-60 minutes | 30-45 minutes with route optimization |

| Warehouse delivery | 30-45 minutes | 20-30 minutes with appointment scheduling |

| Empty return | 45-60 minutes | 30-45 minutes with coordinated repositioning |

Effective drayage operations require seamless coordination between various stakeholders, including shipping lines, terminal operators, customs officials, and receiving facilities. Advanced technologies like transportation management systems (TMS) and real-time communication tools play a crucial role in orchestrating these complex movements.

By understanding and optimizing each step of the drayage process, businesses can significantly improve their supply chain efficiency, reduce costs, and enhance customer satisfaction in international trade operations.

Who are the key stakeholders involved in drayage processes?

![]()

Drayage processes involve a complex network of stakeholders, each playing a crucial role in ensuring the smooth movement of cargo. Understanding these key players and their interactions is essential for effective drayage management in international trade.

Shippers

Shippers are the owners or sellers of the goods being transported. They initiate the drayage process by:

Booking services

Arranging for drayage as part of their overall logistics strategy.

Providing information

Supplying details about the cargo, including type, weight, and special handling requirements.

Setting expectations

Defining delivery timelines and specific instructions for the drayage provider.

Drayage companies

These specialized logistics providers are central to the drayage process:

Fleet management

Maintaining and operating a fleet of trucks suitable for container transport.

Driver coordination

Assigning and managing drivers for efficient pickup and delivery.

Route optimization

Planning the most effective routes for cargo movement.

Compliance

Ensuring adherence to regulations and industry standards.

Port authorities

Port authorities play a crucial role in facilitating drayage operations:

Infrastructure management

Maintaining port facilities and access roads.

Traffic control

Managing the flow of trucks in and out of the port area.

Security oversight

Implementing and enforcing security measures within the port.

Terminal operators

These entities manage the day-to-day operations at ports and rail yards:

Container handling

Loading and unloading containers from ships and trains.

Yard management

Organizing the storage and movement of containers within the terminal.

Gate operations

Processing trucks entering and exiting the terminal.

Customs and border protection

For international shipments, customs officials are key stakeholders:

Cargo inspection

Examining shipments to ensure compliance with import/export regulations.

Documentation review

Verifying and processing customs paperwork.

Clearance issuance

Granting permission for cargo to enter or leave the country.

Consignees

The recipients of the goods play a role in the drayage process:

Delivery coordination

Providing accurate delivery information and being prepared to receive cargo.

Unloading facilities

Ensuring appropriate equipment and space for container unloading.

Documentation

Confirming receipt of goods and completing necessary paperwork.

Freight forwarders and 3PLs

These intermediaries often coordinate drayage as part of broader logistics services:

Service booking

Arranging drayage on behalf of shippers.

Information management

Facilitating communication between various stakeholders.

Problem resolution

Addressing issues that arise during the drayage process.

Chassis providers

Companies that supply the specialized trailers used to transport containers:

Equipment provision

Ensuring availability of appropriate chassis for different container types.

Maintenance

Keeping chassis in good working condition.

Allocation

Managing the distribution of chassis to meet demand.

Technology providers

Companies offering software and systems that support drayage operations:

TMS development

Creating transportation management systems used by drayage companies.

Tracking solutions

Providing real-time visibility tools for cargo tracking.

Data analytics

Offering insights to optimize drayage operations.

The interactions between these stakeholders are complex and multifaceted. To illustrate the interconnectedness of these relationships, consider the following table:

| Stakeholder | Primary Interactions | Key Responsibilities |

|---|---|---|

| Shippers | Drayage companies, Freight forwarders | Initiating shipments, Providing cargo details |

| Drayage companies | Shippers, Terminal operators, Consignees | Executing transport, Managing fleet |

| Port authorities | Terminal operators, Customs officials | Overseeing port operations, Ensuring security |

| Terminal operators | Drayage companies, Port authorities | Managing container movements, Gate operations |

| Customs officials | Shippers, Terminal operators | Inspecting cargo, Clearing shipments |

| Consignees | Drayage companies, Freight forwarders | Receiving goods, Coordinating deliveries |

| Freight forwarders | Shippers, Drayage companies, Customs | Coordinating logistics, Managing information |

| Chassis providers | Drayage companies, Terminal operators | Supplying equipment, Maintenance |

| Technology providers | All stakeholders | Providing operational support systems |

Effective collaboration among these stakeholders is crucial for efficient drayage operations. Clear communication, shared data systems, and aligned processes help minimize delays, reduce costs, and improve overall supply chain performance in international trade.

What technologies are revolutionizing drayage management?

The drayage industry is undergoing a significant transformation driven by technological advancements. These innovations are enhancing efficiency, transparency, and sustainability in drayage operations, ultimately improving the overall performance of global supply chains.

Transportation Management Systems (TMS)

Modern TMS platforms are at the heart of drayage management:

Real-time visibility

Providing up-to-the-minute tracking of containers and trucks.

Automated dispatching

Optimizing driver assignments and routes based on real-time data.

Performance analytics

Offering insights into operational efficiency and areas for improvement.

Internet of Things (IoT) and telematics

IoT devices and telematics systems are revolutionizing fleet management:

Vehicle tracking

Enabling precise location monitoring of drayage trucks.

Predictive maintenance

Identifying potential vehicle issues before they cause breakdowns.

Fuel efficiency monitoring

Optimizing fuel consumption through data-driven insights.

Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML algorithms are enhancing decision-making in drayage operations:

Predictive analytics

Forecasting demand and potential disruptions to optimize resource allocation.

Route optimization

Dynamically adjusting routes based on traffic, weather, and other real-time factors.

Automated appointment scheduling

Streamlining the process of booking slots at terminals and warehouses.

Blockchain technology

Blockchain is improving transparency and security in drayage processes:

Documentation management

Securely storing and sharing shipping documents and customs paperwork.

Smart contracts

Automating payments and contract execution based on predefined conditions.

Supply chain traceability

Enhancing visibility and accountability across the entire logistics chain.

Mobile applications

Smartphone apps are empowering drivers and streamlining operations:

Electronic logging

Simplifying hours of service tracking and compliance.

Digital documentation

Enabling paperless processes for pickup and delivery confirmations.

Real-time communication

Facilitating instant messaging between drivers, dispatchers, and customers.

Autonomous and electric vehicles

Emerging vehicle technologies are set to transform drayage operations:

Self-driving trucks

Potential for increased safety and efficiency in short-haul transport.

Electric drayage vehicles

Reducing emissions and operating costs in urban environments.

Platooning technology

Allowing multiple trucks to operate in close formation for improved efficiency.

Advanced analytics and big data

Leveraging vast amounts of data to drive operational improvements:

Capacity forecasting

Predicting container volumes and equipment needs with greater accuracy.

Performance benchmarking

Comparing operational metrics against industry standards to identify areas for improvement.

Risk assessment

Analyzing historical data to anticipate and mitigate potential disruptions.

Robotics and automation

Automated systems are enhancing efficiency in terminal operations:

Automated guided vehicles (AGVs)Automated guided vehicles (AGVs) streamline container movements within terminals.

Automated stacking cranes

Improving the speed and accuracy of container stacking and retrieval.

Robotic container handling

Enhancing the efficiency of loading and unloading operations.

Cloud computing

Cloud-based solutions are transforming data management and accessibility:

Scalable infrastructure

Allowing drayage companies to adjust their IT resources based on demand.

Collaborative platforms

Facilitating information sharing among various stakeholders in the supply chain.

Remote access

Enabling managers and dispatchers to monitor operations from anywhere.

The impact of these technologies on drayage management is significant:

| Technology | Key Benefit | Potential Impact |

|---|---|---|

| TMS | Improved visibility and efficiency | 15-25% reduction in empty miles |

| IoT/Telematics | Enhanced fleet management | 10-20% increase in asset utilization |

| AI/ML | Optimized decision-making | 20-30% improvement in on-time performance |

| Blockchain | Increased transparency and security | 50-70% reduction in documentation errors |

| Mobile apps | Streamlined driver operations | 30-40% decrease in administrative time |

| Autonomous vehicles | Improved safety and efficiency | Potential 30-50% reduction in operating costs |

| Advanced analytics | Data-driven insights | 10-15% overall efficiency improvement |

| Robotics/Automation | Faster terminal operations | 40-60% increase in container handling speed |

As these technologies continue to evolve and integrate, they promise to address many of the traditional challenges in drayage management, such as inefficient routing, lack of real-time visibility, and manual processes. The result is a more agile, responsive, and cost-effective drayage ecosystem that can better support the demands of modern global trade.

How does drayage impact the economics of global trade?

Drayage plays a crucial role in shaping the economics of global trade, influencing costs, efficiency, and competitiveness across international supply chains. Understanding this impact is essential for businesses and policymakers involved in cross-border commerce.

Cost implications

Drayage costs can significantly affect the overall economics of international trade:

Last-mile expenses

Drayage often represents a disproportionate share of total transportation costs, sometimes accounting for up to 40% of the total cost for containerized shipments.

Pricing volatility

Drayage rates can fluctuate based on factors like fuel prices, labor availability, and equipment shortages, introducing uncertainty into trade economics.

Hidden costs

Inefficient drayage operations can lead to additional expenses such as demurrage and detention charges at ports and terminals.

Supply chain efficiency

Effective drayage operations contribute to overall supply chain performance:

Inventory management

Efficient drayage enables just-in-time inventory strategies, reducing carrying costs and improving working capital management.

Lead time reduction

Streamlined drayage processes can shorten overall transit times, allowing businesses to respond more quickly to market demands.

Capacity utilization

Optimized drayage improves the utilization of transportation assets, enhancing the overall efficiency of global trade flows.

Trade facilitation

Drayage services play a critical role in facilitating international trade:

Port congestion mitigation

Efficient drayage operations help reduce bottlenecks at ports, enabling smoother flow of goods through key trade gateways.

Intermodal connectivity

By linking different modes of transportation, drayage enhances the flexibility and reach of global supply chains.

Customs clearance

Drayage providers often facilitate customs processes, helping to expedite the movement of goods across borders.

Economic multiplier effects

The drayage industry generates broader economic impacts:

Job creation

Drayage operations create employment opportunities in logistics, driving, and related services.

Infrastructure investment

The needs of drayage operations often drive investments in transportation infrastructure, benefiting the wider economy.

Regional economic development

Efficient drayage can enhance a region’s attractiveness for trade and investment, spurring economic growth.

Competitive advantage

Drayage capabilities can influence a country’s or region’s competitiveness in global trade:

Export competitiveness

Efficient and cost-effective drayage can make a country’s exports more price-competitive in international markets.

Foreign direct investment

Regions with strong drayage infrastructure and services are often more attractive to multinational companies for locating production facilities.

Trade balance impacts

By affecting the cost and efficiency of both imports and exports, drayage can influence a country’s overall trade balance.

Environmental considerations

The environmental impact of drayage operations has economic implications:

Emissions costs

As environmental regulations tighten, the emissions associated with drayage activities may incur additional costs or require investments in cleaner technologies.

Sustainability initiatives

Green drayage practices can create new economic opportunities and enhance brand value for companies engaged in international trade.

Urban planning challenges

The need to accommodate drayage operations in urban areas can influence land use policies and property values near ports and logistics hubs.

To illustrate the economic impact of drayage on global trade, consider the following data:

| Factor | Economic Impact | Potential Improvement with Optimized Drayage |

|---|---|---|

| Transportation costs | 10-15% of product value | 2-4% reduction in overall logistics costs |

| Inventory carrying costs | 20-30% of inventory value per year | 5-10% reduction through improved JIT capabilities |

| Port congestion costs | $5-10 billion annually (US estimate) | 15-25% reduction in congestion-related expenses |

| Trade processing times | 1-3 days for customs clearance | 20-30% reduction in clearance times |

| Carbon emissions | 10-20% of transport-related emissions | 15-30% reduction through efficiency and technology |

The economic impact of drayage extends beyond these direct effects. Improved drayage operations can lead to:

Enhanced market access

Efficient drayage expands the reach of businesses, allowing them to access new markets more easily.

Increased trade volumes

By reducing friction in the movement of goods, optimized drayage can facilitate higher overall trade volumes.

Supply chain resilience

Flexible and responsive drayage services enhance the ability of supply chains to adapt to disruptions, reducing economic losses from unforeseen events.

Innovation spillovers

Advancements in drayage technologies and practices often lead to innovations in other areas of logistics and supply chain management.

As global trade continues to evolve, particularly with the growth of e-commerce and the increasing complexity of international supply chains, the economic importance of efficient drayage is likely to grow. Businesses and policymakers must recognize drayage not just as a cost center, but as a strategic lever for enhancing economic competitiveness in the global marketplace.

What challenges do businesses face with international drayage?

International drayage presents a unique set of challenges for businesses engaged in global trade. These challenges can significantly impact operational efficiency, costs, and overall supply chain performance. Understanding and addressing these issues is crucial for companies looking to optimize their international logistics operations.

Port congestion

One of the most persistent challenges in international drayage:

Long wait times

Trucks often face extended queues at port terminals, leading to delays and increased costs.

Unpredictable turnaround times

Congestion makes it difficult to accurately forecast pickup and delivery times.

Capacity constraints

During peak seasons, port congestion can lead to shortages of available drayage capacity.

Equipment imbalances

Managing the flow of containers and chassis presents ongoing challenges:

Empty container repositioning

The cost and logistics of moving empty containers to where they’re needed can be significant.

Chassis shortages

Mismatches between chassis supply and demand can cause delays and additional expenses.

Equipment condition

Ensuring the availability of containers and chassis in good condition is an ongoing concern.

Regulatory compliance

Navigating the complex regulatory landscape of international trade:

Customs clearance

Delays in customs processing can significantly impact drayage operations and overall transit times.

Security requirements

Adhering to various security protocols and inspections adds complexity to drayage processes.

Environmental regulations

Increasing environmental standards, particularly in urban areas, pose challenges for drayage fleets.

Labor issues

The human element in drayage operations presents several challenges:

Driver shortages

Many regions face a shortage of qualified drayage drivers, impacting capacity and costs.

Labor disputes

Strikes or work slowdowns at ports can severely disrupt drayage operations.

Training and retention

Keeping drivers up-to-date with evolving technologies and regulations is an ongoing challenge.

Infrastructure limitations

Physical constraints can impede efficient drayage operations:

Road congestion

Traffic in and around port areas can significantly slow drayage movements.

Inadequate port infrastructure

Some ports lack the necessary facilities to handle increasing container volumes efficiently.

Last-mile challenges

Navigating urban environments for final delivery can be complex and time-consuming.

Visibility and communication

Maintaining clear visibility across the drayage process:

Data silos

Lack of integration between different stakeholders’ systems can lead to information gaps.

Real-time tracking limitations

Not all drayage providers offer comprehensive real-time visibility of shipments.

Communication breakdowns

Miscommunication between parties can lead to delays and inefficiencies.

Cost volatility

Managing the fluctuating costs associated with drayage:

Fuel price fluctuations

Changes in fuel prices can significantly impact drayage costs.

Peak season surcharges

Rates often increase during high-demand periods, affecting budgeting and forecasting.

Detention and demurrage fees

Delays can result in substantial additional charges from terminals and equipment providers.

Technology adoption

Implementing and leveraging new technologies in drayage operations:

Integration challenges

Connecting new systems with existing infrastructure can be complex and costly.

Resistance to change

Adoption of new technologies may face resistance from traditional operators.

Cybersecurity concerns

As operations become more digitized, protecting sensitive data becomes increasingly important.

Capacity planning

Balancing supply and demand in a dynamic environment:

Seasonal fluctuations

Handling variations in demand, especially during peak shipping seasons.

Market unpredictability

Global events and economic shifts can rapidly change drayage capacity needs.

Long-term forecasting

Aligning drayage capabilities with future trade growth projections.

To illustrate the impact of these challenges, consider the following data:

| Challenge | Impact Metric | Industry Average | Best-in-Class Performance |

|---|---|---|---|

| Port congestion | Truck turn time | 90-120 minutes | 45-60 minutes |

| Equipment imbalances | Empty container moves | 15-20% of total moves | 5-10% of total moves |

| Regulatory compliance | Customs clearance time | 1-3 days | Same-day clearance |

| Labor issues | Driver turnover rate | 80-90% annually | 30-40% annually |

| Visibility | Real-time tracking capability | 60-70% of shipments | 95-100% of shipments |

| Cost volatility | Drayage cost variance | ±15-20% annually | ±5-10% annually |

Addressing these challenges requires a multifaceted approach:

Collaborative partnerships

Building strong relationships with drayage providers, terminals, and other stakeholders can help navigate many of these challenges more effectively.

Technology investments

Implementing advanced TMS, visibility tools, and predictive analytics can significantly improve drayage management.

Flexible strategies

Developing adaptable drayage strategies that can respond to changing market conditions and unforeseen disruptions.

Continuous improvement

Regularly reviewing and optimizing drayage processes to address evolving challenges and leverage new opportunities.

Policy engagement

Working with industry associations and policymakers to address systemic issues like infrastructure limitations and regulatory complexities.

By proactively addressing these challenges, businesses can enhance the efficiency of their international drayage operations, leading to improved supply chain performance, cost savings, and ultimately, a stronger competitive position in global markets.

How can companies optimize their drayage strategies for international trade?

Optimizing drayage strategies is crucial for companies engaged in international trade to enhance efficiency, reduce costs, and improve overall supply chain performance. By implementing best practices and leveraging innovative solutions, businesses can significantly improve their drayage operations.

Data-driven planning

Utilizing data analytics to inform drayage strategies:

Demand forecasting

Analyzing historical data and market trends to predict future drayage needs more accurately.

Capacity planning

Using data to optimize the allocation of resources, including trucks, drivers, and equipment.

Performance metrics

Establishing and monitoring key performance indicators (KPIs) to continuously improve drayage operations.

Technology integration

Leveraging advanced technologies to enhance drayage management:

Transportation Management Systems (TMS)

Implementing comprehensive TMS solutions to streamline drayage planning, execution, and tracking.

Internet of Things (IoT) devices

Utilizing IoT sensors for real-time tracking of containers and equipment.

Artificial Intelligence (AI) and Machine Learning (ML)

Employing AI and ML algorithms for route optimization and predictive maintenance.

Collaborative partnerships

Fostering strong relationships with key stakeholders:

Drayage providers

Developing strategic partnerships with reliable drayage companies to ensure consistent service quality.

Port and terminal operators

Collaborating with port authorities and terminal operators to improve coordination and reduce delays.

Customs brokers

Working closely with customs brokers to expedite clearance processes and minimize compliance issues.

Flexible capacity management

Adapting to fluctuating demand and market conditions:

Mix of dedicated and spot market capacity

Balancing long-term contracts with flexible spot market options to manage costs and ensure capacity.

Intermodal options

Considering rail and barge alternatives for certain routes to complement truck drayage.

Regional consolidation centers

Establishing strategic locations for consolidating and deconsolidating shipments to optimize drayage movements.

Process standardization and automation

Streamlining operations through consistent processes and automation:

Standardized operating procedures

Developing and implementing uniform processes across all drayage operations.

Automated appointment scheduling

Using technology to automate the booking of pickup and delivery slots at terminals and warehouses.

Electronic documentation

Implementing paperless systems for all drayage-related documentation.

Risk management and contingency planning

Preparing for potential disruptions and challenges:

Diversified provider base

Maintaining relationships with multiple drayage providers to mitigate the risk of capacity shortages.

Alternative routing options

Identifying and preparing alternative routes and modes of transportation for use during disruptions.

Regular risk assessments

Conducting periodic evaluations of potential risks to drayage operations and developing mitigation strategies.

Sustainability initiatives

Incorporating environmental considerations into drayage strategies:

Green technologies

Investing in or partnering with providers using low-emission or electric vehicles for drayage operations.

Efficient routing and load optimization

Minimizing empty miles and maximizing load factors to reduce overall emissions.

Carbon offset programs

Participating in or implementing carbon offset initiatives to neutralize the environmental impact of drayage activities.

Continuous improvement and training

Fostering a culture of ongoing optimization and skill development:

Regular performance reviews

Conducting periodic assessments of drayage operations to identify areas for improvement.

Employee training programs

Providing ongoing education for staff involved in drayage management to keep them updated on best practices and new technologies.

Industry benchmarking

Comparing performance against industry standards and learning from best-in-class operators.

To illustrate the potential impact of these optimization strategies, consider the following table:

| Optimization Area | Potential Improvement | Impact on Operations |

|---|---|---|

| Data-driven planning | 10-15% increase in forecast accuracy | Improved resource allocation and reduced costs |

| Technology integration | 20-30% reduction in administrative time | Enhanced visibility and faster decision-making |

| Collaborative partnerships | 15-25% decrease in dwell times | Smoother operations and reduced delays |

| Flexible capacity management | 10-20% cost savings during peak periods | Better ability to handle demand fluctuations |

| Process standardization | 30-40% reduction in documentation errors | Fewer delays and improved compliance |

| Risk management | 50-60% faster response to disruptions | Increased supply chain resilience |

| Sustainability initiatives | 20-30% reduction in carbon emissions | Improved brand reputation and regulatory compliance |

Implementing these strategies can lead to significant improvements in drayage performance:

Cost reduction

Optimized drayage strategies can lead to overall cost savings of 10-20% through improved efficiency and reduced waste.

Transit time improvement

Streamlined processes and bettercoordination can reduce transit times by 15-25%, enhancing overall supply chain velocity.

Customer satisfaction

Improved reliability and visibility in drayage operations can increase customer satisfaction scores by 20-30%.

Asset utilization

Optimized strategies can improve container and chassis utilization rates by 15-25%, reducing equipment shortages and associated costs.

Compliance and security

Enhanced processes and technology integration can reduce compliance-related issues by 40-50%, improving security and reducing regulatory risks.

To successfully implement these optimization strategies, companies should:

Conduct a comprehensive assessment

Evaluate current drayage operations to identify specific areas for improvement and prioritize initiatives.

Develop a phased implementation plan

Create a step-by-step roadmap for implementing optimization strategies, starting with quick wins and progressing to more complex initiatives.

Invest in change management

Ensure buy-in from all stakeholders and provide necessary training and support to facilitate smooth adoption of new processes and technologies.

Monitor and adjust

Continuously track performance metrics and be prepared to adjust strategies based on real-world results and changing market conditions.

Foster a culture of innovation

Encourage ongoing exploration of new technologies and approaches to drayage optimization, keeping pace with industry advancements.

By taking a holistic and proactive approach to drayage optimization, companies can transform this critical component of international trade from a potential bottleneck into a source of competitive advantage. Improved drayage strategies not only enhance operational efficiency but also contribute to better overall supply chain performance, positioning businesses for success in the dynamic global marketplace.