What Is Intermodal Connectivity

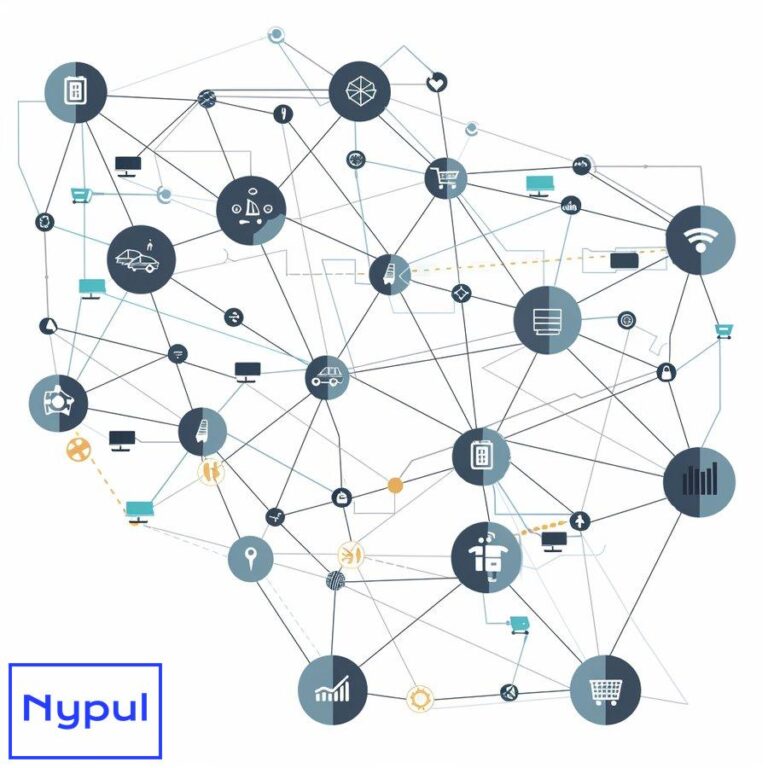

Intermodal connectivity refers to the seamless integration and coordination of different transportation modes to move freight or passengers efficiently from origin to destination. This concept encompasses the physical infrastructure, operational processes, and information systems that enable smooth transfers between modes like rail, road, sea, and air transport.

At its core, intermodal connectivity aims to leverage the strengths of various transportation modes while minimizing their individual limitations. For example, it combines the flexibility of trucking for short distances with the efficiency of rail or maritime shipping for longer hauls. This integration creates a more flexible, cost-effective, and environmentally friendly logistics network.

Key components of intermodal connectivity include:

Intermodal terminals: These facilities serve as transfer points between different modes, equipped with specialized equipment for loading and unloading cargo units like containers or trailers.

Standardized cargo units: Containers and other standardized units allow for easy transfer between modes without unpacking and repacking goods.

Information systems: Advanced tracking and management systems coordinate the movement of cargo across different modes and provide real-time visibility.

Coordinated scheduling: Aligning schedules of different transport modes minimizes waiting times and improves overall efficiency.

Regulatory framework: Harmonized regulations and documentation processes facilitate smoother cross-border and inter-modal transfers.

Intermodal connectivity is not just about physical connections; it also involves the seamless flow of information and documentation throughout the supply chain. This holistic approach ensures that goods move efficiently from producer to consumer, regardless of the modes of transport involved.

For businesses and logistics professionals, understanding intermodal connectivity is crucial for optimizing supply chains, reducing costs, and improving service reliability. It allows for more flexible routing options, better utilization of transportation assets, and often results in reduced environmental impact compared to single-mode transport solutions.

As global trade continues to grow and supply chains become increasingly complex, the importance of effective intermodal connectivity cannot be overstated. It serves as a cornerstone of modern logistics, enabling the efficient movement of goods across vast distances and diverse geographies.

How do different types of intermodal connections work?

Intermodal connections facilitate the seamless transfer of cargo between different transportation modes. Each type of connection has its unique characteristics and operational procedures. Let’s explore the main types of intermodal connections and how they function:

Rail-Road Connections

Rail-road intermodal connections combine the long-haul efficiency of rail with the flexibility of truck transport for first and last-mile delivery. This connection typically involves the following steps:

- Containers or trailers are loaded onto specialized railcars at an intermodal terminal.

- Trains transport the cargo over long distances to another intermodal terminal.

- At the destination terminal, containers are transferred to trucks for final delivery.

Key equipment used in rail-road connections includes gantry cranes, reach stackers, and specialized railcars designed to carry containers or trailers.

Sea-Road Connections

Sea-road connections link maritime shipping with truck transport, essential for moving goods between ports and inland destinations. The process typically includes:

- Containers are unloaded from ships using port cranes.

- Containers are temporarily stored in the port’s container yard.

- Trucks collect containers from the yard for inland transportation.

Ports play a crucial role in this connection, acting as intermodal hubs with sophisticated container handling equipment and information systems.

Sea-Rail Connections

Sea-rail connections integrate maritime and rail transport, often used for moving large volumes of cargo over long distances inland. The process involves:

- Containers are unloaded from ships at the port.

- Containers are transferred directly to railcars or moved to a nearby rail terminal.

- Trains transport containers to inland destinations.

On-dock rail facilities at ports can significantly enhance the efficiency of sea-rail connections by reducing the need for intermediate trucking.

Air-Road Connections

Air-road connections are crucial for high-value or time-sensitive cargo. The process typically includes:

- Cargo is unloaded from aircraft and processed through airport cargo facilities.

- Goods are sorted and consolidated for ground transportation.

- Trucks deliver cargo to final destinations.

Air cargo terminals are equipped with specialized handling equipment and security measures to manage the unique requirements of air freight.

Barge-Road/Rail Connections

Barge transport, often used on inland waterways, can be integrated with road or rail transport. The process involves:

- Containers are loaded onto barges at river ports.

- Barges transport containers along waterways to inland ports.

- At destination ports, containers are transferred to trucks or trains for further transport.

This connection is particularly important in regions with extensive river networks, offering a cost-effective and environmentally friendly transport option.

Table: Comparison of Intermodal Connection Types

| Connection Type | Primary Advantage | Key Infrastructure | Typical Cargo Types |

|---|---|---|---|

| Rail-Road | Cost-effective for long distances | Intermodal rail terminals | Containers, bulk goods |

| Sea-Road | Global connectivity | Seaports, container yards | Containers, various goods |

| Sea-Rail | Efficient for high volumes | On-dock rail facilities | Containers, bulk commodities |

| Air-Road | Speed for high-value goods | Air cargo terminals | High-value, perishable goods |

| Barge-Road/Rail | Eco-friendly for inland transport | River ports, inland terminals | Containers, bulk materials |

Each type of intermodal connection requires specialized infrastructure, equipment, and operational procedures. The choice of connection depends on factors such as cargo type, distance, time sensitivity, and cost considerations. Effective intermodal connectivity often involves combining multiple connection types to create an optimal logistics solution.

For logistics professionals, understanding these different connection types is crucial for designing efficient supply chains. It allows for strategic decision-making in route planning, mode selection, and infrastructure investment. As global trade patterns evolve, the ability to leverage various intermodal connections becomes increasingly important for maintaining competitive advantage in the logistics industry.

What infrastructure is required for effective intermodal connectivity?

![]()

Effective intermodal connectivity relies on a complex network of physical infrastructure, technological systems, and operational facilities. This infrastructure forms the backbone of seamless freight movement across different transportation modes. Let’s examine the key components required:

Intermodal Terminals

Intermodal terminals serve as the primary hubs for transferring cargo between different modes of transport. These facilities require:

- Large open spaces for container storage and maneuvering

- Specialized handling equipment like gantry cranes and reach stackers

- Rail sidings for direct train access

- Truck loading and unloading areas

- Advanced information systems for cargo tracking and management

Intermodal terminals are strategically located near major transportation corridors and often serve as inland ports, providing customs clearance and other value-added services.

Port Infrastructure

Seaports play a crucial role in intermodal connectivity, linking maritime transport with land-based modes. Essential port infrastructure includes:

- Deep-water berths to accommodate large container ships

- Container yards for temporary storage

- On-dock or near-dock rail facilities

- Advanced cargo handling equipment like ship-to-shore cranes

- Truck gates and road connections to the hinterland

Modern ports are increasingly adopting automation technologies to enhance efficiency and reduce turnaround times.

Rail Network

An extensive and well-maintained rail network is vital for long-distance intermodal transport. Key elements include:

- Double-stack rail corridors to increase capacity

- Intermodal-specific railcars designed for container transport

- Rail yards equipped for intermodal operations

- Electrified lines to reduce environmental impact and operating costs

Investments in rail infrastructure often focus on removing bottlenecks and increasing capacity on key freight corridors.

Road Infrastructure

Despite the emphasis on alternative modes, road transport remains crucial for first and last-mile delivery. Essential road infrastructure includes:

- High-capacity highways connecting intermodal terminals

- Dedicated truck lanes in congested urban areas

- Rest areas and service stations for long-haul truckers

- Weigh stations and enforcement facilities

Improving road infrastructure often involves addressing congestion issues and enhancing connectivity to intermodal facilities.

Inland Waterways

For regions with navigable rivers or canals, inland waterway infrastructure is an important component of intermodal connectivity. This includes:

- River ports with container handling capabilities

- Locks and dams to maintain navigable water levels

- Specialized barges designed for container transport

- Shore-side power facilities to reduce emissions during port calls

Inland waterways offer an environmentally friendly alternative for bulk cargo and container transport over medium to long distances.

Information and Communication Technology (ICT) Infrastructure

Modern intermodal connectivity heavily relies on advanced ICT systems. Key components include:

- GPS tracking systems for real-time cargo monitoring

- Electronic Data Interchange (EDI) systems for seamless information flow

- Port Community Systems for coordinating various stakeholders

- Automated gate systems at terminals and ports

- Blockchain technology for enhancing security and traceability

ICT infrastructure enables better coordination between different modes and stakeholders, reducing delays and improving overall efficiency.

Table: Infrastructure Requirements for Different Intermodal Connections

| Connection Type | Key Infrastructure Components | Technological Requirements |

|---|---|---|

| Rail-Road | Intermodal terminals, Rail sidings, Truck gates | Container tracking systems, Automated gate systems |

| Sea-Road | Container ports, Truck staging areas | Port Community Systems, EDI |

| Sea-Rail | On-dock rail facilities, Double-stack corridors | Integrated port-rail management systems |

| Air-Road | Air cargo terminals, Bonded warehouses | Advanced security systems, RFID tracking |

| Barge-Road/Rail | River ports, Intermodal river terminals | River information services, Barge tracking systems |

Developing effective intermodal infrastructure requires significant investment and long-term planning. It involves coordination between various stakeholders, including government agencies, private operators, and technology providers. The goal is to create a seamless network that allows for efficient cargo movement, regardless of the modes involved.

For logistics professionals and policymakers, understanding the infrastructure requirements for intermodal connectivity is crucial for strategic planning and investment decisions. It helps in identifying bottlenecks, prioritizing improvements, and enhancing the overall efficiency of the logistics network. As global trade patterns evolve and new technologies emerge, continuous adaptation and upgrading of intermodal infrastructure will be necessary to meet the changing demands of the logistics industry.

Why is intermodal connectivity important in modern logistics?

Intermodal connectivity has become a cornerstone of modern logistics, playing a crucial role in shaping efficient and sustainable supply chains. Its importance stems from several key factors that address the evolving needs of global trade and consumer demands. Let’s explore why intermodal connectivity is so vital in today’s logistics landscape:

Cost Efficiency

Intermodal connectivity allows for the optimization of transportation costs by leveraging the strengths of different modes:

- Long-haul transport via rail or sea reduces per-unit costs for large volumes.

- Short-haul trucking provides flexibility for first and last-mile delivery.

- Combining modes minimizes empty backhauls, improving asset utilization.

By strategically choosing the most cost-effective combination of modes, businesses can significantly reduce their overall transportation expenses.

Environmental Sustainability

With growing concerns about climate change, intermodal solutions offer a more environmentally friendly approach to logistics:

- Rail and maritime transport generally have lower carbon emissions per ton-mile compared to road transport.

- Reduced road congestion leads to lower overall emissions and improved air quality in urban areas.

- Efficient use of intermodal connections minimizes fuel consumption and energy waste.

Companies focusing on reducing their carbon footprint find intermodal solutions align well with their sustainability goals.

Supply Chain Resilience

Intermodal connectivity enhances the resilience of supply chains by providing alternative routing options:

- Multiple mode choices allow for quick adaptation to disruptions in one mode.

- Diverse routing options mitigate risks associated with geopolitical issues or natural disasters.

- Flexibility in mode selection helps manage seasonal capacity constraints.

This resilience is particularly valuable in today’s volatile global trade environment, where supply chain disruptions can have significant economic impacts.

Capacity and Scalability

Intermodal solutions offer greater capacity and scalability compared to single-mode transport:

- Rail and maritime modes can handle larger volumes, addressing capacity constraints on roads.

- Intermodal terminals act as buffer zones, allowing for better management of volume fluctuations.

- Scalable solutions accommodate business growth without proportional increases in logistics costs.

As global trade volumes continue to grow, the ability to scale logistics operations becomes increasingly important for businesses.

Time Efficiency and Reliability

While often perceived as slower, well-coordinated intermodal solutions can offer improved reliability and sometimes faster transit times:

- Reduced congestion on rail and waterways compared to road networks.

- Scheduled services (e.g., block trains) provide consistent transit times.

- Advanced tracking and coordination systems minimize transfer delays at intermodal points.

For many supply chains, the predictability offered by intermodal solutions is as valuable as speed.

Global Market Access

Intermodal connectivity facilitates access to global markets by bridging geographical barriers:

- Seamless connections between inland points and international gateways.

- Integration of landlocked regions into global supply chains.

- Enablement of door-to-door services across continents.

This global reach is essential for businesses looking to expand their market presence or source materials internationally.

Regulatory Compliance and Security

Intermodal solutions often provide advantages in terms of regulatory compliance and cargo security:

- Reduced handling of goods minimizes the risk of damage or theft.

- Sealed containers can move across borders with minimal customs intervention.

- Advanced tracking systems provide enhanced visibility and security throughout the journey.

These factors are particularly important for high-value or sensitive cargo.

Table: Impact of Intermodal Connectivity on Key Logistics Metrics

| Metric | Impact of Intermodal Connectivity | Potential Improvement |

|---|---|---|

| Transportation Costs | Optimization of mode selection | 10-30% reduction |

| Carbon Emissions | Shift to more efficient modes | 20-50% reduction |

| Supply Chain Flexibility | Multiple routing options | 30-50% improvement |

| Capacity Utilization | Better asset management | 15-25% increase |

| On-Time Performance | Scheduled services and reduced congestion | 10-20% improvement |

| Market Reach | Access to global transportation networks | 50-100% expansion |

Note: Actual improvements may vary based on specific supply chain characteristics and implementation effectiveness.

For logistics professionals, understanding the importance of intermodal connectivity is crucial for developing competitive and sustainable supply chain strategies. It allows for a more holistic approach to transportation planning, considering factors beyond just cost and speed. As global trade patterns become more complex and consumer expectations for fast, reliable, and sustainable delivery continue to rise, the role of intermodal connectivity in modern logistics will only grow in importance.

Businesses that effectively leverage intermodal solutions can gain significant advantages in terms of cost savings, environmental performance, and operational flexibility. However, realizing these benefits requires careful planning, investment in appropriate infrastructure, and adoption of advanced technologies to ensure seamless coordination across different modes and stakeholders.

What are the key benefits of implementing intermodal connectivity?

Implementing intermodal connectivity in logistics operations offers a wide range of benefits that can significantly enhance the efficiency, sustainability, and competitiveness of supply chains. These benefits extend beyond simple cost savings, impacting various aspects of business operations and strategic planning. Let’s explore the key advantages of embracing intermodal connectivity:

Cost Reduction

Intermodal solutions often lead to substantial cost savings:

- Lower per-unit transportation costs for long-distance shipments

- Reduced fuel consumption through more efficient mode utilization

- Decreased labor costs due to automation at intermodal terminals

- Minimized warehousing needs with just-in-time delivery capabilities

For many businesses, these cost reductions can significantly improve profit margins and competitiveness.

Environmental Sustainability

Intermodal transport contributes to reduced environmental impact:

- Lower carbon emissions per ton-mile, especially when utilizing rail and water transport

- Reduced road congestion, leading to decreased overall emissions in urban areas

- More efficient use of energy resources across the supply chain

- Alignment with corporate sustainability goals and regulatory requirements

Companies focusing on green logistics find intermodal solutions particularly attractive for meeting their environmental targets.

Improved Efficiency and Productivity

Intermodal connectivity enhances overall logistics efficiency:

- Optimized use of transportation assets, reducing empty runs

- Faster turnaround times at intermodal terminals through specialized handling equipment

- Increased throughput capacity without proportional increases in infrastructure

- Better utilization of existing transportation networks

These efficiency gains translate into improved productivity and asset utilization across the supply chain.

Enhanced Supply Chain Flexibility

Intermodal solutions provide greater flexibility in logistics planning:

- Multiple routing options to adapt to changing market conditions

- Ability to switch between modes based on cost, time, or capacity constraints

- Easier scaling of operations to meet fluctuating demand

- Reduced dependency on a single mode of transport

This flexibility is crucial for maintaining resilient and responsive supply chains in a dynamic global market.