What Is Intermodal Transportation Strategies

What is intermodal transportation and why is it important?

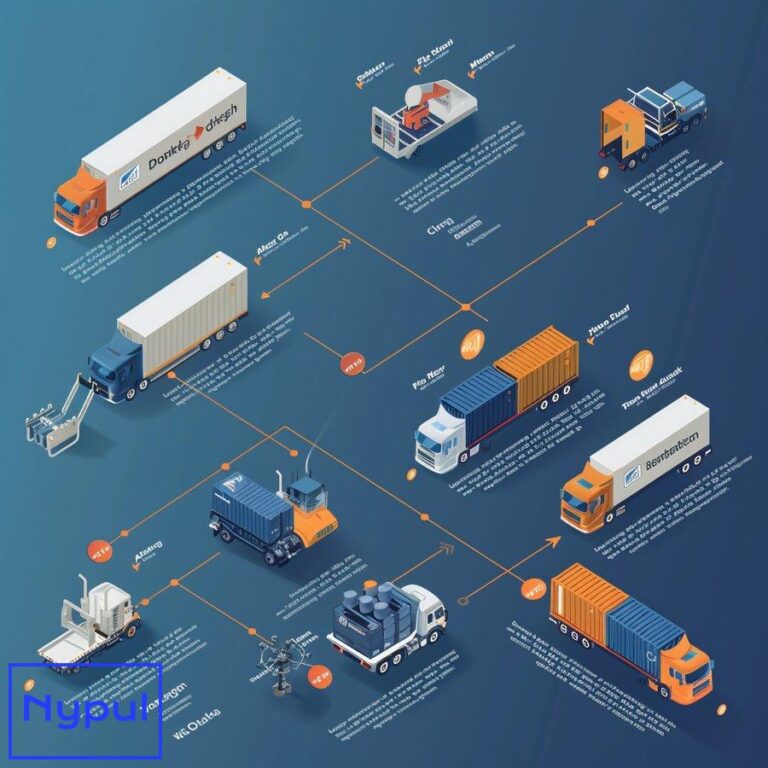

Intermodal transportation is a freight delivery method that utilizes two or more modes of transport to move goods from origin to destination. This seamless integration of different transportation modes—such as trucks, trains, ships, and planes—allows for the efficient and cost-effective movement of cargo across long distances.

The importance of intermodal transportation lies in its ability to leverage the strengths of various transportation methods while minimizing their individual weaknesses. For instance, trucks excel at short-distance deliveries and provide flexibility, while trains are more fuel-efficient and cost-effective for long-distance hauls. By combining these modes, shippers can optimize their supply chains and reduce overall transportation costs.

Key benefits of intermodal transportation:

Cost savings: Intermodal transport often results in lower fuel consumption and reduced labor costs, leading to significant savings for businesses.

Environmental sustainability: The use of rail for long-distance transport reduces carbon emissions compared to long-haul trucking, making intermodal transportation a more environmentally friendly option.

Increased efficiency: By utilizing multiple modes of transport, goods can be moved more quickly and efficiently, reducing transit times and improving overall supply chain performance.

Enhanced security: Intermodal containers are sealed at the point of origin and remain unopened until they reach their final destination, reducing the risk of theft or damage during transit.

Flexibility: Intermodal transportation allows shippers to adapt to changing market conditions and route goods through the most efficient channels.

The importance of intermodal transportation has grown significantly in recent years due to globalization, e-commerce, and the increasing complexity of supply chains. As businesses seek to optimize their logistics operations and reduce costs, intermodal strategies have become essential for maintaining competitiveness in the global marketplace.

Intermodal transportation also plays a crucial role in addressing infrastructure challenges and congestion issues. By shifting long-haul freight from highways to rail, intermodal transport helps reduce road congestion, wear and tear on highways, and the need for costly infrastructure expansions.

For shippers and logistics providers, understanding the intricacies of intermodal transportation is crucial for developing effective supply chain strategies. The ability to seamlessly integrate different modes of transport can lead to improved efficiency, reduced costs, and enhanced customer satisfaction.

How do intermodal transportation strategies differ from traditional freight methods?

Intermodal transportation strategies and traditional freight methods differ in several key aspects, including operational approach, equipment used, and overall efficiency. Understanding these differences is crucial for businesses looking to optimize their supply chain operations.

Operational approach:

Intermodal transportation strategies focus on seamlessly integrating multiple modes of transport to move goods from origin to destination. This approach involves careful coordination between different carriers and transfer points. In contrast, traditional freight methods typically rely on a single mode of transport, such as trucking or air freight, for the entire journey.

Equipment and infrastructure:

Intermodal transport utilizes specialized equipment designed for easy transfer between different modes. The most common example is the intermodal container, which can be easily moved from truck to train to ship without unloading the contents. Traditional freight methods often use mode-specific equipment, which may require goods to be unloaded and reloaded when changing transport modes.

Flexibility and scalability:

Intermodal strategies offer greater flexibility in routing and capacity management. Shippers can adjust their transportation mix based on factors such as cost, speed, and availability. Traditional freight methods are often more rigid, with limited options for adapting to changing market conditions or unexpected disruptions.

Cost structure:

The cost structure of intermodal transportation differs significantly from traditional freight methods. While intermodal transport may have higher initial costs due to the need for specialized equipment and infrastructure, it often results in lower overall transportation costs, especially for long-distance shipments. Traditional freight methods may have lower upfront costs but can be more expensive over long distances.

Environmental impact:

Intermodal transportation strategies generally have a lower environmental impact compared to traditional freight methods, particularly for long-haul shipments. The use of rail for long-distance transport results in lower carbon emissions per ton-mile compared to trucking. Traditional freight methods, especially those relying heavily on road transport, tend to have a higher carbon footprint.

Transit times and reliability:

Transit times for intermodal transportation can be longer than some traditional freight methods due to the need for transfers between modes. However, intermodal strategies often offer more consistent and reliable delivery times, especially for long-distance shipments. Traditional freight methods may offer faster transit times for certain routes but can be more susceptible to delays caused by traffic, weather, or other factors.

Capacity and load size:

Intermodal transportation is particularly well-suited for handling large volumes of freight over long distances. The ability to consolidate shipments into standardized containers allows for efficient use of capacity across different modes. Traditional freight methods may be more appropriate for smaller shipments or time-sensitive deliveries.

Network complexity:

Intermodal transportation strategies involve more complex networks, with multiple transfer points and carriers involved in a single shipment. This complexity requires sophisticated logistics management and coordination. Traditional freight methods often have simpler networks, with fewer handoffs and stakeholders involved.

Technology integration:

Intermodal transportation relies heavily on advanced technology for tracking, scheduling, and coordinating shipments across different modes. Traditional freight methods may use technology as well, but the level of integration and complexity is typically lower.

To illustrate the key differences between intermodal and traditional freight methods, consider the following comparison table:

| Aspect | Intermodal Transportation | Traditional Freight Methods |

|---|---|---|

| Modes of transport | Multiple (e.g., truck, rail, ship) | Typically single mode |

| Equipment | Standardized containers | Mode-specific equipment |

| Flexibility | High adaptability to changing conditions | Limited flexibility |

| Cost structure | Higher initial costs, lower long-term costs | Lower initial costs, potentially higher long-term costs |

| Environmental impact | Lower carbon emissions for long distances | Higher carbon footprint, especially for road transport |

| Transit times | Potentially longer, but more consistent | Can be faster, but less predictable |

| Capacity handling | Efficient for large volumes and long distances | Varies by mode, often better for smaller shipments |

| Network complexity | High, with multiple stakeholders and transfer points | Lower, with fewer handoffs |

| Technology integration | Advanced tracking and coordination systems | Varies, but typically less complex |

Understanding these differences is crucial for businesses when deciding between intermodal and traditional freight methods. The choice depends on factors such as shipment volume, distance, time sensitivity, and overall supply chain strategy. By carefully evaluating these factors, companies can select the most appropriate transportation method to meet their specific needs and optimize their logistics operations.

What are the key components of an effective intermodal transportation strategy?

An effective intermodal transportation strategy comprises several key components that work together to optimize the movement of goods across multiple modes of transport. These components are essential for ensuring efficiency, cost-effectiveness, and reliability in the supply chain.

Network design and optimization:

The foundation of an effective intermodal strategy is a well-designed transportation network. This involves carefully selecting and integrating various modes of transport, transfer points, and routes to create an optimal flow of goods. Network design should consider factors such as shipping volumes, distances, transit times, and cost structures for different modes.

Key considerations for network design:

Modal selection: Choosing the right combination of transportation modes (e.g., truck, rail, ship, air) based on shipment characteristics and requirements.

Route planning: Identifying the most efficient routes that balance speed, cost, and reliability.

Transfer point selection: Strategically locating intermodal terminals and transfer facilities to minimize handling and transit times.

Capacity management:

Effective capacity management is crucial for maximizing the efficiency of intermodal transportation. This involves balancing supply and demand across different modes and ensuring that resources are utilized optimally.

Capacity management strategies:

Demand forecasting: Accurately predicting shipping volumes to allocate appropriate resources.

Asset utilization: Maximizing the use of containers, chassis, and other equipment across the network.

Load consolidation: Combining smaller shipments to take advantage of economies of scale in rail and ocean transport.

Technology integration:

Advanced technology plays a vital role in coordinating and optimizing intermodal transportation. Integrated systems for tracking, scheduling, and managing shipments across different modes are essential for seamless operations.

Key technological components:

Transportation Management Systems (TMS): Software platforms that integrate planning, execution, and optimization of transportation activities.

Real-time tracking: GPS and RFID technologies for monitoring shipment locations and status.

Data analytics: Advanced analytics tools for identifying trends, optimizing routes, and improving decision-making.

Carrier and partner relationships:

Strong relationships with carriers and other partners in the intermodal network are crucial for ensuring reliable and efficient service. This includes both contractual agreements and operational collaboration.

Partnership considerations:

Service level agreements: Establishing clear performance metrics and expectations with carriers and terminal operators.

Information sharing: Developing protocols for sharing data and insights to improve overall network performance.

Joint planning: Collaborating with partners on capacity planning and network optimization.

Risk management and contingency planning:

Effective intermodal strategies must account for potential disruptions and have robust contingency plans in place. This includes identifying potential risks and developing mitigation strategies.

Risk management components:

Risk assessment: Identifying and evaluating potential disruptions to the intermodal network.

Contingency planning: Developing alternative routes and modes for use in case of disruptions.

Insurance and liability management: Ensuring appropriate coverage for goods in transit across different modes.

Performance measurement and continuous improvement:

Implementing a system for measuring and analyzing the performance of the intermodal network is essential for identifying areas for improvement and ensuring ongoing optimization.

Key performance indicators:

Transit time: Measuring the total time from origin to destination, including transfer times.

Cost per unit: Tracking the total transportation cost per unit shipped.

On-time performance: Monitoring the percentage of shipments delivered within the agreed timeframe.

Environmental impact: Assessing the carbon footprint and other environmental metrics of the intermodal network.

Customs and regulatory compliance:

For international shipments, managing customs clearance and regulatory compliance across different jurisdictions is a critical component of an effective intermodal strategy.

Compliance considerations:

Documentation management: Ensuring accurate and complete documentation for customs clearance.

Regulatory tracking: Staying up-to-date with changing regulations in different countries and regions.

Compliance training: Providing ongoing education for staff on customs and regulatory requirements.

Customer service and visibility:

Providing excellent customer service and shipment visibility is increasingly important in intermodal transportation. This includes offering real-time tracking information and responsive support to shippers and consignees.

Customer service elements:

Track and trace capabilities: Offering real-time visibility into shipment status and location.

Proactive communication: Notifying customers of potential delays or issues in advance.

Self-service tools: Providing online portals for customers to manage their shipments and access information.

Sustainability initiatives:

Incorporating sustainability into the intermodal strategy is becoming increasingly important for businesses looking to reduce their environmental impact and meet regulatory requirements.

Sustainability components:

Modal shift: Encouraging the use of more environmentally friendly modes of transport, such as rail for long-haul shipments.

Equipment efficiency: Investing in fuel-efficient vehicles and equipment.

Carbon offsetting: Implementing programs to offset the carbon emissions generated by transportation activities.

By integrating these key components, businesses can develop a comprehensive and effective intermodal transportation strategy that optimizes their supply chain operations, reduces costs, and improves overall performance. The specific implementation of these components will vary based on the unique needs and characteristics of each business, but they provide a solid framework for building a robust intermodal strategy.

How can businesses assess their supply chain needs for intermodal transport?

Assessing supply chain needs for intermodal transport is a critical step for businesses looking to optimize their logistics operations. This assessment process helps companies determine whether intermodal transportation is suitable for their specific requirements and how to best implement it within their supply chain strategy.

Analyze current transportation patterns:

The first step in assessing supply chain needs for intermodal transport is to thoroughly analyze existing transportation patterns and performance. This analysis provides a baseline for comparison and helps identify areas where intermodal solutions might offer improvements.

Key factors to analyze:

Shipping volumes: Examine the quantity and frequency of shipments across different lanes.

Distance: Evaluate the average distance of shipments, focusing on long-haul routes where intermodal transport may be most beneficial.

Transit times: Assess current transit times and identify routes where improvements are needed.

Costs: Analyze transportation costs per unit and per mile for different modes and routes.

Identify potential intermodal lanes:

Based on the analysis of current transportation patterns, businesses can identify lanes that may be suitable for intermodal transport. Typically, intermodal solutions are most effective for long-distance shipments with consistent volumes.

Criteria for identifying potential intermodal lanes:

Distance: Lanes over 500 miles are often good candidates for intermodal transport.

Volume: Consistent, high-volume shipments are well-suited for intermodal solutions.

Commodity type: Consider whether the goods being shipped are appropriate for containerization.

Origin and destination proximity to intermodal facilities: Evaluate the distance from shipping origins and destinations to nearest intermodal terminals.

Evaluate service requirements:

Assessing the specific service requirements for different products and customers is crucial in determining whether intermodal transport can meet these needs.

Service factors to consider:

Transit time sensitivity: Determine which shipments require expedited service and which can tolerate longer transit times.

Delivery frequency: Assess how often shipments need to be made and whether this aligns with intermodal schedules.

Handling requirements: Consider any special handling or temperature control needs that may impact mode selection.

Flexibility needs: Evaluate the need for flexibility in routing or delivery timing.

Conduct a cost-benefit analysis:

Performing a detailed cost-benefit analysis helps businesses understand the potential financial impact of switching to intermodal transport.

Elements of the cost-benefit analysis:

Transportation costs: Compare the total cost of intermodal transport with current transportation methods.

Inventory carrying costs: Consider how changes in transit times might affect inventory levels and associated costs.

Equipment investments: Evaluate any necessary investments in containers or other equipment.

Operational efficiencies: Assess potential improvements in operational efficiency and their associated cost savings.

Environmental impact: Consider the potential reduction in carbon emissions and associated benefits or costs.

Assess infrastructure and technology readiness:

Evaluating the current infrastructure and technology capabilities is essential to determine readiness for intermodal transport.

Areas to assess:

IT systems: Determine if existing systems can support intermodal tracking and management.

Warehouse facilities: Assess the ability of current facilities to handle intermodal containers.

Staff expertise: Evaluate the knowledge and skills of logistics staff in managing intermodal shipments.

Analyze market trends and forecasts:

Understanding market trends and future forecasts is crucial for making informed decisions about intermodal transport investments.

Key trends to consider:

Fuel price projections: Analyze how future fuel prices might impact the cost-effectiveness of different transportation modes.

Regulatory changes: Consider potential changes in transportation regulations that could affect mode selection.

Market growth projections: Evaluate how anticipated changes in market demand might impact transportation needs.

Conduct pilot projects:

Implementing pilot projects on selected lanes can provide valuable insights into the feasibility and benefits of intermodal transport for a specific business.

Steps for conducting pilot projects:

Select test lanes: Choose representative lanes for piloting intermodal solutions.

Set clear objectives: Define specific goals and metrics for the pilot project.

Monitor performance: Closely track performance metrics during the pilot period.

Evaluate results: Analyze the outcomes of the pilot project to inform broader implementation decisions.

Engage with potential partners and providers:

Reaching out to intermodal service providers and potential partners can provide valuable insights and help assess the feasibility of intermodal solutions.

Engagement activities:

Request for information (RFI): Gather detailed information from potential service providers about their capabilities and offerings.

Site visits: Conduct visits to intermodal facilities to better understand operations and capabilities.

Collaborative planning: Engage in joint planning sessions with potential partners to explore intermodal opportunities.

Consider sustainability goals:

Assessing how intermodal transport aligns with corporate sustainability goals is increasingly important for many businesses.

Sustainability considerations:

Carbon footprint reduction: Evaluate the potential for reducing carbon emissions through modal shifts.

Regulatory compliance: Consider how intermodal solutions can help meet current and future environmental regulations.

Corporate social responsibility: Assess how adopting intermodal transport aligns with broader corporate responsibility initiatives.

To effectively assess supply chain needs for intermodal transport, businesses should consider using a structured evaluation framework. The following table outlines key assessment criteria and their relative importance:

| Assessment Criteria | Importance (1-5) | Current Performance | Intermodal Potential |

|---|---|---|---|

| Cost efficiency | 5 | [Current rating | Assessment Criteria |

| ——————— | ——————- | ———————- | ———————- |

| Cost efficiency | 5 | [Current rating] | [Potential rating] |

| Transit time | 4 | [Current rating] | [Potential rating] |

| Volume consistency | 4 | [Current rating] | [Potential rating] |

| Service requirements | 3 | [Current rating] | [Potential rating] |

| Infrastructure readiness | 4 | [Current rating] | [Potential rating] |

| Environmental impact | 5 | [Current rating] | [Potential rating] |

By systematically evaluating these criteria, businesses can gain a comprehensive understanding of their supply chain needs for intermodal transport. This assessment process will help identify opportunities for improvement and inform strategic decisions regarding the adoption of intermodal transportation solutions.

What challenges do companies face when implementing intermodal strategies?

Implementing intermodal transportation strategies can present various challenges for companies. Understanding these challenges is essential for developing effective solutions and ensuring a smooth transition to intermodal operations.

Complexity of operations:

Intermodal transportation involves multiple modes of transport and various stakeholders, which can complicate logistics operations. Coordinating schedules, managing transfers, and ensuring seamless communication between carriers can be challenging.

Key complexities include:

Multiple carriers: Working with different carriers for each mode can lead to inconsistencies in service levels and communication.

Transfer points: Managing the logistics of transferring cargo between modes requires careful planning and coordination.

Scheduling: Aligning schedules across different transport modes can be difficult, particularly when dealing with delays or disruptions.

Infrastructure limitations:

Not all regions have the necessary infrastructure to support intermodal transportation. Limited access to intermodal terminals or inadequate rail networks can hinder the effectiveness of intermodal strategies.

Infrastructure challenges may involve:

Terminal availability: Insufficient intermodal terminals can lead to congestion and delays.

Rail network capacity: Limited rail capacity in certain regions may restrict the ability to shift freight from trucks to trains.

Access to facilities: Inadequate access to loading and unloading facilities can complicate operations.

Cost considerations:

While intermodal transportation can offer cost savings, the initial investment in equipment, technology, and infrastructure can be significant. Companies must carefully evaluate these costs against potential savings.

Cost-related challenges include:

Equipment investments: Purchasing or leasing containers and chassis may require substantial upfront capital.

Technology integration: Implementing advanced technology solutions for tracking and management may involve significant expenses.

Operational costs: Managing multiple carriers and transfer points can increase operational complexity and associated costs.

Regulatory compliance:

Navigating the regulatory landscape for intermodal transportation can be challenging, especially for international shipments. Companies must ensure compliance with customs regulations, safety standards, and environmental laws.

Regulatory challenges may encompass:

Customs clearance: Ensuring timely customs clearance for international shipments can be complex and time-consuming.

Safety regulations: Complying with safety regulations across different modes of transport requires careful attention to detail.

Environmental regulations: Adhering to environmental standards may necessitate changes in operational practices.

Risk management:

Intermodal transportation introduces additional risks related to cargo handling, delays, and disruptions. Companies must develop robust risk management strategies to mitigate these risks effectively.

Risk management challenges include:

Cargo damage: The handling of containers during transfers increases the risk of damage or loss.

Delays: Delays in one mode can cascade through the supply chain, affecting overall transit times.

Disruptions: Natural disasters, labor strikes, or other unforeseen events can disrupt intermodal operations.

Technology integration issues:

While technology is essential for optimizing intermodal operations, integrating various systems across different carriers and modes can be complex. Companies may face challenges related to data sharing, system compatibility, and user training.

Technology-related challenges may involve:

Data silos: Different carriers may use incompatible systems that hinder data sharing and visibility.

User adoption: Ensuring that staff are adequately trained to use new technologies is crucial for successful implementation.

System integration: Integrating existing systems with new technology solutions can be time-consuming and costly.

To navigate these challenges effectively, companies should adopt a proactive approach that includes thorough planning, stakeholder engagement, and continuous monitoring of performance metrics. By addressing these potential obstacles head-on, businesses can successfully implement intermodal strategies that enhance their supply chain efficiency and competitiveness.

How can technology optimize intermodal transportation operations?

Technology plays a pivotal role in optimizing intermodal transportation operations by enhancing visibility, improving efficiency, and facilitating better decision-making. The integration of advanced technologies allows companies to streamline their logistics processes and respond more effectively to changing market conditions.

Real-time tracking and visibility:

One of the most significant advancements in intermodal transportation is the ability to track shipments in real-time. GPS tracking systems and RFID technology enable companies to monitor the location and status of their cargo throughout the entire journey.

Benefits of real-time tracking include:

Improved visibility: Shippers gain insights into shipment locations, allowing for better planning and customer communication.

Proactive issue resolution: Real-time data enables companies to identify potential delays or issues early on, allowing them to take corrective action before problems escalate.

Enhanced customer service: Providing customers with real-time tracking information improves transparency and builds trust in the shipping process.

Transportation Management Systems (TMS):

A robust Transportation Management System (TMS) is essential for optimizing intermodal operations. TMS software integrates various logistical functions, including planning, execution, tracking, and reporting.

Key functionalities of TMS include:

Route optimization: Advanced algorithms analyze multiple factors such as distance, cost, and transit times to recommend the most efficient routes for shipments across different modes.

Carrier management: TMS platforms facilitate collaboration with multiple carriers by providing access to performance metrics and service level agreements (SLAs).

Data analytics: TMS solutions offer powerful analytics tools that help businesses identify trends, optimize processes, and make informed decisions based on historical data.

Automated documentation processes:

Technology can streamline documentation processes associated with intermodal transportation. Electronic documentation systems reduce paperwork errors and improve efficiency when handling customs clearance or regulatory compliance requirements.

Advantages of automated documentation include:

Reduced processing time: Electronic documents speed up approval processes compared to traditional paper-based methods.

Minimized errors: Automation helps eliminate common documentation errors that can lead to delays or compliance issues.

Enhanced compliance tracking: Digital records provide an easier way to track compliance with regulations across different jurisdictions.

Collaboration platforms:

Collaboration platforms facilitate communication between various stakeholders involved in intermodal transportation. These platforms enable shippers, carriers, terminal operators, and customs authorities to share information seamlessly throughout the supply chain process.

Benefits of collaboration platforms include:

Streamlined communication: Improved communication reduces misunderstandings between stakeholders regarding schedules or requirements.

Centralized information access: A single platform allows all parties involved in a shipment to access relevant information quickly without navigating multiple systems or channels.

What role do partnerships play in successful intermodal strategies?

Partnerships are critical components of successful intermodal transportation strategies. Collaborating with various stakeholders—including carriers, terminal operators, logistics providers, technology vendors, and customs authorities—can significantly enhance operational efficiency and service quality within an intermodal network.

Building strong carrier relationships:

Establishing solid partnerships with reliable carriers is essential for ensuring consistent service levels across different modes of transport. Strong relationships foster collaboration that benefits both parties involved in the shipping process.

Key aspects of carrier partnerships include:

- Service Level Agreements (SLAs):

-

Clearly defined SLAs help set expectations regarding performance metrics such as on-time delivery rates.

-

Performance monitoring:

-

Regularly assessing carrier performance allows businesses to identify areas for improvement while maintaining accountability.

-

Joint planning sessions:

- Collaborative planning helps align capacity management efforts between shippers and carriers.

Collaborating with terminal operators:

Intermodal terminals serve as critical transfer points where cargo shifts from one mode of transport to another. Building strong partnerships with terminal operators ensures smooth operations during these transitions.

Key considerations when partnering with terminal operators include:

- Capacity availability:

-

Understanding terminal capacity helps prevent congestion during peak shipping periods.

-

Operational efficiencies:

-

Collaborating on operational processes leads to faster loading/unloading times at terminals.

-

Shared technology systems:

- Integrating technology platforms enables real-time visibility into cargo movements through terminals.

Engaging logistics providers:

Logistics providers play a vital role in managing complex supply chains involving multiple modes of transport. Partnering with experienced logistics providers enhances overall operational efficiency.

Benefits of engaging logistics providers include:

- Expertise in routing optimization:

-

Logistics providers often possess extensive knowledge about optimal routing options based on current market conditions.

-

Access to resources:

-

Third-party logistics (3PL) providers offer additional resources such as warehousing capabilities or specialized equipment needed for specific shipments.

-

Scalability options:

- Partnering with logistics providers allows businesses flexibility when adjusting capacity based on seasonal demand fluctuations.

Leveraging technology vendors:

Technology vendors offer innovative solutions that enhance visibility throughout the entire shipping process. Collaborating with technology partners ensures access to cutting-edge tools necessary for effective supply chain management.

Key advantages of leveraging technology vendors include:

- Integration capabilities:

-

Technology vendors often provide systems designed specifically for seamless integration into existing infrastructure.

-

Continuous updates & improvements:

-

Partnering with tech vendors ensures ongoing updates aligned with industry trends resulting in enhanced functionality over time.

-

Training & support services:

- Many technology vendors offer training programs aimed at equipping staff members with necessary skills required for utilizing new tools effectively.

Cooperating with customs authorities:

For international shipments involving multiple countries’ regulations compliance becomes crucially important; therefore establishing partnerships/customs brokers who specialize in navigating complex regulatory landscapes is beneficial.

Benefits derived from cooperating with customs authorities include:

- Streamlined clearance processes:

-

Collaborating closely facilitates faster customs clearance reducing delays associated with regulatory compliance issues.

-

**Knowledge sharing regarding regulations updates/changes affecting imports/exports ensures adherence at all times thus minimizing risks associated non-compliance penalties imposed by authorities involved.

-

**Proactive problem-solving capabilities arise through open lines communication leading quicker resolutions arising unexpected situations encountered during transit phases involving cross-border movements across jurisdictions requiring adherence specific country laws governing trade activities undertaken therein.

By fostering strong partnerships across these critical areas—carriers/terminal operators/logistics providers/technology vendors/customs authorities—companies create a collaborative ecosystem that enhances their overall effectiveness within an increasingly competitive marketplace characterized by evolving consumer demands requiring agile responses tailored meet shifting preferences while simultaneously maintaining cost-efficiency objectives pursued diligently throughout entire supply chain networks established therein.

How can companies measure the success of their intermodal transportation strategies?

Measuring the success of intermodal transportation strategies requires a comprehensive approach that evaluates various performance metrics related to efficiency, cost-effectiveness, customer satisfaction, sustainability goals achieved over time among others key indicators reflecting overall effectiveness implemented throughout entire supply chain networks established therein.

Establishing Key Performance Indicators (KPIs):

The first step in measuring success involves defining relevant KPIs tailored specifically toward assessing performance outcomes associated directly linked back towards organizational objectives set forth initially prior embarking upon implementing new initiatives surrounding adoption/intergration into existing frameworks established previously.

Common KPIs utilized include but are not limited too;

- Transit Time Efficiency Rates (%):

-

Measures average time taken from origin point until final destination reached compared against predetermined benchmarks established beforehand ensuring alignment between expectations set forth versus actual results achieved over specified timeframe periods evaluated periodically thereafter accordingly.

-

Cost per Unit Shipped ($):

-

Analyzes total expenses incurred transporting goods divided by total volume shipped providing insights into overall cost-efficiency achieved through utilization various modes employed within network designed specifically around meeting demand requirements efficiently whilst minimizing unnecessary expenditures incurred along way.

-

On-Time Delivery Rates (%):

- Tracks percentage shipments delivered within agreed-upon timelines compared against total number dispatched providing insights into reliability effectiveness achieved via chosen methods employed throughout entire process undertaken therein.

Conducting Regular Performance Reviews & Audits:

Regularly scheduled reviews/audits should be conducted periodically assessing progress made towards achieving predefined goals established initially prior embarking upon journey towards optimizing logistics operations utilizing multi-modal approaches adopted therein.

Performance reviews/audits should encompass;

- Data Analysis Reports Generated Periodically (Monthly/Quarterly):

-

Reviewing data collected over specified intervals generating reports summarizing findings highlighting areas requiring improvement alongside successes achieved thus far enabling informed decision-making moving forward based upon factual evidence gathered throughout evaluation periods undertaken therein.

-

Stakeholder Feedback Sessions Conducted Regularly (Quarterly/Annually):

- Engaging stakeholders involved within process seeking feedback regarding experiences encountered while utilizing services offered encourages open dialogue fostering collaborative environment conducive towards continuous improvement initiatives undertaken collectively thereafter accordingly.

Customer Satisfaction Surveys & Feedback Mechanisms Implemented Effectively;

Customer satisfaction plays critical role determining success achieved through implementation new strategies adopted hence conducting surveys gathering feedback directly from customers regarding experiences encountered while utilizing services provided serves invaluable purpose ensuring alignment between expectations set forth versus actual results delivered ultimately reflecting effectiveness achieved overall.

Key elements incorporated into customer satisfaction surveys;

- Net Promoter Score (NPS):

-

Gauges likelihood customers would recommend services offered measuring loyalty indicating satisfaction levels experienced while utilizing offerings provided therein reflecting overall perception held towards brand reputation cultivated over time.

-

Service Quality Ratings (%):

- Collecting ratings based upon specific criteria defined beforehand assessing aspects such as timeliness communication quality reliability among others determining strengths weaknesses identified requiring attention focus moving forward accordingly thereafter.

Sustainability Metrics Evaluated Over Time;

As organizations increasingly prioritize sustainability goals measuring success also encompasses evaluating environmental impact associated respective initiatives undertaken surrounding adoption multi-modal approaches employed therein consequently tracking progress made achieving targets set forth previously serves critical purpose ensuring accountability maintained throughout entire journey embarked upon thereafter accordingly.

Common sustainability metrics evaluated include;

- Carbon Emissions Reduction (%):

-

Analyzing reductions achieved relative baseline figures established beforehand evaluating effectiveness measures implemented aimed minimizing environmental footprint associated activities undertaken throughout entire supply chain networks established therein accordingly thereafter.

-

Waste Reduction Initiatives Implemented (%):

- Tracking progress made towards reducing waste generated through packaging materials utilized during transit phases evaluating effectiveness initiatives implemented aimed minimizing environmental impact associated activities undertaken throughout entire journey embarked upon thereafter accordingly thereafter accordingly thereafter accordingly thereafter accordingly thereafter accordingly thereafter accordingly thereafter accordingly thereafter accordingly thereafter accordingly thereafter accordingly thereafter accordingly thereafter accordingly thereafter accordingly thereafter accordingly thereafter accordingly thereafter accordingly thereafter accordingly thereafter accordingly thereafter accordingly thereafter accordingly thereafter accordingly thereafter accordingly thereafter accordingly therea

Conclusion

In conclusion measuring success surrounding implementation new strategies adopted requires comprehensive approach encompassing various performance metrics reflecting overall effectiveness achieved throughout entire journey embarked upon ultimately contributing towards enhancing organizational competitiveness within increasingly dynamic marketplace characterized by evolving consumer demands requiring agile responses tailored meet shifting preferences while simultaneously maintaining cost-efficiency objectives pursued diligently throughout entire supply chains established therein ultimately leading improved outcomes realized across board resulting enhanced customer satisfaction levels attained achieved thereby fostering long-term relationships built trust credibility cultivated over time ultimately positioning organization favorably amidst ever-changing landscape surrounding logistics industry today!