What Is Port Drayage Trucking

Port drayage trucking is a specialized segment of the transportation industry that plays a crucial role in the global supply chain. This service involves the short-distance movement of shipping containers and cargo between ports, rail yards, and local shipping destinations. Port drayage truckers are responsible for transporting goods from maritime ports to warehouses, distribution centers, or intermodal facilities, typically within a 50-mile radius of the port.

The term “drayage” has its roots in the past, referring to the use of strong sideless carts called drays, which were pulled by dray horses to move goods over short distances. In modern times, drayage has evolved to encompass the use of trucks and specialized equipment to handle containerized cargo.

Port drayage trucking serves as a vital link between ocean carriers and inland transportation modes. It ensures the smooth flow of goods from ships to their next destination, whether that’s a local warehouse or a rail terminal for long-distance transport. This service is essential for maintaining the efficiency of global trade and the timely delivery of imported and exported goods.

Key components of port drayage trucking:

Short-distance transport: Port drayage primarily focuses on moving cargo over relatively short distances, typically within a 50-mile radius of the port.

Containerized cargo handling: Drayage truckers are skilled in handling various types of shipping containers, including standard 20-foot and 40-foot containers, as well as specialized containers for refrigerated or oversized cargo.

Intermodal connections: Port drayage often involves transferring cargo between different modes of transportation, such as from ships to trucks or from trucks to trains.

Time-sensitive operations: Due to the high volume of cargo moving through ports and the need to maintain efficient supply chains, port drayage operations often work under tight schedules and deadlines.

Customs and regulatory compliance: Drayage truckers must be well-versed in customs procedures and regulatory requirements for handling international cargo.

Port drayage trucking differs from long-haul trucking in several key aspects. While long-haul trucking involves transporting goods over long distances, often across state lines or even countries, port drayage focuses on short-distance moves within a localized area. This specialization allows drayage truckers to develop expertise in navigating port complexes, understanding local traffic patterns, and efficiently managing the unique challenges of port operations.

The importance of port drayage trucking in the supply chain cannot be overstated. It serves as the critical first or last mile in the transportation of goods, ensuring that cargo moves smoothly between ocean vessels and inland destinations. Without efficient port drayage services, the entire supply chain would face significant bottlenecks and delays, impacting global trade and the timely delivery of goods to consumers and businesses alike.

As global trade continues to grow and evolve, the role of port drayage trucking becomes increasingly significant. The ability to quickly and efficiently move cargo through ports and into the broader transportation network is essential for maintaining competitive advantages in international commerce. This has led to ongoing innovations in drayage operations, including the adoption of new technologies and the development of more efficient processes to meet the demands of modern supply chains.

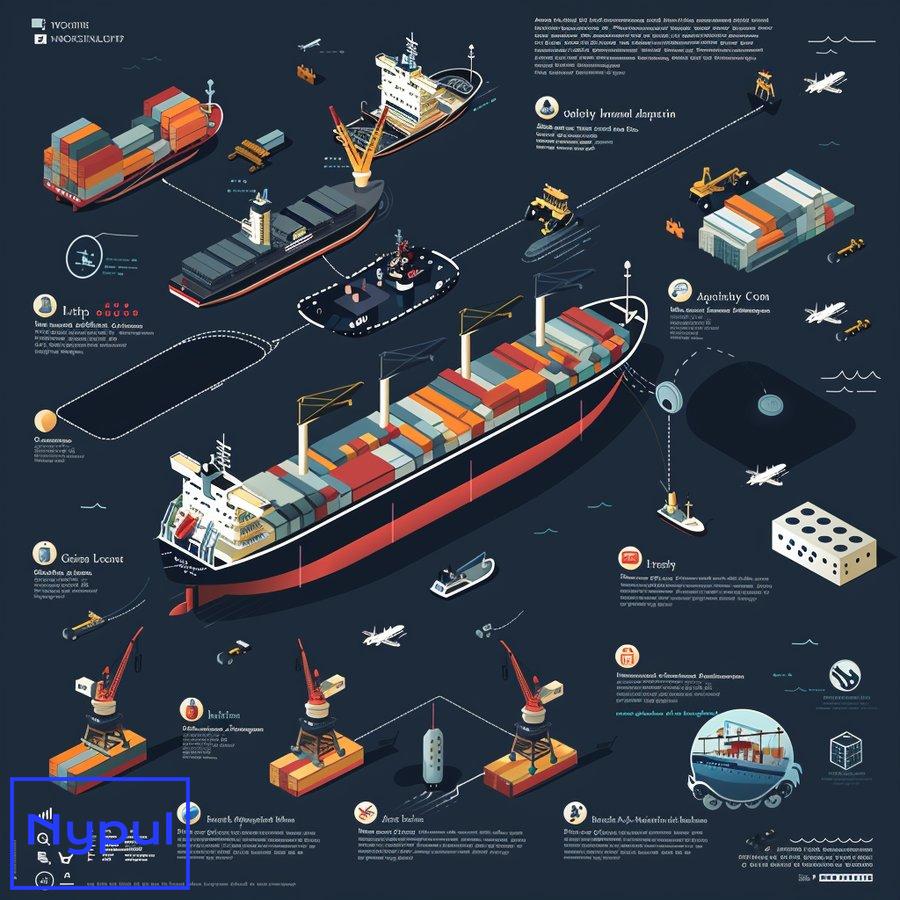

How does port drayage fit into the supply chain?

Port drayage is a critical component of the global supply chain, serving as the vital link between maritime transportation and inland logistics. To fully understand its role, it’s essential to examine how port drayage integrates with various elements of the supply chain and contributes to the overall efficiency of goods movement.

The supply chain ecosystem

The global supply chain is a complex network of interconnected processes, involving multiple stakeholders and modes of transportation. At its core, the supply chain aims to efficiently move goods from manufacturers to end consumers. Port drayage plays a crucial role in this ecosystem by bridging the gap between ocean freight and land-based transportation.

Key connections in the supply chain:

Ocean carriers to inland transport: When cargo arrives at a port via container ships, port drayage truckers are responsible for moving these containers from the port terminal to their next destination. This could be a nearby warehouse, a distribution center, or an intermodal facility for further transport by rail or long-haul trucking.

Warehouses and distribution centers: Port drayage services connect ports to local warehouses and distribution centers. This allows for the efficient storage and processing of imported goods before they are distributed to retailers or end consumers.

Intermodal facilities: Drayage truckers often transport containers to intermodal rail yards, where cargo is transferred onto trains for long-distance transportation. This intermodal connection is crucial for moving goods efficiently across large distances.

Exporters to ports: For outbound cargo, port drayage is responsible for transporting goods from local manufacturers or distribution centers to the port for export. This ensures that products reach the port in time for their scheduled vessel departures.

The flow of goods in port drayage

To better understand how port drayage fits into the supply chain, let’s examine the typical flow of goods for imported cargo:

-

Ocean transport: Goods are shipped in containers across oceans on large container vessels.

-

Port arrival: The container ship arrives at the destination port and is unloaded by port terminal operators.

-

Customs clearance: Containers go through customs inspection and clearance procedures.

-

Drayage pickup: Once cleared, a port drayage trucker picks up the container from the port terminal.

-

Short-haul transport: The drayage trucker transports the container to its next destination, such as a warehouse or intermodal facility.

-

Cargo processing: At the destination, the container is unloaded, and its contents are processed for further distribution.

-

Return of empty container: The drayage trucker often returns the empty container to the port or a designated container depot.

This process demonstrates how port drayage serves as the crucial link between maritime transport and inland logistics, ensuring the smooth flow of goods through the supply chain.

Impact on supply chain efficiency

The efficiency of port drayage operations has a significant impact on the overall performance of the supply chain. Here are some key ways in which port drayage influences supply chain efficiency:

Reducing port congestion: Efficient drayage operations help move containers out of port terminals quickly, reducing congestion and improving the overall throughput of the port.

Minimizing demurrage and detention fees: Timely pickup and return of containers help shippers avoid costly demurrage and detention fees imposed by ocean carriers and terminal operators.

Enabling just-in-time inventory: By providing reliable and timely transport of goods from ports to warehouses, port drayage supports just-in-time inventory strategies, allowing businesses to minimize storage costs and maintain lean operations.

Facilitating intermodal connections: Efficient drayage services ensure smooth transitions between different modes of transportation, reducing delays and improving the overall speed of goods movement.

Supporting e-commerce growth: As e-commerce continues to expand, port drayage plays a crucial role in ensuring the timely delivery of imported goods to fulfillment centers and distribution hubs.

Challenges and opportunities

While port drayage is essential to the supply chain, it also faces several challenges that can impact its efficiency:

Port congestion: High volumes of cargo and limited port capacity can lead to congestion, causing delays in drayage operations.

Equipment imbalances: Mismatches between the supply and demand of containers and chassis can create inefficiencies in drayage movements.

Regulatory compliance: Drayage operators must navigate complex regulations, including emissions standards and hours-of-service rules.

Technology integration: The need to adopt and integrate new technologies to improve efficiency and visibility in drayage operations.

To address these challenges and enhance the role of port drayage in the supply chain, industry stakeholders are focusing on several key areas:

Collaborative planning: Improved coordination between ports, drayage providers, and other supply chain partners to optimize container movements and reduce inefficiencies.

Technology adoption: Implementation of advanced technologies such as GPS tracking, electronic logging devices (ELDs), and port community systems to enhance visibility and streamline operations.

Sustainable practices: Adoption of cleaner technologies and practices to reduce the environmental impact of drayage operations and comply with evolving regulations.

Workforce development: Investing in training and retention programs to address the shortage of qualified drayage drivers and improve the overall quality of service.

By addressing these challenges and capitalizing on opportunities for improvement, port drayage can continue to enhance its critical role in the global supply chain, supporting the efficient movement of goods and contributing to economic growth.

What are the different types of port drayage services?

Port drayage services encompass a variety of specialized operations designed to meet the diverse needs of shippers, carriers, and other stakeholders in the supply chain. Understanding the different types of port drayage services is crucial for businesses to select the most appropriate options for their specific requirements. Let’s explore the main categories of port drayage services and their unique characteristics.

Inter-carrier drayage

Inter-carrier drayage involves the movement of containers between different carriers or modes of transportation within the same local area. This service is essential for facilitating intermodal transportation and ensuring smooth transitions between various segments of the supply chain.

Key features:

– Transfers containers between ocean carriers, railroads, and trucking companies

– Typically occurs within port complexes or nearby intermodal facilities

– Supports efficient cargo handoffs between different transportation providers

Intra-carrier drayage

Intra-carrier drayage refers to the movement of containers between facilities operated by the same carrier. This service helps carriers optimize their operations and manage container positioning within their network.

Key features:

– Moves containers between a carrier’s own terminals, depots, or yards

– Supports efficient equipment utilization and positioning

– Often used for repositioning empty containers or consolidating cargo

Expedited drayage

Expedited drayage services prioritize speed and time-sensitive deliveries. This option is ideal for urgent shipments or cargo that requires immediate attention.

Key features:

– Offers faster pickup and delivery times compared to standard drayage

– Often involves dedicated trucks and drivers for specific shipments

– May include priority handling at port terminals and customs clearance

Door-to-door drayage

Door-to-door drayage provides comprehensive service from the port to the final destination, typically a customer’s facility or distribution center. This option offers convenience and simplifies the logistics process for shippers.

Key features:

– Covers the entire journey from port to final destination

– Includes all necessary documentation and customs clearance

– Often combined with warehousing or distribution services

Shuttle drayage

Shuttle drayage involves the continuous movement of containers between two fixed points, such as a port and a nearby distribution center or rail yard. This service is designed to maintain a steady flow of cargo and reduce congestion at port terminals.

Key features:

– Operates on a fixed schedule between predetermined locations

– Helps alleviate port congestion by quickly moving containers off-site

– Often used in high-volume corridors or for large shippers with consistent cargo flows

Cross-dock drayage

Cross-dock drayage combines transportation with immediate cargo transfer or consolidation. This service minimizes storage time and supports efficient cargo handling for time-sensitive or high-volume shipments.

Key features:

– Involves unloading cargo from incoming containers and immediately reloading onto outbound trucks or containers

– Reduces warehousing needs and accelerates cargo movement

– Often used for retail distribution or just-in-time manufacturing supply chains

Pier drayage

Pier drayage focuses on moving containers within the port complex itself, typically between different terminals or from the port to nearby rail yards or container depots.

Key features:

– Specializes in short-distance moves within the port area

– Requires in-depth knowledge of port layouts and procedures

– Often subject to specific port regulations and security requirements

Bonded drayage

Bonded drayage involves the transportation of goods that have not yet cleared customs. This service allows for the movement of cargo to authorized facilities for inspection or further processing before formal entry into the country.

Key features:

– Requires special permits and compliance with customs regulations

– Involves secure transportation of goods under customs bond

– Often used for in-bond warehousing or transshipment of cargo

Comparison of port drayage services

To better understand the differences between these drayage services, let’s compare their key characteristics:

| Service Type | Primary Focus | Typical Distance | Key Advantage |

|---|---|---|---|

| Inter-carrier | Carrier transfers | Short (within port area) | Facilitates intermodal connections |

| Intra-carrier | Internal carrier moves | Short to medium | Optimizes carrier operations |

| Expedited | Speed | Variable | Fastest delivery times |

| Door-to-door | Comprehensive service | Long (port to final destination) | Convenience for shippers |

| Shuttle | Fixed-route transfers | Short to medium | Reduces port congestion |

| Cross-dock | Immediate transfer | Short | Minimizes storage time |

| Pier | Port-centric moves | Very short (within port) | Specialized port knowledge |

| Bonded | Customs-controlled moves | Variable | Allows movement before customs clearance |

Choosing the right drayage service

Selecting the appropriate drayage service depends on various factors, including:

Cargo type: The nature of the goods being transported may require specialized handling or equipment.

Urgency: Time-sensitive shipments may necessitate expedited or cross-dock drayage services.

Volume: High-volume shippers might benefit from shuttle or dedicated drayage services.

Customs status: Goods that have not cleared customs will require bonded drayage services.

Distance: The required transportation distance will influence the choice between local pier drayage and longer-distance door-to-door services.

Cost considerations: Different drayage services come with varying price points, which must be balanced against the specific needs of the shipment.

By understanding the diverse range of port drayage services available, shippers and logistics professionals can make informed decisions to optimize their supply chain operations. Each type of drayage service offers unique benefits and is suited to specific scenarios, allowing for tailored solutions that meet the complex demands of modern global trade.

What equipment is used in port drayage operations?

Port drayage operations rely on a diverse array of specialized equipment to efficiently handle and transport containerized cargo. The right equipment is crucial for ensuring safe, timely, and cost-effective movement of goods between ports and inland destinations. Let’s explore the various types of equipment used in port drayage and their specific roles in the operation.

Trucks and tractors

The backbone of port drayage operations is the fleet of trucks and tractors used to move containers. These vehicles are designed to handle the heavy loads and unique requirements of container transportation.

Day cab trucks: These trucks have a compact cab without a sleeping compartment, making them ideal for short-haul drayage operations. They offer good maneuverability in tight port environments.

Sleeper cab trucks: While less common in drayage, sleeper cabs may be used for longer drayage routes or when drivers need to rest between shifts.

Yard tractors: Also known as yard trucks or terminal tractors, these specialized vehicles are designed for moving trailers and containers within port terminals or large distribution centers.

Key features of drayage trucks:

– High torque engines to handle heavy loads

– Reinforced frames and suspensions for durability

– Specialized coupling systems for attaching to various types of trailers and chassis

Chassis and trailers

Chassis and trailers are essential components that work in conjunction with trucks to transport containers. Different types are used depending on the container size and cargo requirements.

Container chassis: These are specialized trailers designed to carry shipping containers. They come in various configurations to accommodate different container sizes:

– 20-foot chassis

– 40-foot chassis

– 45-foot chassis

– Extendable chassis (adjustable to fit different container lengths)

Flatbed trailers: Used for oversized or non-containerized cargo that requires open-air transportation.

Lowboy trailers: Designed for transporting tall or heavy equipment that exceeds standard height restrictions.

Specialized chassis:

– Tri-axle chassis for heavier loads

– Gooseneck chassis for improved weight distribution

– Slider chassis for adjustable axle positioning

Container handling equipment

Efficient loading and unloading of containers require specialized handling equipment at port terminals and intermodal facilities.

Reach stackers: Mobile machines used for handling containers in smaller ports or intermodal yards. They can stack containers up to 5 high and move them short distances.

Top loaders: Similar to reach stackers but designed for heavier loads and higher stacking capabilities.

Straddle carriers: These machines straddle a container, lift it, and transport it within the terminal. They offer flexibility in container movement and stacking.

Rail-mounted gantry cranes (RMGs): Large cranes that move on rails to handle containers in rail yards or port terminals. They can span multiple lanes of containers or rail tracks.

Rubber-tyred gantry cranes (RTGs): Similar to RMGs but mounted on rubber tires for greater mobility within the terminal.

Ship-to-shore cranes: Massive cranes used to load and unload containers from ships. While not directly part of drayage operations, they play a crucial role in the overallport container handling process.

Auxiliary equipment

Various auxiliary equipment supports the main drayage operations and ensures smooth handling of containers and cargo.

Container spreaders: Attachments used with cranes and lifting equipment to securely grip and lift containers.

Twist locks: Locking mechanisms that secure containers to chassis or other containers during transport.

Landing gear: Retractable legs on trailers that support the front end when not connected to a truck.

Gensets: Portable generators used to power refrigerated containers (reefers) during transport.

Container scales: Used to verify container weights for compliance with safety regulations and shipping requirements.

Safety equipment

Safety is paramount in port drayage operations, and various equipment is used to ensure the well-being of workers and the integrity of cargo.

Personal protective equipment (PPE): Includes hard hats, safety vests, steel-toed boots, and gloves for drayage workers.

Vehicle safety systems: Includes backup cameras, blind-spot detection systems, and collision avoidance technology.

Container inspection tools: Used to check for structural integrity and security seals on containers.

Fire suppression systems: Installed on trucks and in port facilities to mitigate fire risks.

Technological equipment

Modern port drayage operations increasingly rely on technology to improve efficiency, tracking, and communication.

GPS tracking devices: Used to monitor the real-time location of trucks and containers.

Electronic logging devices (ELDs): Mandated by regulations to track driver hours of service and ensure compliance.

Mobile devices and tablets: Used by drivers and dispatchers for communication, documentation, and workflow management.

RFID scanners: Used for automated identification and tracking of containers and equipment.

Optical character recognition (OCR) systems: Used at terminal gates to automatically capture container and truck information.

Comparison of key drayage equipment

| Equipment Type | Primary Function | Key Advantages | Typical Use Case |

|---|---|---|---|

| Day cab truck | Short-haul container transport | Maneuverability, efficiency | Local port to warehouse moves |

| Container chassis | Carry shipping containers | Versatility, standardization | All container drayage operations |

| Reach stacker | Container handling and stacking | Flexibility, mobility | Smaller ports, intermodal yards |

| Straddle carrier | Container transport within terminal | Efficiency, stacking capability | Large port terminals |

| Genset | Power refrigerated containers | Maintain cargo temperature | Reefer container transport |

| GPS tracking device | Real-time location monitoring | Visibility, security | All drayage trucks and containers |

The diverse array of equipment used in port drayage operations reflects the complexity and specialized nature of this crucial link in the supply chain. From the trucks that form the backbone of the drayage fleet to the sophisticated container handling equipment at ports, each piece plays a vital role in ensuring the efficient movement of goods.

As technology continues to advance, we can expect to see further innovations in drayage equipment, such as the development of electric and autonomous vehicles, more advanced tracking systems, and improved container handling technologies. These advancements will help address ongoing challenges in the industry, including environmental concerns, operational efficiency, and safety improvements.

Understanding the various types of equipment used in port drayage is essential for logistics professionals, shippers, and anyone involved in the maritime supply chain. This knowledge helps in making informed decisions about equipment selection, maintenance, and investment, ultimately contributing to more efficient and cost-effective drayage operations.

How does a typical port drayage move work?

A typical port drayage move involves a series of coordinated steps that ensure the smooth transition of containerized cargo from a port to its inland destination or vice versa. Understanding this process is crucial for anyone involved in international trade or logistics. Let’s break down the typical port drayage move into its key stages and examine the activities and stakeholders involved at each point.

Pre-arrival planning

Before a container even arrives at the port, several preparatory steps take place:

Booking and documentation: The shipper or freight forwarder books the drayage service and prepares necessary documentation, including customs paperwork and delivery instructions.

Equipment allocation: The drayage company assigns appropriate trucks and chassis based on the container specifications and delivery requirements.

Route planning: Dispatchers plan the most efficient route, considering factors such as traffic patterns, port congestion, and delivery deadlines.

Customs pre-clearance: When possible, customs documentation is submitted in advance to expedite the clearance process upon arrival.

Port arrival and container discharge

Once the vessel arrives at the port, the following activities occur:

Vessel berthing: The container ship docks at the assigned berth in the port.

Container unloading: Ship-to-shore cranes unload containers from the vessel onto the port terminal.

Initial container placement: Containers are placed in the terminal yard, organized based on various factors such as destination, customs status, and priority.

Customs clearance and release

Before a container can leave the port, it must clear customs:

Document verification: Customs officials review import documentation and may conduct physical inspections of the cargo.

Duty payment: Any applicable import duties or taxes are paid.

Container release: Once cleared, the container is released for pickup by the drayage carrier.

Drayage pickup process

The actual drayage move begins with the pickup of the container from the port:

Truck arrival at port: The drayage truck arrives at the port terminal during its assigned appointment window.

Driver check-in: The driver presents necessary credentials and pickup information at the terminal gate.

Container location: The driver is directed to the specific location of the container within the terminal.

Container loading: Terminal equipment loads the container onto the truck’s chassis.

Outgate process: The driver exits the terminal, with the container’s details and truck information recorded at the gate.

Transportation to destination

Once the container is secured, the drayage move continues:

Transit: The driver transports the container to its designated destination, following the planned route.

Real-time tracking: GPS and other tracking technologies provide visibility of the container’s location throughout the journey.

Communication: The driver stays in contact with dispatch for any updates or issues during transit.

Delivery and unloading

Upon reaching the destination, the final steps of the drayage move occur:

Arrival at destination: The truck arrives at the consignee’s location, which may be a warehouse, distribution center, or another intermodal facility.

Check-in and verification: The driver checks in with the receiving facility and verifies delivery details.

Container unloading: The container is unloaded from the truck, either by the facility’s equipment or by the truck’s own mechanisms if it’s equipped with a tilting bed.

Documentation completion: Delivery receipts and any necessary paperwork are completed and signed.

Empty container return

After delivery, the empty container typically needs to be returned:

Return instructions: The driver receives instructions on where to return the empty container, which may be back to the port, a designated container depot, or another location.

Empty container drop-off: The driver delivers the empty container to the specified location.

Equipment inspection: The empty container is inspected for damage and cleanliness before being accepted for return.

Completion and billing

The drayage move concludes with administrative tasks:

Trip completion: The driver reports the completion of the move to dispatch.

Documentation submission: All relevant documents, including proof of delivery, are submitted to the drayage company.

Invoicing: The drayage company prepares and sends an invoice for the completed service.

Key stakeholders in a port drayage move

A successful port drayage move involves coordination among various stakeholders:

Shippers: Initiate the shipment and provide cargo details.

Consignees: Receive the cargo at the destination.

Drayage companies: Provide the transportation service.

Port authorities: Manage port operations and infrastructure.

Terminal operators: Handle container storage and movement within the port.

Customs officials: Oversee import/export compliance and clearance.

Freight forwarders: Coordinate logistics and documentation.

Trucking companies: Provide the actual trucks and drivers for the drayage move.

Challenges in port drayage moves

Several challenges can impact the efficiency of port drayage moves:

Port congestion: High volumes of cargo can lead to delays in container availability and truck queuing.

Equipment availability: Shortages of chassis or specific container types can cause delays.

Documentation errors: Incorrect or incomplete paperwork can hold up customs clearance and release.

Traffic and road conditions: Urban congestion and road construction can impact transit times.

Labor shortages: A lack of qualified drivers can affect drayage capacity and service levels.

Technological integration: Ensuring seamless communication between various systems used by different stakeholders.

Factors influencing drayage efficiency

Several factors can significantly impact the efficiency of port drayage moves:

Appointment systems: Well-managed terminal appointment systems can reduce truck wait times and improve overall port fluidity.

Extended gate hours: Ports that offer night and weekend operations can help spread out truck traffic and reduce congestion.

Information sharing: Real-time data exchange between ports, truckers, and shippers can improve planning and reduce delays.

Chassis pools: Efficient management of shared chassis pools can improve equipment availability and reduce empty moves.

Truck staging areas: Designated areas near ports for trucks to wait for their turn can help manage traffic flow and reduce congestion on surrounding roads.

Technology adoption: Implementation of technologies like automated gate systems, GPS tracking, and mobile apps can streamline operations and improve visibility.

Understanding the intricacies of a typical port drayage move is essential for optimizing supply chain operations. By recognizing the various stages, stakeholders, and potential challenges involved, businesses can better plan their logistics strategies and work towards more efficient and cost-effective drayage operations. As the global supply chain continues to evolve, staying informed about best practices and emerging technologies in port drayage will be crucial for maintaining competitiveness in international trade.

What challenges do port drayage truckers face?

Port drayage truckers play a crucial role in the global supply chain, but they face numerous challenges that can impact their efficiency, profitability, and overall job satisfaction. Understanding these challenges is essential for developing effective solutions and improving the drayage industry as a whole. Let’s explore the major challenges faced by port drayage truckers and their implications for the broader logistics ecosystem.

Port congestion and long wait times

One of the most significant challenges for drayage truckers is port congestion, which often results in extended wait times at terminal gates and within port facilities.

Causes of port congestion:

– Increasing vessel sizes leading to larger cargo volumes per ship

– Limited port infrastructure and capacity

– Inefficient cargo handling processes

– Imbalanced cargo flows and equipment shortages

Impact on truckers:

– Reduced productivity and fewer trips per day

– Increased fuel consumption and operational costs

– Potential violations of hours-of-service regulations

– Stress and fatigue from long, unpredictable wait times

Potential solutions:

– Implementation of appointment systems and extended gate hours

– Improved port automation and cargo handling technologies

– Development of off-dock container yards and inland ports

– Real-time information sharing to better manage truck arrivals and departures

Equipment availability and imbalances

Drayage truckers often struggle with the availability and management of essential equipment, particularly chassis.

Key equipment challenges:

– Chassis shortages or mismatches between chassis types and container needs

– Inefficient chassis provisioning systems

– Maintenance and repair issues with aging chassis fleets

– Imbalances in container availability between import and export flows

Impact on truckers:

– Lost time searching for or waiting for available chassis

– Inability to complete moves due to equipment shortages

– Increased operational costs from chassis rental fees or repositioning

– Reduced efficiency and productivity

Potential solutions:

– Development of more efficient chassis pool models

– Investment in newer, more reliable chassis fleets

– Implementation of advanced tracking and management systems for equipment

– Improved coordination between truckers, terminals, and equipment providers

Regulatory compliance and driver hours of service

Drayage truckers must navigate complex regulatory environments, including strict hours-of-service rules that can be challenging to comply with given the unpredictable nature of port operations.

Regulatory challenges:

– Balancing hours-of-service limitations with port wait times and delivery schedules

– Compliance with electronic logging device (ELD) mandates

– Adhering to evolving environmental regulations and emissions standards

– Navigating complex customs and security requirements

Impact on truckers:

– Reduced flexibility in managing workloads and schedules

– Potential for violations and fines due to port delays beyond their control

– Increased administrative burden for compliance documentation

– Need for ongoing training and education on regulatory changes

Potential solutions:

– Advocacy for more flexible hours-of-service rules for drayage operations

– Development of technologies to streamline compliance processes

– Improved coordination between regulatory bodies and industry stakeholders

– Support for clean truck programs and incentives for adopting low-emission vehicles

Infrastructure and road conditions

The condition of road infrastructure in and around ports can significantly impact drayage operations.

Infrastructure challenges:

– Congested urban roads leading to and from ports

– Aging bridges and tunnels with weight or height restrictions

– Limited parking and rest areas for trucks near ports

– Inadequate signage and wayfinding in complex port environments

Impact on truckers:

– Increased transit times and fuel consumption

– Higher vehicle maintenance costs due to poor road conditions

– Safety concerns when navigating through congested or poorly maintained areas

– Difficulty finding safe and legal parking for required rest periods

Potential solutions:

– Investment in dedicated freight corridors and port access roads

– Development of truck parking facilities and rest areas near ports

– Implementation of intelligent transportation systems for improved traffic management

– Collaboration between port authorities and local governments on infrastructure planning

Technology adoption and integration

While technology offers many potential benefits, its adoption and integration can present challenges for drayage truckers.

Technology-related challenges:

– Learning and adapting to new software and hardware systems

– Integration of multiple technologies from different stakeholders (ports, shippers, carriers)

– Costs associated with acquiring and maintaining new technologies

– Concerns about data privacy and cybersecurity

Impact on truckers:

– Potential for increased efficiency but also added complexity in daily operations

– Need for ongoing training and skill development

– Initial productivity losses during technology implementation phases

– Dependence on reliable internet and GPS connectivity

Potential solutions:

– Development of user-friendly, integrated technology solutions

– Provision of comprehensive training and support for new technologies

– Industry-wide standards for data sharing and system interoperability

– Incentives or subsidies for small operators to adopt new technologies

Labor shortages and workforce challenges

The drayage industry faces ongoing challenges related to workforce recruitment, retention, and development.

Workforce challenges:

– Aging driver population and difficulties attracting younger workers

– High turnover rates due to job stress and lifestyle challenges

– Competition from other sectors of the trucking industry

– Need for ongoing training to keep up with technological and regulatory changes

Impact on truckers:

– Increased workloads and pressure on existing drivers

– Potential for reduced service quality due to inexperienced or overworked drivers

– Limited opportunities for career advancement or skill development

– Challenges in maintaining work-life balance

Potential solutions:

– Development of driver apprenticeship and mentoring programs

– Improvement of working conditions and compensation packages

– Implementation of technologies to make the job more attractive to younger workers

– Creation of clear career pathways within the drayage and broader logistics industry

Environmental concerns and sustainability pressures

Drayage truckers are increasingly facing pressure to reduce their environmental impact and adopt more sustainable practices.

Environmental challenges:

– Stricter emissions standards and air quality regulations

– Pressure to adopt alternative fuels or electric vehicles

– Need to reduce idling and improve fuel efficiency

– Balancing environmental goals with operational and economic realities

Impact on truckers:

– Increased costs associated with upgrading to cleaner vehicles

– Potential operational changes to meet environmental regulations

– Need for additional training on new technologies and best practices

– Challenges in finding appropriate infrastructure for alternative fuel vehicles

Potential solutions:

– Government incentives for adopting clean technologies

– Development of more affordable and practical alternative fuel vehicles

– Implementation of port-wide environmental programs with stakeholder input

– Education and awareness campaigns on sustainable drayage practices

Economic pressures and rate volatility

Drayage truckers often face economic challenges due to rate fluctuations and increasing operational costs.

Economic challenges:

– Volatile fuel prices impacting operational costs

– Pressure to maintain competitive rates in a crowded market

– Increasing insurance and compliance-related expenses

– Difficulty in securing consistent, well-paying contracts

Impact on truckers:

– Financial instability and cash flow challenges

– Difficulty in planning for long-term investments or upgrades

– Pressure to take on more work or longer hours to maintain income

– Reduced ability to invest in new technologies or equipment

Potential solutions:

– Development of fair and transparent pricing models for drayage services

– Implementation of fuel surcharge mechanisms to mitigate price volatility

– Creation of cooperative or consortium models for small operators

– Improved financial education and business management training for owner-operators

The challenges faced by port drayage truckers are complex and interconnected, requiring a multi-faceted approach to address them effectively. By understanding these challenges, industry stakeholders can work together to develop innovative solutions that improve the efficiency, sustainability, and profitability of drayage operations.

Addressing these challenges will require collaboration among various stakeholders, including port authorities, shippers, technology providers, and government agencies. By working together to implement targeted solutions, the industry can create a more resilient and efficient drayage ecosystem that benefits truckers, ports, and the broader supply chain.

How is technology improving port drayage efficiency?

Technology is playing an increasingly crucial role in enhancing the efficiency of port drayage operations. From streamlining communication to optimizing route planning, technological advancements are transforming the way drayage truckers, port operators, and shippers interact and manage their operations. Let’s explore the various technologies that are making a significant impact on port drayage efficiency.

GPS tracking and real-time visibility

GPS tracking technology has revolutionized the ability to monitor and manage drayage operations in real-time.

Key features:

– Precise location tracking of trucks and containers

– Real-time updates on estimated arrival times

– Geofencing capabilities for automated notifications

– Integration with traffic data for accurate transit time predictions

Benefits:

– Improved visibility for shippers and consignees

– Enhanced ability to manage exceptions and delays

– Reduced phone calls and manual check-ins

– Better coordination between truckers and terminal operators

Implementation challenges:

– Ensuring consistent connectivity in port environments

– Integrating data from multiple tracking systems

– Balancing tracking capabilities with driver privacy concerns

Terminal appointment systems

Advanced terminal appointment systems help manage truck flow and reduce congestion at port gates.

Key features:

– Online booking of pickup and delivery slots

– Integration with terminal operating systems

– Automated gate processing using OCR and RFID technologies

– Dynamic slot allocation based on real-time terminal conditions

Benefits:

– Reduced truck turn times and wait periods

– More efficient use of terminal resources

– Improved planning capabilities for truckers and terminal operators

– Decreased overall port congestion

Implementation challenges:

– Ensuring system reliability and uptime

– Managing exceptions and last-minute changes

– Encouraging adoption among smaller trucking companies

Mobile applications for drivers

Purpose-built mobile apps provide drayage drivers with essential tools and information at their fingertips.

Key features:

– Digital documentation and paperwork management

– Turn-by-turn navigation optimized for truck routes

– Real-time communication with dispatchers and terminal operators

– Access to port-specific information and updates

Benefits:

– Reduced administrative burden for drivers

– Improved communication and information flow

– Enhanced ability to respond to changes in real-time

– Increased overall driver productivity and satisfaction

Implementation challenges:

– Ensuring user-friendly interfaces for diverse driver populations

– Managing app updates and device compatibility

– Addressing concerns about driver distraction and safety

Automated gate systems

Automated gate systems use a combination of technologies to streamline the entry and exit process at port terminals.

Key features:

– Optical character recognition (OCR) for container and license plate reading

– RFID-enabled driver identification

– Automated damage inspection systems

– Integration with terminal operating systems for rapid processing

Benefits:

– Significantly reduced gate processing times

– Improved accuracy in data capture and record-keeping

– Enhanced security through automated verification processes

– Reduced labor costs for terminal operators

Implementation challenges:

– High initial investment costs

– Need for redundancy systems to handle equipment failures

– Training requirements for drivers and terminal staff

Predictive analytics and machine learning

Advanced analytics and machine learning algorithms are being applied to optimize various aspects of drayage operations.

Key applications:

– Predictive maintenance for trucks and equipment

– Optimized route planning based on historical and real-time data

– Dynamic pricing models for drayage services

– Forecasting of container volumes and equipment needs

Benefits:

– Improved operational efficiency and resource allocation

– Reduced downtime due to equipment failures

– More accurate planning and forecasting capabilities

– Enhanced ability to adapt to changing conditions

Implementation challenges:

– Ensuring data quality and consistency across multiple sources

– Developing accurate models that account for complex port dynamics

– Balancing automated decision-making with human oversight

Blockchain for documentation and transactions

Blockchain technology is being explored to streamline documentation processes and enhance transparency in drayage operations.

Key applications:

– Secure sharing of shipping documents and customs information

– Smart contracts for automated payment and settlement

– Tracking of container ownership and custody changes

– Verification of driver credentials and equipment certifications

Benefits:

– Reduced paperwork and administrative costs

– Improved transparency and traceability in the supply chain

– Faster processing of payments and settlements

– Enhanced security and reduced fraud risk

Implementation challenges:

– Achieving industry-wide adoption and standardization

– Integrating blockchain with existing legacy systems

– Addressing concerns about data privacy and governance

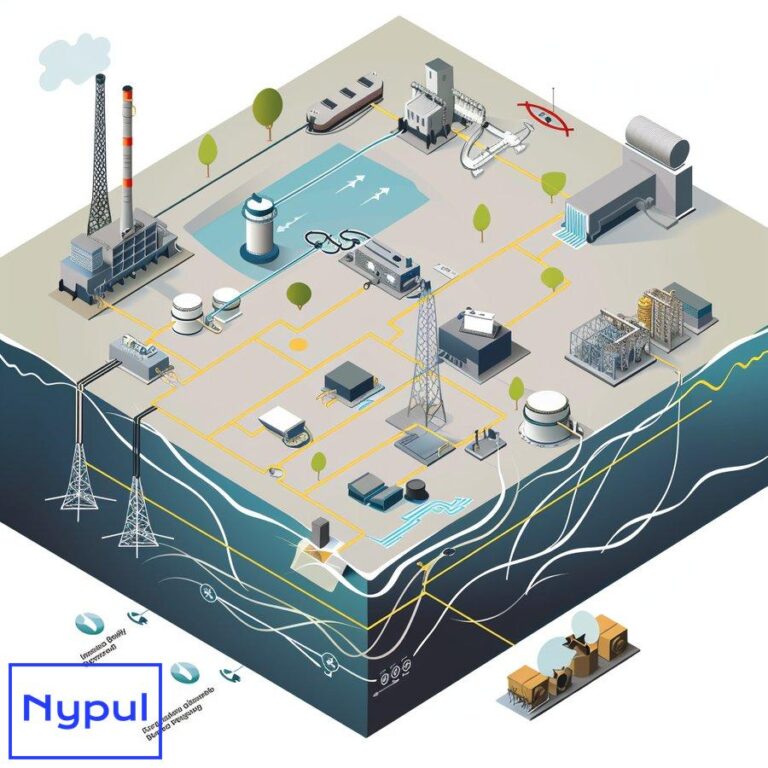

Internet of Things (IoT) and sensor technology

IoT devices and sensors are being deployed to gather real-time data on various aspects of drayage operations.

Key applications:

– Remote monitoring of container conditions (temperature, humidity, etc.)

– Automated equipment health monitoring and diagnostics

– Real-time tracking of chassis and other assets

– Environmental monitoring for regulatory compliance

Benefits:

– Improved visibility and control over cargo conditions

– Proactive maintenance and reduced equipment downtime

– Enhanced asset utilization and management

– Better compliance with environmental regulations

Implementation challenges:

– Managing the large volumes of data generated by IoT devices

– Ensuring the security of connected devices and networks

– Standardizing protocols for data sharing and interoperability

Autonomous and semi-autonomous vehicles

While still in the early stages, autonomous vehicle technology has the potential to significantly impact drayage operations in the future.

Potential applications:

– Automated container movements within terminals

– Platooning of drayage trucks for improved efficiency

– Semi-autonomous systems for improved safety and fuel efficiency

– Fully autonomous drayage operations in controlled environments

Potential benefits:

– Increased operational efficiency and 24/7 capabilities

– Improved safety and reduced accident rates

– Mitigation of driver shortage issues

– Reduced fuel consumption and emissions

Implementation challenges:

– Developing technology capable of handling complex port environments

– Addressing regulatory and liability concerns

– Managing the transition and potential job displacement

– Ensuring public acceptance and trust in autonomous systems

The integration of these technologies is gradually transforming port drayage operations, leading to improved efficiency, reduced costs, and enhanced visibility throughout the supply chain. However, successful implementation requires careful planning, investment, and collaboration among all stakeholders in the drayage ecosystem.

As these technologies continue to evolve and mature, we can expect to see even greater improvements in port drayage efficiency. The key to success will be the ability to integrate these various technologies into cohesive systems that can communicate and work together seamlessly. This will require ongoing cooperation between technology providers, port authorities, drayage companies, and other stakeholders to develop standards and best practices for technology adoption and use.

Moreover, as the industry embraces these technological advancements, it’s crucial to consider the human element. Training programs and change management strategies will be essential to ensure that drayage truckers and other workers can effectively utilize these new tools and adapt to changing job requirements.

By leveraging these technological innovations, the port drayage industry can address many of its longstanding challenges, creating a more efficient, sustainable, and resilient supply chain for the future.

What economic impact does port drayage have?

Port drayage plays a crucial role in the global supply chain, serving as the critical link between maritime shipping and inland transportation. The economic impact of port drayage extends far beyond the immediate transportation sector, influencing various aspects of local, national, and international economies. Let’s explore the multifaceted economic implications of port drayage operations.

Direct economic contributions

Port drayage directly contributes to the economy through job creation, revenue generation, and business activities.

Employment generation:

– Drayage truck drivers

– Dispatchers and logistics coordinators

– Maintenance and repair technicians

– Administrative and support staff

Revenue streams:

– Drayage service fees

– Equipment leasing and rental income

– Fuel sales and related services

– Maintenance and repair services

Business activities:

– Drayage companies and owner-operators

– Equipment manufacturers and suppliers

– Technology and software providers

– Insurance and financial services for the drayage industry

The direct economic impact of port drayage can be substantial, particularly in regions with major port facilities. For example, a study by the American Transportation Research Institute found that the drayage industry in the Port of New York and New Jersey alone supported over 7,000 jobs and generated nearly $1 billion in economic activity annually.

Indirect economic effects

The ripple effects of port drayage extend to various related industries and services.

Supply chain efficiency:

– Facilitates timely delivery of goods to manufacturers and retailers

– Supports just-in-time inventory management systems

– Enables efficient intermodal connections for long-distance freight movement

Port competitiveness:

– Efficient drayage operations enhance a port’s attractiveness to shippers and carriers

– Contributes to increased cargo volumes and port revenues

– Supports port expansion and infrastructure development projects

Regional economic development:

– Attracts warehousing and distribution facilities to port-adjacent areas

– Stimulates growth in related industries such as logistics and freight forwarding

– Contributes to the development of transportation corridors and infrastructure

International trade facilitation:

– Enables smooth flow of imported and exported goods

– Supports the growth of export-oriented industries

– Facilitates participation in global supply chains for local businesses

A study by the Port of Los Angeles estimated that for every direct job in port drayage, an additional 2.8 jobs were created in the regional economy through indirect and induced effects.

Economic multiplier effects

The economic activity generated by port drayage has a multiplier effect throughout the broader economy.

Household spending:

– Wages earned by drayage workers contribute to local consumer spending

– Supports jobs in retail, services, and other sectors of the economy

Tax revenue generation:

– Income taxes from drayage workers and businesses

– Fuel taxes and vehicle registration fees

– Corporate taxes from drayage companies and related businesses

Investment stimulation:

– Encourages investment in port infrastructure and technology

– Attracts capital for the development of logistics parks and distribution centers

– Stimulates research and development in transportation technologies

The multiplier effect can significantly amplify the economic impact of port drayage. For instance, a study by Martin Associates on the economic impact of the Port of Baltimore found that every dollar of direct business revenue generated by port activities, including drayage, resulted in an additional $1.47 in re-spending and consumption throughout the state economy.

Cost implications for businesses and consumers

The efficiency of port drayage operations has direct implications for the cost of goods and overall economic competitiveness.

Supply chain costs:

– Efficient drayage reduces transportation costs for shippers

– Minimizes inventory holding costs through timely deliveries

– Reduces the risk of stockouts and production delays

Consumer prices:

– Lower transportation costs can lead to reduced prices for consumer goods

– Efficient drayage supports the availability of a wide range of imported products

Business competitiveness:

– Enables businesses to compete effectively in global markets

– Supports export-oriented industries by providing cost-effective access to ports

Economic resilience:

– Efficient drayage operations help mitigate the impact of supply chain disruptions

– Supports the ability of businesses to adapt to changing market conditions

A study by the Federal Maritime Commission highlighted that inefficiencies in port drayage operations could add significant costs to the supply chain, potentially increasing the price of imported goods by up to 2%.

Environmental economic impacts

The environmental aspects of port drayage operations have increasingly significant economic implications.

Emissions reduction efforts:

– Investments in cleaner technologies create jobs in green industries

– Reduction in healthcare costs associated with air pollution

– Potential for carbon credit trading and environmental incentives

Congestion mitigation:

– Reduced traffic congestion leads to lower fuel consumption and time savings

– Decreased wear and tear on road infrastructure, reducing maintenance costs

Sustainability initiatives:

– Creates opportunities for innovation in sustainable logistics practices

– Enhances the reputation of ports and regions, potentially attracting environmentally conscious businesses

The California Air Resources Board estimated that the implementation of clean truck programs in California ports would result in health cost savings of over $5 billion by 2025 due to reduced emissions.

Economic challenges and considerations

While port drayage provides significant economic benefits, it also faces challenges that can impact its economic contributions.

Infrastructure constraints:

– Inadequate port infrastructure can lead to inefficiencies and increased costs

– Requires significant public and private investment to maintain and improve

Labor issues:

– Driver shortages can lead to increased labor costs and service disruptions

– Labor disputes can have significant economic impacts on port operations and related industries

Technological disruption:

– Automation and new technologies may displace some traditional jobs

– Requires ongoing investment in workforce training and development

Regulatory compliance:

– Environmental and safety regulations can increase operational costs

– Compliance requirements may impact the competitiveness of smaller operators

Addressing these challenges requires careful planning and collaboration between public and private stakeholders to ensure the continued economic viability of port drayage operations.

Quantifying the economic impact

Accurately measuring the full economic impact of port drayage can be challenging due to its interconnected nature with other aspects of the supply chain. However, various studies have attempted to quantify its contributions:

| Impact Category | Example Metric | Sample Data Point |

|---|---|---|

| Direct Employment | Jobs created | 7,000+ jobs in NY/NJ port drayage |

| Economic Output | Annual revenue generated | $1 billion+ in NY/NJ port area |

| Multiplier Effect | Additional jobs created | 2.8 indirect jobs per direct job (Port of LA) |

| Cost Savings | Potential price impact on goods | Up to 2% increase due to inefficiencies |

| Environmental Benefits | Health cost savings | $5 billion+ by 2025 (California ports) |

These figures illustrate the significant and wide-ranging economic impact of port drayage operations. However, it’s important to note that the specific impact can vary greatly depending on the size and nature of the port, regional economic conditions, and other factors.

In conclusion, port drayage plays a vital role in the economic ecosystem surrounding ports and international trade. Its impact extends far beyond the immediate transportation sector, influencing employment, regional development, trade facilitation, and even environmental economics. As global trade continues to grow and evolve, the economic significance of efficient and sustainable port drayage operations is likely to increase, making it a critical area for ongoing investment, innovation, and policy attention.

How do you choose the right port drayage provider?

Selecting the right port drayage provider is crucial for ensuring efficient, reliable, and cost-effective transportation of goods between ports and inland destinations. The choice of a drayage provider can significantly impact your supply chain performance, customer satisfaction, and bottom line. Here’s a comprehensive guide on how to choose the right port drayage provider for your business needs.

Assess your specific requirements

Before beginning your search for a drayage provider, it’s essential to clearly define your needs and expectations.

Consider the following factors:

– Volume and frequency of shipments

– Types of cargo (e.g., standard containers, oversized loads, hazardous materials)

– Specific port and destination requirements

– Time-sensitivity of your shipments

– Integration needs with your existing systems and processes

Evaluate the provider’s experience and expertise

Look for a drayage provider with a proven track record in handling operations similar to your requirements.

Key considerations:

– Years of experience in port drayage operations

– Familiarity with specific ports and terminals you work with

– Expertise in handling your type of cargo

– Knowledge of relevant regulations and compliance requirements

– Industry certifications and affiliations

Tip: Request case studies or references from clients with similar needs to yours.

Assess fleet capacity and equipment availability

Ensure the provider has the necessary fleet size and equipment types to handle your shipments reliably.

Key factors to consider:

– Size and composition of the truck fleet

– Availability of specialized equipment (e.g., chassis for different container sizes)

– Age and condition of the fleet

– Maintenance practices and equipment reliability

– Ability to scale operations to meet fluctuating demand

Tip: Ask about the provider’s equipment utilization rates and their ability to handle peak season volumes.

Evaluate technology and visibility capabilities

In today’s digital age, advanced technology and real-time visibility are crucial for efficient drayage operations.

Look for providers offering:

– GPS tracking and real-time shipment visibility

– Electronic Data Interchange (EDI) capabilities

– Web-based portals for booking and shipment management

– Mobile apps for drivers and customers

– Integration capabilities with your existing systems

– Data analytics and reporting tools

Tip: Request a demo of the provider’s technology platform to assess its user-friendliness and functionality.

Consider geographical coverage and network strength

Choose a provider with strong coverage in the areas most important to your business.

Evaluate the provider’s:

– Network of terminals and depots

– Relationships with port authorities and terminal operators

– Ability to handle both local and long-distance drayage moves

— Partnerships with other carriers for extended coverage

– Presence in key markets and trade lanes relevant to your business

Tip: If you operate in multiple regions, consider providers with a national or international presence for consistency across your network.

Analyze pricing structure and cost transparency

While cost shouldn’t be the only factor, it’s important to understand the provider’s pricing model and ensure it aligns with your budget and expectations.

Key considerations:

– Transparency in pricing structure

– Breakdown of base rates, fuel surcharges, and additional fees

– Pricing stability and mechanisms for rate adjustments

– Volume discounts or long-term contract options

– Billing accuracy and invoice clarity

Tip: Request a detailed sample invoice to understand how charges are calculated and presented.

Assess operational flexibility and responsiveness

Look for a provider that can adapt to your changing needs and respond quickly to unexpected situations.

Evaluate the provider’s:

– Ability to handle rush orders or last-minute changes

– Contingency plans for equipment breakdowns or port disruptions

– Flexibility in scheduling and appointment management

– Responsiveness to customer inquiries and issue resolution

– After-hours support and communication channels

Tip: Ask about the provider’s average response time to customer requests and their process for handling exceptions.

Review safety record and compliance history

Ensure the provider maintains high standards of safety and regulatory compliance.

Key factors to consider:

– Safety ratings and accident history

– Compliance with hours-of-service regulations

– Driver training and certification programs

– Insurance coverage and liability protection

– Environmental compliance and sustainability initiatives

Tip: Check the provider’s safety record through the Federal Motor Carrier Safety Administration’s (FMCSA) Safety and Fitness Electronic Records (SAFER) System.

Evaluate customer service and support

Strong customer service is crucial for a smooth drayage operation and resolving any issues that may arise.

Look for providers offering:

– Dedicated account management

– Clear communication channels and escalation procedures

– Proactive notification of delays or issues

– Regular performance reviews and continuous improvement initiatives

– Willingness to customize services to meet your specific needs

Tip: Speak with the provider’s customer service team to gauge their responsiveness and problem-solving approach.

Consider financial stability and business continuity

Choose a provider with a strong financial foundation to ensure long-term reliability and service continuity.

Evaluate the provider’s:

– Financial health and stability

– Years in business and growth trajectory

– Investments in technology and equipment

– Business continuity and disaster recovery plans

– Long-term strategic vision and market position

Tip: Request financial references or credit reports to assess the provider’s financial stability.

Assess cultural fit and partnership potential

Beyond operational capabilities, consider how well the provider’s culture and values align with your organization.

Consider factors such as:

– Commitment to innovation and continuous improvement

– Approach to sustainability and corporate social responsibility

– Willingness to collaborate and form strategic partnerships

– Alignment with your company’s values and business ethics

– Potential for long-term growth and mutual success

Tip: Arrange site visits or meetings with key personnel to get a sense of the provider’s culture and working style.

Decision matrix for selecting a port drayage provider

To help you objectively evaluate potential providers, consider using a decision matrix that weighs various factors based on their importance to your business. Here’s an example:

| Criteria | Weight | Provider A | Provider B | Provider C |

|---|---|---|---|---|

| Experience & Expertise | 20% | |||

| Fleet Capacity | 15% | |||

| Technology & Visibility | 15% | |||

| Geographical Coverage | 10% | |||

| Pricing & Cost | 15% | |||

| Operational Flexibility | 10% | |||

| Safety & Compliance | 10% | |||

| Customer Service | 5% | |||

| Total Score | 100% |

Rate each provider on a scale (e.g., 1-5) for each criterion, multiply by the weight, and sum the scores to get a total. This approach can provide a quantitative basis for your decision while still allowing for qualitative considerations.

Steps for making the final decision:

-

Create a shortlist: Based on your initial research and the decision matrix, narrow down your options to 2-3 top contenders.

-

Conduct site visits: If possible, visit the providers’ facilities to get a firsthand look at their operations and meet key personnel.

-

Request and check references: Speak with current clients of the providers to get insights into their performance and reliability.

-

Review contracts carefully: Pay close attention to service level agreements, performance metrics, and termination clauses.

-

Negotiate terms: Don’t hesitate to negotiate on pricing, service levels, or contract terms to ensure the agreement meets your needs.

-

Plan for onboarding: Once you’ve made your decision, work closely with the chosen provider to develop a comprehensive onboarding plan.

-

Establish performance metrics: Set clear key performance indicators (KPIs) to measure the provider’s performance and ensure ongoing alignment with your needs.

Choosing the right port drayage provider is a critical decision that can significantly impact your supply chain efficiency and overall business performance. By carefully considering these factors and following a structured evaluation process, you can select a provider that not only meets your current needs but also supports your long-term business goals. Remember that the best provider for your business may not necessarily be the largest or the cheapest, but rather the one that offers the best combination of capabilities, reliability, and cultural fit for your organization.