What Is Port Operations and Cargo Handling

What are port operations and cargo handling?

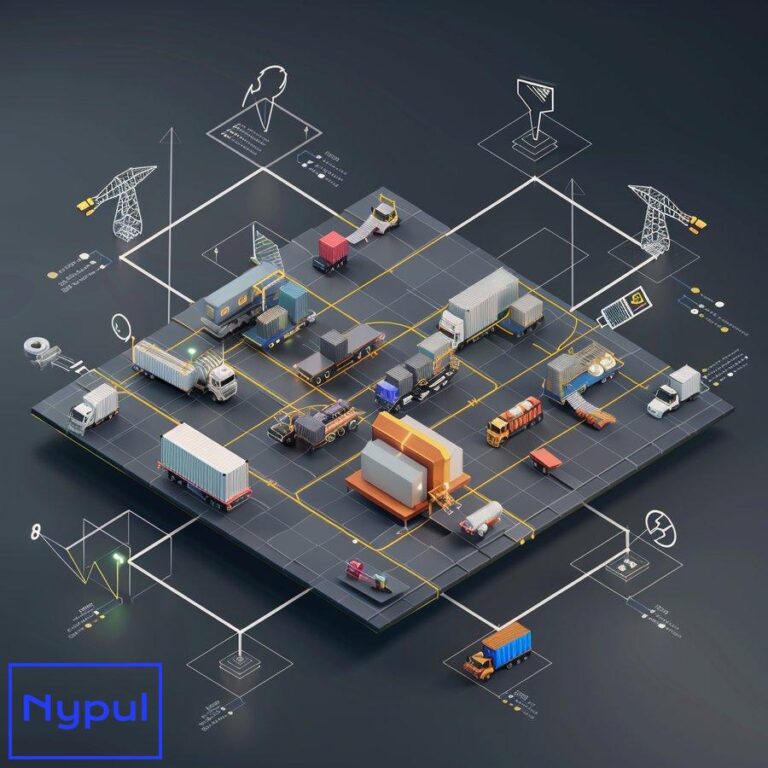

Port operations and cargo handling encompass the complex array of activities and processes involved in managing the movement of goods and vessels through seaports and inland ports. These operations form the backbone of global trade, facilitating the seamless transfer of cargo between ships, trucks, trains, and other modes of transportation.

At its core, port operations involve the coordination of various stakeholders, including port authorities, shipping lines, terminal operators, customs officials, and logistics providers. The primary goal is to ensure the efficient and safe movement of cargo while minimizing delays and maximizing the utilization of port resources.

Cargo handling, a critical component of port operations, refers to the physical movement and processing of goods within the port area. This includes loading and unloading vessels, storing cargo in warehouses or yards, and preparing shipments for onward transportation.

The scope of port operations and cargo handling extends far beyond the visible activities at the waterfront. It includes:

Vessel Traffic Management: Coordinating the arrival, berthing, and departure of ships to optimize port capacity and ensure safety.

Cargo Documentation: Processing and verifying the necessary paperwork for imports, exports, and transshipments.

Customs Clearance: Facilitating the inspection and clearance of goods by customs authorities.

Storage and Warehousing: Managing inventory and providing temporary storage solutions for various types of cargo.

Intermodal Connections: Coordinating the transfer of goods between different modes of transportation, such as ships, trucks, and trains.

Equipment Management: Maintaining and operating specialized machinery like cranes, forklifts, and container handlers.

Security and Safety: Implementing measures to protect cargo, vessels, and port personnel from theft, accidents, and other risks.

The efficiency of port operations and cargo handling directly impacts global supply chains. Delays or disruptions at ports can have far-reaching consequences, affecting manufacturers, retailers, and consumers worldwide. Therefore, continuous improvement and innovation in these areas are essential for maintaining the smooth flow of international trade.

Modern ports are increasingly adopting advanced technologies and management systems to enhance their operations. These include automated container terminals, real-time tracking systems, and artificial intelligence-powered planning tools. Such innovations aim to increase productivity, reduce costs, and improve the overall reliability of port services.

Environmental considerations have also become a significant aspect of port operations. Many ports are implementing sustainable practices to reduce their carbon footprint and minimize the impact on local ecosystems. This includes initiatives such as shore power for ships, electric cargo handling equipment, and improved waste management systems.

The complexity of port operations and cargo handling requires a highly skilled workforce. Port professionals must possess a diverse range of expertise, including logistics management, maritime law, environmental regulations, and advanced technology systems. Continuous training and development are essential to keep pace with the evolving nature of the industry.

In essence, port operations and cargo handling serve as the vital link between land and sea transportation, playing a crucial role in facilitating global trade. The efficiency and effectiveness of these operations have a direct impact on the competitiveness of nations and the overall health of the global economy.

How do ports manage vessel traffic and berth allocation?

Effective management of vessel traffic and berth allocation is fundamental to the smooth operation of any port. This process involves a delicate balance of scheduling, resource allocation, and real-time decision-making to ensure the safe and efficient movement of ships through the port.

Vessel Traffic Management Systems (VTMS)

At the heart of vessel traffic management is the Vessel Traffic Management System (VTMS). This sophisticated system integrates various technologies to monitor and control ship movements within the port and its approaches. Key components of a VTMS include:

Radar Systems: These provide real-time tracking of vessel positions and movements.

Automatic Identification System (AIS): AIS transmits and receives ship data, including vessel identity, position, course, and speed.

VHF Radio Communication: Enables direct communication between port authorities and ships.

Weather Monitoring Equipment: Provides up-to-date information on weather conditions that may affect vessel movements.

CCTV Cameras: Offer visual monitoring of key areas within the port.

The VTMS allows port authorities to maintain a comprehensive overview of all vessel traffic, enabling them to identify potential conflicts or safety hazards and take proactive measures to prevent incidents.

Vessel Scheduling and Prioritization

Efficient vessel scheduling is critical for maximizing port capacity and minimizing delays. Ports typically use advanced software systems to manage vessel arrivals and departures. These systems consider various factors, including:

Vessel Size and Draft: Larger vessels may require specific berths or tide conditions.

Cargo Type: Different types of cargo require different handling facilities.

Contractual Agreements: Some shipping lines may have priority berthing rights.

Port Congestion: Current and projected port occupancy levels.

Tidal Windows: For ports with tidal restrictions.

Ports often employ a priority system for vessel scheduling. For instance, container ships on regular liner services may receive higher priority due to their tight schedules and the economic importance of their cargo. In contrast, bulk carriers or tankers might have more flexibility in their arrival times.

Berth Allocation Strategies

Berth allocation is a complex optimization problem that ports must solve continuously. The goal is to assign incoming vessels to the most suitable berths while considering various constraints and objectives. Common berth allocation strategies include:

First-Come, First-Served (FCFS): The simplest approach, where vessels are assigned berths in the order of their arrival.

Priority-Based Allocation: Vessels are assigned berths based on predetermined priority levels.

Dynamic Allocation: Berths are assigned based on real-time port conditions and vessel characteristics.

Many modern ports use sophisticated algorithms and simulation models to optimize berth allocation. These systems can consider multiple factors simultaneously, such as:

Berth Length and Draft: Ensuring the berth can accommodate the vessel’s dimensions.

Cargo Handling Equipment: Matching the vessel with a berth that has the necessary equipment for efficient cargo operations.

Minimize Port Stay Time: Allocating berths to minimize the overall time vessels spend in port.

Maximize Berth Utilization: Ensuring efficient use of all available berth space.

Table: Factors Considered in Berth Allocation

| Factor | Description | Impact |

|---|---|---|

| Vessel Size | Length, beam, and draft of the ship | Determines suitable berths |

| Cargo Type | Container, bulk, liquid, etc. | Affects required handling equipment |

| Expected Time of Arrival | Scheduled arrival time of the vessel | Influences berth availability |

| Estimated Time of Operation | Duration of cargo handling | Affects berth occupancy planning |

| Terminal Preferences | Contractual agreements or operational preferences | May prioritize certain vessels |

| Tidal Restrictions | Depth requirements at different tide levels | Limits berthing options for larger vessels |

Collaboration and Information Sharing

Effective vessel traffic management and berth allocation require close collaboration between various stakeholders. This includes:

Port Authorities: Oversee overall port operations and safety.

Terminal Operators: Manage individual berths and cargo handling operations.

Shipping Lines: Provide vessel schedules and cargo information.

Pilots and Tugs: Assist with vessel navigation and berthing.

Customs and Immigration: Process necessary documentation for vessel and crew entry.

To facilitate this collaboration, many ports have implemented Port Community Systems (PCS). These digital platforms allow for real-time information sharing among all stakeholders, improving coordination and decision-making.

Handling Disruptions and Contingencies

Despite careful planning, ports must be prepared to handle unexpected disruptions to vessel traffic and berth allocation. Common challenges include:

Weather-Related Delays: Storms or fog can disrupt vessel arrivals and departures.

Equipment Breakdowns: Malfunctioning cranes or other cargo handling equipment can cause delays.

Labor Disputes: Strikes or work stoppages can significantly impact port operations.

Security Incidents: Heightened security measures may delay vessel processing.

Ports typically have contingency plans in place to address these situations. This may involve reallocating resources, adjusting schedules, or diverting vessels to alternative berths or ports.

Environmental Considerations

Increasingly, ports are incorporating environmental factors into their vessel traffic management and berth allocation strategies. This includes:

Emissions Reduction: Prioritizing berths with shore power capabilities for vessels equipped to use them.

Noise Mitigation: Considering the impact of nighttime operations on nearby communities.

Wildlife Protection: Adjusting vessel routes or speeds to protect marine life.

By effectively managing vessel traffic and optimizing berth allocation, ports can significantly enhance their operational efficiency, improve safety, and reduce environmental impact. As global trade continues to grow and vessels become larger and more complex, the importance of sophisticated traffic management and berth allocation systems will only increase.

What types of cargo are handled in ports and how?

Ports handle a diverse range of cargo types, each requiring specialized equipment, storage facilities, and handling procedures. The efficient management of these various cargo types is essential for the smooth operation of global supply chains. Let’s explore the main categories of cargo and the specific methods used to handle them.

Container Cargo

Containerized cargo is the most common type handled in modern ports. Standardized shipping containers have revolutionized global trade by providing a uniform, secure, and efficient means of transporting goods.

Handling Methods:

Gantry Cranes: Large, rail-mounted cranes that load and unload containers from ships.

Straddle Carriers: Mobile machines that can lift and transport containers within the terminal.

Automated Guided Vehicles (AGVs): Self-driving vehicles used in fully or semi-automated container terminals.

Reach Stackers: Versatile machines used for stacking and moving containers in smaller terminals or inland ports.

Storage: Containers are typically stored in large stacking areas called container yards. Modern terminals use sophisticated software to optimize container placement and retrieval.

Challenges: Managing the high volume of containers, ensuring accurate tracking, and optimizing storage density are key challenges in container handling.

Bulk Cargo

Bulk cargo refers to commodities that are transported unpackaged in large quantities. This category is further divided into dry bulk and liquid bulk.

Dry Bulk Cargo

Examples include coal, grain, iron ore, and cement.

Handling Methods:

Conveyor Systems: Used for continuous loading or unloading of materials like grain or coal.

Grab Cranes: Equipped with large buckets or grabs to scoop up bulk materials from ship holds.

Pneumatic Systems: Used for powdery materials like cement, using air pressure for transfer.

Storage: Dry bulk cargo is often stored in large silos or open stockpiles, depending on the material’s characteristics and environmental considerations.

Challenges: Dust control, preventing cargo contamination, and managing different grades or types of bulk materials.

Liquid Bulk Cargo

This category includes crude oil, petroleum products, chemicals, and liquefied natural gas (LNG).

Handling Methods:

Pipelines: Used to transfer liquid cargo directly between ships and storage tanks.

Pumps: Specialized pumps are used to move different types of liquid cargo.

Loading Arms: Articulated pipes that connect ships to shore-based pipelines.

Storage: Large tanks are used to store liquid bulk cargo, often with specific temperature and pressure requirements.

Challenges: Ensuring environmental protection, managing different grades of products, and maintaining strict safety protocols due to the often hazardous nature of liquid bulk cargo.

Break Bulk Cargo

Break bulk cargo consists of goods that must be loaded individually, not in containers or in bulk. Examples include machinery, vehicles, steel coils, and timber.

Handling Methods:

Multi-Purpose Cranes: Versatile cranes equipped with various attachments to handle different types of break bulk cargo.

Forklifts: Used for smaller or palletized break bulk items.

Roll-on/Roll-off (RoRo) Ramps: For wheeled cargo like vehicles or heavy machinery.

Storage: Break bulk cargo is often stored in warehouses or open yards, depending on the nature of the goods and climate conditions.

Challenges: Careful planning is required to ensure efficient use of space and proper handling of diverse cargo types.

Project Cargo

Project cargo refers to large, heavy, high-value pieces of equipment often related to major construction or engineering projects. Examples include wind turbine components, industrial boilers, and large construction equipment.

Handling Methods:

Heavy Lift Cranes: Specialized cranes capable of lifting extremely heavy or oversized cargo.

Self-Propelled Modular Transporters (SPMTs): Used for moving extremely heavy loads within the port area.

Floating Cranes: For ports that lack sufficient shore-based heavy lift capabilities.

Storage: Project cargo often requires specially prepared storage areas with reinforced surfaces to support the weight.

Challenges: Careful planning and engineering are required to safely handle and transport project cargo, often involving custom lifting solutions.

Refrigerated Cargo (Reefer)

Refrigerated cargo includes perishable goods that require temperature-controlled environments, such as fruits, vegetables, meat, and pharmaceuticals.

Handling Methods:

Specialized Container Cranes: Similar to standard container cranes but equipped to handle reefer containers.

Reefer Stations: Electrical power points in the container yard to maintain temperature control.

Monitoring Systems: Advanced systems to track and maintain required temperatures.

Storage: Reefer containers are often stacked separately with access to power supply. Some ports have cold storage warehouses for break bulk refrigerated cargo.

Challenges: Maintaining the cold chain, managing different temperature requirements, and ensuring rapid processing to preserve cargo quality.

Table: Comparison of Cargo Types and Handling Methods

| Cargo Type | Examples | Primary Handling Equipment | Storage Method | Key Challenges |

|---|---|---|---|---|

| Container | Consumer goods, manufactured products | Gantry cranes, Straddle carriers | Container yards | High volume management, tracking |

| Dry Bulk | Coal, grain, ore | Conveyor systems, Grab cranes | Silos, Open stockpiles | Dust control, contamination prevention |

| Liquid Bulk | Oil, chemicals, LNG | Pipelines, Pumps | Storage tanks | Environmental protection, safety |

| Break Bulk | Machinery, steel coils | Multi-purpose cranes, Forklifts | Warehouses, Open yards | Space utilization, diverse handling needs |

| Project Cargo | Wind turbines, industrial equipment | Heavy lift cranes, SPMTs | Reinforced storage areas | Custom handling solutions, careful planning |

| Refrigerated | Fruits, meat, pharmaceuticals | Specialized container cranes, Reefer stations | Powered stacks, Cold storage warehouses | Temperature control, rapid processing |

Specialized Cargo Handling Facilities

Many ports have developed specialized facilities to handle specific types of cargo more efficiently:

Grain Terminals: Equipped with specialized conveyor systems and storage silos for efficient handling of grain exports or imports.

Auto Terminals: Designed for the efficient processing of vehicles, with large parking areas and specialized RoRo berths.

LNG Terminals: Highly specialized facilities for the safe handling and storage of liquefied natural gas.

Cruise Terminals: While not cargo-related, many ports have dedicated facilities for handling passenger cruise ships and their associated logistics.

Safety and Environmental Considerations

Cargo handling in ports involves significant safety and environmental risks. Ports implement strict protocols and invest in equipment and training to address these concerns:

Personal Protective Equipment (PPE): Required for all personnel involved in cargo handling operations.

Hazardous Materials Handling: Specialized procedures and storage facilities for dangerous goods.

Spill Prevention and Response: Equipment and trained personnel to quickly respond to potential spills, especially for liquid bulk cargo.

Dust Suppression Systems: Used in dry bulk handling to minimize air pollution.

Noise Reduction Measures: To minimize the impact of port operations on surrounding communities.

Wildlife Protection: Measures to protect marine life and birds from the impacts of port operations and potential cargo spills.

The diverse nature of cargo handled in ports necessitates a flexible and adaptable approach to port operations. Ports must continually invest in infrastructure, equipment, and training to efficiently handle the ever-changing mix of cargo types driven by global trade patterns. As technology advances and environmental concerns grow, the methods of cargo handling in ports will continue to evolve, striving for greater efficiency, safety, and sustainability.

How do intermodal connections function in port operations?

Intermodal connections are the lifeblood of modern port operations, serving as the critical links that enable the seamless transfer of cargo between different modes of transportation. These connections integrate seaborne trade with land-based logistics networks, allowing goods to move efficiently from ships to trucks, trains, and inland waterways, and vice versa. The effectiveness of a port’s intermodal connections can significantly impact its competitiveness and overall operational efficiency.

Components of Intermodal Connections

Intermodal connections in port operations typically involve several key components:

On-Dock Rail Facilities: These allow for the direct transfer of containers between ships and trains without the need for intermediate truck transportation.

Truck Gates: Specialized entry and exit points for trucks, often equipped with automated systems for processing and security checks.

**Inland Container Depots(Continuing from where I left off)

Inland Container Depots (ICDs): Also known as dry ports, these facilities serve as satellite locations for container storage and processing, reducing congestion at the main port.

Barge Terminals: For ports with access to inland waterways, these facilities enable the transfer of cargo to and from river barges.

Intermodal Yards: Dedicated areas within the port for transferring cargo between different modes of transport.

The Intermodal Transfer Process

The process of intermodal transfer varies depending on the types of transportation involved, but generally follows these steps:

Vessel Discharge: Cargo is unloaded from the ship using specialized equipment such as gantry cranes.

Temporary Storage: Goods may be temporarily stored in the port’s container yard or warehouse facilities.

Documentation and Customs Clearance: Necessary paperwork is processed, and customs inspections are conducted if required.

Mode Transfer: Cargo is loaded onto the next mode of transport (truck, train, or barge) using appropriate handling equipment.

Dispatch: The cargo departs the port for its next destination.

Key Technologies in Intermodal Connections

Modern ports leverage various technologies to enhance the efficiency of their intermodal connections:

Terminal Operating Systems (TOS): These software platforms optimize the movement and storage of cargo within the port, including intermodal transfers.

Optical Character Recognition (OCR): Used at truck gates to automatically capture container and vehicle information.

Radio-Frequency Identification (RFID): Enables tracking of containers and other cargo units throughout the intermodal transfer process.

Global Positioning System (GPS): Allows real-time tracking of vehicles and cargo within the port and beyond.

Automated Guided Vehicles (AGVs): Self-driving vehicles used in some ports to move containers between ships, storage areas, and intermodal transfer points.

Challenges in Intermodal Connections

Ports face several challenges in managing effective intermodal connections:

Congestion: High volumes of truck traffic can lead to bottlenecks at port entrances and surrounding roads.

Coordination: Synchronizing the arrival and departure of different modes of transport to minimize dwell times and maximize efficiency.

Infrastructure Limitations: Many ports face constraints in expanding their intermodal facilities due to limited available land or aging infrastructure.

Environmental Concerns: The concentration of transport activities in port areas can lead to increased air pollution and noise.

Strategies for Improving Intermodal Connections

Ports employ various strategies to enhance their intermodal capabilities:

Expanding On-Dock Rail: Investing in rail infrastructure within the port to reduce reliance on truck transportation.

Implementing Appointment Systems: Scheduling truck arrivals to spread traffic more evenly throughout the day.

Developing Inland Ports: Creating satellite facilities away from the main port to handle some intermodal transfers and reduce congestion.

Adopting Green Technologies: Implementing electric or hybrid vehicles for internal port operations to reduce emissions.

Enhancing Information Systems: Improving data sharing between different stakeholders to optimize intermodal transfers.

Table: Comparison of Intermodal Transport Modes in Port Operations

| Mode | Advantages | Disadvantages | Typical Cargo Types |

|---|---|---|---|

| Truck | Flexible, door-to-door service | Congestion, higher emissions per unit | Containers, break bulk |

| Rail | High capacity, lower emissions | Less flexible, requires significant infrastructure | Containers, bulk cargo |

| Barge | Very high capacity, low cost for bulk goods | Limited to waterway routes, slower speed | Bulk cargo, containers |

| Pipeline | Continuous flow, low operating cost | Limited to liquid or gas cargo, high initial investment | Oil, gas, chemicals |

The Role of Hinterland Connections

A port’s efficiency is not only determined by its immediate intermodal facilities but also by the quality of its connections to the wider hinterland. This includes:

Road Networks: Well-maintained highways and dedicated freight corridors connecting the port to major industrial and population centers.

Rail Corridors: High-capacity rail lines linking the port to inland distribution hubs and major markets.

Inland Waterways: Where available, river and canal systems that can handle barge traffic for long-distance, high-volume cargo transport.

Ports often work closely with regional and national governments to ensure that these hinterland connections are developed and maintained to support efficient cargo movement.

Future Trends in Intermodal Connections

As global trade continues to evolve, several trends are shaping the future of intermodal connections in ports:

Automation: Increasing use of automated systems for container handling and intermodal transfers.

Digitalization: Greater integration of digital technologies for seamless information flow across different transport modes.

Sustainable Transport: Growing focus on reducing the environmental impact of intermodal operations through electrification and alternative fuels.

Multimodal Logistics Platforms: Development of integrated facilities that combine different transport modes with value-added services.

Blockchain Technology: Potential application for enhancing transparency and security in intermodal cargo tracking and documentation.

Effective intermodal connections are essential for modern ports to remain competitive in the global shipping industry. By optimizing these connections, ports can reduce transit times, lower costs, and improve overall supply chain efficiency. As technology advances and environmental concerns grow, the development of smart, sustainable intermodal solutions will continue to be a priority for port operators and logistics providers worldwide.

What technologies are revolutionizing modern port operations?

The maritime industry is undergoing a significant transformation, driven by technological advancements that are revolutionizing port operations. These innovations are enhancing efficiency, safety, and sustainability across various aspects of port activities. Let’s explore the key technologies that are reshaping the landscape of modern ports.

Automation and Robotics

Automation is perhaps the most visible technological revolution in port operations. It encompasses a wide range of applications, from container handling to vessel berthing.

Automated Container Terminals: These facilities use a combination of automated stacking cranes (ASCs), automated guided vehicles (AGVs), and automated rail-mounted gantry cranes (ARMGs) to move containers with minimal human intervention.

Robotic Container Handling: Advanced robotic systems can perform tasks such as twist-lock handling and container inspection, reducing the need for human workers in potentially dangerous areas.

Automated Mooring Systems: These systems use vacuum or magnetic technology to secure vessels to the berth, improving safety and reducing turnaround times.

Automated Gate Systems: Using optical character recognition (OCR) and RFID technology, these systems streamline the entry and exit of trucks, reducing congestion and improving security.

The implementation of automation technologies has led to significant improvements in operational efficiency, with some automated terminals reporting productivity increases of up to 30% compared to conventional terminals.

Artificial Intelligence and Machine Learning

AI and machine learning are being applied to various aspects of port operations, enabling smarter decision-making and predictive capabilities.

Predictive Maintenance: AI algorithms analyze data from sensors on port equipment to predict potential failures before they occur, reducing downtime and maintenance costs.

Berth Planning Optimization: Machine learning models can optimize berth allocation and vessel schedules based on multiple factors, including vessel characteristics, cargo type, and port congestion.

Cargo Flow Prediction: AI systems can analyze historical data and current trends to predict future cargo volumes, helping ports to allocate resources more effectively.

Dynamic Pricing Models: Some ports are experimenting with AI-driven pricing systems that adjust tariffs based on real-time demand and capacity.

The integration of AI and machine learning is enabling ports to move from reactive to proactive operational models, improving overall efficiency and resource utilization.

Internet of Things (IoT) and Sensors

The proliferation of IoT devices and sensors is creating a new level of visibility and control in port operations.

Container Tracking: Smart containers equipped with IoT sensors can provide real-time information on location, temperature, humidity, and shock events.

Equipment Monitoring: Sensors on cranes, vehicles, and other port equipment enable real-time monitoring of performance and condition.

Environmental Monitoring: IoT devices can measure air and water quality, noise levels, and other environmental factors, helping ports to manage their environmental impact.

Energy Management: Smart grids and IoT-enabled energy systems help ports optimize their power consumption and integrate renewable energy sources.

The data generated by these IoT devices is creating new opportunities for optimization and is forming the foundation for the concept of “smart ports.”

Blockchain Technology

Blockchain is being explored as a solution to enhance transparency, security, and efficiency in port operations and maritime logistics.

Documentation and Customs Clearance: Blockchain can streamline the processing of shipping documents and customs declarations, reducing paperwork and the potential for fraud.

Supply Chain Visibility: Blockchain-based platforms can provide end-to-end visibility of cargo movements, enhancing trust among stakeholders.

Port Community Systems: Some ports are developing blockchain-based community systems to facilitate secure information sharing among various port stakeholders.

Smart Contracts: Automated, blockchain-based contracts can streamline transactions and agreements between shipping lines, port operators, and other parties.

While still in the early stages of adoption, blockchain technology has the potential to significantly reduce administrative costs and improve the speed and reliability of port operations.

5G and Advanced Connectivity

The rollout of 5G networks is enabling new levels of connectivity and data transfer speeds in port environments.

Real-time Video Analytics: High-bandwidth 5G networks allow for the deployment of advanced video analytics systems for security and operational monitoring.

Remote Equipment Operation: 5G’s low latency enables the remote operation of port equipment, potentially from locations far from the port itself.

Enhanced AR and VR Applications: 5G supports the use of augmented and virtual reality for training, maintenance, and operational support.

Autonomous Vehicle Communication: The high-speed, low-latency characteristics of 5G are crucial for the safe operation of autonomous vehicles in port environments.

The implementation of 5G technology is laying the groundwork for more advanced and interconnected port operations in the future.

Digital Twins

Digital twin technology is creating virtual replicas of port facilities and operations, enabling advanced simulation and optimization.

Operational Simulation: Digital twins allow port operators to simulate different operational scenarios and test process improvements without disrupting actual operations.

Infrastructure Planning: Virtual models of port infrastructure can be used to plan expansions or modifications, optimizing designs before physical construction begins.

Training and Safety: Digital twins provide realistic environments for training port personnel and conducting safety drills.

Real-time Optimization: By continuously updating the digital model with real-time data, ports can optimize operations on the fly.

The use of digital twins is enabling ports to make more informed decisions and improve their long-term planning capabilities.

Table: Comparison of Key Port Technologies

| Technology | Primary Benefits | Implementation Challenges | Adoption Stage |

|---|---|---|---|

| Automation and Robotics | Increased efficiency, reduced labor costs | High initial investment, workforce transition | Widely adopted in large ports |

| AI and Machine Learning | Improved decision-making, predictive capabilities | Data quality and integration, skill requirements | Growing adoption |

| IoT and Sensors | Enhanced visibility, real-time monitoring | Data management, cybersecurity concerns | Rapidly expanding |

| Blockchain | Increased transparency, reduced paperwork | Standardization, industry-wide adoption | Early stages, pilot projects |

| 5G Connectivity | Faster data transfer, support for advanced applications | Infrastructure costs, spectrum allocation | Early implementation |

| Digital Twins | Improved planning and simulation capabilities | Complex integration, data accuracy | Growing adoption in larger ports |

Challenges and Considerations

While these technologies offer significant benefits, their implementation also presents challenges:

High Initial Costs: Many of these technologies require substantial upfront investment, which can be a barrier for smaller ports.

Cybersecurity Risks: The increased connectivity and reliance on digital systems also increase vulnerability to cyber attacks.

Workforce Transition: The shift towards automation and AI requires retraining of existing workers and may lead to job displacements in some areas.

Standardization: The lack of industry-wide standards for some technologies can hinder interoperability and widespread adoption.

Regulatory Compliance: New technologies must comply with existing maritime regulations, which may not always keep pace with technological advancements.

Future Outlook

The future of port operations is likely to see further integration of these technologies, leading to the concept of “Port 4.0” – fully digitalized and interconnected port ecosystems. We can expect to see:

Increased Autonomy: More autonomous vessels and fully automated terminals becoming commonplace.

Data-Driven Operations: Greater reliance on big data analytics for all aspects of port management and planning.

Sustainable Technologies: Integration of renewable energy sources and zero-emission equipment to meet environmental goals.

Seamless Intermodal Connections: Enhanced integration between port operations and hinterland logistics through digital platforms.

Adaptive Infrastructure: Flexible and modular port designs that can quickly adapt to changing trade patterns and vessel sizes.

The technologies revolutionizing modern port operations are not just enhancing efficiency and productivity; they are fundamentally changing the way ports function within the global supply chain. As these innovations continue to evolve and integrate, they will play a crucial role in shaping the future of maritime trade and logistics.

How do ports optimize their operations and measure performance?

Ports play a critical role in global trade, serving as vital nodes in international supply chains. To remain competitive and efficient, ports must continuously optimize their operations and measure their performance. This process involves a combination of strategic planning, operational improvements, and performance monitoring. Let’s explore the key aspects of how ports optimize their operations and measure their performance.

Strategic Planning and Goal Setting

The foundation of port optimization lies in strategic planning and clear goal setting. This involves:

Long-term Vision: Developing a comprehensive long-term strategy that aligns with regional and global trade trends.

Stakeholder Engagement: Collaborating with shipping lines, terminal operators, logistics providers, and local communities to understand their needs and expectations.

Infrastructure Planning: Assessing current capabilities and planning future infrastructure investments to meet projected demand.

Environmental and Sustainability Goals: Setting targets for reducing environmental impact and improving sustainability.

Operational Optimization

Once strategic goals are established, ports focus on optimizing their day-to-day operations:

Process Reengineering: Analyzing and redesigning operational processes to eliminate inefficiencies and bottlenecks.

Resource Allocation: Optimizing the use of equipment, labor, and space to maximize productivity.

Scheduling and Berth Management: Implementing advanced scheduling systems to optimize vessel arrivals, berth allocation, and cargo handling.

Intermodal Connectivity: Enhancing connections between maritime and land-based transportation to improve cargo flow.

Technology Integration: Leveraging technologies such as automation, AI, and IoT to improve operational efficiency.

Performance Measurement

To assess the effectiveness of their optimization efforts and identify areas for improvement, ports employ various performance measurement techniques:

Key Performance Indicators (KPIs)

Ports use a range of KPIs to measure different aspects of their performance. Some common KPIs include:

Operational Efficiency:

– Container moves per hour

– Vessel turnaround time

– Berth occupancy rate

– Yard utilization

Financial Performance:

– Revenue per TEU (Twenty-foot Equivalent Unit)

– Operating margin

– Return on invested capital

Customer Service:

– Truck turnaround time

– Cargo dwell time

– Customer satisfaction scores

Safety and Security:

– Accident frequency rate

– Security incident rate

Environmental Performance:

– Carbon emissions per TEU

– Energy consumption per TEU

– Waste recycling rate

Table: Example Port Performance KPIs and Their Significance

| KPI Category | Example KPI | Significance |

|---|---|---|

| Operational Efficiency | Container moves per hour | Measures productivity of container handling operations |

| Financial Performance | Revenue per TEU | Indicates the port’s ability to generate income from its core business |

| Customer Service | Truck turnaround time | Reflects efficiency of landside operations and impact on hinterland logistics |

| Safety and Security | Accident frequency rate | Indicates the effectiveness of safety measures and protocols |

| Environmental Performance | Carbon emissions per TEU | Measures the port’s progress towards sustainability goals |

Benchmarking

Ports often engage in benchmarking exercises to compare their performance against industry standards and competitors. This can involve:

Internal Benchmarking: Comparing performance across different terminals or time periods within the same port.

External Benchmarking: Comparing performance with other ports of similar size or in the same region.

Best Practice Benchmarking: Identifying and adopting best practices from top-performing ports globally.

Data Analytics and Business Intelligence

Modern ports leverage advanced data analytics and business intelligence tools to gain deeper insights into their performance:

Real-time Dashboards: Providing up-to-the-minute visibility of key operational metrics.

Predictive Analytics: Using historical data and machine learning algorithms to forecast future performance and identify potential issues.

Scenario Analysis: Running simulations to understand the potential impact of different operational strategies or external factors.

Performance Improvement Initiatives

Based on the insights gained from performance measurement, ports implement various improvement initiatives:

Continuous Improvement Programs: Implementing methodologies like Lean or Six Sigma to drive ongoing operational enhancements.

Technology Upgrades: Investing in new technologies to address(Continuing from where I left off)

Technology Upgrades: Investing in new technologies to address identified performance gaps or inefficiencies.

Training and Skill Development: Enhancing workforce capabilities to improve overall port performance.

Process Automation: Implementing automated systems to reduce manual errors and increase efficiency.

Infrastructure Improvements: Upgrading physical infrastructure based on performance data and future projections.

Stakeholder Collaboration

Optimizing port operations often requires collaboration with various stakeholders:

Shipping Lines: Working closely with carriers to align port operations with vessel schedules and service requirements.

Terminal Operators: Collaborating on performance targets and improvement initiatives.

Customs and Regulatory Agencies: Streamlining processes to reduce cargo dwell times and improve clearance procedures.

Hinterland Connections: Coordinating with rail, road, and inland waterway operators to enhance intermodal efficiency.

Performance-Based Contracts

Some ports are adopting performance-based contracts with terminal operators and service providers. These contracts include:

Defined Performance Metrics: Clearly outlined KPIs that operators must meet.

Incentive Structures: Financial rewards for exceeding performance targets.

Penalty Clauses: Consequences for failing to meet agreed-upon performance levels.

Environmental and Sustainability Performance

As environmental concerns become increasingly important, ports are placing greater emphasis on measuring and improving their sustainability performance:

Carbon Footprint Measurement: Tracking and reporting greenhouse gas emissions from port operations.

Energy Efficiency Initiatives: Implementing programs to reduce energy consumption and increase the use of renewable energy sources.

Water and Air Quality Monitoring: Regular testing and reporting of environmental quality indicators.

Waste Management Performance: Measuring recycling rates and implementing circular economy principles in port operations.

Challenges in Port Performance Optimization

Ports face several challenges in their efforts to optimize operations and measure performance:

Data Quality and Integration: Ensuring accurate, timely, and integrated data across various port systems and stakeholders.

Balancing Competing Priorities: Managing trade-offs between operational efficiency, financial performance, and environmental sustainability.

Adapting to Changing Trade Patterns: Remaining flexible and responsive to shifts in global trade flows and vessel sizes.

Cybersecurity Risks: Protecting increasingly digitalized port operations from cyber threats.

Regulatory Compliance: Keeping pace with evolving regulations while maintaining operational efficiency.

Future Trends in Port Performance Optimization

Looking ahead, several trends are likely to shape the future of port performance optimization:

Artificial Intelligence and Machine Learning: Advanced AI systems will enable more sophisticated predictive analytics and autonomous decision-making in port operations.

Internet of Things (IoT) and 5G: Increased connectivity and real-time data collection will provide even more granular insights into port performance.

Blockchain Technology: Improved transparency and traceability in supply chains will enhance overall port efficiency and security.

Autonomous Vessels and Equipment: The rise of autonomous ships and port equipment will require new performance metrics and optimization strategies.

Green Port Initiatives: Growing emphasis on environmental performance will drive innovation in sustainable port operations.

In conclusion, optimizing port operations and measuring performance is a complex, ongoing process that requires a holistic approach. By leveraging advanced technologies, fostering collaboration among stakeholders, and maintaining a focus on continuous improvement, ports can enhance their efficiency, competitiveness, and sustainability in the ever-evolving global maritime landscape. As ports continue to adapt to new challenges and opportunities, their ability to effectively optimize operations and measure performance will be crucial in determining their success in the years to come.

What are the main challenges in port operations and cargo handling?

Port operations and cargo handling face a myriad of challenges in today’s rapidly evolving global trade environment. These challenges span operational, technological, environmental, and regulatory domains, requiring ports to be agile, innovative, and forward-thinking in their approach. Let’s explore the main challenges that ports encounter in their day-to-day operations and long-term planning.

Capacity Constraints and Infrastructure Limitations

One of the most pressing challenges for many ports is managing growing cargo volumes within existing infrastructure limitations.

Berth Capacity: As vessels grow larger, ports struggle to provide sufficient berth space and water depth to accommodate them.

Yard Space: Limited land availability in many port areas constrains the expansion of container yards and storage facilities.

Hinterland Connections: Inadequate road and rail infrastructure can create bottlenecks in cargo movement to and from the port.

Equipment Capacity: Keeping pace with the need for larger, more efficient cargo handling equipment requires significant investment.

Ports are addressing these challenges through:

Smart Planning: Utilizing advanced simulation and modeling tools to optimize existing space.

Vertical Development: Implementing high-density storage solutions and multi-level facilities.

Public-Private Partnerships: Collaborating with governments and private entities to fund infrastructure improvements.

Operational Efficiency and Productivity

Maintaining high levels of operational efficiency in the face of increasing complexity is a constant challenge for ports.

Vessel Size and Cargo Volume Fluctuations: The trend towards larger vessels leads to peaks in cargo handling demand.

Labor Management: Balancing workforce needs with automation and technological advancements.

Equipment Utilization: Ensuring optimal use of expensive handling equipment across varying operational conditions.

Intermodal Coordination: Synchronizing operations between maritime and land-based transportation modes.

Strategies to address these challenges include:

Process Reengineering: Continuously analyzing and optimizing operational workflows.

Workforce Training: Investing in skill development to enhance productivity and adaptability.

Advanced Scheduling Systems: Implementing AI-driven systems for better resource allocation and planning.

Technological Integration and Cybersecurity

While technology offers solutions to many challenges, its integration and security pose their own set of issues.

System Integration: Ensuring interoperability between various technological systems and platforms.

Data Management: Handling the vast amounts of data generated by port operations effectively.

Cybersecurity Threats: Protecting critical port infrastructure and information systems from cyber attacks.

Technology Adoption Costs: Managing the high costs associated with implementing and maintaining advanced technologies.

Ports are tackling these challenges through:

Comprehensive Digital Strategies: Developing holistic approaches to technology integration and data management.

Cybersecurity Investments: Implementing robust security measures and conducting regular vulnerability assessments.

Collaborative Platforms: Developing port community systems to enhance data sharing and integration.

Environmental Sustainability and Regulatory Compliance

Ports face increasing pressure to reduce their environmental impact while complying with stringent regulations.

Emissions Reduction: Meeting targets for reducing greenhouse gas emissions from port operations and visiting vessels.

Water and Soil Pollution: Managing the environmental impact of cargo handling and ship-related activities.

Noise and Light Pollution: Minimizing disturbances to surrounding communities.

Regulatory Compliance: Adhering to evolving international and local environmental regulations.

Approaches to address these challenges include:

Green Port Initiatives: Implementing comprehensive sustainability programs.

Alternative Energy Sources: Investing in renewable energy and shore power facilities for vessels.

Environmental Monitoring Systems: Deploying advanced sensors and analytics for real-time environmental impact assessment.

Stakeholder Collaboration: Working with shipping lines, trucking companies, and local communities to develop holistic environmental solutions.

Global Trade Dynamics and Market Volatility

Ports must navigate the uncertainties of global trade patterns and economic fluctuations.

Trade War Impacts: Adapting to shifts in trade routes and volumes due to geopolitical tensions.

Economic Cycles: Managing operations through periods of economic growth and recession.

Changing Trade Patterns: Responding to evolving global supply chains and emerging trade corridors.

Competition from Neighboring Ports: Maintaining competitiveness in a crowded market.

Strategies to address these challenges include:

Diversification: Expanding service offerings and targeting diverse cargo types.

Scenario Planning: Developing flexible strategies to respond to various potential future scenarios.

Strategic Partnerships: Forming alliances with shipping lines and inland logistics providers to secure cargo volumes.

Safety and Security Concerns

Ensuring the safety of personnel and the security of cargo remains a paramount concern for ports.

Accident Prevention: Minimizing workplace accidents in a high-risk operational environment.

Cargo Security: Preventing theft, smuggling, and tampering of goods.

Terrorism Threats: Protecting port facilities from potential terrorist activities.

Health and Pandemic Risks: Adapting operations to manage health crises, as highlighted by the COVID-19 pandemic.

Ports are addressing these challenges through:

Advanced Security Systems: Implementing state-of-the-art surveillance and access control technologies.

Safety Training Programs: Conducting regular safety drills and education for port personnel.

International Security Standards: Adhering to protocols like the International Ship and Port Facility Security (ISPS) Code.

Health and Sanitation Measures: Developing robust protocols for managing health risks and pandemics.

Table: Key Challenges in Port Operations and Cargo Handling

| Challenge Category | Specific Challenges | Potential Solutions |

|---|---|---|

| Capacity Constraints | Limited berth space, yard congestion | Smart planning, vertical development |

| Operational Efficiency | Vessel size fluctuations, labor management | Process reengineering, advanced scheduling |

| Technological Integration | System interoperability, cybersecurity | Comprehensive digital strategies, security investments |

| Environmental Sustainability | Emissions reduction, pollution management | Green port initiatives, alternative energy sources |

| Global Trade Dynamics | Trade war impacts, economic cycles | Diversification, scenario planning |

| Safety and Security | Accident prevention, terrorism threats | Advanced security systems, safety training programs |

Future Outlook and Emerging Challenges

As the maritime industry continues to evolve, ports must also prepare for emerging challenges:

Autonomous Vessels: Adapting port infrastructure and operations to accommodate self-navigating ships.

Climate Change Impacts: Preparing for rising sea levels, increased storm intensity, and other climate-related risks.

Digitalization of Trade: Evolving to handle the increasing digitalization of trade documentation and processes.

Energy Transition: Adapting to the shift towards alternative fuels and propulsion technologies in shipping.

Workforce Evolution: Managing the transition towards a more technology-driven workforce while addressing potential job displacement.

Addressing these future challenges will require:

Long-term Strategic Planning: Developing flexible, forward-looking strategies that anticipate future trends.

Innovation and Research: Investing in R&D to develop novel solutions for emerging challenges.

Collaborative Approaches: Working closely with industry partners, academia, and government bodies to address complex, systemic issues.

Adaptive Infrastructure: Designing port facilities that can be easily modified to meet changing needs.

In conclusion, the challenges facing port operations and cargo handling are multifaceted and ever-evolving. Success in this dynamic environment requires a combination of strategic foresight, technological innovation, operational excellence, and collaborative problem-solving. By proactively addressing these challenges, ports can not only enhance their efficiency and competitiveness but also play a crucial role in shaping the future of global trade and maritime logistics. As ports continue to adapt and innovate, they will remain essential hubs in the global supply chain, driving economic growth and facilitating international commerce in an increasingly interconnected world.