What Is Reefer Drayage

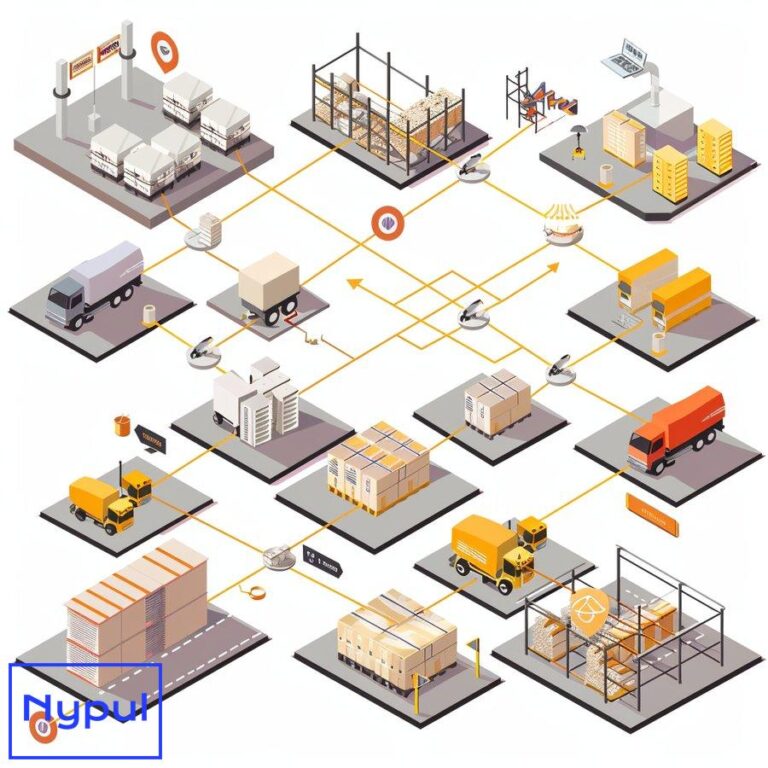

Reefer drayage is a specialized logistics service that involves the short-distance transportation of temperature-controlled containers, known as reefers, between ports, rail yards, and nearby warehouses or distribution centers. This crucial component of the cold chain ensures that perishable goods maintain their required temperature throughout the journey.

Reefer drayage combines two essential elements of logistics:

Reefer containers: These are refrigerated shipping containers equipped with temperature control systems. They maintain a consistent internal temperature, which can be adjusted based on the cargo’s requirements.

Drayage: This refers to the short-distance transportation of goods, typically within a local area or metropolitan region.

The primary purpose of reefer drayage is to bridge the gap between long-distance transportation methods (such as ocean shipping or rail) and the final destination of temperature-sensitive goods. It plays a vital role in preserving the quality and safety of perishable products during the critical first and last miles of their journey.

Key characteristics of reefer drayage include:

Temperature control: Reefer containers maintain precise temperatures, ranging from -65°C to 40°C (-85°F to 104°F), depending on the cargo requirements.

Short distances: Typically, reefer drayage covers distances of 100 miles or less from ports or rail terminals.

Time-sensitive: Due to the perishable nature of the cargo, reefer drayage operations often operate under tight schedules to minimize the risk of spoilage.

Specialized equipment: Reefer drayage requires specialized trucks equipped to power and monitor the temperature control systems of reefer containers.

Regulatory compliance: Operators must adhere to strict food safety regulations and temperature monitoring requirements.

The importance of reefer drayage in the supply chain cannot be overstated. It ensures that temperature-sensitive goods, such as fresh produce, pharmaceuticals, and frozen foods, reach their destinations in optimal condition. This service is essential for maintaining product quality, reducing waste, and meeting consumer demands for fresh and safe products.

| Aspect | Reefer Drayage | Standard Drayage |

|---|---|---|

| Cargo Type | Temperature-sensitive goods | General cargo |

| Equipment | Refrigerated containers | Standard containers |

| Temperature Control | Required | Not required |

| Energy Requirements | Higher (for refrigeration) | Lower |

| Regulatory Compliance | Stricter (food safety, pharma) | Standard regulations |

| Cost | Generally higher | Lower |

| Time Sensitivity | Often more critical | Varies |

As global trade in perishable goods continues to grow, the demand for efficient and reliable reefer drayage services is increasing. This specialized sector of logistics requires expertise in temperature-controlled transportation, advanced technology for monitoring and tracking, and a deep understanding of the unique challenges posed by different types of perishable cargo.

How does reefer drayage differ from standard drayage?

While reefer drayage and standard drayage share the common goal of transporting goods over short distances, they differ significantly in several key aspects. Understanding these differences is crucial for shippers, logistics providers, and anyone involved in the transportation of temperature-sensitive goods.

Temperature Control

Reefer drayage: The primary distinguishing feature of reefer drayage is its ability to maintain a specific temperature range throughout the transportation process. Reefer containers are equipped with sophisticated cooling systems that can be adjusted to meet the exact temperature requirements of the cargo, whether it’s frozen goods, chilled products, or items that need to be kept at room temperature.

Standard drayage: In contrast, standard drayage uses non-refrigerated containers that do not offer temperature control. The internal temperature of these containers fluctuates with the ambient temperature, making them unsuitable for transporting perishable or temperature-sensitive goods.

Equipment Complexity

Reefer drayage: The equipment used in reefer drayage is more complex and specialized. Reefer containers require:

– Refrigeration units

– Temperature monitoring systems

– Power sources (either built-in generators or external power connections)

– Insulated walls to maintain temperature

Standard drayage: Standard containers are simpler in design, consisting of a basic metal or composite structure without any built-in climate control systems.

Energy Requirements

Reefer drayage: Due to the need for constant temperature control, reefer drayage has higher energy requirements. Reefer containers must be connected to a power source at all times, either through the truck’s power system or external power supplies at ports and warehouses.

Standard drayage: Standard containers do not require any power source, resulting in lower energy consumption and operational costs.

Cargo Types

Reefer drayage: This service is specifically designed for temperature-sensitive goods such as:

– Fresh produce (fruits, vegetables)

– Dairy products

– Frozen foods

– Pharmaceuticals and vaccines

– Chemicals requiring temperature control

– Certain electronics and precision instruments

Standard drayage: This service handles a wide range of non-perishable goods, including:

– Manufactured goods

– Textiles

– Building materials

– Non-perishable food items

– General merchandise

Regulatory Compliance

Reefer drayage: Operators must adhere to stricter regulations, particularly when transporting food or pharmaceutical products. This includes:

– Compliance with food safety standards (e.g., FSMA in the United States)

– Adherence to Good Distribution Practice (GDP) for pharmaceuticals

– Maintaining detailed temperature logs

– Regular equipment inspections and certifications

Standard drayage: While still subject to general transportation regulations, standard drayage typically faces fewer industry-specific compliance requirements.

Cost Considerations

Reefer drayage: Generally more expensive due to:

– Higher equipment costs

– Increased energy consumption

– Specialized handling requirements

– More frequent maintenance needs

– Higher insurance premiums due to the value and sensitivity of cargo

Standard drayage: Typically less expensive, with costs primarily driven by distance, fuel, and labor.

Time Sensitivity

Reefer drayage: Often more time-critical due to the perishable nature of the cargo. Delays can lead to product spoilage or degradation, resulting in significant financial losses.

Standard drayage: While timely delivery is always important, standard drayage generally has more flexibility in scheduling and transit times.

Handling and Loading

Reefer drayage: Requires specialized handling procedures to maintain the cold chain:

– Pre-cooling of containers before loading

– Rapid loading and unloading to minimize temperature fluctuations

– Careful arrangement of goods to ensure proper air circulation

Standard drayage: Loading and unloading procedures are generally simpler and faster, with fewer specific requirements.

Monitoring and Tracking

Reefer drayage: Requires continuous monitoring of temperature and humidity levels throughout the journey. Advanced tracking systems are often employed to provide real-time data on container conditions.

Standard drayage: While tracking is important for all shipments, standard drayage typically focuses on location tracking rather than environmental conditions.

| Aspect | Reefer Drayage | Standard Drayage |

|---|---|---|

| Temperature Control | Required (adjustable range) | Not available |

| Equipment | Refrigerated containers with cooling systems | Basic containers |

| Energy Needs | High (constant power required) | Low (no power needed) |

| Typical Cargo | Perishables, pharmaceuticals | Non-perishable goods |

| Regulatory Compliance | Strict (food safety, pharma regulations) | General transportation rules |

| Cost | Higher | Lower |

| Time Sensitivity | Often critical | Variable |

| Handling Procedures | Specialized (maintain cold chain) | Standard |

| Monitoring | Continuous (temp, humidity) | Basic location tracking |

Understanding these differences is crucial for businesses involved in shipping temperature-sensitive goods. The choice between reefer drayage and standard drayage directly impacts the quality, safety, and viability of the transported products, making it a critical decision in supply chain management.

What types of goods are transported through reefer drayage?

Reefer drayage is essential for transporting a wide variety of temperature-sensitive goods that require specific environmental conditions to maintain their quality, safety, and efficacy. The ability to control temperature and humidity during short-distance transportation makes reefer drayage crucial for numerous industries. Here’s a comprehensive look at the types of goods commonly transported through reefer drayage:

Fresh Produce

Fruits: Berries, citrus fruits, tropical fruits, apples, pears

Vegetables: Leafy greens, tomatoes, cucumbers, peppers, broccoli

Mushrooms and other delicate produce

Fresh produce requires precise temperature control to prevent ripening, spoilage, and maintain freshness. Different fruits and vegetables often need varying temperature ranges, making reefer drayage essential for preserving their quality from harvest to store shelves.

Dairy Products

Milk and cream

Cheese (both fresh and aged varieties)

Yogurt and cultured dairy products

Butter and margarine

Ice cream and frozen dairy desserts

Dairy products are highly perishable and susceptible to bacterial growth. Reefer drayage ensures these products remain at safe temperatures, typically between 0°C and 4°C (32°F to 39°F), to maintain their quality and prevent spoilage.

Meat and Poultry

Fresh meat (beef, pork, lamb)

Poultry (chicken, turkey, duck)

Fish and seafood

Processed meats (sausages, deli meats)

These products require strict temperature control to prevent bacterial growth and maintain freshness. Reefer drayage typically maintains temperatures between -1°C and 4°C (30°F to 39°F) for fresh meats and much lower for frozen products.

Frozen Foods

Frozen vegetables and fruits

Frozen prepared meals

Frozen meat and seafood

Ice cream and frozen desserts

Frozen foods must be kept at consistently low temperatures, usually below -18°C (0°F), to maintain their quality and prevent thawing. Reefer drayage is crucial for maintaining the cold chain for these products.

Pharmaceuticals and Medical Supplies

Vaccines

Insulin and other temperature-sensitive medications

Blood and plasma products

Biological samples

Certain medical devices

The pharmaceutical industry relies heavily on reefer drayage to transport products that require precise temperature control. Vaccines, for instance, often need to be kept within a narrow temperature range to maintain their efficacy.

Chemicals and Industrial Products

Certain chemicals and solvents

Temperature-sensitive industrial materials

Adhesives and resins

Photographic materials

Many industrial products and chemicals require specific temperature conditions to maintain their properties and prevent degradation or unwanted reactions.

Flowers and Plants

Cut flowers

Live plants and seedlings

Floral arrangements

The floral industry depends on reefer drayage to keep flowers and plants fresh during transportation. Temperature control prevents wilting and extends the shelf life of these delicate products.

Beverages

Wine and craft beers

Certain fruit juices and concentrates

Specialty coffee and tea products

While not all beverages require refrigeration, some premium or artisanal products benefit from temperature-controlled transportation to maintain their quality and flavor profiles.

Confectionery Products

Chocolates

Certain candies and gums

Specialty baked goods

These products often require temperature control to prevent melting, texture changes, or spoilage, especially in warmer climates.

Cosmetics and Personal Care Products

Certain makeup products

Natural and organic skincare items

Temperature-sensitive beauty products

Some cosmetic formulations can be affected by temperature extremes, making reefer drayage necessary to maintain product integrity.

Electronics and Precision Instruments

Certain electronic components

Precision scientific instruments

Photographic equipment

While not perishable in the traditional sense, some high-value electronics and instruments benefit from temperature-controlled transportation to prevent damage from extreme temperatures or humidity.

| Category | Examples | Typical Temperature Range |

|---|---|---|

| Fresh Produce | Berries, leafy greens | 0°C to 4°C (32°F to 39°F) |

| Dairy Products | Milk, cheese, yogurt | 0°C to 4°C (32°F to 39°F) |

| Meat and Poultry | Fresh beef, chicken | -1°C to 4°C (30°F to 39°F) |

| Frozen Foods | Frozen meals, ice cream | Below -18°C (0°F) |

| Pharmaceuticals | Vaccines, insulin | 2°C to 8°C (36°F to 46°F) |

| Flowers | Cut flowers, live plants | 2°C to 7°C (36°F to 45°F) |

| Wine | Premium wines | 10°C to 15°C (50°F to 59°F) |

| Chocolates | Fine chocolates | 15°C to 18°C (59°F to 64°F) |

The diverse range of goods transported through reefer drayage underscores its importance in modern supply chains. From ensuring food safety to maintaining the efficacy of life-saving medications, reefer drayage plays a crucial role in preserving the quality and integrity of temperature-sensitive products during the critical last mile of their journey.

How does the reefer drayage process work?

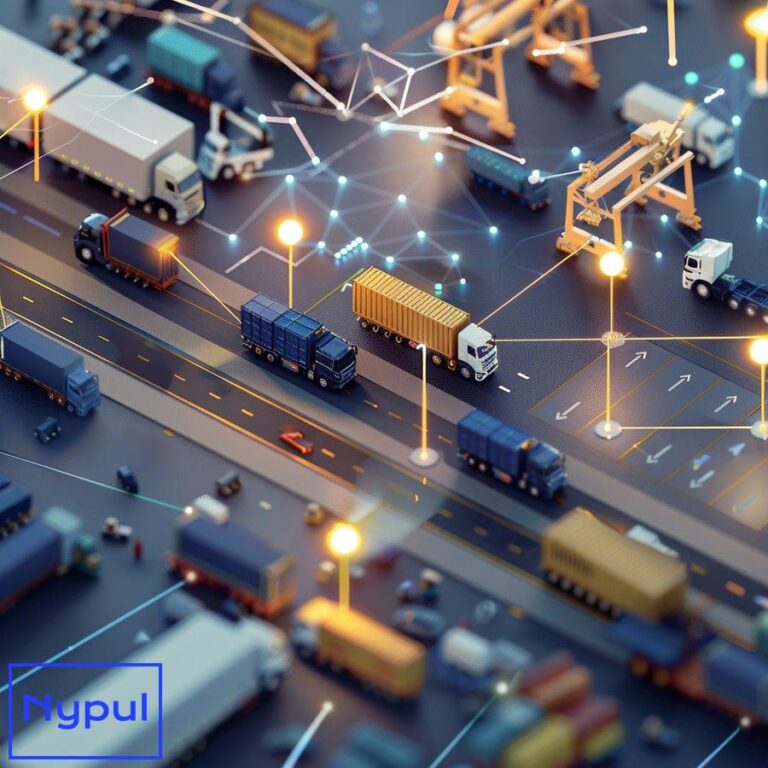

The reefer drayage process is a complex operation that requires careful coordination, specialized equipment, and strict adherence to temperature control protocols. Understanding this process is crucial for shippers, logistics providers, and recipients of temperature-sensitive goods. Here’s a detailed look at how the reefer drayage process typically works:

Pre-Trip Preparation

Equipment Inspection: Before any reefer drayage operation begins, the refrigerated container and the truck are thoroughly inspected. This includes checking the refrigeration unit, ensuring proper insulation, and verifying that all monitoring systems are functioning correctly.

Pre-Cooling: The reefer container is pre-cooled to the required temperature for the specific cargo. This step is crucial to ensure that the container is at the optimal temperature before loading begins.

Documentation: All necessary paperwork, including temperature requirements, cargo details, and any special handling instructions, is prepared and reviewed.

Loading at Origin

Temperature Verification: The internal temperature of the reefer container is verified to match the cargo requirements before loading begins.

Rapid Loading: Goods are quickly loaded into the pre-cooled container to minimize temperature fluctuations. This often involves using temperature-controlled loading docks.

Proper Stacking: Cargo is arranged to allow for proper air circulation within the container. This ensures even cooling throughout the shipment.

Temperature Probe Placement: For highly sensitive cargo, temperature probes may be placed at various points within the load to monitor internal temperatures during transit.

Sealing: Once loading is complete, the container is sealed to maintain temperature integrity and for security purposes.

Transportation

Power Supply: The reefer container is connected to the truck’s power supply to maintain constant temperature control during transit.

Continuous Monitoring: Throughout the journey, the temperature inside the container is continuously monitored. Many modern reefer units are equipped with GPS and telematics systems that provide real-time data on location and temperature.

Route Planning: Drivers follow pre-planned routes optimized for reefer transportation, considering factors like traffic, weather conditions, and potential refueling stops.

Genset Operation: For longer journeys or during stops, a generator set (genset) may be used to power the refrigeration unit when the truck’s engine is off.

Intermediate Handling

Port or Rail Yard Transfer: If the reefer container needs to be transferred between different modes of transport (e.g., from ship to truck), special care is taken to minimize the time the container is unpowered.

Cold Storage Facilities: In cases where immediate delivery is not possible, reefer containers may be stored in specialized cold storage facilities that provide the necessary power and temperature control.

Delivery and Unloading

Pre-Delivery Checks: Before arriving at the final destination, the driver verifies that the cargo temperature has remained within the specified range throughout the journey.

Rapid Unloading: Similar to the loading process, unloading is conducted quickly and efficiently to maintain the cold chain.

Temperature Verification: The recipient often checks the cargo temperature upon arrival to ensure it meets the required specifications.

Documentation Handover: All relevant documentation, including temperature logs, is handed over to the recipient.

Post-Trip Procedures

Equipment Cleaning: After unloading, the reefer container is thoroughly cleaned and sanitized to prepare it for the next shipment.

Maintenance Checks: Any issues noted during the trip are addressed, and routine maintenance is performed on the refrigeration unit and container.

Data Analysis: Temperature logs and other data collected during the trip are analyzed to ensure compliance and identify any areas for improvement in the process.

Key Considerations Throughout the Process

Temperature Consistency: Maintaining a consistent temperature is paramount. Even small fluctuations can impact the quality and safety of sensitive cargo.

Time Management: Reefer drayage often operates under tight time constraints to minimize the risk of product degradation.

Regulatory Compliance:Regulatory Compliance: Throughout the reefer drayage process, strict adherence to regulations is essential. Operators must ensure compliance with food safety standards, pharmaceutical guidelines, and other industry-specific regulations. This includes maintaining accurate temperature logs and ensuring that all equipment is certified and in good working order.

Technology Integration: The use of technology, such as GPS tracking and temperature monitoring systems, enhances visibility and accountability throughout the reefer drayage process. Real-time data allows for proactive management of any potential issues that may arise during transit.

| Step | Description | Key Considerations |

|---|---|---|

| Pre-Trip Preparation | Inspect equipment, pre-cool containers, prepare documentation | Ensure refrigeration units are functioning properly |

| Loading at Origin | Verify temperatures, rapidly load cargo, arrange for air circulation | Minimize temperature fluctuations during loading |

| Transportation | Maintain power supply, monitor temperatures continuously | Optimize routes for efficiency |

| Intermediate Handling | Transfer between transport modes, use cold storage if needed | Minimize downtime for unpowered containers |

| Delivery and Unloading | Check temperatures pre-delivery, rapid unloading | Ensure compliance with temperature requirements |

| Post-Trip Procedures | Clean and maintain equipment, analyze data | Address any issues noted during transit |

The reefer drayage process is a well-orchestrated operation that requires attention to detail at every stage. By following these steps and maintaining strict temperature control, logistics providers can ensure that temperature-sensitive goods arrive at their destination in optimal condition.

What equipment is essential for reefer drayage?

The successful execution of reefer drayage relies on specialized equipment designed to maintain the required temperature for perishable goods. Understanding the essential equipment involved in this process is vital for logistics providers and shippers alike. Here’s an overview of the key equipment used in reefer drayage operations:

Reefer Containers

Reefer containers are the backbone of reefer drayage. These insulated containers are equipped with refrigeration units that maintain a consistent internal temperature. Key features include:

-

Temperature Control Systems: These systems allow operators to set and monitor specific temperature ranges based on the cargo requirements.

-

Insulation: High-quality insulation prevents heat transfer between the container’s interior and exterior environments.

-

Airflow Management: Proper airflow design ensures even cooling throughout the container, preventing hot spots that could lead to spoilage.

Refrigerated Trucks

Refrigerated trucks are specifically designed to transport reefer containers while maintaining the necessary temperature control. Essential features include:

-

Power Supply: Refrigerated trucks are equipped with power sources to keep the refrigeration unit operational during transit.

-

Temperature Monitoring Systems: Many refrigerated trucks come with built-in monitoring systems that track internal temperatures in real-time.

-

Insulated Cargo Areas: The cargo area is designed to minimize heat exchange and maintain consistent temperatures during transportation.

Temperature Monitoring Devices

Accurate temperature monitoring is critical in reefer drayage. Various devices are used to ensure that cargo remains within specified temperature ranges:

-

Data Loggers: These devices record temperature data throughout the journey, providing a historical log that can be reviewed upon delivery.

-

Real-Time Monitoring Systems: Advanced systems provide continuous updates on temperature conditions via GPS tracking and alerts for any deviations from set parameters.

-

Wireless Sensors: These sensors can transmit data remotely to operators or shippers, enhancing visibility throughout the supply chain.

Power Generators (Gensets)

For longer journeys or when containers are stationary, power generators (gensets) are used to provide electricity to reefer containers. Key aspects include:

-

Portable Power Supply: Gensets ensure that refrigeration units remain operational even when disconnected from the truck’s power source.

-

Fuel Efficiency: Modern gensets are designed for fuel efficiency and reduced emissions, making them environmentally friendly options for maintaining cold chain integrity.

Loading Equipment

Proper loading equipment is essential for efficiently handling reefer containers while minimizing exposure to ambient temperatures:

-

Forklifts with Refrigeration Capabilities: Specialized forklifts equipped with refrigeration units can help load and unload goods without compromising temperature control.

-

Temperature-Controlled Loading Docks: These facilities maintain a consistent environment during loading and unloading processes.

-

Pallets and Racking Systems: Properly designed pallets and racking systems facilitate airflow around products within the reefer container.

Cold Storage Facilities

Cold storage facilities play a crucial role in the reefer drayage process by providing temporary storage solutions for perishable goods. Key features include:

-

Temperature Regulation Systems: These facilities maintain specific temperature ranges suitable for various types of perishable goods.

-

Monitoring Systems: Cold storage facilities often have advanced monitoring systems in place to ensure compliance with safety regulations.

-

Efficient Loading/Unloading Areas: Designed for quick access to refrigerated trucks or containers, these areas minimize time spent outside controlled environments.

| Equipment Type | Purpose | Key Features |

|---|---|---|

| Reefer Containers | Maintain temperature control during transport | Insulation, airflow management |

| Refrigerated Trucks | Transport reefer containers while preserving cold chain | Power supply, monitoring systems |

| Temperature Monitoring Devices | Track internal temperatures throughout transit | Data loggers, real-time systems |

| Power Generators (Gensets) | Provide power when not connected to trucks | Portable supply, fuel efficiency |

| Loading Equipment | Facilitate efficient loading/unloading of goods | Refrigerated forklifts, controlled docks |

| Cold Storage Facilities | Temporarily store perishable goods before delivery | Temperature regulation, efficient access |

The combination of these specialized pieces of equipment ensures that reefer drayage operations run smoothly while maintaining strict adherence to temperature control protocols. This ultimately protects product quality and safety throughout the supply chain.

What are the main challenges in reefer drayage operations?

Reefer drayage operations face several unique challenges that can impact efficiency, safety, and product quality. Understanding these challenges is crucial for logistics providers and shippers involved in transporting temperature-sensitive goods. Here’s an overview of some of the main challenges encountered in reefer drayage:

Temperature Control Issues

Maintaining consistent temperatures throughout the transportation process is paramount. Challenges include:

-

Equipment Malfunctions: Refrigeration units may fail due to mechanical issues or lack of maintenance, leading to temperature fluctuations that can spoil cargo.

-

Power Supply Interruptions: Loss of power during transit can result from generator failures or disconnections from truck power sources. This risk necessitates redundancy measures such as backup generators.

-

Thermal Shock During Loading/Unloading: Rapid changes in temperature can occur when loading or unloading cargo if proper procedures aren’t followed. This can compromise product integrity.

Regulatory Compliance

Compliance with stringent regulations governing food safety and pharmaceuticals presents ongoing challenges:

-

Documentation Requirements: Maintaining accurate records of temperatures during transit is essential but can be cumbersome and prone to errors if not managed properly.

-

Regular Inspections and Certifications: Reefer equipment must be regularly inspected and certified to meet industry standards. Failure to comply can result in fines or loss of business licenses.

-

Training Requirements for Personnel: Employees involved in handling perishable goods must be trained on proper procedures and regulations, which requires time and resources.

Logistical Coordination

The complexity of coordinating multiple parties involved in reefer drayage adds layers of difficulty:

-

Scheduling Conflicts: Tight schedules often lead to conflicts between loading/unloading times at ports or warehouses, which can delay deliveries.

-

Multiple Modes of Transport: Transferring cargo between different transportation modes (e.g., truck to rail) requires precise timing and coordination to minimize exposure to ambient temperatures.

-

Communication Gaps Among Stakeholders: Effective communication among shippers, carriers, port authorities, and receivers is essential but can be hindered by misunderstandings or lack of information sharing.

Cost Management

Reefer drayage often incurs higher operational costs compared to standard drayage due to various factors:

-

Equipment Costs: The initial investment in refrigerated containers and trucks is significantly higher than standard vehicles.

-

Increased Fuel Consumption: Refrigeration units consume more fuel than standard trucks due to their energy demands.

-

Insurance Premiums: The value of perishable goods often leads to higher insurance premiums compared to non-perishable items.

Market Volatility

Fluctuations in demand for perishable products can impact planning and profitability:

-

Seasonal Variability in Demand: Certain products may see spikes in demand based on seasons or holidays (e.g., fresh produce), requiring adjustments in capacity planning.

-

Price Volatility for Perishables: Changes in market prices can affect profitability margins for logistics providers handling perishable goods.

How do regulations impact reefer drayage?

Regulations play a critical role in shaping how reefer drayage operations are conducted. Compliance with these regulations ensures the safety of perishable goods while protecting public health. Here’s an overview of how various regulations impact reefer drayage operations:

Food Safety Regulations

Food safety regulations govern how perishable food items must be handled throughout their journey from origin to destination. Key aspects include:

![]()

-

Temperature Control Standards: Regulations such as the Food Safety Modernization Act (FSMA) require specific temperature ranges for different types of food products during transportation. Failure to comply can result in spoilage or contamination issues.

-

Traceability Requirements: Shippers must maintain detailed records regarding product origins, handling processes, and transportation conditions. This traceability is crucial for responding quickly in case of recalls or foodborne illness outbreaks.

Pharmaceutical Regulations

The pharmaceutical industry faces stringent regulations regarding the transportation of medications and vaccines:

-

Good Distribution Practice (GDP): GDP guidelines outline best practices for transporting pharmaceuticals safely. This includes maintaining specific temperature ranges (typically between 2°C and 8°C) during transit.

-

Documentation Requirements: Pharmaceuticals require extensive documentation detailing storage conditions throughout their journey. This includes tracking temperatures at various points along the supply chain.

Environmental Regulations

Environmental regulations impact how refrigerated transport operates:

-

Emissions Standards: Many jurisdictions have established emissions standards that apply specifically to refrigerated vehicles due to their higher fuel consumption rates.

-

Refrigerant Regulations: The use of certain refrigerants has been restricted due to environmental concerns related to ozone depletion and greenhouse gas emissions. Operators must comply with these restrictions when choosing refrigeration technologies.

International Trade Regulations

For international shipments involving reefers:

-

Customs Compliance: Reefer shipments must adhere to customs regulations regarding documentation requirements for importing/exporting perishable goods across borders.

-

Sanitary Phytosanitary (SPS) Measures: Countries may impose specific SPS measures aimed at preventing pests or diseases from entering their borders through imported food products. Reefer operators must ensure compliance with these measures during transport.

Local Regulations

Local regulations may also impact how reefer drayage operations are conducted:

-

Zoning Laws: Local zoning laws may dictate where refrigerated trucks can operate or park while waiting for loading/unloading.

-

Noise Ordinances: Some areas have noise ordinances that restrict engine idling times or operation hours for refrigerated vehicles due to noise pollution concerns.

Compliance Challenges

While adhering to these numerous regulations is essential for safe operations, it also presents challenges:

-

Increased Operational Complexity: The need for compliance adds complexity to logistics operations requiring additional training for personnel involved in handling perishables.

-

Cost Implications: Compliance with regulations often leads to increased costs associated with training programs, equipment upgrades, documentation processes, and potential fines for non-compliance.

What technologies are used in modern reefer drayage?

Modern technology plays a pivotal role in enhancing the efficiency, reliability, and safety of reefer drayage operations. By leveraging advanced technologies, logistics providers can better monitor conditions throughout transit while ensuring compliance with regulatory standards. Here’s an overview of key technologies utilized in modern reefer drayage:

Temperature Monitoring Systems

Temperature monitoring systems enable real-time tracking of internal conditions within refrigerated containers:

-

Data Loggers: These devices record temperature data at regular intervals throughout transit. They provide historical records that can be reviewed upon delivery.

-

Wireless Sensors: Wireless sensors transmit real-time data regarding internal temperatures directly to shippers or logistics managers via cloud-based platforms.

GPS Tracking

GPS tracking technology enhances visibility throughout the shipping process:

-

Real-Time Location Tracking: Logistics providers can monitor container locations at any given moment using GPS tracking systems integrated into refrigerated trucks.

-

Route Optimization: GPS technology allows logistics managers to optimize routes based on traffic conditions or weather forecasts—ensuring timely deliveries while minimizing delays caused by unexpected events.

Telematics Systems

Telematics systems combine GPS tracking with vehicle diagnostics information:

- Performance Monitoring: Telematics provides insights into vehicle performance metrics such as fuel consumption rates or engine health—allowing operators to proactively address maintenance needs before they become critical issues.

Automated Temperature Control

Automated systems help maintain precise temperature settings throughout transit:

- Smart Refrigeration Units: Advanced refrigeration units feature automated controls that adjust cooling settings based on external temperatures—ensuring consistent internal conditions regardless of environmental changes.

Blockchain Technology

Blockchain technology offers enhanced transparency within supply chains by providing immutable records regarding product origins:

- Traceability Solutions: Blockchain enables stakeholders across various points along a supply chain—including producers/shippers/receivers—to access verified information about product handling conditions—facilitating swift responses during recalls if necessary.

Mobile Applications

Mobile applications improve communication among stakeholders involved in reefers’ transportation processes:

- Real-Time Notifications: Mobile apps allow drivers/logistics managers/receivers access real-time notifications regarding shipment status—enabling proactive decision-making based on up-to-date information about delays/malfunctions etc.

Artificial Intelligence (AI)

Artificial Intelligence enhances decision-making capabilities within logistics operations through predictive analytics tools:

- Demand Forecasting Models: AI algorithms analyze historical data patterns related both demand fluctuations & seasonal trends—allowing better capacity planning decisions resulting from more accurate forecasts about future needs based on past performance metrics etc.

Internet of Things (IoT)

IoT devices extend connectivity across multiple aspects involved within reefers’ transportation processes:

- Connected Devices: IoT-enabled devices facilitate seamless communication between various components—from sensors installed inside containers—to centralized platforms where data gets aggregated/analyzed—providing comprehensive insights into overall supply chain performance metrics etc.

Robotics Automation

Robotics automation streamlines warehouse operations related specifically towards handling/retrieving items stored inside refrigerated facilities efficiently without compromising quality standards etc.:

| Technology Type | Purpose | Key Benefits |

|---|---|---|

| Temperature Monitoring | Track internal conditions | Real-time alerts & historical data |

| GPS Tracking | Monitor container locations | Enhanced visibility & route optimization |

| Telematics Systems | Combine GPS tracking with diagnostics | Proactive maintenance & performance insights |

| Automated Temperature Control | Maintain precise settings | Consistent internal conditions |

| Blockchain Technology | Enhance traceability | Immutable records & swift recall responses |

| Mobile Applications | Improve communication | Real-time notifications & updates |

| Artificial Intelligence | Enhance decision-making | Predictive analytics & demand forecasting |

| Internet of Things (IoT) | Extend connectivity | Comprehensive insights into supply chain performance |

| Robotics Automation | Streamline warehouse operations | Efficient handling without compromising quality |

By integrating these advanced technologies into their operations, logistics providers can enhance their ability not only monitor conditions but also respond proactively when issues arise—ultimately ensuring successful delivery outcomes while safeguarding product quality/safety standards throughout every step involved within reefers’ transportation processes etc., thereby improving overall efficiency levels across entire supply chains overall etc..

How do you choose a reliable reefer drayage provider?

Selecting a reliable reefer drayage provider is crucial for ensuring that your temperature-sensitive goods reach their destination safely and efficiently. Here are key factors you should consider when evaluating potential providers:

Experience and Expertise

Look for providers with extensive experience specifically within reefer logistics:

-

Evaluate their track record concerning transporting similar types of cargo requiring specialized handling procedures like pharmaceuticals/fresh produce etc., ensuring they understand unique challenges associated with each type effectively etc..

-

Inquire about certifications relevant towards food safety/pharmaceutical guidelines confirming compliance adherence levels maintained consistently over time etc..

Equipment Quality

Assessing equipment quality ensures optimal performance during transportation processes:

-

Verify whether they utilize modern well-maintained refrigerated containers/trucks equipped capable managing varying environmental conditions effectively etc..

-

Confirm availability/accessibility towards necessary supporting equipment like gensets/loading docks/temperature monitoring devices ensuring seamless operation continuity throughout entire journey length etc..

Regulatory Compliance

Ensure potential providers comply fully with all relevant regulatory requirements:

-

Request documentation confirming adherence towards local/national/international standards governing food safety/pharmaceutical distribution practices etc..

-

Inquire about training programs implemented ensuring personnel involved possess adequate knowledge regarding necessary protocols/procedures required when handling perishables effectively etc..

Technology Integration

Evaluate how well potential providers leverage technology within their operations:

-

Assess whether they utilize advanced monitoring systems/data loggers enabling real-time visibility concerning shipment status/conditions maintained throughout transit periods effectively etc..

-

Confirm usage towards telematics solutions facilitating proactive maintenance checks allowing timely interventions whenever issues arise reducing risks associated with delays/spoilages occurring unexpectedly etc..

Customer Service

Strong customer service plays an essential role within successful partnerships:

-

Look into reviews/testimonials provided by previous clients assessing responsiveness/effectiveness regarding addressing concerns/questions raised promptly whenever necessary etc..

-

Consider whether they offer dedicated support teams available 24/7 assisting clients whenever needed enhancing overall satisfaction levels experienced consistently over time etc..

Cost Structure

Understanding cost structures helps ensure budget considerations align appropriately:

-

Request detailed quotes outlining all fees associated including hidden costs potentially impacting total expenses incurred eventually leading towards unexpected financial burdens later down road etc..

-

Compare pricing models among different providers evaluating value offered relative towards services provided ensuring fair compensation levels achieved consistently across board overall etc..

Insurance Coverage

Verify insurance coverage options available protecting against potential losses incurred:

-

Confirm whether they carry adequate liability coverage safeguarding against damages incurred during transportation processes ensuring peace-of-mind experienced consistently over time etc..

-

Inquire about claims procedures ensuring prompt resolutions achieved whenever issues arise safeguarding interests effectively overall etc..

References and Reviews

Seek references from previous clients confirming reliability levels experienced consistently over time:

-

Ask potential providers directly requesting contact details enabling follow-up discussions assessing firsthand experiences shared concerning partnerships established previously enhancing confidence levels achieved overall etc..

-

Research online reviews assessing reputation built over years evaluating strengths/weaknesses highlighted consistently across platforms utilized regularly by industry professionals seeking reliable partners effectively overall etc..

By carefully considering these factors when selecting a reliable reefer drayage provider you’ll enhance your ability not only safeguard quality/safety standards maintained throughout entire transportation journeys but also foster long-term partnerships contributing positively towards overall success achieved within your organization’s supply chain management strategies implemented effectively over time as well!