What Is Sealing of Containers

What is container sealing and why is it important?

Container sealing is a critical process in the logistics and shipping industry that involves securing cargo containers with tamper-evident devices. These seals serve as both a physical barrier and a security measure, ensuring the integrity of the container’s contents throughout its journey from origin to destination.

The importance of container sealing cannot be overstated in the global supply chain. It plays a pivotal role in:

Cargo Security: Container seals act as the first line of defense against theft, tampering, and unauthorized access. They provide a visible deterrent to potential intruders and make it difficult for anyone to gain entry without leaving evidence.

Regulatory Compliance: Many countries and international organizations mandate the use of specific types of container seals to meet security standards. Proper sealing is essential for compliance with customs regulations and trade agreements.

Supply Chain Integrity: Seals help maintain the chain of custody, providing assurance that the cargo has not been compromised during transit. This is particularly crucial for sensitive or high-value goods.

Risk Management: By reducing the likelihood of theft and tampering, container sealing helps mitigate financial risks associated with cargo loss or damage.

Trade Facilitation: Properly sealed containers can expedite customs clearance processes, as they demonstrate compliance with security protocols and reduce the need for extensive inspections.

Quality Assurance: For certain types of cargo, such as food products or pharmaceuticals, seals help maintain product integrity by preventing contamination or environmental exposure.

The sealing process involves attaching a uniquely identifiable seal to the container’s locking mechanism. This seal typically bears a unique serial number or barcode, which is recorded in shipping documents and can be tracked throughout the container’s journey.

Container seals come in various types, each designed for specific security needs and regulatory requirements. The most common types include:

Bolt Seals: These high-security seals consist of a steel bolt with a locking mechanism. They are durable and difficult to remove without specialized tools.

Cable Seals: Flexible steel cables with a locking head, suitable for containers with non-standard locking mechanisms.

Electronic Seals (E-seals): Advanced seals that incorporate RFID or GPS technology for real-time tracking and tamper detection.

The choice of seal depends on factors such as the value and sensitivity of the cargo, regulatory requirements, and the specific risks associated with the shipping route.

Proper sealing procedures are crucial for maintaining the effectiveness of container seals. This includes:

- Inspecting the container for any pre-existing damage or vulnerabilities

- Correctly applying the seal to the container’s locking mechanism

- Recording the seal number and other relevant details in shipping documents

- Verifying the seal’s integrity at key points throughout the shipping process

Container sealing is not just about applying a physical device; it’s an integral part of a comprehensive security strategy. It involves training personnel, implementing robust documentation procedures, and integrating with broader supply chain management systems.

As global trade continues to grow and evolve, the importance of effective container sealing becomes even more pronounced. It serves as a critical link in ensuring the security, efficiency, and reliability of international shipping operations.

How do different types of container seals work?

Container seals come in various forms, each designed to provide specific levels of security and functionality. Understanding how these different types work is crucial for logistics professionals, shippers, and anyone involved in the supply chain. Let’s explore the main categories of container seals and their operational mechanisms.

Mechanical Seals

Mechanical seals are the most common and traditional type of container seals. They rely on physical locking mechanisms to secure the container doors.

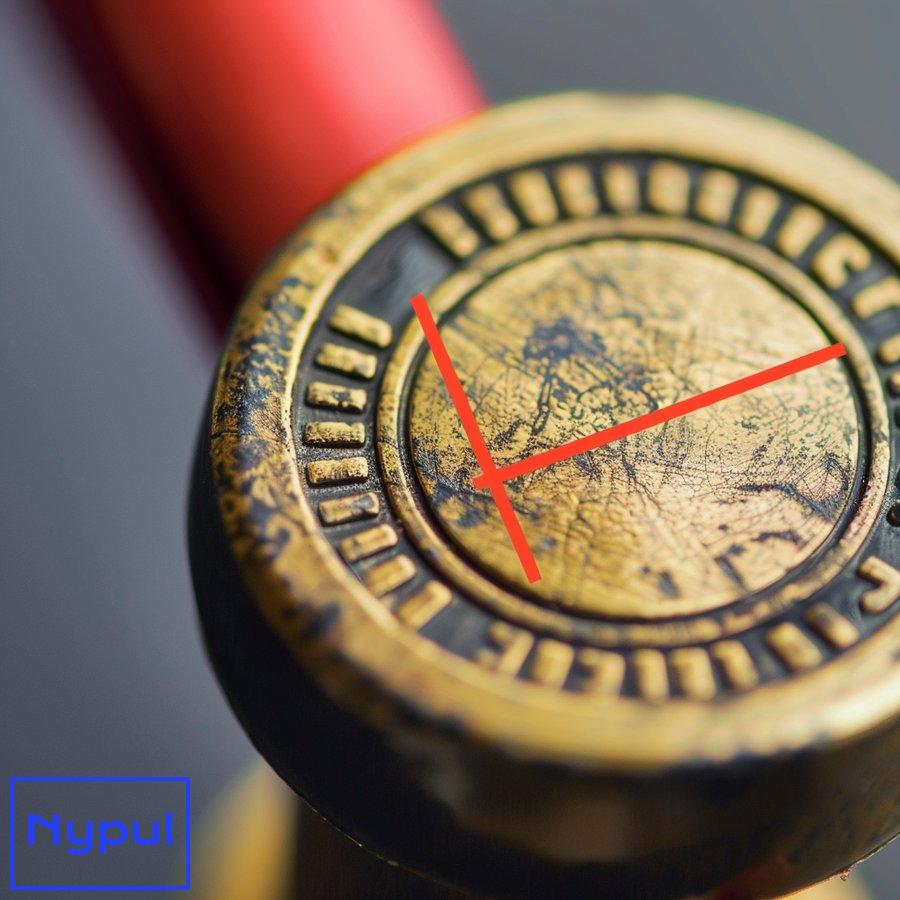

Bolt Seals

Bolt seals are high-security devices consisting of a steel bolt and a locking body. Here’s how they work:

- The bolt is inserted through the container’s locking hasp.

- The locking body is then attached to the bolt and snapped shut.

- Once closed, the seal can only be removed by cutting the bolt.

Bolt seals are known for their durability and resistance to tampering. They’re often used for high-value or sensitive cargo due to their robust construction.

Cable Seals

Cable seals feature a flexible steel cable with a locking mechanism. Their operation involves:

- Threading the cable through the container’s locking points.

- Inserting the cable end into the locking body.

- The locking body secures the cable, creating a loop.

Cable seals offer flexibility for containers with non-standard locking mechanisms or when multiple closure points need to be secured.

Padlock Seals

Padlock seals resemble traditional padlocks but are designed for single use. Their working principle includes:

- The seal is locked onto the container’s hasp.

- A unique serial number is recorded for tracking.

- The seal must be cut to open, preventing reuse.

These seals provide a visual deterrent and are often used in conjunction with other security measures.

Electronic Seals (E-seals)

E-seals represent the cutting edge of container sealing technology, incorporating electronic components for enhanced security and tracking.

RFID Seals

RFID (Radio-Frequency Identification) seals combine physical sealing with electronic tracking:

- The seal contains an RFID chip with a unique identifier.

- When the seal is applied, its data is recorded in a database.

- RFID readers can scan the seal at various points in the supply chain.

- Any tampering or unauthorized opening triggers an alert.

RFID seals enable real-time tracking and provide an additional layer of security through electronic verification.

GPS-Enabled Seals

GPS seals take electronic tracking a step further:

- The seal includes a GPS module and cellular communication capabilities.

- It transmits location data and seal status in real-time.

- Any deviation from the planned route or seal tampering triggers immediate alerts.

These seals offer the highest level of security and visibility, particularly valuable for high-risk or sensitive shipments.

Indicative Seals

Indicative seals are simpler devices designed to show evidence of tampering rather than prevent access.

Plastic Seals

Plastic seals are cost-effective options for lower-risk shipments:

- The seal is threaded through the container’s locking mechanism.

- A locking mechanism snaps shut, securing the seal.

- Any attempt to open the container breaks the seal, providing visual evidence of tampering.

While not as secure as bolt or cable seals, plastic seals are useful for detecting unauthorized access attempts.

Security Tape

Security tape works on a similar principle to plastic seals:

- The tape is applied across the container door seams.

- Special adhesives or tamper-evident patterns reveal any attempts to remove or reapply the tape.

- Intact tape indicates the container hasn’t been opened since sealing.

Security tape is often used in conjunction with other sealing methods for added assurance.

| Seal Type | Security Level | Tamper Evidence | Reusability | Tracking Capability |

|---|---|---|---|---|

| Bolt Seal | High | Yes | No | Manual |

| Cable Seal | Medium-High | Yes | No | Manual |

| Padlock Seal | Medium | Yes | No | Manual |

| RFID Seal | High | Yes | No | Electronic |

| GPS Seal | Very High | Yes | No | Real-time |

| Plastic Seal | Low-Medium | Yes | No | Manual |

| Security Tape | Low | Yes | No | Visual |

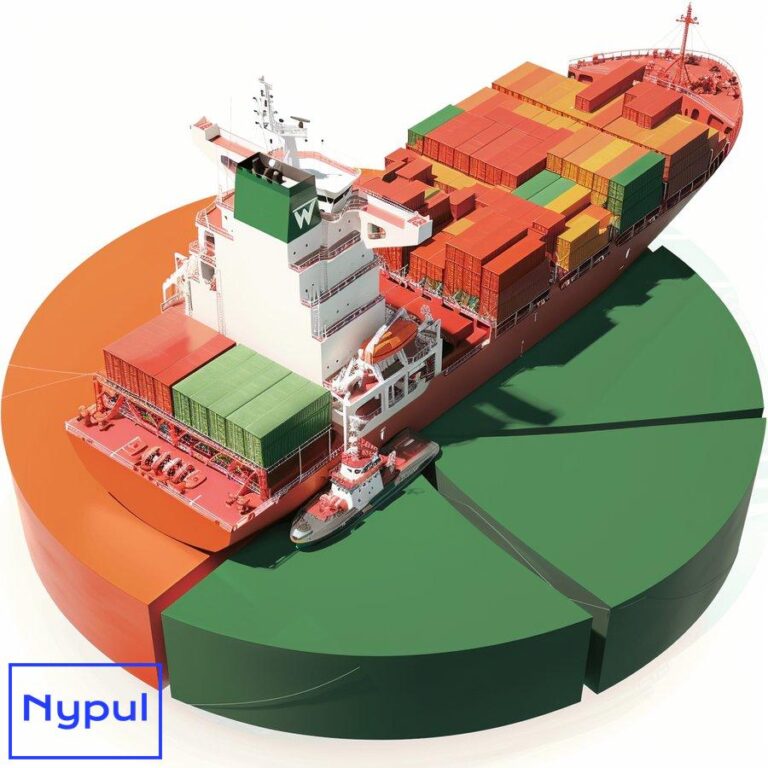

The choice of seal depends on various factors, including:

- Value and sensitivity of the cargo

- Regulatory requirements

- Risk assessment of the shipping route

- Budget considerations

- Operational needs (e.g., ease of application and removal)

Understanding how different seal types work allows stakeholders to make informed decisions about which sealing methods best suit their specific needs. As technology advances, we can expect to see further innovations in container sealing, potentially combining multiple security features for even more robust protection of global cargo.

What are the ISO 17712 standards for container seals?

The International Organization for Standardization (ISO) 17712 standards are a set of globally recognized guidelines that define the specifications for mechanical seals used on freight containers. These standards are crucial for ensuring uniformity, reliability, and security in international shipping and logistics operations.

Purpose of ISO 17712

The primary objectives of the ISO 17712 standards are to:

- Establish consistent criteria for high-security seals

- Provide a framework for testing and certifying seal quality

- Enhance global supply chain security

- Facilitate international trade by standardizing seal requirements

Key Components of ISO 17712

The ISO 17712 standards cover several critical aspects of container seals:

Classification of Seals

ISO 17712 categorizes seals into three main classes:

-

“H” (High Security) Seals: These meet the highest security requirements and are suitable for international cargo shipments.

-

“S” (Security) Seals: While robust, these do not meet all the criteria for high-security classification.

-

“I” (Indicative) Seals: These provide evidence of tampering but offer lower physical security.

Physical Specifications

The standards define specific physical attributes for each seal class:

- Minimum tensile strength

- Shear strength requirements

- Bending moment resistance

- Impact resistance at various temperatures

For example, “H” class seals must withstand a minimum tensile strength of 1000 kgf (kilogram-force), while “S” class seals require 250 kgf.

Testing Procedures

ISO 17712 outlines rigorous testing methods to ensure seal integrity:

- Tensile strength tests

- Shear tests

- Bending tests

- Impact tests at room temperature and in extreme cold (-40°C)

- Corrosion resistance tests

These tests simulate various scenarios that seals might encounter during transit, ensuring they can withstand typical handling and environmental conditions.

Marking and Identification

The standards mandate specific marking requirements:

- Each seal must bear a unique identifier

- Manufacturer’s name or logo must be clearly visible

- The seal’s security level (“H”, “S”, or “I”) must be marked

- Markings should be permanent and legible

Evidence of Tampering

ISO 17712 requires that seals provide clear evidence of tampering attempts:

- Seals should show visible damage if forcibly removed

- Any attempt to reassemble a broken seal should be evident

Material Requirements

The standards specify material quality to ensure durability and security:

- Seals must be constructed from materials that prevent undetectable removal

- Materials should withstand environmental extremes (temperature, humidity, etc.)

Certification and Compliance

To meet ISO 17712 standards, seal manufacturers must:

- Submit their products for independent laboratory testing

- Provide documentation of compliance

- Undergo periodic re-certification to maintain their status

Importance in Global Trade

ISO 17712 compliance is often mandatory for international shipping:

- Many customs authorities require the use of ISO 17712 compliant seals

- Compliance facilitates faster customs clearance processes

- It’s a key component of various supply chain security programs (e.g., C-TPAT in the U.S.)

Evolution of the Standards

ISO 17712 is periodically reviewed and updated:

- The latest version (as of 2024) was published in 2013

- Updates consider emerging technologies and security threats

- Revisions aim to address any identified vulnerabilities or industry needs

Implementation Challenges

While ISO 17712 provides a robust framework, challenges in implementation include:

- Ensuring consistent application across different countries and jurisdictions

- Balancing security requirements with operational efficiency

- Keeping pace with evolving security threats and technologies

Best Practices for Compliance

To effectively implement ISO 17712 standards:

- Use only certified seals from reputable manufacturers

- Train personnel in proper seal application and verification procedures

- Maintain detailed records of seal usage and inspections

- Regularly audit sealing processes to ensure ongoing compliance

- Stay informed about any updates or revisions to the standards

The ISO 17712 standards play a vital role in enhancing global supply chain security. By providing a common framework for container seal quality and performance, these standards contribute to more secure, efficient, and reliable international trade operations. As the logistics industry continues to evolve, adherence to and understanding of these standards remains crucial for all stakeholders involved in container shipping and security.

How should containers be properly sealed?

Proper container sealing is a critical process that ensures the security and integrity of cargo throughout its journey. Following correct sealing procedures not only enhances security but also facilitates smooth customs clearance and maintains compliance with international regulations. Here’s a comprehensive guide on how containers should be properly sealed.

Pre-Sealing Inspection

Before applying any seal, a thorough inspection of the container is essential:

-

Exterior Check: Examine the container’s exterior for any damage, holes, or signs of tampering.

-

Interior Inspection: Ensure the container is clean, dry, and free from any residual cargo or pests.

-

Door Mechanism: Verify that the door locking rods and cam fittings are in good working condition.

-

Locking Points: Check that the hasp, where the seal will be applied, is intact and secure.

Seal Selection

Choose the appropriate seal based on:

- Cargo value and sensitivity

- Regulatory requirements

- Risk assessment of the shipping route

- Customer or insurance specifications

Ensure the selected seal complies with relevant standards (e.g., ISO 17712 for high-security seals).

Sealing Process

The actual sealing procedure involves several critical steps:

-

Cargo Loading: Ensure all cargo is properly loaded and secured within the container.

-

Door Closure: Close both container doors securely, engaging all locking mechanisms.

-

Seal Application:

- For bolt seals:

a. Insert the bolt through the right-hand door’s locking handle.

b. Attach the locking body and push until it clicks into place. -

For cable seals:

a. Thread the cable through both door handles.

b. Insert the cable end into the locking mechanism until it’s secure. -

Seal Verification: Tug on the seal to ensure it’s properly locked and cannot be removed without breaking.

-

Recording Seal Information:

- Note the seal number in all relevant shipping documents.

- If using electronic seals, ensure the seal is activated and registered in the tracking system.

Documentation

Proper documentation is crucial for maintaining the chain of custody:

- Seal Number Recording: Document the seal number on:

- Bill of Lading

- Shipping Manifest

- Customs Declaration Forms

-

Any other relevant shipping documents

-

Photographic Evidence: Take clear photos of the applied seal, showing its number and proper application.

-

Seal Application Log: Maintain a log detailing:

- Date and time of sealing

- Container number

- Seal number

- Name and signature of the person applying the seal

Seal Integrity Verification

Throughout the container’s journey, seal integrity should be verified at key points:

- At the point of departure

- During any transshipments or transfers

- Upon arrival at the destination

- At any customs inspection points

Verification involves:

1. Checking the seal number against shipping documents

2. Inspecting the seal for any signs of tampering or damage

3. Ensuring the seal is still securely fastened

Special Considerations

Temperature-Controlled Containers: For reefer containers, ensure the seal doesn’t interfere with temperature control mechanisms or monitoring devices.

Multiple Seals: Some shipments may require multiple seals (e.g., customs seal in addition to shipper’s seal). Ensure all seals are properly documented.

High-Risk Cargo: For valuable or sensitive cargo, consider using additional security measures such as GPS tracking or tamper-evident tape in conjunction with seals.

Training and Compliance

Proper sealing requires well-trained personnel:

- Provide regular training on sealing procedures and seal verification.

- Ensure all staff involved in container handling understand the importance of seal integrity.

- Conduct periodic audits to verify compliance with sealing protocols.

Technology Integration

Leverage technology to enhance the sealing process:

- Use electronic seal management systems to track seal application and verification.

- Implement barcode or RFID scanning for quick and accurate seal number recording.

- Consider blockchain technology for immutable record-keeping of seal data.

Handling Seal Discrepancies

Establish clear procedures for handling seal discrepancies:

- If a seal is found damaged or tampered with:

- Do not open the container

- Immediately report to supervisors and relevant authorities

- Document the discrepancy with photographs and written reports

-

Follow established protocols for container quarantine and inspection

-

For seal number mismatches:

- Cross-verify with all shipping documents

- Contact the shipper or relevant parties for clarification

-## What are the key aspects of seal management and control?

Effective seal management and control are crucial for maintaining the integrity of containerized cargo throughout its journey. This involves not just the application of seals but also the systematic tracking, monitoring, and documentation of seal usage to ensure compliance with security protocols and regulatory requirements. Here are the key aspects of seal management and control:

Seal Inventory Management

Maintaining an accurate inventory of seals is essential for effective management:

-

Tracking Seal Types: Keep detailed records of different types of seals in inventory, including high-security, indicative, and electronic seals.

-

Usage Logs: Document each seal’s usage, including:

- Seal number

- Date of application

- Container number

-

Cargo description

-

Reorder Levels: Set reorder levels for different types of seals to ensure that inventory is always sufficient to meet operational needs.

Seal Application Procedures

Establish clear procedures for applying seals to containers:

-

Standard Operating Procedures (SOPs): Develop SOPs that outline the steps for seal application, including pre-sealing inspections and documentation requirements.

-

Training Programs: Implement training programs for personnel involved in the sealing process to ensure they understand the importance of proper application and verification.

-

Quality Control Checks: Conduct regular quality control checks to verify that seals are being applied correctly and consistently.

Documentation and Record Keeping

Accurate documentation is vital for compliance and accountability:

-

Seal Tracking Systems: Utilize electronic systems or software to track seal application and status in real-time.

-

Shipping Documentation: Ensure that all shipping documents (e.g., bills of lading, manifests) include relevant seal information, such as numbers and types.

-

Audit Trails: Maintain comprehensive audit trails that document every step in the sealing process, from application to verification upon delivery.

Monitoring and Verification

Regular monitoring and verification help maintain seal integrity throughout transit:

-

Checkpoint Inspections: Conduct inspections at key checkpoints during the shipping process to verify seal status.

-

Tamper Evidence Checks: Train personnel to recognize signs of tampering or damage on seals during inspections.

-

Incident Reporting Protocols: Establish protocols for reporting any discrepancies or issues related to seals immediately.

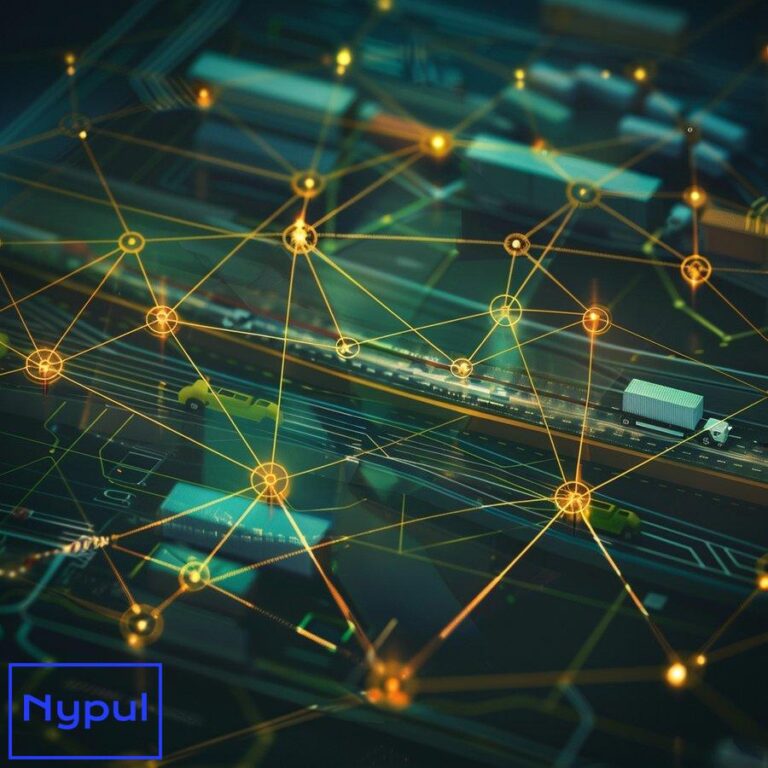

Integration with Supply Chain Management

Effective seal management should be integrated into broader supply chain management practices:

-

Collaboration with Stakeholders: Work closely with shipping lines, customs authorities, and logistics partners to ensure consistent seal practices across the supply chain.

-

Data Sharing Platforms: Use data sharing platforms that allow stakeholders to access real-time information about seal status and cargo integrity.

-

Continuous Improvement Programs: Implement continuous improvement programs based on feedback from stakeholders regarding seal management practices.

When and how should container seals be broken and replaced?

Breaking and replacing container seals is a critical procedure that must be conducted with care to maintain cargo integrity and comply with regulations. Understanding when and how to perform this task ensures that all parties involved in the supply chain can manage risks effectively while adhering to best practices.

When to Break Container Seals

Container seals should be broken under specific circumstances:

-

Arrival at Destination: Seals should be broken only when the container has arrived at its final destination or designated inspection point.

-

Customs Inspections: If customs authorities require inspection, seals may need to be broken under their supervision.

-

Significant Delays or Incidents: If there are significant delays during transit or if there are indications of tampering or damage, seals may need to be broken for inspection purposes.

-

Cargo Transfer Points: In cases where cargo is transferred from one container to another (e.g., during transshipment), seals may need to be broken under controlled conditions.

-

Emergency Situations: In emergencies where access to cargo is necessary (e.g., medical supplies), breaking the seal may be warranted, but this should be documented thoroughly.

How to Break Container Seals Safely

When breaking a container seal, follow these steps:

-

Verify Documentation: Before breaking a seal, ensure you have verified all relevant shipping documents against the container’s information (seal number, container number).

-

Inspect Seal Condition: Examine the condition of the seal before removal:

- Look for signs of tampering.

-

Ensure that breaking the seal will not compromise any ongoing investigations or security protocols.

-

Use Proper Tools: Utilize appropriate tools for breaking seals:

- For bolt seals, use bolt cutters.

- For cable seals, use wire cutters.

-

Ensure tools are clean and free from contaminants.

-

Document Seal Breaking:

- Record the date, time, reason for breaking the seal, and who performed the action.

- Take photographs of both the intact seal before removal and any evidence of tampering if applicable.

-

Update shipping documents accordingly.

-

Replace with New Seal if Necessary:

- If cargo is being transferred or inspected, apply a new seal after verifying that all items are accounted for.

- Record the new seal number in all relevant documentation.

-

Ensure that new seals comply with applicable standards (e.g., ISO 17712).

-

Notify Relevant Parties:

- Inform all stakeholders (e.g., logistics partners, customs officials) about the broken seal and provide updated documentation.

- Maintain communication throughout the process to ensure transparency.

What are the customs and border protection requirements for container sealing?

![]()

Customs and Border Protection (CBP) agencies around the world have established specific requirements for container sealing as part of their efforts to enhance security in international trade while facilitating efficient customs clearance processes. Understanding these requirements is essential for shippers, logistics providers, and anyone involved in international shipping operations.

Key Customs Requirements

- Use of Approved Seals

- CBP mandates that containers carrying goods into or out of a country must be sealed with approved high-security seals.

-

These seals must meet recognized standards such as ISO 17712 for high-security classification (“H” class).

-

Seal Integrity Verification

- Customs authorities may conduct random inspections at ports or border crossings to verify that containers are properly sealed.

-

Any discrepancies between shipping documents (seal numbers) and actual seals will result in delays or additional inspections.

-

Documentation Requirements

- Shippers must include detailed information about container seals in shipping documents:

- Seal number

- Type of seal used

- Date of sealing

- Name of personnel who applied the seal

-

Accurate record-keeping is essential for compliance with customs regulations.

-

Tamper-Evident Requirements

- Seals must provide clear evidence of tampering attempts.

-

CBP requires that any signs of tampering must be reported immediately upon discovery during inspections or at destination points.

-

Compliance with Security Programs

- Participation in security programs such as Customs-Trade Partnership Against Terrorism (C-TPAT) can enhance compliance with sealing requirements.

- C-TPAT members must demonstrate adherence to established security measures, including proper sealing procedures throughout their supply chains.

International Standards Compliance

- Alignment with International Agreements

- Many countries align their customs sealing requirements with international agreements such as the World Customs Organization’s SAFE Framework.

-

Compliance with these frameworks enhances global trade security while ensuring smooth customs operations across borders.

-

Adherence to Local Regulations

- In addition to international standards, shippers must also comply with local regulations regarding container sealing specific to each country they operate in.

- This includes understanding any unique requirements set forth by local customs authorities regarding sealing procedures or documentation practices.

Consequences of Non-Compliance

- Delays in Customs Clearance

- Failure to adhere to customs sealing requirements can lead to significant delays in cargo clearance at ports.

-

Containers may be subject to additional inspections if discrepancies arise between documented information and actual conditions upon arrival.

-

Fines and Penalties

- Non-compliance can result in financial penalties imposed by customs authorities.

-

Repeated violations may lead to increased scrutiny from regulatory bodies or even loss of export/import privileges for certain entities.

-

Increased Security Risks

- Non-compliance undermines overall supply chain security efforts by increasing vulnerability to theft or tampering during transit.

- This can lead not only to financial losses but also reputational damage for businesses involved in international trade operations.

Best Practices for Compliance

- Training Personnel on Customs Requirements

- Regular training sessions should be conducted for staff involved in shipping operations regarding customs sealing requirements.

-

Ensure personnel understand how proper sealing impacts overall compliance efforts within their organizations’ supply chains.

-

Regular Audits of Sealing Procedures

- Conduct periodic audits on sealing processes within your organization’s operations.

-

Identify areas where improvements can be made based on evolving customs regulations or industry best practices.

-

Maintain Open Communication with Customs Authorities

- Establish strong communication channels with local customs offices regarding any updates on sealing requirements or regulatory changes.

- Engage proactively with customs officials during inspections or inquiries related specifically to container sealing practices within your organization’s operations.

How is technology enhancing container sealing processes?

Technology is rapidly transforming various aspects of logistics and supply chain management, including container sealing processes. The integration of innovative technologies enhances security, efficiency, visibility, and compliance throughout the shipping lifecycle. Below are some key ways technology is enhancing container sealing processes:

Electronic Seals

-

RFID Technology

- Radio-Frequency Identification (RFID) technology allows for real-time tracking of containers equipped with RFID-enabled seals.

- RFID tags embedded within electronic seals transmit data wirelessly when scanned by readers at various checkpoints along the supply chain.

- This enables logistics providers to monitor container movements continuously while providing instant updates on seal status (intact or tampered).

-

GPS Tracking

- Global Positioning System (GPS) technology enables precise location tracking for containers equipped with GPS-enabled electronic seals.

- Real-time location data helps shippers monitor cargo movements effectively while allowing them to respond quickly if deviations from planned routes occur.

- GPS tracking enhances security by providing alerts when containers enter restricted areas or experience unexpected stops along their journey.

Blockchain Technology

-

Immutable Record-Keeping

- Blockchain technology offers a decentralized ledger system that provides an immutable record of all transactions related to container shipments.

- Each time a container is sealed or opened, details such as timestamps, locations, personnel involved, and associated documentation can be recorded on a blockchain ledger securely.

- This transparency fosters trust among stakeholders while ensuring accountability throughout the supply chain process.

-

Enhanced Traceability

- Blockchain enables end-to-end traceability by allowing all parties involved—shippers, carriers, customs authorities—to access real-time information about each shipment’s status.

- In case of disputes over cargo integrity or claims related to theft/tampering incidents; blockchain records serve as reliable evidence supporting accountability among stakeholders.

IoT Integration

-

Smart Sensors

- Internet-of-Things (IoT) devices equipped with sensors can monitor environmental conditions within containers (temperature/humidity).

- These smart sensors provide alerts if conditions deviate from acceptable ranges; thus ensuring sensitive cargo remains safe during transit while minimizing spoilage risks.

-

Automated Monitoring Systems

- IoT-enabled systems facilitate automated monitoring processes by integrating data from multiple sources—RFID readers/sensors—into centralized dashboards accessible by relevant personnel across organizations.

- This streamlines communication among stakeholders while improving response times when issues arise related specifically to sealing processes.

Data Analytics

-

Predictive Analytics Tools

- Advanced analytics tools utilize historical data patterns combined with machine learning algorithms; enabling predictive insights into potential risks associated with specific routes/sealing practices over time.

- By analyzing trends related specifically towards theft/tampering incidents across different regions/periods; organizations can proactively adjust their strategies accordingly.

-

Performance Metrics Evaluation

- Data analytics allows organizations engaged within logistics/supply chain sectors evaluate performance metrics associated directly towards their sealing processes—such as average time taken per shipment/percentage rate concerning damaged goods due solely due improper sealing methods utilized previously.

Mobile Applications

-

Seal Management Apps

- Mobile applications designed specifically for managing container seals enable users—drivers/logistics managers—to record details quickly about applied/broken/replaced seals directly via smartphones/tablets while on-the-go!

- These applications often integrate seamlessly into existing software systems utilized across organizations; thus reducing manual paperwork errors significantly!

-

Real-Time Communication Tools

* Mobile apps facilitate real-time communication among team members responsible for handling shipments; ensuring everyone stays informed regarding any changes made concerning applied/broken/replaced seals!

Conclusion

The integration of technology into container sealing processes significantly enhances security while improving operational efficiency within logistics/supply chain sectors! By leveraging electronic solutions like RFID/GPS technology alongside innovative approaches such as blockchain/IOT/data analytics/mobile applications; organizations can effectively manage risks associated directly towards cargo integrity throughout its journey! As technology continues evolving further still; we can expect even more advancements aimed at optimizing this critical aspect concerning global trade operations!