What Is the Difference Between Container and Drayage

What is Container Shipping and How Does It Work?

Container shipping is the transportation of goods in standardized intermodal containers that can be easily transferred between ships, trains, and trucks. This method of shipping has revolutionized global trade by enabling the efficient movement of large volumes of cargo across long distances.

The container shipping process typically involves several key steps:

Packing and Loading

Goods are packed into containers at the point of origin, such as a factory or warehouse. Containers come in standard sizes, with the most common being 20-foot and 40-foot lengths. They are designed to be sturdy, secure, and stackable for optimal space utilization on ships and other transport vehicles.

Inland Transportation

Once loaded, containers are transported by truck or rail to a seaport or intermodal terminal. This leg of the journey is often referred to as the “first mile” and is crucial for ensuring that containers arrive at the port in time for their scheduled vessel departure.

Port Handling

At the port, containers are unloaded from trucks or trains and staged in a designated area. They are then loaded onto ships using specialized cranes that can efficiently move the heavy containers. Containers are stacked on the ship in a specific order to ensure vessel stability and optimize space utilization.

Ocean Voyage

The ship transports the containers to their destination port, which may involve crossing oceans and passing through canals such as the Panama or Suez. The duration of the voyage depends on factors such as distance, route, and vessel speed. Modern container ships can carry thousands of containers and travel at speeds of up to 25 knots.

Port Discharge

Upon arrival at the destination port, containers are unloaded from the ship using cranes and staged in the port terminal. They are then cleared through customs and other regulatory procedures before being released for inland transportation.

Inland Transportation

Containers are loaded onto trucks or trains for transport to their final destination, such as a distribution center or customer’s premises. This final leg of the journey is often referred to as the “last mile” and involves careful coordination to ensure timely delivery.

Throughout the container shipping process, advanced information systems are used to track the location and status of each container. This visibility enables supply chain participants to plan and execute their operations effectively.

The standardization of containers and the development of specialized handling equipment and infrastructure have made container shipping highly efficient and cost-effective compared to traditional break-bulk shipping methods. This has facilitated the growth of global trade and the development of complex international supply chains.

What is Drayage and Why is It Important in Logistics?

Drayage refers to the transportation of goods over a short distance, typically within a single metropolitan area or between a seaport and an inland intermodal terminal. It is a crucial component of the intermodal transportation system, as it connects the various modes of transport and enables the seamless movement of cargo.

The Role of Drayage in Logistics

Drayage plays a vital role in the overall logistics process by:

- Connecting Modes of Transport: Drayage trucks move containers between seaports, rail terminals, and other intermodal facilities, enabling the transfer of cargo from one mode of transport to another.

- Facilitating First and Last Mile Delivery: Drayage is often used for the initial and final legs of a shipment’s journey, known as the “first mile” and “last mile.” This involves transporting containers from a shipper’s facility to an intermodal terminal and from the terminal to the consignee’s premises.

- Optimizing Port and Terminal Operations: Efficient drayage operations help to reduce congestion and improve the flow of containers through ports and terminals. This is critical for maintaining the smooth functioning of the intermodal system.

- Supporting Just-in-Time Delivery: Drayage enables the timely delivery of goods to support just-in-time manufacturing and inventory management strategies. This helps businesses reduce costs and improve customer service.

Types of Drayage

There are several types of drayage, each serving a specific purpose in the intermodal transportation system:

| Type | Description |

|---|---|

| Inter-Carrier Drayage | Moving containers between different carriers, such as from rail to ship or vice versa. |

| Intra-Carrier Drayage | Moving containers between different locations within the same carrier’s network. |

| Expedited Drayage | Providing fast, time-sensitive transportation for urgent shipments. |

| Door-to-Door Drayage | Transporting containers directly from the shipper’s facility to the consignee’s premises. |

| Shuttle Drayage | Moving containers between congested ports and nearby off-site facilities for temporary storage. |

Challenges in Drayage Operations

While drayage is essential for the smooth functioning of intermodal logistics, it also presents several challenges:

- Congestion: Drayage operations are often concentrated around busy ports and terminals, leading to traffic congestion and delays.

- Driver Shortages: The drayage industry faces a chronic shortage of qualified drivers, which can impact capacity and service reliability.

- Equipment Imbalances: The uneven flow of containers can result in imbalances, with a surplus of empty containers in some locations and a shortage in others.

- Regulatory Compliance: Drayage operators must comply with a range of regulations related to safety, emissions, and labor practices, which can increase costs and complexity.

Despite these challenges, drayage remains a critical component of the intermodal logistics system. Innovations such as technology-enabled dispatching, collaborative planning, and alternative fuel vehicles are helping to improve the efficiency and sustainability of drayage operations.

How Do Container Shipping and Drayage Differ in Scope and Purpose?

While container shipping and drayage are both essential components of the intermodal transportation system, they differ in their scope and purpose.

Scope

Container shipping involves the long-distance transportation of goods, often across international borders and via ocean routes. It is a key enabler of global trade, connecting manufacturers, suppliers, and consumers around the world.

In contrast, drayage operates on a much smaller geographic scale, typically within a single metropolitan area or region. Its primary function is to connect the various modes of transport involved in intermodal shipping, such as ships, trains, and trucks.

Purpose

The main purpose of container shipping is to efficiently and cost-effectively transport large volumes of goods over long distances. By using standardized containers that can be easily transferred between different modes of transport, container shipping has revolutionized global supply chains and made it possible to move goods from one continent to another in a matter of weeks.

Drayage, on the other hand, serves as a critical link in the intermodal transportation chain. Its purpose is to facilitate the smooth flow of containers between different modes of transport and to enable the timely delivery of goods to their final destination.

Comparison Table

| Aspect | Container Shipping | Drayage |

|---|---|---|

| Geographic Scope | Global, long-distance | Local, short-distance |

| Primary Purpose | Efficient long-distance transportation | Connecting modes of transport |

| Modes of Transport | Ships, trains, trucks | Primarily trucks |

| Key Enabler of | Global trade | Intermodal logistics |

| Typical Distance | Hundreds to thousands of miles | Less than 100 miles |

| Duration | Days to weeks | Hours to days |

While container shipping and drayage serve different purposes and operate on different scales, they are both essential for the functioning of modern supply chains. Container shipping enables the global movement of goods, while drayage ensures that those goods can be efficiently transferred between modes of transport and delivered to their final destination.

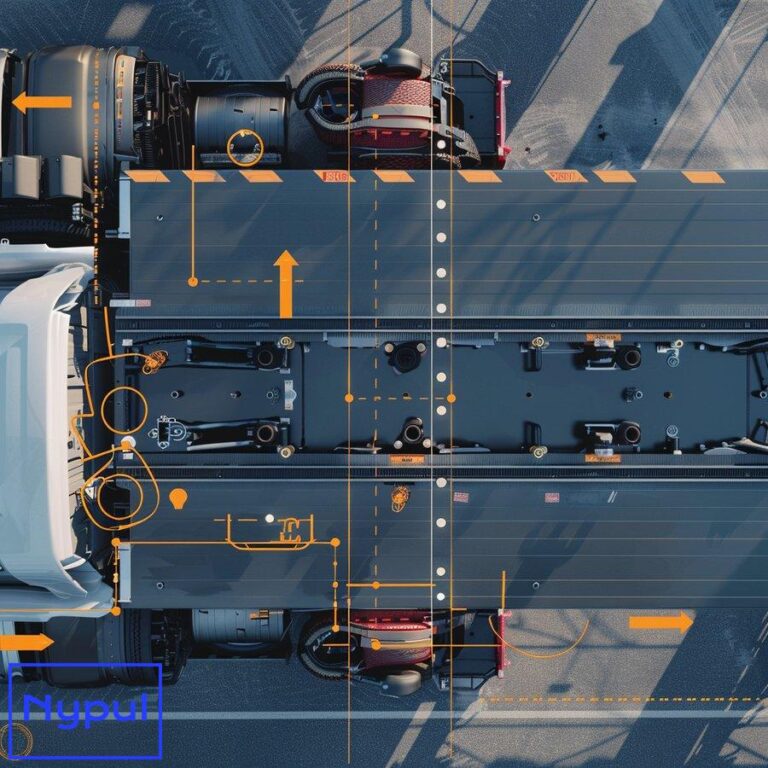

What Equipment and Infrastructure are Used in Container Shipping vs. Drayage?

Container shipping and drayage rely on specialized equipment and infrastructure to efficiently move containers and cargo. While there is some overlap, the specific equipment and infrastructure used in each segment of the intermodal transportation system are tailored to their unique operational requirements.

Container Shipping Equipment and Infrastructure

- Ships: Container ships are specifically designed to carry large numbers of standardized containers. They come in various sizes, with the largest capable of carrying over 20,000 twenty-foot equivalent units (TEUs). Key features include reinforced hulls, specialized cargo holds, and on-deck container stacking systems.

- Containers: Standardized intermodal containers are the backbone of the container shipping industry. The most common sizes are 20-foot and 40-foot lengths, with heights of 8 feet and 6 inches or 9 feet and 6 inches. They are made of sturdy materials like steel or aluminum and are designed to be stackable and secure.

- Ports: Container ports are specialized facilities designed to handle the loading, unloading, and storage of containers. They feature deep-water berths for large ships, extensive container storage yards, and specialized handling equipment like gantry cranes and straddle carriers.

- Intermodal Terminals: These facilities serve as connection points between different modes of transport, such as ships, trains, and trucks. They are equipped with cranes, storage areas, and other handling equipment to facilitate the efficient transfer of containers between modes.

Drayage Equipment and Infrastructure

- Trucks: Drayage primarily relies on trucks to transport containers over short distances. These trucks are typically designed to carry one or two containers at a time and may be equipped with specialized chassis for secure container transport.

- Chassis: Container chassis are trailers specifically designed to carry intermodal containers over the road. They come in various sizes to accommodate different container lengths and are equipped with locking mechanisms to secure the container during transport.

- Intermodal Terminals: Drayage operations often involve moving containers to and from intermodal terminals, which serve as key transfer points between modes of transport. These terminals are equipped with handling equipment and storage areas to facilitate the efficient flow of containers.

- Container Yards: These facilities are used for the temporary storage of containers awaiting pickup by drayage trucks or delivery to customers. They are equipped with handling equipment like reach stackers and may offer additional services like container maintenance and repair.

Comparison Table

| Equipment/Infrastructure | Container Shipping | Drayage |

|---|---|---|

| Primary Transport Mode | Ships | Trucks |

| Key Handling Equipment | Gantry cranes, straddle carriers | Chassis, reach stackers |

| Main Facilities | Ports, intermodal terminals | Intermodal terminals, container yards |

| Typical Container Sizes | 20-foot, 40-foot | 20-foot, 40-foot, 53-foot domestic |

| Specialized Infrastructure | Deep-water berths, container stacking systems | Chassis pools, maintenance facilities |

While container shipping and drayage use some of the same equipment and infrastructure, such as standardized containers and intermodal terminals, they also have unique requirements based on their specific roles in the transportation system. The specialized equipment and infrastructure used in each segment are designed to optimize efficiency, safety, and reliability in their respective operations.

How Do Cost Structures Vary Between Container Shipping and Drayage?

Container shipping and drayage have distinct cost structures that reflect the differences in their operations, equipment, and infrastructure requirements. Understanding these cost structures is essential for businesses to effectively manage their supply chain expenses and make informed decisions about transportation options.

Container Shipping Costs

The cost structure of container shipping is influenced by several key factors:

- Vessel Costs: These include the capital costs of purchasing or leasing ships, as well as ongoing expenses like fuel, crew wages, and maintenance. Larger ships generally have lower per-unit costs due to economies of scale.

- Port Charges: Container shipping lines must pay various fees to ports, including terminal handling charges, berthing fees, and storage costs. These charges can vary significantly between ports and are often a major component of overall shipping costs.

- Bunker Fuel: Fuel is a significant expense for container shipping lines, and costs can fluctuate based on global oil prices. Many carriers use fuel surcharges to pass these costs on to shippers.

- Canal Fees: Ships transiting key waterways like the Panama and Suez Canals must pay tolls, which can add significantly to the cost of a voyage.

- Overhead Costs: Container shipping lines have substantial overhead expenses, including administrative staff, information technology systems, and marketing costs.

Drayage Costs

Drayage cost structures are influenced by factors specific to short-distance trucking operations:

- Labor Costs: Driver wages and benefits are a significant expense for drayage providers, particularly in light of industry-wide driver shortages.

- Equipment Costs: Drayage companies must purchase or lease trucks and chassis, which involve both upfront capital costs and ongoing maintenance expenses.

- Fuel Costs: While drayage operations cover shorter distances than long-haul trucking, fuel is still a significant expense and can fluctuate based on local market conditions.

- Insurance and Regulatory Compliance: Drayage providers must maintain insurance coverage and comply with various safety and environmental regulations, which can add to their cost structure.

- Operational Inefficiencies: Drayage operations are often subject to delays and inefficiencies due to factors like port congestion, equipment imbalances, and customs clearance issues. These can increase costs and impact profitability.

Comparison Table

| Cost Component | Container Shipping | Drayage |

|---|---|---|

| Primary Cost Drivers | Vessel costs, port charges, fuel | Labor, equipment, fuel |

| Fuel Cost Exposure | High, subject to global oil prices | Moderate, subject to local market conditions |

| Regulatory Costs | Environmental regulations, canal fees | Safety regulations, emissions standards |

| Operational Inefficiencies | Port congestion, vessel delays | Port congestion, equipment imbalances |

| Overhead Costs | High, due to global scale of operations | Moderate, focused on local operations |

While both container shipping and drayage face cost pressures, the specific drivers and magnitude of these costs can vary significantly. Container shipping costs are heavily influenced by global economic factors and the capital-intensive nature of vessel operations, while drayage costs are more closely tied to local labor and equipment expenses.

Businesses must carefully evaluate the cost structures of both container shipping and drayage when making transportation decisions, as well as consider the potential impact of operational inefficiencies and regulatory compliance requirements. By understanding these cost drivers, companies can optimize their supply chain strategies and effectively manage transportation expenses.

What Are the Regulatory Considerations for Container Shipping and Drayage?

Container shipping and drayage are subject to a range of regulations at the international, national, and local levels. These regulations are designed to ensure safety, security, and environmental protection in the intermodal transportation system. Compliance with these regulations is essential for businesses to avoid penalties, maintain operational efficiency, and protect their reputation.

Container Shipping Regulations

- International Maritime Organization (IMO) Standards: The IMO sets global standards for the safety and environmental performance of ships, including container vessels. Key regulations include the International Convention for the Safety of Life at Sea (SOLAS) and the International Convention for the Prevention of Pollution from Ships (MARPOL).

- Port State Control: Countries have the authority to inspect foreign ships calling at their ports to ensure compliance with international regulations. Ships that fail to meet standards may be detained or fined.

- Customs Regulations: Container shipping is subject to customs regulations in both the exporting and importing countries. These regulations govern the documentation, inspection, and clearance of containerized cargo.

- Security Regulations: The International Ship and Port Facility Security (ISPS) Code sets global standards for the security of ships and port facilities. It requires measures like security assessments, access control, and monitoring to prevent threats like terrorism and smuggling.

Drayage Regulations

- Federal Motor Carrier Safety Regulations: In the United States, drayage operations are subject to safety regulations set by the Federal Motor Carrier Safety Administration (FMCSA). These regulations cover areas like driver qualifications, hours of service, vehicle maintenance, and cargo securement.

- Environmental Regulations: Drayage trucks are subject to emissions standards set by the Environmental Protection Agency (EPA) and state or local authorities. Some ports have implemented clean truck programs that set additional requirements for drayage vehicles to reduce air pollution.

- Labor Regulations: Drayage operations are subject to labor regulations governing issues like minimum wage, overtime pay, and worker classification. The classification of drayage drivers as employees or independent contractors has been a contentious issue in some jurisdictions.

- Local Port and Terminal Regulations: Individual ports and terminals may have their own regulations and requirements for drayage operations, such as mandatory appointment systems, equipment standards, and insurance requirements.

Comparison Table

| Regulatory Area | Container Shipping | Drayage |

|---|---|---|

| Safety | IMO SOLAS Convention | FMCSA Regulations |

| Environmental | IMO MARPOL Convention | EPA Emissions Standards, Clean Truck ProgramsEnvironmental |

| Security | ISPS Code | FMCSA Hazardous Materials Regulations |

| Customs | International Customs Regulations | Domestic Customs Regulations |

| Labor | International Labor Organization Standards | Domestic Labor Laws, Port-Specific Requirements |

Compliance with these regulations is critical for both container shipping and drayage operations. Failure to meet regulatory requirements can result in penalties, delays, and reputational damage. Some key considerations for businesses include:

- Staying Up-to-Date: Regulations are subject to change, so it’s essential to stay informed about new requirements and deadlines. Industry associations and legal counsel can provide guidance on regulatory compliance.

- Investing in Compliance: Complying with regulations may require investments in areas like equipment upgrades, staff training, and recordkeeping systems. These investments should be factored into business planning and budgeting.

- Partnering with Compliant Providers: When selecting container shipping lines and drayage providers, businesses should consider their compliance record and commitment to meeting regulatory standards. Working with compliant partners can help mitigate risk and ensure smooth operations.

- Proactive Management: Businesses should take a proactive approach to regulatory compliance, rather than waiting for issues to arise. This may involve conducting internal audits, establishing clear policies and procedures, and fostering a culture of compliance throughout the organization.

By understanding and effectively managing the regulatory considerations for container shipping and drayage, businesses can ensure the safety, security, and sustainability of their intermodal transportation operations.

How Do Container Shipping and Drayage Integrate in the Supply Chain?

Container shipping and drayage are critical components of the intermodal transportation system that enables the global flow of goods. While each segment has its own distinct role and characteristics, they must work together seamlessly to ensure the efficient and reliable movement of cargo through the supply chain.

The Intermodal Supply Chain

The integration of container shipping and drayage occurs within the context of the broader intermodal supply chain, which involves the use of multiple modes of transportation to move goods from origin to destination. A typical intermodal supply chain may include the following steps:

- Origin Drayage: Goods are loaded into containers at the shipper’s facility and transported by truck to an intermodal terminal or port.

- Container Shipping: The containers are loaded onto a ship and transported to the destination port, often via ocean routes.

- Destination Drayage: Once the ship arrives at the port, the containers are unloaded and transported by truck to the consignee’s facility or a nearby intermodal terminal.

- Inland Transportation: If the final destination is not located near the port, the containers may be loaded onto trains or trucks for further inland transportation.

Throughout this process, container shipping and drayage must be carefully coordinated to ensure that containers are moved efficiently and arrive at their intended destination on time.

Key Integration Points

There are several key points where container shipping and drayage operations must integrate to facilitate the smooth flow of cargo:

- Intermodal Terminals: These facilities serve as the primary connection points between container shipping and drayage. Terminals must be designed and operated to enable the efficient transfer of containers between ships, trains, and trucks.

- Port Operations: Ports play a critical role in integrating container shipping and drayage by providing the infrastructure and services needed to load and unload ships, store containers, and process cargo through customs.

- Information Sharing: Effective integration requires the sharing of timely and accurate information between container shipping lines, drayage providers, and other supply chain partners. This may involve the use of electronic data interchange (EDI) systems, application programming interfaces (APIs), and other digital technologies.

- Scheduling and Planning: The schedules of container ships and drayage operations must be carefully coordinated to minimize delays and ensure the efficient use of resources. This may involve the use of advanced planning and optimization tools to align vessel arrivals, truck dispatching, and container movements.

Benefits of Effective Integration

When container shipping and drayage are effectively integrated, it can provide significant benefits for supply chain stakeholders, including:

- Reduced Costs: Seamless integration can help minimize delays, reduce container dwell times, and optimize the use of transportation assets, leading to lower overall supply chain costs.

- Improved Reliability: Effective integration can help ensure that cargo arrives at its intended destination on time and in good condition, improving the reliability of the supply chain.

- Enhanced Visibility: The sharing of real-time information between container shipping lines and drayage providers can provide greater visibility into the status and location of cargo, enabling better decision-making and problem-solving.

- Increased Efficiency: By optimizing the flow of containers through the intermodal system, effective integration can help increase the overall efficiency of the supply chain, reducing waste and maximizing resource utilization.

To achieve these benefits, supply chain stakeholders must work together to develop and implement effective strategies for integrating container shipping and drayage operations. This may involve investments in infrastructure, technology, and process improvements, as well as ongoing collaboration and communication between partners.

By recognizing the critical role that container shipping and drayage play in the intermodal supply chain and taking steps to ensure their effective integration, businesses can create more resilient, efficient, and responsive supply chains that are better equipped to meet the challenges of today’s global marketplace.