What Is the Difference Between Drayage and Transloading

What are drayage and transloading in logistics?

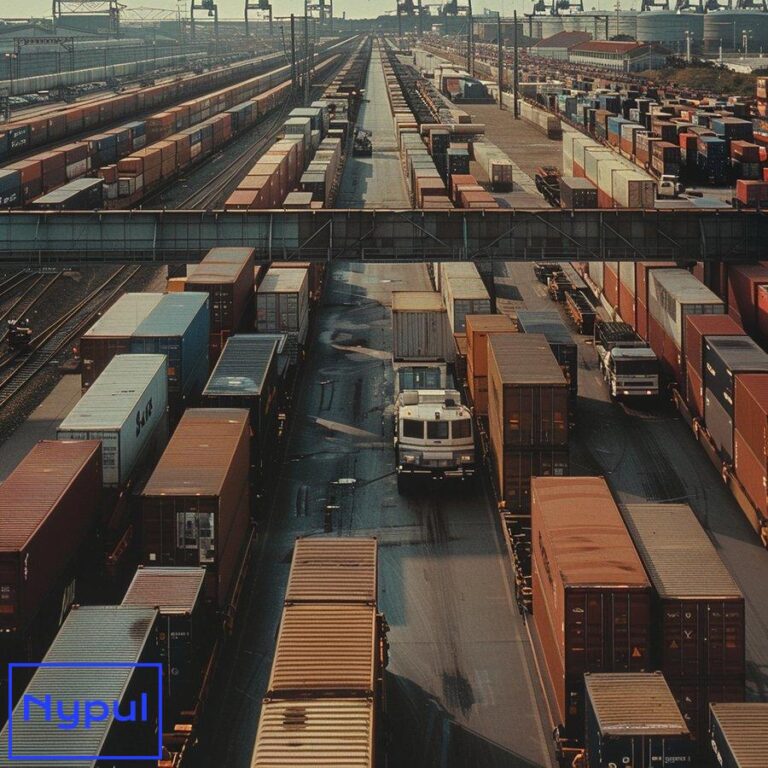

Drayage and transloading are integral components of the logistics and supply chain management landscape. Understanding these terms is essential for businesses engaged in shipping and receiving goods, especially in today’s complex global market.

Defining Drayage

Drayage refers to the short-distance transportation of goods, typically involving the movement of shipping containers from ports, rail yards, or warehouses to their next destination. The term originates from the use of horse-drawn wagons, known as “drays,” which were employed to haul goods before the advent of modern transportation methods.

Drayage services are critical in the logistics chain, facilitating the transfer of cargo for final delivery. This process often involves specialized equipment, such as chassis designed for shipping containers, to ensure safe and efficient transport.

Defining Transloading

Transloading, on the other hand, is the process of transferring goods from one mode of transportation to another. This typically occurs at intermodal facilities where cargo is moved from a shipping container to a truck or rail car. Transloading is essential for optimizing shipping efficiency, as it allows for the consolidation of goods into larger containers, often resulting in cost savings and reduced transit times.

Transloading can involve multiple steps, including unloading goods from a container, storing them temporarily, and then loading them onto a different vehicle for further transport. This process is especially advantageous for businesses that need to move goods over long distances or require flexibility in their shipping operations.

Summary of Differences

| Aspect | Drayage | Transloading |

|---|---|---|

| Definition | Short-distance transport of goods | Transfer of goods between transport modes |

| Purpose | Final delivery to a destination | Optimize shipping efficiency |

| Equipment Used | Chassis for containers | Forklifts, storage facilities |

| Distance | Typically within a few miles | Can cover longer distances |

Understanding these definitions sets the stage for exploring the differences in purpose and function between drayage and transloading.

How do drayage and transloading differ in purpose and function?

The distinction between drayage and transloading lies primarily in their respective purposes and functions within the logistics process.

Purpose of Drayage

Drayage serves a specific function in the logistics chain: it is designed to move goods over short distances. This service is essential for transporting containers from ports or rail yards directly to warehouses or distribution centers. Drayage is often the final leg of the transportation journey, ensuring that goods reach their destination quickly and efficiently.

Purpose of Transloading

Transloading, in contrast, is more versatile and is utilized for transferring goods across different modes of transportation. This process is particularly useful when goods need to be moved from a shipping container to a truck or rail car for further distribution. Transloading enables businesses to consolidate shipments, optimize space, and reduce overall shipping costs.

Functional Differences

-

Drayage is focused on the short-haul aspect of logistics, ensuring timely delivery of goods to their final destination. It involves minimal handling and is often executed quickly to reduce delays in the supply chain.

-

Transloading involves multiple handling steps, including unloading, storage, and reloading of goods. This process can be more complex due to the need for coordination between different transportation modes and facilities.

Conclusion

In summary, drayage is a short-distance transport service aimed at final delivery, while transloading is a multi-step process that facilitates the transfer of goods between various transportation modes. Understanding these differences is crucial for businesses seeking to optimize their logistics operations.

What are the key steps in the drayage process?

The drayage process involves several key steps that ensure the efficient movement of goods from one location to another. Each step plays a vital role in maintaining the integrity and timeliness of the logistics operation.

Step 1: Container Pickup

The first step in the drayage process is the pickup of the shipping container from a port or rail yard. This involves coordinating with the shipping line or rail operator to ensure that the container is ready for transport.

Step 2: Transport to Destination

Once the container is picked up, it is transported to its next destination, which could be a warehouse, distribution center, or directly to the customer. This step requires careful planning to ensure that the route is efficient and that any potential delays are minimized.

Step 3: Unloading and Delivery

Upon arrival at the destination, the container is unloaded. This may involve the use of specialized equipment, such as forklifts or cranes, to safely remove the goods from the container. After unloading, the goods are delivered to the designated location within the facility.

Step 4: Container Return

After the delivery of the goods, the empty container is returned to the port or rail yard. This step is crucial, as it ensures that containers are available for future shipments and helps to maintain the flow of logistics operations.

Summary of the Drayage Process

| Step | Description |

|---|---|

| Container Pickup | Retrieve container from port or rail yard |

| Transport | Move container to the destination |

| Unloading | Safely unload goods from the container |

| Container Return | Return empty container to port or rail yard |

Conclusion

Each step in the drayage process is designed to ensure that goods are transported efficiently and safely. Understanding these steps can help businesses better manage their logistics operations and improve overall supply chain performance.

How does the transloading process work?

Transloading is a multi-faceted process that involves several stages to ensure the efficient transfer of goods between different modes of transportation. Each stage is critical for optimizing shipping efficiency and reducing costs.

Step 1: Arrival at Transloading Facility

The transloading process begins with the arrival of goods at a transloading facility. This facility is typically equipped with the necessary infrastructure, such as loading docks and storage areas, to handle various types of cargo.

![]()

Step 2: Unloading Goods

Once the goods arrive, they are unloaded from the shipping container. This is often done using forklifts or pallet jacks, which allow for the safe and efficient removal of pallets from the container.

Step 3: Temporary Storage

After unloading, the goods may be stored temporarily at the transloading facility. This step is essential when there is a delay in transferring the goods to the next mode of transportation. Proper storage conditions are maintained to prevent damage to the cargo.

Step 4: Loading onto New Transportation

Once the next mode of transportation is ready, the goods are loaded onto trucks, rail cars, or other shipping containers. This step may involve consolidating multiple shipments into a single container to maximize space and reduce costs.

Step 5: Departure for Final Destination

After loading, the goods are dispatched to their final destination. This could involve further transport via truck or rail, depending on the logistics plan.

Summary of the Transloading Process

| Step | Description |

|---|---|

| Arrival | Goods arrive at the transloading facility |

| Unloading | Goods are unloaded from the shipping container |

| Temporary Storage | Goods may be stored until the next transport is ready |

| Loading | Goods are loaded onto the new mode of transport |

| Departure | Goods are dispatched to their final destination |

Conclusion

The transloading process is designed to facilitate the efficient transfer of goods between different transportation modes. By understanding each step, businesses can better manage their logistics operations and improve supply chain efficiency.

When should you choose drayage over transloading?

Choosing between drayage and transloading depends on various factors related to the specific logistics needs of a business. Understanding when to utilize each service is essential for optimizing shipping efficiency and cost-effectiveness.

![]()

When to Choose Drayage

Drayage is the preferred option in situations where:

-

Short Distances: When the goods need to be transported over short distances, such as from a port to a nearby warehouse or distribution center, drayage is the most efficient choice.

-

Final Delivery: If the goal is to complete the last leg of the delivery process, drayage is essential for ensuring that goods reach their final destination quickly.

-

Limited Handling: In cases where minimal handling is required, drayage reduces the risk of damage to the cargo, making it a safer option.

When to Choose Transloading

Transloading should be considered when:

-

Long-Distance Transport: If goods need to be moved over long distances, transloading allows for the consolidation of shipments, making it more cost-effective.

-

Multiple Modes of Transport: When shipments require multiple modes of transport (e.g., from ship to truck), transloading is necessary to facilitate this transfer.

-

Space Optimization: If there is a need to maximize container space, transloading enables businesses to combine multiple shipments into larger containers, reducing overall shipping costs.

Summary of Considerations

| Factor | Drayage | Transloading |

|---|---|---|

| Distance | Short distances | Long distances |

| Delivery Type | Final delivery | Multiple transport modes |

| Handling | Minimal handling | Requires more handling |

| Cost Efficiency | Less cost-effective for long distances | More cost-effective for long distances |

Conclusion

The decision to choose drayage or transloading hinges on the specific logistics requirements of a business. By evaluating the distance, delivery type, handling needs, and cost considerations, businesses can make informed choices that enhance their supply chain efficiency.

How do drayage and transloading impact supply chain efficiency?

Both drayage and transloading play significant roles in enhancing supply chain efficiency. Understanding their impact can help businesses optimize their logistics operations and improve overall performance.

Impact of Drayage on Supply Chain Efficiency

-

Speed of Delivery: Drayage facilitates quick transport of goods from ports or rail yards to their final destinations. This speed is crucial for businesses that rely on timely deliveries to meet customer demands.

-

Reduced Handling Time: With drayage, goods are transported directly to their destination with minimal handling. This reduces the risk of damage and delays associated with multiple transfers.

-

Improved Coordination: Drayage services often involve close coordination with shipping lines and rail operators, ensuring that containers are picked up and delivered on time.

Impact of Transloading on Supply Chain Efficiency

-

Cost Savings: Transloading allows businesses to consolidate shipments, reducing overall shipping costs. By maximizing container space, companies can save on transportation expenses.

-

Flexibility in Shipping: Transloading provides businesses with the flexibility to adapt their shipping strategies based on changing needs. This adaptability is essential in a dynamic market.

-

Streamlined Operations: By facilitating the transfer of goods between different modes of transport, transloading streamlines logistics operations, reducing bottlenecks and improving overall efficiency.

Summary of Impact on Supply Chain Efficiency

| Aspect | Drayage | Transloading |

|---|---|---|

| Delivery Speed | Quick transport to final destinations | Efficient transfer between transport modes |

| Handling Time | Minimal handling | More handling, but optimized |

| Cost Efficiency | Less cost-effective for long distances | More cost-effective for long distances |

| Coordination | Improved coordination with carriers | Streamlined operations |

Conclusion

Both drayage and transloading significantly impact supply chain efficiency. By leveraging these services effectively, businesses can enhance their logistics operations, reduce costs, and improve customer satisfaction.

What technologies are revolutionizing drayage and transloading operations?

![]()

The logistics industry is undergoing a technological transformation that is revolutionizing drayage and transloading operations. Emerging technologies are enhancing efficiency, reducing costs, and improving overall service quality.

Automation in Drayage

-

Automated Vehicles: The introduction of automated trucks and delivery vehicles is streamlining drayage operations. These vehicles can operate with minimal human intervention, reducing labor costs and increasing efficiency.

-

Real-Time Tracking: Advanced tracking systems allow businesses to monitor the location and status of their shipments in real time. This transparency improves coordination and helps mitigate delays.

Data Analytics in Transloading

-

Predictive Analytics: Data analytics tools enable businesses to forecast demand and optimize their shipping strategies. By analyzing historical data, companies can make informed decisions about when and how to transload goods.

-

Inventory Management: Advanced inventory management systems help businesses track their stock levels and optimize storage space at transloading facilities. This efficiency reduces the risk of overstocking or stockouts.

Integration of IoT

-

Internet of Things (IoT): IoT devices are being used to monitor cargo conditions during transport. Sensors can track temperature, humidity, and other factors, ensuring that goods are transported under optimal conditions.

-

Connected Supply Chains: IoT technology enables seamless communication between different stakeholders in the supply chain, improving coordination and reducing delays.

Summary of Technological Innovations

| Technology | Impact on Drayage | Impact on Transloading |

|---|---|---|

| Automation | Streamlined operations | Enhanced efficiency |

| Real-Time Tracking | Improved coordination | Better shipment visibility |

| Predictive Analytics | Informed decision-making | Optimized shipping strategies |

| Inventory Management | Efficient use of storage | Reduced risk of overstocking |

| IoT | Enhanced cargo monitoring | Connected supply chains |

Conclusion

Technological advancements are transforming drayage and transloading operations, leading to increased efficiency and cost savings. By embracing these innovations, businesses can enhance their logistics capabilities and remain competitive in the evolving market.

In conclusion, understanding the differences between drayage and transloading is essential for businesses engaged in logistics. By leveraging these services effectively and embracing technological advancements, companies can optimize their supply chain operations and improve overall efficiency.