What Is the Most Common Transportation for Hazardous Materials

What are hazardous materials and why is their transportation important?

Hazardous materials, often referred to as hazmat, are substances or materials that pose potential risks to health, safety, property, or the environment during transportation. These materials can be in various forms – solids, liquids, or gases – and include items like explosives, flammable liquids, toxic substances, radioactive materials, and corrosives.

The U.S. Department of Transportation (DOT) classifies hazardous materials into nine primary classes:

Class 1: Explosives – Substances and articles that have a mass explosion hazard, such as fireworks, ammunition, and blasting agents.

Class 2: Gases – Flammable, non-flammable, and toxic gases like propane, helium, and chlorine.

Class 3: Flammable Liquids – Liquids with a flash point below 60°C (140°F), including gasoline, diesel fuel, and paint thinners.

Class 4: Flammable Solids – Materials that are readily combustible or may cause fire through friction, such as matches and certain metal powders.

Class 5: Oxidizing Substances and Organic Peroxides – Materials that yield oxygen and can intensify fires, like hydrogen peroxide and ammonium nitrate.

Class 6: Toxic and Infectious Substances – Materials that are poisonous or can spread diseases, including pesticides and biological samples.

Class 7: Radioactive Materials – Substances that emit ionizing radiation, such as uranium and medical isotopes.

Class 8: Corrosive Substances – Materials that can destroy living tissue or corrode metals, like sulfuric acid and sodium hydroxide.

Class 9: Miscellaneous Hazardous Materials – Materials that present a hazard during transport but do not meet the criteria of other classes, such as lithium batteries and dry ice.

The transportation of hazardous materials is crucial for various industries and sectors of the economy. These materials play essential roles in manufacturing, agriculture, healthcare, energy production, and countless other applications. For example:

- Chemicals are transported to factories for use in production processes.

- Fuels are delivered to gas stations and power plants.

- Medical isotopes are shipped to hospitals for diagnostic and therapeutic purposes.

- Pesticides and fertilizers are distributed to farms to support agricultural production.

The safe and efficient transportation of hazardous materials ensures that these vital substances reach their destinations while minimizing risks to public safety and the environment. Without a robust hazmat transportation system, many industries would grind to a halt, and essential services would be disrupted.

However, the transportation of hazardous materials also presents significant challenges. The inherent dangers associated with these substances require strict regulations, specialized handling procedures, and comprehensive safety measures. Accidents involving hazardous materials can have severe consequences, including fires, explosions, toxic releases, and environmental contamination.

To illustrate the scale and importance of hazardous materials transportation, consider the following statistics from the U.S. Department of Transportation:

| Statistic | Value |

|---|---|

| Annual hazmat shipments in the U.S. | Over 3 billion tons |

| Daily hazmat shipments in the U.S. | Approximately 1 million |

| Percentage of all freight tonnage that is hazmat | 7-10% |

| Annual value of hazmat shipments | Over $1.4 trillion |

These figures underscore the critical role that hazardous materials transportation plays in the U.S. economy and daily life. The sheer volume of hazmat shipments highlights the need for a reliable, efficient, and safe transportation system.

The importance of hazardous materials transportation extends beyond economic considerations. Proper handling and transport of these materials are essential for:

Public Safety – Preventing accidents and minimizing risks to communities along transportation routes.

Environmental Protection – Safeguarding ecosystems from potential contamination due to spills or releases.

Emergency Response – Ensuring that first responders have accurate information about the materials involved in case of an incident.

Regulatory Compliance – Meeting national and international standards for the safe movement of dangerous goods.

Supply Chain Efficiency – Enabling just-in-time delivery of critical materials to support various industries.

Innovation and Research – Facilitating the movement of specialized materials needed for scientific and technological advancements.

The transportation of hazardous materials requires a delicate balance between efficiency and safety. As industries continue to evolve and new hazardous materials are developed, the importance of a robust and adaptable transportation system becomes even more pronounced. The next sections will explore why road transportation has emerged as the dominant mode for moving these critical yet potentially dangerous substances.

Why is road transportation the most common method for hazardous materials?

Road transportation has emerged as the predominant method for moving hazardous materials, outpacing other modes such as rail, air, and sea. This dominance stems from a combination of factors that make trucking particularly well-suited for the unique challenges posed by hazmat shipments.

Flexibility and Accessibility

One of the primary advantages of road transportation is its unparalleled flexibility. Trucks can reach virtually any location with a road connection, providing door-to-door service that other modes cannot match. This flexibility is crucial for hazardous materials, which often need to be delivered to specific facilities or locations that may not have direct access to rail lines, ports, or airports.

Road networks are extensively developed in most countries, offering a vast and interconnected system of highways, roads, and streets. This extensive infrastructure allows for:

- Direct routing to final destinations

- Ability to serve remote or rural areas

- Quick adaptation to changes in demand or emergencies

- Seamless intermodal connections when needed

Cost-Effectiveness

For many hazardous materials shipments, especially over short to medium distances, road transportation offers the most cost-effective solution. Factors contributing to this cost-effectiveness include:

- Lower initial capital investment compared to rail or air transport

- Ability to transport smaller quantities economically

- Reduced handling and transfer points, minimizing potential risks

- Competitive pricing due to a large number of carriers in the market

To illustrate the cost advantage, consider the following comparison of transportation costs for a hypothetical 500-mile hazmat shipment:

| Mode of Transport | Cost per Ton-Mile | Total Cost for 500 Miles (10-ton shipment) |

|---|---|---|

| Road (Truck) | $0.15 – $0.30 | $750 – $1,500 |

| Rail | $0.03 – $0.08 | $150 – $400 (plus additional trucking costs) |

| Air Freight | $1.50 – $4.50 | $7,500 – $22,500 |

While rail may appear cheaper at first glance, the additional costs of trucking to and from rail terminals often make road transport more economical, especially for shorter distances or when door-to-door service is required.

Speed and Timeliness

Road transportation offers a balance of speed and reliability that is particularly valuable for hazardous materials shipments. Trucks can often deliver hazmat cargo faster than rail for short to medium distances, and with greater predictability than air freight, which is subject to weather delays and limited scheduling options.

The ability to provide just-in-time delivery is crucial for many industries that rely on hazardous materials. For example:

- Hospitals requiring regular deliveries of medical gases

- Manufacturing plants needing specific chemicals for production processes

- Gas stations requiring frequent fuel deliveries

Road transport allows for precise scheduling and rapid response to changing demand, minimizing storage requirements and associated risks at both origin and destination points.

Regulatory Familiarity and Compliance

The trucking industry has a long history of transporting hazardous materials, resulting in a well-established regulatory framework and a high level of familiarity among carriers, shippers, and regulators. This regulatory environment includes:

- Comprehensive driver training programs specific to hazmat transportation

- Well-defined packaging and labeling requirements

- Established emergency response procedures

- Regular inspections and compliance checks

The familiarity with hazmat regulations within the trucking industry contributes to a higher level of compliance and safety compared to other modes of transport that may handle hazardous materials less frequently.

Shipment Size and Frequency

Many hazardous materials shipments are relatively small in volume or require frequent deliveries, making road transportation the most practical option. Trucks can efficiently handle shipments ranging from a few hundred pounds to full truckloads, providing scalability that other modes struggle to match.

This scalability is particularly important for:

- Just-in-time inventory management

- Serving diverse customer bases with varying needs

- Handling specialized or custom hazardous materials

Direct Oversight and Control

Road transportation allows for direct oversight of hazardous materials throughout the entire journey. A trained hazmat driver can:

- Monitor the cargo continuously

- Respond quickly to any issues that arise

- Communicate effectively with shippers, receivers, and emergency responders if necessary

This level of control is often preferable for high-risk or high-value hazardous materials shipments where constant vigilance is required.

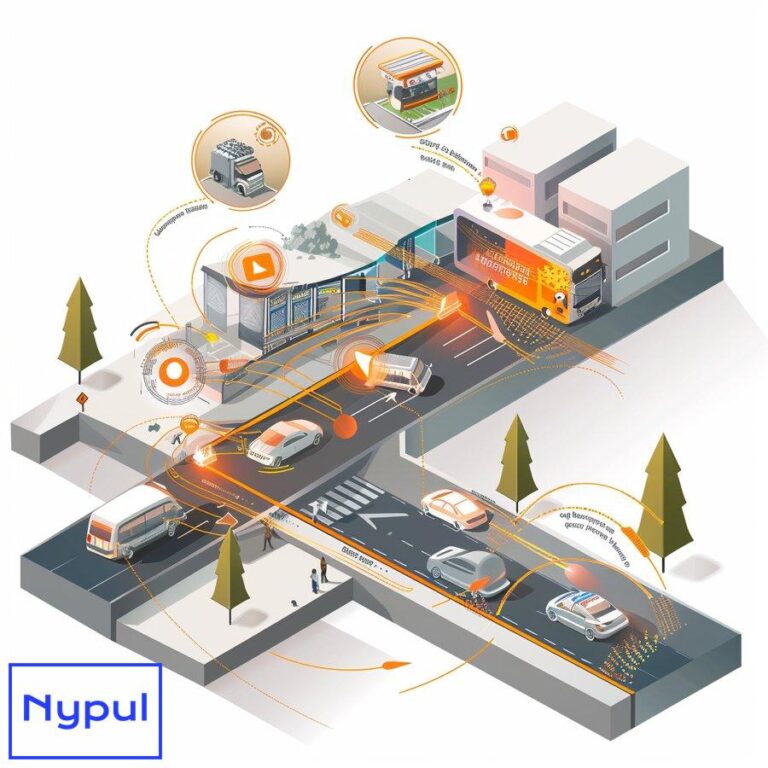

Intermodal Connectivity

While road transportation is often the primary mode for hazardous materials, it also plays a crucial role in intermodal shipments. Trucks serve as the first and last mile for many rail and air shipments, providing essential connections between different modes of transport.

This intermodal capability allows for:

- Optimal routing using a combination of transportation modes

- Access to remote locations not served by other modes

- Flexibility in responding to disruptions or changes in other transportation networks

Environmental Considerations

Although trucks are often criticized for their environmental impact, advancements in vehicle technology and fuel efficiency have made road transportation increasingly competitive from an environmental standpoint, especially for shorter distances. For hazardous materials transport, the ability to use specialized equipment and follow specific routes can actually reduce environmental risks compared to other modes.

The dominance of road transportation in hazardous materials shipping is not without challenges. Issues such as traffic congestion, driver shortages, and the potential for accidents on public roads are ongoing concerns. However, the combination of flexibility, cost-effectiveness, regulatory familiarity, and direct control continues to make trucking the preferred choice for most hazmat shipments.

As we delve deeper into the specifics of hazardous materials transportation by road, the next section will explore the types of vehicles used for these specialized shipments and how they contribute to the safety and efficiency of hazmat transport.

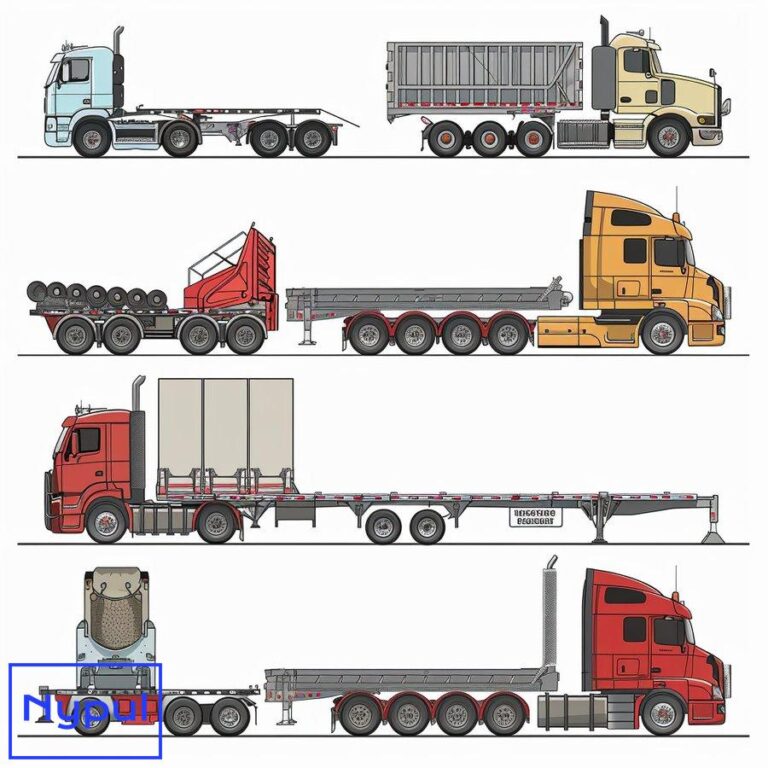

What types of vehicles are used for transporting hazardous materials by road?

The transportation of hazardous materials by road requires specialized vehicles designed to handle the unique challenges and risks associated with these dangerous goods. The type of vehicle used depends on the specific hazardous material being transported, its physical state (solid, liquid, or gas), the quantity being shipped, and the applicable regulations. Here’s an overview of the main types of vehicles used for hazmat transportation:

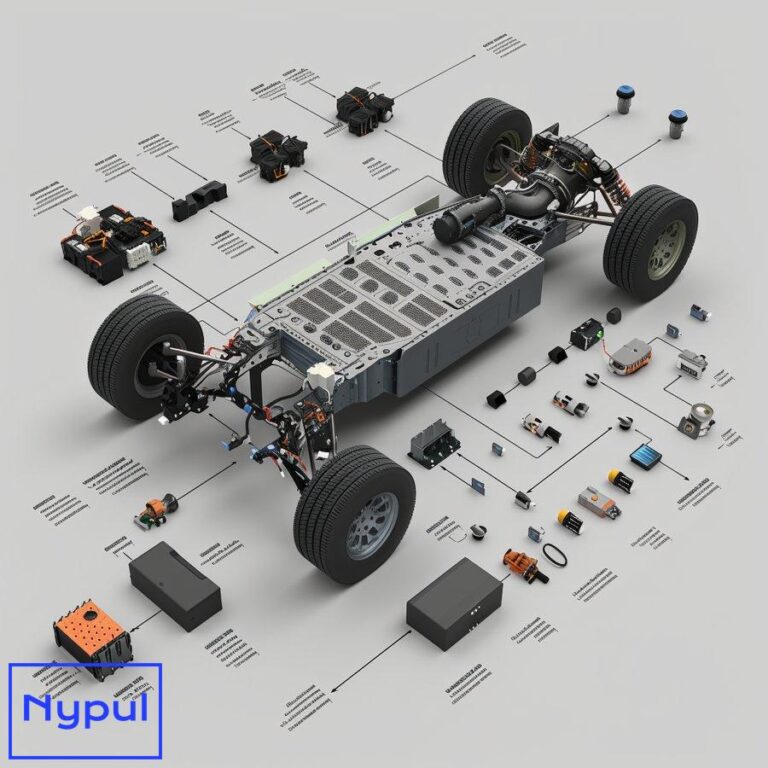

Tank Trucks

Tank trucks, also known as tankers, are among the most common vehicles used for transporting liquid and gaseous hazardous materials. These vehicles come in various configurations:

- Straight Trucks: Single-unit vehicles with the tank mounted directly on the truck chassis.

- Tractor-Trailers: Articulated vehicles consisting of a tractor unit pulling a tank trailer.

Tank trucks are further categorized based on their design and the materials they carry:

MC-Series Tanks: These are Department of Transportation (DOT) specification tanks designed for specific types of hazardous materials.

- MC-306/DOT-406: For flammable liquids like gasoline

- MC-307/DOT-407: For corrosive materials and low-pressure liquids

- MC-312/DOT-412: For corrosive materials and other hazardous liquids

- MC-331: For compressed gases like propane

Non-Specification Tanks: Used for less hazardous materials that don’t require DOT specification tanks.

Tank trucks are equipped with various safety features, including:

- Pressure relief valves

- Emergency shut-off systems

- Anti-rollover technology

- Specialized venting systems

Dry Bulk Trucks

Dry bulk trucks are used for transporting solid hazardous materials in granular, powdered, or pelletized form. These vehicles typically feature:

- Pneumatic tanks for materials that can be unloaded using air pressure

- Hopper bottoms for gravity unloading

- Specialized linings to prevent contamination or reaction with the cargo

Examples of hazardous materials transported in dry bulk trucks include:

- Cement (which can be caustic)

- Certain types of fertilizers

- Plastic pellets (which can be an environmental hazard)

Box Trucks and Van Trailers

For hazardous materials that are packaged in drums, boxes, or other containers, standard box trucks or van trailers may be used. These vehicles are often employed for:

- Mixed loads of different hazardous materials

- Smaller quantities of hazardous materials

- Materials that require temperature control

When used for hazmat transport, these vehicles must be properly placarded and may require additional safety equipment such as:

- Spill containment kits

- Fire extinguishers

- Personal protective equipment (PPE) for drivers

Flatbed Trucks

Flatbed trucks are sometimes used for transporting large containers or packaged hazardous materials that don’t require enclosed transportation. This might include:

- Intermediate Bulk Containers (IBCs)

- Cylinders of compressed gases

- Packaged radioactive materials

When using flatbeds, proper securing of the cargo is critical, and additional measures like tarping may be required to protect the load from the elements.

Specialized Vehicles

Some hazardous materials require highly specialized vehicles designed for specific types of cargo:

Explosives Trucks: Vehicles designed to transport explosives feature reinforced bodies, special suspension systems, and may include blast-mitigation technologies.

Cryogenic Tankers: Used for transporting super-cooled liquefied gases like liquid nitrogen or liquid oxygen. These feature highly insulated tanks and specialized pressure control systems.

Nuclear Transport Trucks: Vehicles for transporting radioactive materials are designed with extensive shielding and security features to protect the cargo and prevent unauthorized access.

To illustrate the diversity of hazmat vehicles and their applications, consider the following table:

| Vehicle Type | Common Hazmat Cargo | Key Features |

|---|---|---|

| MC-306 Tank Truck | Gasoline, Diesel | Aluminum shell, low pressure design |

| MC-331 Tank Truck | Propane, Ammonia | High pressure vessel, thick steel construction |

| Dry Bulk Truck | Cement, Fertilizers | Pneumatic or gravity unloading systems |

| Refrigerated Van | Temperature-sensitive chemicals | Temperature control, insulation |

| Flatbed with Conex | Packaged hazardous waste | Secure tie-down points, weather protection |

| Explosives Truck | Fireworks, Mining explosives | Reinforced body, special electrical systems |

Vehicle Selection Criteria

The selection of the appropriate vehicle for hazardous materials transportation depends on several factors:

Material Properties: The physical and chemical characteristics of the hazardous material dictate the type of containment required.

Quantity: The volume or weight of the material being shipped influences the size and capacity of the vehicle needed.

Regulatory Requirements: Different classes of hazardous materials have specific transportation requirements that must be met.

Route Considerations: The planned route may impact vehicle selection, especially if there are restrictions on certain types of vehicles in urban areas or on specific roadways.

Loading and Unloading Methods: The equipment available at origin and destination points may influence the choice of vehicle to ensure efficient handling.

Safety Features: The level of risk associated with the material may necessitate additional safety features or specialized vehicle designs.

Maintenance and Inspection

Vehicles used for hazardous materials transportation are subject to rigorous maintenance schedules and regular inspections. These include:

- Daily pre-trip inspections by drivers

- Periodic comprehensive inspections by qualified technicians

- Pressure testing for tank vehicles

- Specialized cleaning and decontamination procedures

The maintenance and inspection regimes are designed to ensure that vehicles remain in top condition, minimizing the risk of mechanical failures that could lead to accidents or releases of hazardous materials.

Future Trends

The field of hazardous materials transportation is continuously evolving, with new vehicle technologies emerging to enhance safety and efficiency:

- Alternative Fuel Vehicles: Development of electric and hydrogen-powered trucks for hazmat transport to reduce environmental impact.

- Advanced Telematics: Integration of real-time monitoring systems to track vehicle performance, cargo conditions, and driver behavior.

- Autonomous Technologies: Research into semi-autonomous or fully autonomous vehicles for hazardous materials transportation, potentially reducing human error.

- Smart Containment Systems: Development of “smart” tanks and containers with built-in sensors to detect leaks, pressure changes, or other potential issues.

The diverse array of vehicles used for hazardous materials transportation reflects the complexity and variety of materials being shipped. Each vehicle type is designed to address specific safety concerns and operational requirements, ensuring that hazardous materials can be transported efficiently while minimizing risks to public safety and the environment.

As we continue to explore the world of hazardous materials transportation, the next section will delve into the regulatory framework that gov## How do regulations govern the road transportation of hazardous materials?

The transportation of hazardous materials by road is subject to a comprehensive regulatory framework designed to ensure the safe movement of these dangerous goods. The primary regulations governing hazmat transport in the United States are:

Title 49 of the Code of Federal Regulations (49 CFR)

This set of regulations, published by the U.S. Department of Transportation (DOT), covers the classification, packaging, communication, and handling requirements for hazardous materials transported in the United States. Key parts of 49 CFR include:

- Part 171: General information, regulations, and definitions

- Part 172: Hazardous materials table, special provisions, and hazardous materials communications

- Part 173: Shippers – general requirements for shipments and packages

- Part 177: Carriage by public highway

International Maritime Dangerous Goods (IMDG) Code

While primarily focused on ocean transport, the IMDG Code also applies to road transport when hazardous materials are moved to or from ports as part of an international shipment.

International Air Transport Association (IATA) Dangerous Goods Regulations (DGR)

Similar to the IMDG Code, the IATA DGR provides requirements for air transport but may be referenced for road transport of materials destined for air shipment.

United Nations Recommendations on the Transport of Dangerous Goods (UN Model Regulations)

These recommendations serve as a basis for many national and international regulations, including 49 CFR, and provide a framework for the safe transport of hazardous materials.

Hazardous Materials Regulations (HMR)

The HMR, found in 49 CFR Parts 171-180, are the primary regulations governing the transportation of hazardous materials in the United States. The HMR cover:

- Classification and identification of hazardous materials

- Packaging requirements for containment of hazardous materials

- Hazard communication through labels, placards, and shipping papers

- Operational requirements for loading, unloading, and handling

- Training standards for personnel involved in hazmat transport

- Security requirements to prevent the misuse of hazardous materials

- Incident reporting and emergency response procedures

Hazardous Materials Safety Permits (HMSP)

The HMSP program requires certain motor carriers transporting high-risk hazardous materials to obtain a safety permit from the Federal Motor Carrier Safety Administration (FMCSA). To qualify for an HMSP, carriers must meet stringent safety requirements and demonstrate a strong safety record.

State and Local Regulations

In addition to federal regulations, some states and local jurisdictions have enacted their own laws and ordinances governing the transportation of hazardous materials. These may include:

- Route restrictions prohibiting hazmat transport on certain roads or through specific areas

- Time-of-day or day-of-week restrictions to avoid peak traffic periods or weekends

- Permitting requirements for hazmat transport within state or local boundaries

- Emergency response planning and coordination with local authorities

Enforcement and Penalties

The DOT and other agencies enforce hazardous materials regulations through:

- Roadside inspections of vehicles and cargo

- Compliance reviews of motor carriers

- Investigations of incidents and accidents involving hazardous materials

Violations of hazmat regulations can result in significant penalties, including:

- Civil penalties of up to $81,993 per violation

- Criminal penalties for willful violations, including fines and imprisonment

- Revocation or suspension of hazardous materials transportation privileges

The comprehensive regulatory framework governing hazardous materials transportation by road is designed to protect public safety, the environment, and transportation workers. By establishing clear standards for classification, packaging, communication, and handling, the regulations aim to minimize the risks associated with moving dangerous goods.

Compliance with hazmat regulations is a shared responsibility among shippers, carriers, drivers, and emergency responders. The next section will explore the specific safety measures implemented to ensure the safe transport of hazardous materials by road.

What safety measures are implemented in hazardous materials road transport?

The transportation of hazardous materials by road involves a multi-layered approach to safety, with numerous measures in place to protect the public, emergency responders, and the environment. These safety measures include:

Packaging and Containment

Hazardous materials must be packaged in containers that meet specific design, construction, and testing requirements. Packaging options include:

- Non-bulk packages like drums, boxes, and cans

- Intermediate Bulk Containers (IBCs)

- Portable tanks

- Cargo tanks for liquids and gases

Packages must be able to withstand the rigors of transportation without leaking or rupturing, even in the event of an accident or incident.

Hazard Communication

Clear communication of hazards is essential for the safe transport of dangerous goods. Hazmat shipments must be properly labeled, placarded, and accompanied by shipping papers that provide critical information about the materials being transported. This includes:

- Hazard class labels on individual packages

- Placards on the exterior of vehicles

- Emergency response information for first responders

- 24-hour emergency response telephone numbers

Vehicle Inspection and Maintenance

Vehicles used for hazardous materials transport undergo rigorous inspection and maintenance programs to ensure their roadworthiness and safety. This includes:

- Pre-trip inspections by drivers

- Periodic comprehensive inspections by qualified technicians

- Maintenance of brakes, tires, lights, and other critical systems

- Cleaning and decontamination to prevent cross-contamination or residue buildup

Driver Training and Qualifications

Drivers transporting hazardous materials must meet specific training and qualification requirements, including:

- Obtaining a Commercial Driver’s License (CDL) with a hazardous materials endorsement

- Completing hazmat-specific training on topics like hazard identification, emergency procedures, and loading/unloading techniques

- Passing a Transportation Security Administration (TSA) security background check

- Undergoing periodic recurrent training to maintain proficiency

Route Planning and Selection

Careful planning of transportation routes is essential for minimizing risks. Factors considered in route selection include:

- Proximity to population centers, schools, hospitals, and other sensitive areas

- Presence of bridges, tunnels, and other infrastructure limitations

- Potential for congestion and delays

- Availability of safe stopping locations and rest areas

Security Measures

Security measures are implemented to prevent the theft or misuse of hazardous materials during transport. These include:

- Locking and securing vehicles when unattended

- Conducting security background checks on drivers and other personnel

- Implementing chain-of-custody procedures to track custody of hazmat shipments

- Reporting any suspicious activities or security breaches to authorities

Emergency Response Planning

In the event of an accident or incident involving hazardous materials, emergency response planning is critical. Measures include:

- Providing emergency response information to first responders

- Maintaining spill response and containment equipment on vehicles

- Conducting joint training exercises with local emergency responders

- Developing pre-planned evacuation routes and shelter-in-place procedures

Incident Reporting and Investigation

Carriers are required to report any incidents involving hazardous materials to the National Response Center. These incidents are then investigated to determine the root cause and identify opportunities for improvement in safety practices.

Compliance Audits and Assessments

Shippers and carriers are subject to regular compliance audits and assessments by regulatory agencies and third-party auditors. These evaluations help ensure that safety measures are being properly implemented and maintained.

The combination of packaging requirements, hazard communication, vehicle inspections, driver training, route planning, security measures, and emergency response planning creates a comprehensive safety system for hazardous materials transportation by road. While the potential for accidents always exists, these measures significantly reduce the risks and help protect the public, transportation workers, and the environment.

As we continue to explore the world of hazardous materials transportation, the next section will compare road transport to other modes and examine the factors that contribute to the dominance of trucking for these specialized shipments.

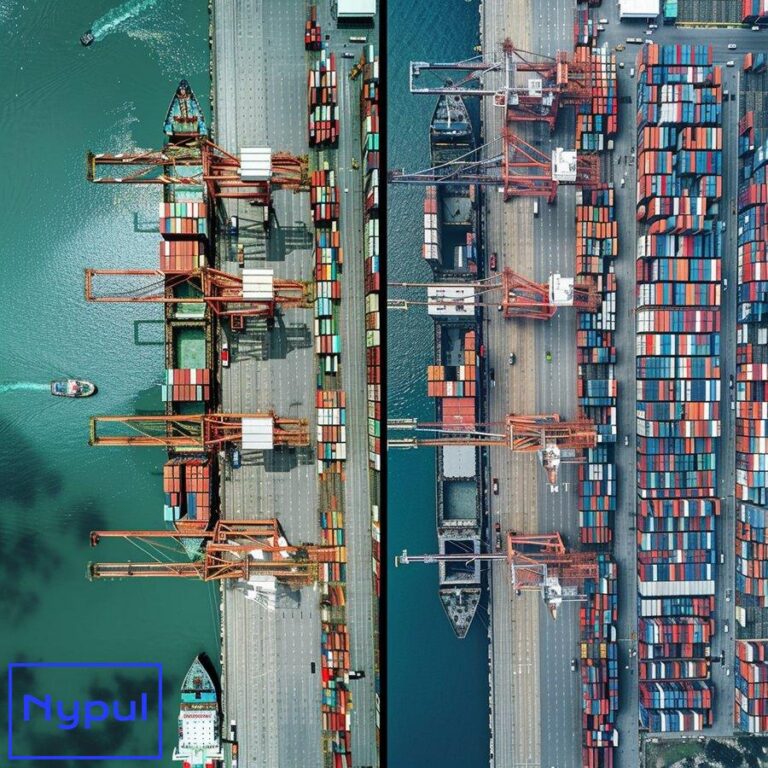

How does road transportation compare to other methods for hazardous materials?

While road transportation is the most common method for moving hazardous materials, other modes like rail, air, and water transport also play important roles in the overall hazmat supply chain. Each mode has its own advantages, disadvantages, and unique considerations when it comes to transporting dangerous goods. Let’s compare road transport to the other main methods:

Rail Transportation

Rail transport offers several advantages for hazardous materials shipments:

- Ability to move large volumes of hazardous materials efficiently

- Reduced exposure to traffic congestion and delays

- Lower fuel consumption and emissions per ton-mile compared to trucks

However, rail transport also has some drawbacks:

- Limited accessibility to final destinations, requiring additional trucking for first and last mile

- Potential for derailments and accidents that can result in large-scale releases

- Longer transit times compared to road transport for shorter distances

Air Transportation

Air transport is used primarily for small, high-value, or time-sensitive hazardous materials shipments:

- Fastest transit times for long-distance transport

- Ability to reach remote locations not served by other modes

- Reduced risk of ground-based accidents and spills

Disadvantages of air transport include:

- Strict quantity limitations on hazardous materials

- Higher costs compared to other modes

- Potential for delays due to weather or other air traffic issues

Water Transportation

Water transport, including ocean freight and inland waterways, is well-suited for large-volume, low-value hazardous materials:

- Ability to move massive quantities of hazardous materials efficiently

- Lower costs per ton compared to other modes

- Reduced road and rail congestion by moving freight via water

Drawbacks of water transport include:

- Slower transit times compared to other modes

- Limited accessibility to inland destinations without port facilities

- Potential for spills and environmental damage in the event of an accident

To illustrate the differences in hazardous materials transportation by mode, consider the following table:

| Mode | Advantages | Disadvantages |

|---|---|---|

| Road | – Flexibility and accessibility – Cost-effectiveness for short/medium distances – Speed and reliability – Familiarity with regulations |

– Exposure to traffic congestion – Potential for accidents on public roads – Limited capacity compared to rail or water |

| Rail | – Ability to move large volumes efficiently – Lower fuel consumption and emissions per ton-mile – Reduced exposure to traffic delays |

– Limited accessibility to final destinations – Potential for derailments and large-scale releases – Longer transit times for short distances |

| Air | – Fastest transit times for long distances – Ability to reach remote locations – Reduced risk of ground-based accidents |

– Strict quantity limitations – Higher costs – Potential for weather and air traffic delays |

| Water | – Ability to move massive quantities efficiently – Lower costs per ton – Reduced road and rail congestion |

– Slower transit times – Limited accessibility to inland destinations – Potential for environmental damage in case of spills |

The choice of transportation mode for hazardous materials depends on various factors, including:

- Quantity and volume of the shipment

- Time sensitivity and delivery requirements

- Proximity to ports, airports, and rail terminals

- Compatibility with the mode’s capacity and handling capabilities

- Applicable regulations and restrictions for each mode

While road transport is the most common method overall, other modes play crucial roles in the hazardous materials supply chain, particularly for long-distance, high-volume, or specialized shipments. The use of intermodal transportation, where multiple modes are combined for a single shipment, can help optimize efficiency and safety while leveraging the strengths of each mode.

As we delve deeper into the factors contributing to the dominance of road transport for hazardous materials, the next section will explore the unique characteristics of trucking that make it the preferred choice for many shippers and carriers.

What factors contribute to the dominance of road transport for hazardous materials?

Several key factors contribute to the dominance of road transportation for hazardous materials, making it the preferred choice for many shippers and carriers. These factors include:

Flexibility and Accessibility

As discussed earlier, the extensive network of roads and highways in most countries provides unparalleled flexibility and accessibility for hazardous materials transport. Trucks can reach virtually any destination with a road connection, offering door-to-door service that other modes cannot match. This flexibility is particularly valuable for:

- Serving remote or rural areas

- Delivering to specific facilities or locations

- Responding quickly to changes in demand or emergencies

Cost-Effectiveness

For many hazardous materials shipments, especially over short to medium distances, road transport offers the most cost-effective solution. Factors contributing to the cost-effectiveness of trucking include:

- Lower initial capital investment compared to rail or air transport

- Ability to transport smaller quantities economically

- Reduced handling and transfer points, minimizing potential risks

- Competitive pricing due to a large number of carriers in the market

Speed and Reliability

Road transportation provides a balance of speed and reliability that is particularly valuable for hazardous materials shipments. Trucks can often deliver hazmat cargo faster than rail for short to medium distances, and with greater predictability than air freight, which is subject to weather delays and limited scheduling options.

The ability to provide just-in-time delivery is crucial for many industries that rely on hazardous materials. Road transport allows for precise scheduling and rapid response to changing demand, minimizing storage requirements and associated risks at both origin and destination points.

Regulatory Familiarity and Compliance

The trucking industry has a long history of transporting hazardous materials, resulting in a well-established regulatory framework and a high level of familiarity among carriers, shippers, and regulators. This regulatory environment includes:

- Comprehensive driver training programs specific to hazmat transportation

- Well-defined packaging and labeling requirements

- Established emergency response procedures

- Regular inspections and compliance checks

The familiarity with hazmat regulations within the trucking industry contributes to a higher level of compliance and safety compared to other modes of transport that may handle hazardous materials less frequently.

Shipment Size and Frequency

Many hazardous materials shipments are relatively small in volume or require frequent deliveries, making road transportation the most practical option. Trucks can efficiently handle shipments ranging from a few hundred pounds to full truckloads, providing scalability that other modes struggle to match.

This scalability is particularly important for:

- Just-in-time inventory management

- Serving diverse customer bases with varying needs

- Handling specialized or custom hazardous materials

Direct Oversight and Control

Road transportation allows for direct oversight of hazardous materials throughout the entire journey. A trained hazmat driver can:

- Monitor the cargo continuously

- Respond quickly to any issues that arise

- Communicate effectively with shippers, receivers, and emergency responders if necessary

This level of control is often preferable for high-risk or high-value hazardous materials shipments where constant vigilance is required.

Intermodal Connectivity

While road transportation is often the primary mode for hazardous materials, it also plays a crucial role in intermodal shipments. Trucks serve as the first and last mile for many rail and air shipments, providing essential connections between different modes of transport.

This intermodal capability allows for:

- Optimal routing using a combination of transportation modes

- Access to remote locations not served by other modes

- Flexibility in responding to disruptions or changes in other transportation networks

Environmental Considerations

Although trucks are often criticized for their environmental impact, advancements in vehicle technology and fuel efficiency have made road transportation increasingly competitive from an environmental standpoint, especially for shorter distances. For hazardous materials transport, the ability to use specialized equipment and follow specific routes can actually reduce environmental risks compared to other modes.

The dominance of road transportation in hazardous materials shipping is not without challenges. Issues such as traffic congestion, driver shortages, and the potential for accidents on public roads are ongoing concerns. However, the combination of flexibility, cost-effectiveness, regulatory familiarity, and direct control continues to make trucking the preferred choice for most hazmat shipments.

As we continue to explore the world of hazardous materials transportation, the next section will delve into the main challenges and risks associated with moving these dangerous goods by road.

What are the main challenges and risks in road transportation of hazardous materials?

While road transportation is the most common method for moving hazardous materials, it also presents unique challenges and risks that must be carefully managed. Some of the main challenges and risks include:

Traffic Congestion and Delays

Hazardous materials transport by road is subject to the same traffic congestion and delays asTraffic Congestion and Delays

Hazardous materials transport by road is subject to the same traffic congestion and delays as other freight. Traffic jams can significantly impact delivery schedules, leading to increased costs and potential safety risks. Delays can also hinder emergency response efforts in case of an incident involving hazardous materials.

To mitigate these issues, carriers often employ route optimization strategies, utilizing real-time traffic data to adjust routes and avoid congested areas. However, unexpected road closures, construction, or accidents can still pose challenges.

Driver Shortages and Training

The trucking industry faces a persistent shortage of qualified drivers, which can impact the availability of vehicles for transporting hazardous materials. This shortage is compounded by the specialized training required for hazmat drivers, including obtaining a Commercial Driver’s License (CDL) with a hazardous materials endorsement.

The rigorous training and background checks necessary for hazmat transportation can deter potential drivers from entering the field. As a result, carriers may struggle to find enough qualified personnel to meet demand, leading to potential delays in shipments.

Accidents and Spills

Despite stringent safety measures, accidents involving hazardous materials can still occur. Vehicle collisions, rollovers, or mechanical failures can lead to spills or releases of dangerous substances, posing risks to public safety and the environment. The consequences of such incidents can be severe:

- Injuries or fatalities for drivers, passengers, and bystanders

- Environmental contamination affecting air, water, and soil

- Economic losses due to cleanup costs and regulatory fines

To minimize the risk of accidents, carriers must adhere to strict maintenance schedules and conduct regular inspections of vehicles. Additionally, drivers must be trained in defensive driving techniques and emergency response procedures.

Regulatory Compliance

Navigating the complex web of federal, state, and local regulations governing hazardous materials transportation can be challenging for shippers and carriers. Compliance with these regulations is essential but can also be resource-intensive:

- Keeping up-to-date with changing regulations

- Training employees on compliance requirements

- Maintaining accurate records for inspections and shipments

Failure to comply with hazmat regulations can result in significant penalties, including fines and loss of operating authority. This creates additional pressure on carriers to ensure that all aspects of their operations are compliant.

Public Perception and Community Relations

Public perception of hazardous materials transportation can be negative due to concerns about safety and environmental risks. Communities near major transportation routes may express opposition to hazmat shipments passing through their neighborhoods. This opposition can lead to:

- Increased regulatory scrutiny

- Local ordinances restricting hazmat transport

- Community protests or activism

To address these concerns, carriers must engage in proactive communication with local communities, providing information about safety measures in place and addressing any misconceptions about the risks associated with hazmat transport.

Emerging Threats

The transportation of hazardous materials is also facing new challenges from emerging threats such as cyberattacks or terrorism. The increasing reliance on technology for logistics and tracking systems makes the industry vulnerable to cyber threats that could compromise safety or lead to unauthorized access to hazardous materials.

Carriers must invest in cybersecurity measures to protect sensitive information and ensure that their systems are resilient against potential attacks.

Overall, while road transportation remains the dominant method for moving hazardous materials due to its flexibility and cost-effectiveness, it is not without its challenges. Addressing these risks requires a concerted effort from all stakeholders involved in hazmat transport—shippers, carriers, drivers, regulators, and communities—to ensure that safety remains a top priority.

As we conclude our exploration of hazardous materials transportation by road, the final section will examine how shippers and carriers ensure compliance in this critical area.

How do shippers and carriers ensure compliance in hazardous materials transport?

Ensuring compliance with regulations governing hazardous materials transport is critical for shippers and carriers alike. A robust compliance program involves several key components designed to meet regulatory requirements while promoting safety throughout the transport process.

Training Programs

Training is essential for all personnel involved in hazardous materials transport. Shippers must provide comprehensive training programs that cover:

- Hazardous material classification: Understanding how to identify different types of hazardous materials based on their properties.

- Packaging requirements: Proper methods for packaging hazardous materials according to regulations.

- Labeling and placarding: Ensuring that all packages are correctly labeled with hazard symbols and that vehicles display appropriate placards.

- Emergency response procedures: Training employees on how to respond effectively in case of an incident involving hazardous materials.

Regular refresher courses should also be conducted to keep employees informed about changes in regulations or best practices.

Documentation and Recordkeeping

Accurate documentation is vital for demonstrating compliance with hazardous materials regulations. Shippers and carriers must maintain detailed records that include:

- Shipping papers: Documents that accompany each shipment detailing the contents, hazards, handling instructions, and emergency contact information.

- Inspection reports: Records of vehicle inspections and maintenance activities.

- Training records: Documentation showing that employees have completed required training programs.

These records should be readily accessible for review by regulatory agencies during inspections or audits.

Risk Assessment Procedures

Conducting thorough risk assessments helps shippers identify potential hazards associated with their operations. This includes evaluating:

- Types of hazardous materials being transported

- Transportation routes

- Vehicle conditions

By identifying risks early on, shippers can implement appropriate mitigation strategies such as route planning adjustments or enhanced training programs for drivers.

Safety Management Systems (SMS)

Implementing a Safety Management System (SMS) allows shippers and carriers to systematically manage safety risks associated with hazardous materials transport. An effective SMS includes:

- Safety policies: Clear guidelines outlining expectations for safe operations.

- Incident reporting systems: Mechanisms for reporting accidents or near misses.

- Performance monitoring: Regular assessments of compliance performance metrics.

An SMS fosters a culture of safety within organizations by encouraging proactive identification of hazards and continuous improvement efforts.

Collaboration with Regulatory Agencies

Maintaining open lines of communication with regulatory agencies is crucial for ensuring compliance. Shippers and carriers should:

- Stay informed about regulatory changes: Subscribe to updates from agencies like the DOT or state-level regulators.

- Participate in industry forums or workshops: Engage with peers to share best practices related to hazmat transport.

By fostering collaborative relationships with regulators, organizations can better navigate compliance challenges while enhancing their understanding of evolving requirements.

Emergency Response Planning

Developing comprehensive emergency response plans ensures that shippers are prepared for incidents involving hazardous materials. Key components include:

- Coordination with local emergency responders: Establishing relationships with fire departments, police departments, and other first responders who may be called upon during an incident.

- Conducting drills or exercises: Regularly practicing emergency response procedures helps ensure readiness in case of an actual event.

Effective emergency response planning not only enhances safety but also demonstrates a commitment to compliance with regulatory requirements.

In conclusion, shippers and carriers play a vital role in ensuring compliance during the transportation of hazardous materials by road. By implementing comprehensive training programs, maintaining accurate documentation, conducting risk assessments, establishing Safety Management Systems (SMS), collaborating with regulatory agencies, and developing emergency response plans, they can effectively navigate the complexities associated with hazmat transport while prioritizing safety.

The safe transportation of hazardous materials is essential not only for public safety but also for supporting various industries that rely on these critical substances. As regulations continue to evolve alongside advancements in technology and logistics practices, ongoing vigilance will be necessary to ensure that compliance remains at the forefront of hazmat transportation efforts.