What Is the Process of Drayage

What is drayage and why is it important in logistics?

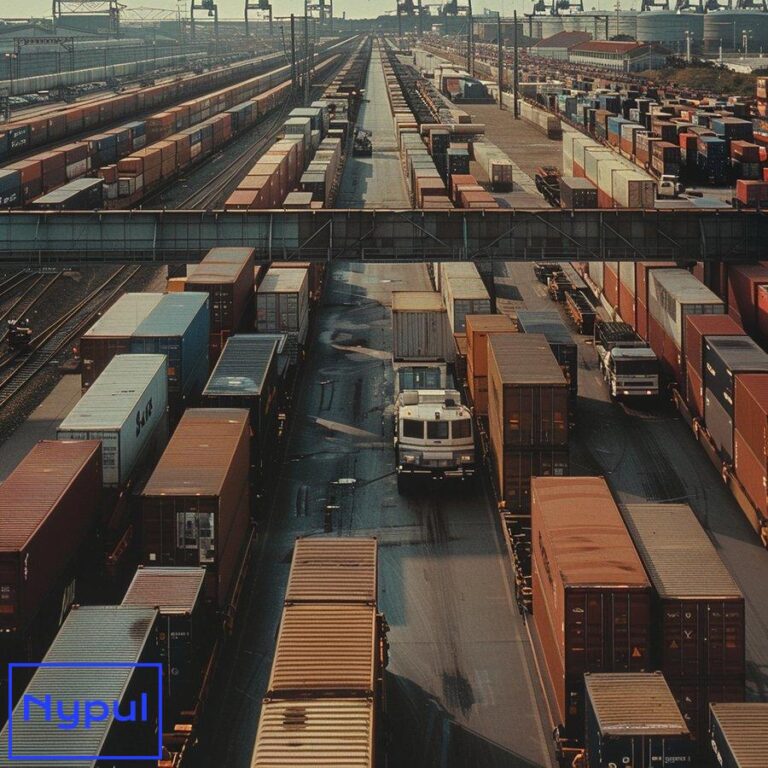

Drayage refers to the transportation of goods over a short distance, typically as part of a longer shipping process. This term is most commonly associated with the movement of containers from ports to nearby warehouses or distribution centers. The importance of drayage in logistics cannot be overstated, as it serves as a critical link in the supply chain, ensuring that goods are efficiently transferred from maritime transport to land-based transport.

Understanding drayage is vital for several reasons:

-

Facilitates Supply Chain Efficiency: Drayage plays a pivotal role in maintaining the flow of goods, reducing delays, and improving overall supply chain efficiency.

-

Supports Global Trade: As global trade continues to expand, drayage operations are essential for moving imported goods to their final destinations quickly and effectively.

-

Enhances Inventory Management: Efficient drayage allows for better inventory management, enabling businesses to respond swiftly to market demands.

Drayage operations typically involve a series of steps, including scheduling, loading, transportation, and unloading. Each of these steps is essential for ensuring that goods are delivered on time and in good condition.

How does the drayage process work from start to finish?

The drayage process encompasses several stages, each crucial to the successful movement of goods. Understanding these stages helps stakeholders manage their logistics effectively.

Step 1: Booking and Scheduling

The drayage process begins with booking and scheduling. Shippers or freight forwarders coordinate with drayage providers to schedule the pickup and delivery of containers. This step often involves:

-

Selecting a Drayage Carrier: Shippers choose a drayage carrier based on factors such as reliability, cost, and service area.

-

Confirming Availability: The carrier confirms the availability of equipment and drivers for the scheduled date.

Step 2: Container Pickup

Once the booking is confirmed, the drayage carrier proceeds to pick up the container from the port or terminal. This phase includes:

-

Documentation Review: Ensuring all necessary paperwork, such as bills of lading and customs clearance, is in order.

-

Equipment Inspection: Inspecting the container and equipment to ensure they are in good condition for transport.

Step 3: Transportation

The transportation phase involves moving the container from the port to its destination. Key aspects include:

-

Route Planning: The carrier plans the most efficient route, considering factors like traffic, road conditions, and delivery deadlines.

-

Monitoring: Real-time tracking systems enable stakeholders to monitor the shipment’s progress.

Step 4: Delivery and Unloading

Upon arrival at the destination, the container is unloaded. This phase consists of:

-

Receiving Inspection: Conducting a thorough inspection of the goods to ensure they match the shipping documents.

-

Final Documentation: Completing any necessary paperwork for the delivery, including proof of delivery.

Step 5: Return of Equipment

After unloading, the drayage carrier returns the empty container to the port or terminal. This step includes:

-

Scheduling Return: Coordinating the return of the empty container to avoid additional fees.

-

Final Inspection: Ensuring the container is returned in good condition.

Understanding the drayage process from start to finish allows businesses to identify potential bottlenecks and streamline their operations for improved efficiency.

Who are the key players involved in drayage operations?

Drayage operations involve various stakeholders, each playing a vital role in ensuring the smooth movement of goods. Identifying these players helps clarify responsibilities and improve collaboration.

Shippers

Shippers are businesses or individuals who need to transport goods. They initiate the drayage process by booking services with carriers. Their responsibilities include:

-

Providing Accurate Information: Shippers must provide precise details about the shipment, including dimensions, weight, and delivery requirements.

-

Coordinating with Carriers: They work closely with drayage carriers to schedule pickups and deliveries.

Drayage Carriers

Drayage carriers are transportation companies specializing in short-distance hauling. Their roles encompass:

-

Transporting Containers: They are responsible for moving containers from ports to designated locations.

-

Managing Logistics: Carriers handle the logistics of scheduling, routing, and equipment management.

Freight Forwarders

Freight forwarders act as intermediaries between shippers and carriers. Their responsibilities include:

-

Coordinating Shipments: They manage the entire shipping process, including drayage.

-

Providing Documentation: Freight forwarders ensure all necessary paperwork is completed for customs clearance and delivery.

Port Authorities

Port authorities oversee the operations of ports and terminals. Their roles include:

-

Regulating Access: They control access to port facilities and ensure compliance with safety regulations.

-

Facilitating Operations: Port authorities work to streamline operations, reducing congestion and improving efficiency.

Customs Brokers

Customs brokers assist with the clearance of goods through customs. Their responsibilities include:

-

Handling Documentation: They ensure all customs paperwork is completed accurately.

-

Advising on Regulations: Customs brokers provide guidance on import/export regulations and compliance.

Understanding the roles of these key players helps streamline communication and collaboration, leading to more efficient drayage operations.

What equipment and technology are essential for efficient drayage?

Efficient drayage operations rely on specialized equipment and technology to ensure timely and safe transportation of goods. Identifying these tools is essential for optimizing logistics.

Essential Equipment

-

Trucks: Drayage trucks are specifically designed for short-distance hauling. They must comply with weight regulations and be equipped for container transport.

-

Chassis: Chassis are the frames on which containers are mounted for transport. They must be compatible with the specific container sizes being moved.

-

Forklifts: Forklifts are used for loading and unloading containers at terminals and warehouses. They enhance efficiency by quickly handling heavy loads.

Technology Solutions

-

Tracking Systems: GPS and RFID technology allow for real-time tracking of containers during transport. This visibility helps stakeholders monitor progress and address any issues promptly.

-

Transportation Management Systems (TMS): TMS software facilitates planning, execution, and optimization of logistics operations. It aids in route planning, scheduling, and documentation management.

-

Electronic Logging Devices (ELDs): ELDs monitor driving hours and ensure compliance with regulations. They enhance safety and accountability in drayage operations.

Table: Equipment and Technology Overview

| Equipment/Technology | Purpose |

|---|---|

| Trucks | Transport goods over short distances |

| Chassis | Support containers during transport |

| Forklifts | Load and unload containers efficiently |

| Tracking Systems | Provide real-time visibility of shipments |

| Transportation Management Systems | Optimize logistics operations |

| Electronic Logging Devices | Ensure compliance and enhance safety |

Utilizing the right equipment and technology is critical for improving efficiency and reducing costs in drayage operations.

How are drayage costs calculated and what factors influence pricing?

Understanding how drayage costs are calculated is essential for businesses looking to manage their logistics budgets effectively. Several factors influence pricing, and being aware of these can help in making informed decisions.

Cost Components

-

Base Rate: This is the standard charge for drayage services, often determined by distance and the type of cargo.

-

Fuel Surcharge: Fluctuations in fuel prices can lead to additional charges, known as fuel surcharges, which are typically calculated as a percentage of the base rate.

-

Accessorial Charges: These are additional fees for services beyond standard transport, such as:

-

Waiting Time: Charges incurred if the driver has to wait beyond a specified time for loading or unloading.

-

Detention Fees: Fees applied when a container is not returned within the agreed timeframe.

Factors Influencing Pricing

-

Distance: The distance between the port and the delivery location directly impacts costs. Longer distances typically result in higher charges.

-

Container Size and Weight: Larger and heavier containers may incur higher fees due to increased handling and transport complexities.

-

Market Demand: Fluctuations in demand for drayage services can influence pricing. During peak seasons, rates may increase due to higher demand.

-

Regulatory Compliance: Compliance with local regulations and safety standards may result in additional costs, particularly if specialized equipment is required.

Table: Factors Influencing Drayage Costs

| Factor | Description |

|---|---|

| Distance | Longer distances increase costs |

| Container Size and Weight | Larger/heavier containers incur higher fees |

| Market Demand | High demand can lead to increased rates |

| Regulatory Compliance | Compliance costs may add to overall pricing |

Understanding these cost components and influencing factors enables businesses to budget effectively and negotiate better rates with drayage providers.

What are the main challenges in drayage and how can they be addressed?

Drayage operations face several challenges that can impact efficiency and cost-effectiveness. Identifying these challenges and implementing solutions is essential for optimizing logistics.

Common Challenges

-

Congestion at Ports: High traffic volumes at ports can lead to delays in loading and unloading, impacting overall logistics timelines.

-

Equipment Shortages: A shortage of available trucks and chassis can hinder the timely movement of containers, leading to increased costs.

-

Regulatory Compliance: Navigating complex regulations and ensuring compliance can be challenging, particularly for international shipments.

-

Communication Gaps: Ineffective communication between stakeholders can lead to misunderstandings and delays in the drayage process.

Solutions to Address Challenges

-

Improved Planning and Scheduling: Utilizing advanced planning tools can help optimize schedules and minimize congestion at ports.

-

Investing in Equipment: Drayage companies should invest in maintaining and expanding their fleet to ensure they have sufficient equipment to meet demand.

-

Training and Education: Providing training for staff on regulatory compliance and best practices can help mitigate challenges related to regulations.

-

Enhancing Communication: Implementing communication platforms that facilitate real-time updates among stakeholders can improve coordination and reduce delays.

Table: Challenges and Solutions Overview

| Challenge | Solution |

|---|---|

| Congestion at Ports | Improved planning and scheduling |

| Equipment Shortages | Invest in fleet maintenance and expansion |

| Regulatory Compliance | Training and education for staff |

| Communication Gaps | Enhance communication platforms |

Addressing these challenges proactively can lead to more efficient drayage operations and improved overall logistics performance.

What regulations govern drayage operations and safety standards?

Drayage operations are subject to various regulations and safety standards designed to ensure the safe and efficient movement of goods. Understanding these regulations is crucial for compliance and risk management.

Key Regulations

-

Federal Motor Carrier Safety Administration (FMCSA): The FMCSA regulates commercial motor vehicle operations in the United States, including drayage services. Their regulations cover driver qualifications, vehicle maintenance, and hours of service.

-

Environmental Protection Agency (EPA): The EPA sets emissions standards for vehicles, including those used in drayage. Compliance with these standards is essential for reducing environmental impact.

-

Occupational Safety and Health Administration (OSHA): OSHA regulations govern workplace safety, including safety practices for loading and unloading containers. Compliance helps prevent accidents and injuries.

Safety Standards

-

Vehicle Maintenance: Regular maintenance of trucks and equipment is essential to ensure safety and compliance with regulations.

-

Driver Training: Ensuring that drivers are trained in safe driving practices and emergency procedures is critical for minimizing risks.

-

Load Securement: Properly securing loads is essential to prevent accidents during transport. Compliance with load securement standards is mandatory.

Table: Regulatory Bodies and Their Roles

| Regulatory Body | Role |

|---|---|

| FMCSA | Regulates commercial motor vehicle operations |

| EPA | Sets emissions standards for vehicles |

| OSHA | Governs workplace safety practices |

Adhering to these regulations and safety standards is essential for ensuring the smooth operation of drayage services and minimizing legal risks.

In conclusion, understanding the drayage process, the key players involved, the necessary equipment and technology, cost calculations, challenges, and regulations is vital for businesses engaged in logistics. By optimizing drayage operations, companies can enhance their supply chain efficiency and maintain a competitive edge in the market.