What Is the Purpose of Port-Centric Logistics

What is port-centric logistics?

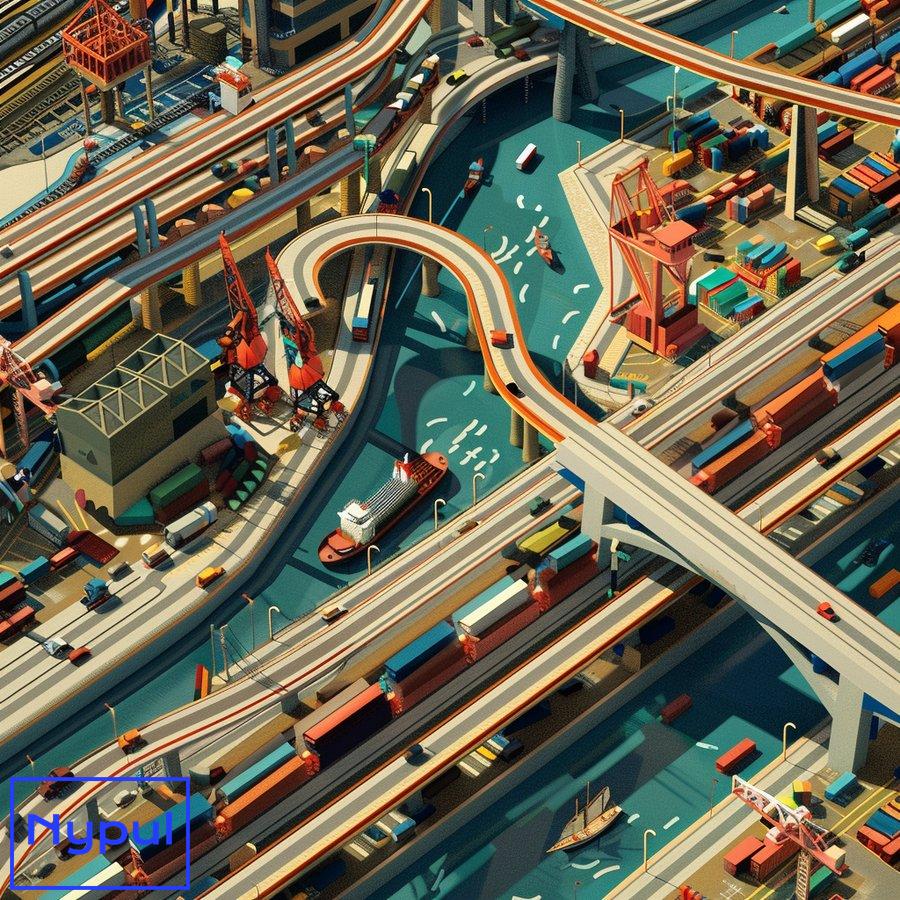

Port-centric logistics represents a strategic approach to supply chain management that centers around port facilities. This model integrates various logistics activities directly within or in close proximity to seaports, creating a seamless flow of goods from ship to shore and beyond. Port-centric logistics encompasses a range of services, including warehousing, distribution, value-added activities, and transportation, all conducted near the port area.

The concept of port-centric logistics emerged as a response to the increasing complexities and demands of global trade. As international commerce expanded, traditional logistics models struggled to keep pace with the volume and speed requirements of modern supply chains. Port-centric logistics addresses these challenges by consolidating operations at the point of entry or exit for goods.

Key Components of Port-Centric Logistics

Warehousing and Storage: Port-centric logistics facilities often include extensive warehousing capabilities. These warehouses are strategically located to receive goods directly from ships, allowing for immediate storage and inventory management.

Distribution Centers: Many port-centric logistics operations incorporate distribution centers that serve as hubs for sorting, repackaging, and dispatching goods to their final destinations.

Value-Added Services: Beyond basic storage and distribution, port-centric logistics often includes value-added activities such as assembly, customization, labeling, and quality control.

Intermodal Connections: Efficient connections to various transportation modes, including rail, road, and inland waterways, are crucial for port-centric logistics. These connections facilitate the smooth onward movement of goods.

Customs and Regulatory Compliance: Port-centric logistics operations typically include facilities and expertise for handling customs clearance and ensuring compliance with import/export regulations.

Information Technology Systems: Advanced IT systems are essential for managing the complex flow of goods, information, and documentation in port-centric logistics.

The port-centric logistics model offers numerous benefits to businesses engaged in international trade. By consolidating activities at the port, companies can reduce transportation costs, minimize handling and potential damage to goods, and decrease lead times. This approach also allows for greater flexibility in responding to market demands and managing inventory levels.

For ports themselves, embracing port-centric logistics can lead to increased competitiveness and economic growth. Ports that offer comprehensive logistics services become more attractive to shippers and carriers, potentially increasing their market share and revenue streams.

As global trade continues to evolve, port-centric logistics is likely to play an increasingly important role in shaping efficient and responsive supply chains. The integration of advanced technologies, such as automation and artificial intelligence, is expected to further enhance the capabilities and benefits of port-centric logistics in the future.

How does port-centric logistics differ from traditional logistics approaches?

Port-centric logistics represents a significant departure from traditional logistics approaches, offering a more integrated and streamlined model for managing the flow of goods. To understand these differences, it’s essential to examine the key characteristics of both approaches and how they impact supply chain operations.

Traditional Logistics Approach

The traditional logistics model typically involves multiple stages and locations in the movement of goods from origin to destination. This approach often includes:

Inland Transportation: Goods are transported from the point of origin to a port or airport using various modes of transport, such as trucks or trains.

Port Operations: At the port, goods are loaded onto ships for international transport. This process may involve temporary storage and handling at the port.

Ocean Freight: Goods are shipped across international waters to the destination country.

Destination Port Operations: Upon arrival, goods are unloaded and may be temporarily stored at the destination port.

Inland Transportation (Destination): Goods are then transported to inland distribution centers or warehouses.

Final Distribution: From these inland facilities, goods are distributed to retailers or end customers.

This traditional model often results in multiple handling points, increased transportation costs, and longer lead times. It also typically involves separate entities managing different stages of the logistics process, which can lead to coordination challenges and potential inefficiencies.

Port-Centric Logistics Approach

In contrast, port-centric logistics aims to consolidate many of these activities at or near the port itself. Key features of this approach include:

Integrated Port Facilities: Warehousing, distribution, and value-added services are located within or adjacent to the port area.

Direct Ship-to-Shore Operations: Goods can be moved directly from ships to storage or processing facilities without intermediate transportation.

Consolidated Services: Multiple logistics functions, such as customs clearance, quality control, and inventory management, are performed in a single location.

Immediate Inland Distribution: Goods can be prepared for final distribution directly from the port area, reducing the need for inland transportation to intermediate facilities.

To illustrate the differences more clearly, let’s compare these approaches using a table:

| Aspect | Traditional Logistics | Port-Centric Logistics |

|---|---|---|

| Number of Handling Points | Multiple (5-7 typical) | Fewer (2-3 typical) |

| Transportation Stages | Multiple inland movements | Minimized inland movements |

| Lead Time | Longer due to multiple stages | Shorter due to consolidated operations |

| Inventory Management | Often spread across multiple locations | Centralized at port |

| Customs Clearance | May occur at various points | Typically performed at port |

| Value-Added Services | Often performed at inland facilities | Integrated at port |

| Supply Chain Visibility | Can be fragmented | More centralized and transparent |

| Environmental Impact | Higher due to multiple transport stages | Lower due to reduced transportation |

Key Differences and Implications

Handling and Transportation: Port-centric logistics significantly reduces the number of times goods are handled and transported, leading to lower costs and reduced risk of damage or loss.

Lead Time: By eliminating several stages in the traditional logistics chain, port-centric logistics can dramatically shorten lead times, allowing for faster market responsiveness.

Inventory Management: Centralized inventory management at the port enables better control and visibility of stock levels, potentially reducing overall inventory costs.

Flexibility: The proximity of various logistics services at the port allows for greater flexibility in responding to market demands or supply chain disruptions.

Cost Efficiency: While initial investment in port-centric facilities may be higher, the overall logistics costs can be lower due to reduced transportation and handling expenses.

Environmental Impact: By minimizing inland transportation, port-centric logistics can lead to a reduction in carbon emissions and overall environmental footprint.

Supply Chain Visibility: The consolidation of activities at the port can provide better end-to-end visibility of the supply chain, facilitating more effective planning and decision-making.

Port-centric logistics represents a more integrated and efficient approach to managing the flow of goods compared to traditional logistics models. By consolidating activities at the port, this approach offers potential benefits in terms of cost reduction, improved lead times, and enhanced supply chain visibility. However, the suitability of port-centric logistics depends on various factors, including the nature of the goods, trade volumes, and specific supply chain requirements of individual businesses.

What are the primary objectives of implementing port-centric logistics?

The implementation of port-centric logistics is driven by several key objectives that aim to enhance the efficiency, cost-effectiveness, and overall performance of supply chain operations. These objectives reflect the evolving needs of global trade and the increasing pressure on businesses to optimize their logistics processes. Understanding these primary objectives is crucial for organizations considering the adoption of a port-centric logistics strategy.

Cost Reduction

One of the foremost objectives of port-centric logistics is to achieve significant cost reductions across the supply chain. This goal is pursued through various means:

Transportation Cost Minimization: By consolidating logistics activities at the port, businesses can reduce the need for multiple inland transportation legs, thereby lowering overall transportation costs.

Handling Cost Reduction: Fewer handling points mean reduced labor costs and decreased risk of damage to goods during transit.

Inventory Cost Optimization: Centralized inventory management at the port can lead to more efficient stock control, potentially reducing inventory holding costs.

Lead Time Reduction

Shortening the time from product arrival at the port to final delivery is a critical objective of port-centric logistics:

Streamlined Processes: By integrating various logistics activities at the port, businesses can eliminate time-consuming transfers between different facilities.

Immediate Processing: Goods can be processed, sorted, and prepared for distribution as soon as they arrive at the port, reducing waiting times.

Faster Customs Clearance: On-site customs facilities can expedite the clearance process, further reducing delays.

Enhanced Supply Chain Visibility

Improving transparency and control over the movement of goods is another key objective:

Centralized Information: Consolidating logistics activities at a single location allows for more comprehensive and real-time tracking of goods.

Improved Decision-Making: Enhanced visibility enables quicker and more informed decisions regarding inventory management and distribution.

Risk Mitigation: Better visibility helps in identifying and addressing potential supply chain disruptions more effectively.

Increased Flexibility and Responsiveness

Port-centric logistics aims to create more agile supply chains:

Demand-Driven Distribution: The proximity to port facilities allows for quicker responses to changes in market demand.

Customization Capabilities: Value-added services at the port enable last-minute product customization or modifications.

Scalability: Port-centric facilities can often more easily scale operations up or down based on seasonal or market-driven fluctuations.

Environmental Sustainability

Reducing the environmental impact of logistics operations is an increasingly important objective:

Carbon Footprint Reduction: Minimizing inland transportation leads to lower carbon emissions.

Efficient Resource Use: Consolidated operations can lead to more efficient use of energy and resources.

Green Technologies: Port-centric facilities often have the scale to implement advanced, environmentally friendly technologies.

Service Level Improvement

Enhancing the overall quality of logistics services is a crucial objective:

Consistency: Centralized operations can lead to more consistent service delivery.

Value-Added Services: Port-centric facilities can offer a wider range of value-added services, improving the overall service offering.

Customer Satisfaction: Faster delivery times and improved reliability can enhance customer satisfaction.

Risk Management

Mitigating various supply chain risks is another important objective:

Inventory Risk Reduction: Better inventory control can reduce the risks associated with overstocking or stockouts.

Compliance Management: Centralized operations can facilitate better compliance with customs and regulatory requirements.

Security Enhancement: Port-centric facilities often have advanced security measures, reducing the risk of theft or tampering.

To illustrate the relative importance and potential impact of these objectives, consider the following table:

| Objective | Potential Impact | Implementation Complexity |

|---|---|---|

| Cost Reduction | High | Medium |

| Lead Time Reduction | High | Medium |

| Supply Chain Visibility | Medium-High | Medium-High |

| Flexibility and Responsiveness | Medium-High | Medium |

| Environmental Sustainability | Medium | Medium-High |

| Service Level Improvement | Medium-High | Medium |

| Risk Management | Medium | High |

The primary objectives of implementing port-centric logistics reflect a comprehensive approach to optimizing supply chain operations. By focusing on cost reduction, lead time improvement, enhanced visibility, increased flexibility, sustainability, service quality, and risk management, port-centric logistics aims to create more efficient and responsive supply chains. These objectives align with the broader trends in global trade, including the need for faster, more cost-effective, and environmentally sustainable logistics solutions.

For businesses considering the adoption of port-centric logistics, it’s essential to evaluate how these objectives align with their specific supply chain needs and overall business strategy. While the potential benefits are significant, the implementation of port-centric logistics requires careful planning, investment, and often a shift in operational paradigms. The success of port-centric logistics initiatives depends on how effectively organizations can align these objectives with their unique supply chain requirements and market conditions.

How does port-centric logistics optimize supply chain operations?

Port-centric logistics plays a crucial role in optimizing supply chain operations by streamlining processes, reducing inefficiencies, and leveraging the strategic advantages of port locations. This approach to logistics management transforms traditional supply chain models, offering significant improvements in various aspects of operations. Let’s explore how port-centric logistics achieves these optimizations:

Streamlined Flow of Goods

Port-centric logistics optimizes the movement of goods by minimizing handling and transportation stages:

Direct Ship-to-Shore Operations: Goods can be unloaded from ships and moved directly to nearby warehouses or distribution centers, eliminating intermediate transportation steps.

Reduced Handling: Fewer touch points mean less risk of damage and faster processing times.

Efficient Sorting and Distribution: Proximity to port facilities allows for immediate sorting and preparation for onward distribution.

Enhanced Inventory Management

Centralized inventory control at the port offers several advantages:

Real-Time Visibility: Port-centric facilities often utilize advanced inventory management systems, providing real-time updates on stock levels.

Just-in-Time Capabilities: The proximity to shipping lanes enables more accurate timing of inventory replenishment.

Reduced Safety Stock: Better visibility and shorter lead times can lead to reduced safety stock requirements.

Improved Customs and Regulatory Compliance

Port-centric logistics facilities often include on-site customs capabilities:

Faster Clearance: On-site customs officers can process documentation more quickly, reducing delays.

Compliance Expertise: Specialized staff at port-centric facilities are well-versed in customs regulations, ensuring smoother compliance.

Reduced Risk of Delays: Immediate access to customs services minimizes the risk of shipments being held up due to documentation issues.

Optimized Transportation Networks

Port-centric logistics leverages strategic port locations to optimize transportation:

Intermodal Connectivity: Efficient connections to rail, road, and inland waterways facilitate seamless onward transportation.

Reduced Inland Transportation: By processing and distributing goods from the port, the need for long-distance inland transportation is minimized.

Consolidated Shipments: The ability to consolidate multiple shipments at the port can lead to more efficient use of transportation resources.

Value-Added Services Integration

Port-centric facilities often offer a range of value-added services that enhance supply chain efficiency:

Product Customization: Goods can be customized or modified at the port to meet specific market requirements.

Quality Control: On-site quality checks can identify and address issues before goods are distributed.

Packaging and Labeling: Products can be prepared for specific markets or retailers directly at the port.

Enhanced Supply Chain Visibility

Centralized operations at the port improve overall supply chain transparency:

End-to-End Tracking: Integration of port operations with logistics systems provides comprehensive visibility from arrival to final distribution.

Data Analytics: Centralized data collection enables more effective analysis and optimization of supply chain performance.

Proactive Issue Management: Enhanced visibility allows for early detection and resolution of potential supply chain disruptions.

Flexibility and Scalability

Port-centric logistics offers greater adaptability to changing market conditions:

Demand-Responsive Operations: Proximity to major transportation hubs allows for quicker responses to fluctuations in demand.

Scalable Capacity: Port-centric facilities can often more easily scale operations up or down based on seasonal or market-driven changes.

Agile Decision-Making: Centralized operations enable faster decision-making and implementation of changes in logistics strategies.

Cost Optimization

Port-centric logistics contributes to overall cost reduction in several ways:

Reduced Transportation Costs: Minimizing inland transportation leads to significant cost savings.

Lower Inventory Costs: Improved inventory management can reduce carrying costs and the risk of obsolescence.

Economies of Scale: Consolidation of activities at the port can lead to economies of scale in operations and resource utilization.

To illustrate the impact of port-centric logistics on supply chain optimization, consider the following comparative table:

| Supply Chain Aspect | Traditional Approach | Port-Centric Approach | Optimization Impact |

|---|---|---|---|

| Goods Flow | Multiple handling stages | Streamlined, fewer stages | High |

| Inventory Management | Distributed across locations | Centralized at port | Medium-High |

| Customs Clearance | Potential for delays | Faster, on-site processing | High |

| Transportation | Multiple inland movements | Minimized inland transport | High |

| Value-Added Services | Often performed inland | Integrated at port | Medium-High |

| Supply Chain Visibility | Often fragmented | Comprehensive, centralized | Medium-High |

| Flexibility | Limited by distributed operations | Enhanced by centralized operations | Medium |

| Cost Efficiency | Higher due to multiple stages | Improved through consolidation | High |

Port-centric logistics optimizes supply chain operations by fundamentally restructuring the flow of goods and associated activities. By centralizing operations at or near the port, this approach eliminates inefficiencies, reduces costs, and enhances overall supply chain performance. The integration of various logistics functions at a single location creates a more streamlined, visible, and responsive supply chain.

The optimization benefits of port-centric logistics are particularly significant for businesses dealing with high volumes of imported or exported goods. However, the degree of optimization can vary depending on factors such as the nature of the products, trade volumes, and specific supply chain requirements.

For organizations considering the adoption of port-centric logistics, it’s crucial to conduct a thorough analysis of their current supply chain operations and assess how port-centric strategies could deliver specific optimizations. While the potential for improvement is substantial, successful implementation requires careful planning, investment in infrastructure and technology, and often a shift in operational mindset.

As global trade continues to evolve, port-centric logistics is likely to play an increasingly important role in supply chain optimization. The integration of advanced technologies such as artificial intelligence, Internet of Things (IoT), and blockchain into port-centriclogistics will further enhance the capabilities and efficiencies of this approach, making it an essential component of modern supply chain management.

What operational advantages does port-centric logistics offer?

Port-centric logistics provides a range of operational advantages that can significantly enhance the efficiency and effectiveness of supply chain management. These advantages stem from the strategic positioning of logistics activities at or near port facilities, allowing businesses to leverage the unique benefits of port locations. Here are some of the key operational advantages:

Reduced Transportation Costs

One of the most compelling advantages of port-centric logistics is the potential for reduced transportation costs. By consolidating logistics activities at the port, businesses can minimize the need for long-distance inland transportation. This reduction in transportation legs leads to:

-

Lower freight costs: Fewer miles traveled result in decreased fuel expenses and overall transportation charges.

-

Decreased handling fees: With fewer transfers between facilities, businesses can save on handling costs associated with loading and unloading goods.

Faster Turnaround Times

Port-centric logistics enables faster turnaround times for shipments, which is crucial in today’s fast-paced market. This advantage is achieved through:

-

Direct access to distribution centers: Goods can be moved directly from ships to storage or processing facilities, eliminating delays associated with inland transportation.

-

Immediate processing capabilities: Port-centric facilities often have the resources to process shipments quickly, allowing for faster delivery to end customers.

Enhanced Supply Chain Flexibility

The proximity of logistics services at the port allows for greater flexibility in responding to changes in demand or disruptions in the supply chain. Key aspects include:

-

Agile operations: Businesses can quickly adjust their logistics strategies to accommodate fluctuations in demand or unexpected supply chain challenges.

-

Customization options: Port-centric facilities can offer value-added services, such as product assembly or repackaging, that allow businesses to tailor their offerings to specific market needs.

Improved Inventory Management

Centralized inventory management at port-centric facilities provides several operational benefits:

-

Real-time visibility: Businesses can monitor inventory levels in real-time, enabling better decision-making regarding stock replenishment and distribution.

-

Reduced safety stock: With shorter lead times and improved visibility, businesses can maintain lower levels of safety stock, reducing carrying costs.

Streamlined Customs Processes

Port-centric logistics often includes on-site customs facilities, which can significantly streamline the customs clearance process. Benefits include:

-

Faster clearance times: On-site customs officers can expedite the processing of shipments, reducing delays associated with customs inspections.

-

Enhanced compliance: Specialized staff at port-centric facilities are knowledgeable about customs regulations, ensuring that shipments meet all necessary requirements.

Better Risk Management

The consolidation of logistics activities at the port can lead to improved risk management capabilities:

-

Reduced risk of disruptions: Fewer handling points and transportation legs mean that the likelihood of disruptions due to delays or damages is minimized.

-

Enhanced security measures: Port-centric facilities often have advanced security protocols in place, reducing the risk of theft or tampering with goods.

Sustainability Benefits

Port-centric logistics can also contribute to sustainability efforts by reducing the environmental impact of logistics operations:

-

Lower carbon emissions: By minimizing inland transportation, businesses can significantly reduce their carbon footprint.

-

Efficient resource utilization: Consolidated operations at the port can lead to more efficient use of energy and resources.

To summarize the operational advantages of port-centric logistics, consider the following table:

| Advantage | Description |

|---|---|

| Reduced Transportation Costs | Lower freight and handling fees due to minimized inland transport. |

| Faster Turnaround Times | Direct access to distribution centers enables quicker processing and delivery. |

| Enhanced Supply Chain Flexibility | Agile operations and customization options allow for rapid response to market changes. |

| Improved Inventory Management | Real-time visibility and reduced safety stock lead to more efficient inventory control. |

| Streamlined Customs Processes | On-site customs facilities expedite clearance and enhance compliance. |

| Better Risk Management | Fewer handling points and advanced security measures reduce risks. |

| Sustainability Benefits | Lower carbon emissions and efficient resource utilization contribute to environmental goals. |

The operational advantages of port-centric logistics make it an attractive option for businesses looking to optimize their supply chain processes. By leveraging the strategic benefits of port facilities, organizations can enhance efficiency, reduce costs, and improve overall service levels.

Why is port-centric logistics strategically important in global trade?

Port-centric logistics holds strategic importance in global trade due to its ability to enhance the efficiency and effectiveness of supply chain operations. As international trade continues to grow and evolve, businesses face increasing pressure to optimize their logistics processes. Here are several reasons why port-centric logistics is strategically important:

Facilitating Global Trade Flows

Ports serve as critical gateways for international trade, and port-centric logistics enhances the flow of goods across borders:

-

Efficient import/export processes: By consolidating logistics activities at the port, businesses can streamline the import and export processes, facilitating smoother trade flows.

-

Increased capacity for handling goods: Port-centric logistics allows for greater capacity to handle large volumes of goods, accommodating the demands of global trade.

Enhancing Competitiveness

Businesses that adopt port-centric logistics can gain a competitive edge in the marketplace:

-

Cost advantages: Reduced transportation and handling costs can lead to lower overall logistics expenses, allowing businesses to offer more competitive pricing.

-

Improved service levels: Faster turnaround times and enhanced flexibility can lead to higher customer satisfaction, giving businesses an advantage over competitors.

Supporting Supply Chain Resilience

The COVID-19 pandemic and other global disruptions have highlighted the need for resilient supply chains. Port-centric logistics contributes to resilience in several ways:

-

Reduced vulnerability to disruptions: Fewer handling points and transportation legs minimize the risk of delays and disruptions.

-

Greater adaptability: The flexibility of port-centric logistics allows businesses to quickly adjust their operations in response to changing market conditions.

Promoting Sustainability in Trade

As sustainability becomes an increasingly important consideration in global trade, port-centric logistics can contribute to greener supply chain practices:

-

Lower emissions: By minimizing inland transportation, port-centric logistics can significantly reduce carbon emissions associated with logistics operations.

-

Efficient resource use: Consolidated operations at the port can lead to more efficient use of energy and resources, supporting sustainability goals.

Leveraging Technological Advancements

The integration of technology in port-centric logistics can enhance efficiency and effectiveness:

-

Automation and AI: Advanced technologies can streamline operations, improve inventory management, and enhance decision-making.

-

Data analytics: Real-time data collection and analysis can provide valuable insights into supply chain performance, enabling continuous improvement.

Strengthening Local Economies

Port-centric logistics can have positive economic impacts on local communities:

-

Job creation: The establishment of port-centric facilities can create jobs in logistics, warehousing, and transportation.

-

Economic growth: Increased trade activity can stimulate local economies and contribute to regional development.

To summarize the strategic importance of port-centric logistics in global trade, consider the following table:

| Strategic Importance | Description |

|---|---|

| Facilitating Global Trade Flows | Streamlined import/export processes enhance trade efficiency. |

| Enhancing Competitiveness | Cost advantages and improved service levels provide a competitive edge. |

| Supporting Supply Chain Resilience | Reduced vulnerability to disruptions and greater adaptability. |

| Promoting Sustainability in Trade | Lower emissions and efficient resource use contribute to greener practices. |

| Leveraging Technological Advancements | Integration of automation and data analytics enhances operations. |

| Strengthening Local Economies | Job creation and economic growth in local communities. |

Port-centric logistics is strategically important in global trade as it addresses the challenges and demands of modern supply chains. By facilitating trade flows, enhancing competitiveness, supporting resilience, promoting sustainability, leveraging technology, and strengthening local economies, port-centric logistics plays a vital role in shaping the future of international commerce.

What infrastructure is required for effective port-centric logistics?

The effectiveness of port-centric logistics relies heavily on the presence of robust infrastructure that supports the various logistics activities conducted at or near port facilities. This infrastructure must be designed to facilitate the efficient movement of goods, streamline operations, and enhance connectivity. Here are the key components of infrastructure required for effective port-centric logistics:

Port Facilities

The physical infrastructure of the port itself is critical for port-centric logistics:

-

Container Terminals: Efficient container handling facilities are essential for the rapid loading and unloading of containers from ships.

-

Warehousing and Distribution Centers: Adequate warehousing space near the port allows for the storage and distribution of goods, enabling immediate processing.

-

Customs Facilities: On-site customs offices are necessary to expedite the clearance of goods and ensure compliance with regulations.

Transportation Infrastructure

Robust transportation networks are crucial for connecting port facilities with inland destinations:

-

Road Networks: Well-maintained roads are essential for facilitating truck transportation to and from the port.

-

Rail Connections: Access to rail networks allows for efficient movement of goods to inland destinations, reducing reliance on trucks.

-

Intermodal Facilities: Infrastructure that supports intermodal transportation, such as container transfer facilities, enhances the efficiency of moving goods between different modes of transport.

Information Technology Systems

Advanced IT systems are vital for managing the complex flow of goods and information in port-centric logistics:

-

Warehouse Management Systems (WMS): These systems help manage inventory levels, track shipments, and optimize warehouse operations.

-

Transportation Management Systems (TMS): TMS software facilitates the planning, execution, and optimization of transportation operations.

-

Supply Chain Visibility Tools: Real-time tracking and monitoring systems provide visibility into the movement of goods throughout the supply chain.

Value-Added Service Facilities

Infrastructure to support value-added services is essential for enhancing the capabilities of port-centric logistics:

-

Processing and Assembly Areas: Dedicated spaces for product customization, assembly, and quality control can improve service offerings.

-

Packaging Facilities: On-site packaging capabilities allow for efficient preparation of goods for distribution.

Security Infrastructure

Robust security measures are necessary to protect goods and ensure compliance with regulations:

-

Surveillance Systems: Advanced surveillance technologies help monitor port activities and enhance security.

-

Access Control: Effective access control measures are essential for regulating entry to port facilities and ensuring the safety of goods.

Sustainability Infrastructure

As sustainability becomes a priority, infrastructure that supports eco-friendly practices is increasingly important:

-

Renewable Energy Sources: Investments in renewable energy infrastructure, such as solar panels or wind turbines, can reduce the carbon footprint of port operations.

-

Waste Management Systems: Effective waste management and recycling programs contribute to sustainability goals.

To summarize the infrastructure requirements for effective port-centric logistics, consider the following table:

| Infrastructure Component | Description |

|---|---|

| Port Facilities | Container terminals, warehousing, and customs facilities are essential for efficient operations. |

| Transportation Infrastructure | Well-maintained road and rail networks facilitate the movement of goods to and from the port. |

| Information Technology Systems | Advanced IT systems enhance inventory management, transportation planning, and supply chain visibility. |

| Value-Added Service Facilities | Dedicated spaces for processing, assembly, and packaging improve service offerings. |

| Security Infrastructure | Robust security measures protect goods and ensure regulatory compliance. |

| Sustainability Infrastructure | Investments in renewable energy and waste management support eco-friendly practices. |

The infrastructure required for effective port-centric logistics is multifaceted and must be designed to support the various activities involved in the movement of goods. By investing in the right infrastructure, ports can enhance their capabilities and position themselves as key players in the global logistics landscape.

How do businesses overcome challenges in implementing port-centric logistics?

While port-centric logistics offers numerous benefits, businesses may encounter challenges when implementing this model. These challenges can arise from various factors, including operational complexities, regulatory requirements, and the need for significant investment in infrastructure and technology. Here are some strategies that businesses can employ to overcome these challenges:

Conducting Comprehensive Feasibility Studies

Before implementing port-centric logistics, businesses should conduct thorough feasibility studies to assess the potential benefits and challenges. This process involves:

-

Evaluating market demand: Understanding the specific logistics needs of the target market can help businesses tailor their port-centric strategies.

-

Analyzing costs and benefits: A detailed cost-benefit analysis can identify potential savings and justify the investment in port-centric infrastructure.

Investing in Technology and Infrastructure

Successful implementation of port-centric logistics requires significant investment in technology and infrastructure. Businesses should focus on:

-

Upgrading IT systems: Investing in advanced warehouse management and transportation management systems can enhance operational efficiency.

-

Developing port facilities: Building or upgrading warehousing, distribution, and customs facilities near the port is essential for effective operations.

Building Strong Partnerships

Collaboration with key stakeholders is critical for overcoming challenges in port-centric logistics:

-

Engaging with port authorities: Building strong relationships with port authorities can facilitate smoother operations and access to necessary resources.

-

Collaborating with logistics providers: Partnering with third-party logistics (3PL) providers can enhance capabilities and provide expertise in managing port-centric operations.

Navigating Regulatory Compliance

Compliance with customs and regulatory requirements can be a significant challenge in port-centric logistics. Businesses can address this by:

-

Investing in compliance training: Providing training for staff on customs regulations and compliance requirements can reduce the risk of delays and penalties.

-

Utilizing customs brokers: Engaging with experienced customs brokers can streamline the clearance process and ensure compliance with regulations.

Enhancing Supply Chain Visibility

Improving visibility across the supply chain is essential for managing the complexities of port-centric logistics:

-

Implementing tracking systems: Utilizing real-time tracking and monitoring technologies can enhance visibility and enable proactive issue management.

-

Sharing information with partners: Collaborating with logistics partners to share data and insights can improve overall supply chain transparency.

Fostering a Culture of Continuous Improvement

Businesses should cultivate a culture of continuous improvement to address challenges and optimize port-centric logistics operations:

-

Encouraging feedback: Soliciting feedback from employees and stakeholders can identify areas for improvement and drive innovation.

-

Implementing performance metrics: Establishing key performance indicators (KPIs) can help businesses measure the effectiveness of their port-centric logistics strategies and make data-driven decisions.

To summarize the strategies for overcoming challenges in implementing port-centric logistics, consider the following table:

| Challenge | Strategy |

|---|---|

| Operational Complexities | Conduct comprehensive feasibility studies to assess potential benefits and challenges. |

| Investment in Infrastructure | Invest in technology and infrastructure to enhance operational efficiency. |

| Regulatory Compliance | Engage with customs brokers and provide compliance training to staff. |

| Supply Chain Visibility | Implement tracking systems and share information with logistics partners. |

| Continuous Improvement | Foster a culture of continuous improvement through feedback and performance metrics. |

By employing these strategies, businesses can successfully navigate the challenges associated with implementing port-centric logistics. The key lies in careful planning, investment in resources, and collaboration with stakeholders to create a seamless and efficient logistics operation.

What real-world examples demonstrate successful port-centric logistics?

Several real-world examples illustrate the successful implementation of port-centric logistics, showcasing how businesses have leveraged this model to enhance efficiency, reduce costs, and improve service levels. These examples highlight the diverse applications of port-centric logistics across various industries and regions.

Example 1: Port of Rotterdam, Netherlands

The Port of Rotterdam is one of the largest and most advanced ports in the world, and it has successfully implemented port-centric logistics strategies. Key features include:

-

Integrated Logistics Hub: The port serves as a major logistics hub for Europe, with extensive warehousing and distribution facilities located in close proximity to the port.

-

Advanced IT Systems: The Port of Rotterdam utilizes advanced information technology systems to enhance supply chain visibility and streamline operations.

-

Sustainability Initiatives: The port has invested in sustainable practices, including renewable energy sources and efficient waste management systems.

Example 2: Port of Los Angeles, USA

The Port of Los Angeles is a prime example of port-centric logistics in action, particularly in the context of international trade with Asia. Notable aspects include:

-

Direct Access to Inland Markets: The port’s strategic location allows for efficient connections to major highways and rail networks, facilitating the movement of goods to inland markets.

-

Customs Facilities: On-site customs services expedite the clearance process, reducing delays for importers and exporters.

-

Collaboration with Stakeholders: The Port of Los Angeles has established partnerships with logistics providers and local businesses to enhance supply chain efficiency.

Example 3: Port of Hamburg, Germany

The Port of Hamburg has embraced port-centric logistics to enhance its competitiveness in global trade. Key initiatives include:

-

Intermodal Transportation: The port offers extensive intermodal transportation options, including rail, road, and inland waterways, allowing for seamless movement of goods.

-

Value-Added Services: Port-centric facilities provide a range of value-added services, such as packaging, assembly, and quality control, enabling businesses to customize their offerings.

-

Focus on Sustainability: The Port of Hamburg has implemented various sustainability initiatives, including reducing emissions and promoting eco-friendly practices.

Example 4: DP World Jebel Ali Port, UAE

DP World Jebel Ali Port is a leading example of port-centric logistics in the Middle East. Key features include:

-

Free Trade Zone: The port includes a free trade zone that allows businesses to operate with reduced customs duties and regulations, attracting international trade.

-

Advanced Logistics Facilities: The port has invested in state-of-the-art logistics facilities, including warehouses and distribution centers, to support efficient operations.

-

Strong Connectivity: Jebel Ali Port offers excellent connectivity to regional and global markets, enhancing its role as a logistics hub.

Example 5: Port of Singapore

The Port of Singapore is a global leader in port-centric logistics, known for its efficiency and advanced infrastructure. Notable aspects include:

-

Integrated Logistics Ecosystem: The port has developed a comprehensive logistics ecosystem that includes warehousing, distribution, and value-added services.

-

Smart Port Initiatives: The Port of Singapore has embraced smart technologies, such as automation and data analytics, to enhance operational efficiency.

-

Sustainability Goals: The port is committed to sustainability, with initiatives aimed at reducing emissions and promoting green logistics practices.

To summarize these real-world examples, consider the following table:

| Port | Key Features |

|---|---|

| Port of Rotterdam | Integrated logistics hub, advanced IT systems, sustainability initiatives. |

| Port of Los Angeles | Direct access to inland markets, customs facilities, collaboration with stakeholders. |

| Port of Hamburg | Intermodal transportation, value-added services, focus on sustainability. |

| DP World Jebel Ali Port | Free trade zone, advanced logistics facilities, strong connectivity. |

| Port of Singapore | Integrated logistics ecosystem, smart port initiatives, sustainability goals. |

These examples demonstrate the diverse applications and benefits of port-centric logistics across various global contexts. By leveraging the unique advantages of port facilities, these ports and businesses have successfully optimized their supply chain operations, reduced costs, and enhanced service levels. As global trade continues to evolve, port-centric logistics will likely play an increasingly important role in shaping the future of logistics and supply chain management.