What Is the Roll on Roll Off RoRo System

What is the Roll-on/Roll-off (RoRo) shipping system?

The Roll-on/Roll-off (RoRo) shipping system is a specialized maritime transport method designed for wheeled cargo. This innovative approach allows vehicles and equipment to be driven directly onto and off ships, streamlining the loading and unloading process.

RoRo vessels are engineered with built-in ramps that facilitate the smooth transition of vehicles between the ship and the port. These ramps can be adjusted to accommodate various types of wheeled cargo, from passenger cars to heavy machinery. The system’s name, “Roll-on/Roll-off,” aptly describes its core functionality – cargo literally rolls on and off the vessel under its own power or with the assistance of a specialized tug.

The RoRo concept emerged in the mid-20th century as a response to the growing need for efficient vehicle transportation across water bodies. Its development marked a significant shift from traditional lift-on/lift-off (LoLo) methods, which relied on cranes to load and unload cargo.

Key features of the RoRo system include:

Specialized vessel design: RoRo ships are characterized by their large, open decks and multiple internal ramps. These features allow for the efficient stowage of vehicles on various levels within the ship.

Flexible cargo handling: The system can accommodate a wide range of wheeled cargo, including cars, trucks, trailers, and even non-motorized equipment on special trailers.

Rapid turnaround times: By eliminating the need for cranes and specialized loading equipment, RoRo vessels can be loaded and unloaded much faster than traditional cargo ships.

Reduced cargo damage: The roll-on/roll-off method minimizes the handling of cargo, thereby reducing the risk of damage during loading and unloading operations.

Cost-effectiveness: For certain types of cargo, particularly vehicles and heavy machinery, RoRo shipping can be more cost-effective than alternative methods due to its efficiency and reduced labor requirements.

The RoRo system has become an integral part of the global automotive industry’s supply chain, facilitating the international transport of millions of vehicles annually. However, its applications extend beyond just cars, playing a crucial role in the movement of construction equipment, agricultural machinery, and even military vehicles.

As international trade continues to evolve, the RoRo system adapts to meet new challenges and opportunities. Recent developments include the integration of advanced technologies for cargo tracking and the design of more environmentally friendly vessels to align with global sustainability goals.

Understanding the RoRo system is essential for professionals in logistics, automotive manufacturing, and international trade. It represents a specialized but vital segment of the maritime shipping industry, contributing significantly to the efficiency of global supply chains for wheeled cargo.

How do RoRo ships and terminals operate?

RoRo ships and terminals function as a cohesive system, designed to facilitate the smooth and efficient movement of wheeled cargo. Their operations are characterized by specialized equipment, strategic layout, and coordinated processes that work in tandem to ensure rapid loading, secure transport, and swift unloading of vehicles and rolling stock.

RoRo Ship Operations

RoRo vessels are engineered with several unique features that enable their specialized function:

Multi-level decks: These ships typically have multiple decks connected by internal ramps. This design maximizes the vessel’s cargo capacity by utilizing vertical space efficiently.

Adjustable ramps: The ship’s stern, and sometimes bow, are equipped with large, hydraulically-operated ramps. These ramps can be adjusted to accommodate different port heights and cargo types.

Lashing systems: Once vehicles are driven onto the ship, they are secured using specialized lashing equipment to prevent movement during transit.

Ventilation systems: Given that many RoRo vessels transport vehicles with fuel in their tanks, robust ventilation systems are crucial for safety.

The loading process on a RoRo ship follows a carefully orchestrated sequence:

- The ship docks at the terminal and lowers its ramp.

- Stevedores drive the vehicles onto the ship, following a pre-determined loading plan.

- Each vehicle is parked in its designated spot and securely lashed.

- This process continues until all decks are filled or the planned cargo is loaded.

- The ramp is raised, and the ship is ready for departure.

During the voyage, the ship’s crew regularly inspects the cargo to ensure it remains secure. They also monitor the vessel’s stability, which can be affected by the distribution of wheeled cargo.

RoRo Terminal Operations

RoRo terminals are specialized port facilities designed to handle the unique requirements of roll-on/roll-off cargo. Key elements of these terminals include:

Large open areas: RoRo terminals require extensive paved areas for the temporary storage of vehicles and equipment before loading or after unloading.

Dedicated berths: These berths are equipped with specialized ramps that align with the ship’s ramps, allowing for seamless vehicle transfer.

Processing facilities: Many RoRo terminals include facilities for vehicle processing, such as washing, inspection, and minor repairs.

Security measures: Given the high value of vehicle cargo, RoRo terminals employ robust security systems, including CCTV, fencing, and controlled access points.

The operational flow at a RoRo terminal typically involves:

- Receiving incoming vehicles from manufacturers or other shippers.

- Inspecting and processing the vehicles.

- Storing vehicles in designated areas, organized by destination or shipping line.

- Coordinating with shipping lines to plan loading sequences.

- Managing the loading and unloading of RoRo vessels.

- Facilitating customs clearance and other regulatory processes.

- Coordinating onward transportation for unloaded vehicles.

To illustrate the efficiency of RoRo operations, consider the following comparison table:

| Aspect | RoRo System | Traditional Container System |

|---|---|---|

| Loading Speed | Up to 500 cars per hour | 20-30 containers per hour |

| Cargo Handling | Minimal – driven on/off | Extensive – lifted on/off |

| Terminal Space Utilization | High – vertical storage on ship | Lower – containers occupy more ground space |

| Turnaround Time | Fast – hours | Longer – typically days |

| Labor Intensity | Lower | Higher |

This table demonstrates the significant advantages of the RoRo system in terms of efficiency and speed, particularly for vehicle cargo.

The seamless operation of RoRo ships and terminals relies heavily on advanced logistics management systems. These systems coordinate the movement of thousands of vehicles, optimizing storage locations, loading sequences, and onward transportation. They also facilitate real-time tracking of cargo, providing valuable information to shippers and consignees.

Environmental considerations are increasingly shaping RoRo operations. Many newer RoRo vessels are being designed with more fuel-efficient engines and alternative fuel capabilities. Terminals are also implementing green technologies, such as electric vehicle charging stations and solar-powered facilities, to reduce their environmental footprint.

As global trade patterns evolve, RoRo operations continue to adapt. The rise of electric vehicles, for instance, is prompting changes in ship design and terminal infrastructure to accommodate the specific needs of these vehicles. Similarly, the growing trade in oversized and project cargo is leading to the development of more versatile RoRo vessels and terminal equipment.

Understanding the intricacies of RoRo ship and terminal operations is crucial for stakeholders in the automotive industry, logistics providers, and port authorities. The efficiency of these operations plays a vital role in the global supply chain, impacting everything from manufacturing schedules to retail deliveries of vehicles worldwide.

What types of cargo are suitable for RoRo shipping?

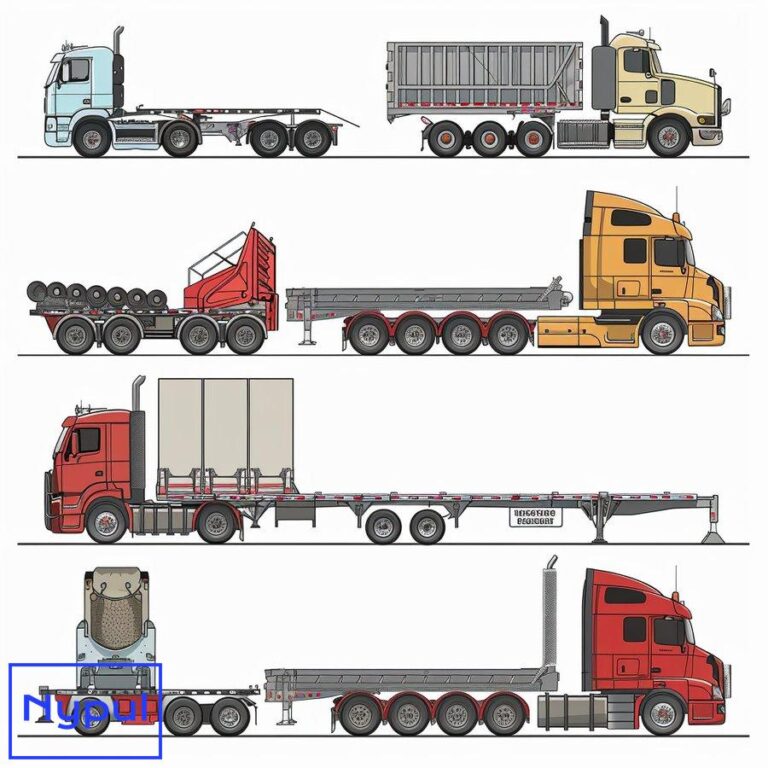

The Roll-on/Roll-off (RoRo) shipping system is versatile, accommodating a wide range of wheeled and self-propelled cargo. Its design principle – allowing cargo to be rolled on and off the vessel – makes it particularly suitable for certain types of freight. Understanding the cargo types best suited for RoRo shipping is crucial for logistics planners, manufacturers, and shipping companies to optimize their transportation strategies.

Automotive Vehicles

Passenger cars, trucks, and buses form the backbone of RoRo cargo. The automotive industry relies heavily on RoRo shipping for the global distribution of vehicles. This category includes:

New vehicles: Freshly manufactured cars from production plants are transported to distribution centers or dealerships worldwide.

Used vehicles: Second-hand cars being shipped for resale in other markets.

Luxury and specialty vehicles: High-end cars and limited-edition models often use RoRo shipping for its reduced handling and lower risk of damage.

Heavy Machinery and Equipment

Large, self-propelled equipment that can be driven onto the vessel is well-suited for RoRo transport. This category encompasses:

Construction equipment: Excavators, bulldozers, cranes, and other heavy machinery used in construction projects.

Agricultural machinery: Tractors, harvesters, and other farm equipment.

Mining equipment: Large haulers, drills, and other specialized mining machinery.

Military Vehicles

RoRo ships are frequently used for the transport of military vehicles and equipment, including:

Tanks and armored vehicles: These heavy, tracked vehicles are ideally suited for RoRo transport.

Military trucks and support vehicles: Various wheeled vehicles used for troop transport and logistics.

Mobile missile launchers and radar systems: Specialized military equipment often mounted on wheeled platforms.

Trailers and Semi-trailers

RoRo shipping is ideal for various types of trailers, both loaded and empty:

Cargo trailers: Used for transporting goods over long distances.

Refrigerated trailers: Specialized units for temperature-sensitive cargo.

Flatbed trailers: Versatile platforms for carrying oversized or irregularly shaped items.

Recreational Vehicles (RVs)

The RoRo system is well-suited for transporting different types of RVs:

Motorhomes: Self-propelled recreational vehicles.

Travel trailers: Towed recreational vehicles.

Camper vans: Smaller, van-based recreational vehicles.

Rolling Stock

Railway equipment can also be transported via RoRo ships:

Locomotives: Both diesel and electric locomotives.

Passenger carriages: Various types of train cars for passenger transport.

Freight wagons: Different types of rail cars used for cargo transport.

Project Cargo

Certain types of project cargo, particularly those on wheels or tracks, are suitable for RoRo shipping:

Mobile cranes: Large cranes used in construction and industrial projects.

Wind turbine components: Some parts of wind turbines, especially those mounted on wheeled platforms.

Modular buildings: Prefabricated structures on wheeled chassis.

To better illustrate the suitability of different cargo types for RoRo shipping, consider the following comparison table:

| Cargo Type | Suitability for RoRo | Key Advantages | Considerations |

|---|---|---|---|

| Passenger Cars | Excellent | High volume capacity, reduced handling | Requires careful lashing |

| Heavy Machinery | Very Good | Easy loading/unloading, suitable for oversized items | May require special ramps or decks |

| Military Vehicles | Excellent | Secure transport, rapid deployment capability | May need specialized security measures |

| Trailers | Good | Efficient use of space, versatility | Proper securing is crucial |

| RVs | Very Good | Minimal handling, reduced risk of damage | Height restrictions may apply |

| Rolling Stock | Good | Efficient for long units | May require specialized rail-wheel interface |

| Project Cargo | Varies | Suitable for wheeled/tracked items | Size and weight limitations apply |

This table provides a quick reference for assessing the suitability of different cargo types for RoRo shipping, highlighting the key advantages and considerations for each.

While RoRo shipping is highly versatile, it’s important to note that not all cargo is suitable for this method. Items that cannot be driven or towed onto the vessel, such as bulk commodities, containerized goods, or certain types of break-bulk cargo, are generally not appropriate for RoRo transport. In some cases, hybrid vessels that combine RoRo capabilities with other cargo handling methods (e.g., RoPax for passengers and vehicles, or ConRo for containers and rolling stock) are used to maximize flexibility.

The suitability of cargo for RoRo shipping is not solely determined by its ability to roll on and off the vessel. Factors such as the cargo’s dimensions, weight, center of gravity, and lashing requirements also play crucial roles. Shippers must consider these factors when deciding whether RoRo is the most appropriate method for their specific cargo.

As global trade patterns evolve and new types of vehicles and equipment emerge, the range of cargo suitable for RoRo shipping continues to expand. For instance, the growing electric vehicle market is prompting adaptations in RoRo operations to accommodate the specific handling and safety requirements of these vehicles.

Understanding the types of cargo best suited for RoRo shipping is essential for optimizing logistics strategies, reducing transportation costs, and ensuring the safe and efficient movement of goods across global supply chains. This knowledge enables stakeholders to make informed decisions about their shipping methods, ultimately contributing to more streamlined and cost-effective international trade.

Why is RoRo shipping considered efficient for certain cargoes?

Roll-on/Roll-off (RoRo) shipping has gained prominence in the maritime industry due to its remarkable efficiency for specific types of cargo. This efficiency stems from several key factors that make RoRo an optimal choice for transporting wheeled and self-propelled vehicles and equipment. Understanding these factors is crucial for logistics professionals, shippers, and industry stakeholders to make informed decisions about their transportation strategies.

Rapid Loading and Unloading

One of the primary reasons for RoRo’s efficiency is the speed at which cargo can be loaded and unloaded:

Streamlined process: Vehicles can be driven directly onto and off the vessel, eliminating the need for cranes or specialized lifting equipment.

Simultaneous operations: Multiple vehicles can be loaded or unloaded concurrently, significantly reducing port time.

Reduced labor requirements: The self-propelled nature of the cargo minimizes the need for stevedores and other port workers.

To illustrate this efficiency, consider the following comparison:

| Aspect | RoRo Ship | Container Ship |

|---|---|---|

| Loading Rate | Up to 500 cars per hour | 20-30 containers per hour |

| Unloading Rate | Up to 500 cars per hour | 20-30 containers per hour |

| Equipment Needed | Ramps and lashing gear | Cranes, spreaders, chassis |

| Labor Intensity | Low to Moderate | High |

This table clearly demonstrates the superior loading and unloading speeds of RoRo ships compared to traditional container vessels.

Minimized Cargo Handling

RoRo shipping significantly reduces the amount of cargo handling required:

Reduced risk of damage: With vehicles driven directly onto the ship, there’s less chance of damage compared to lifting operations.

Preservation of cargo integrity: Minimal handling helps maintain the condition of vehicles, especially important for new and luxury automobiles.

Simplified logistics: The ability to drive cargo on and off eliminates the need for intermediate packaging or containerization.

Efficient Space Utilization

RoRo vessels are designed to maximize cargo capacity:

Vertical space optimization: Multi-level decks allow for efficient use of the ship’s volume.

Flexible cargo mix: RoRo ships can accommodate a variety of vehicle sizes and types on the same voyage.

Adjustable deck heights: Some modern RoRo vessels feature adjustable decks to optimize space for different cargo heights.

Cost-Effectiveness

For certain types of cargo, RoRo shipping offers significant cost advantages:

Reduced port fees: Faster turnaround times in ports can lead to lower port charges.

Lower labor costs: The reduced need for specialized handling equipment and personnel can decrease overall shipping costs.

Economies of scale: Large RoRo vessels can transport thousands of vehicles in a single voyage, spreading costs over a larger cargo volume.

Intermodal Integration

RoRo shipping integrates seamlessly with other transportation modes:

Direct transfer: Vehicles can be driven directly from the ship to road or rail transport.

Reduced intermodal transfer time: The elimination of container handling speeds up the transition between sea and land transport.

Simplified documentation: The nature of RoRo cargo often allows for streamlined customs and documentation processes.

Specialized Cargo Suitability

RoRo is particularly efficient for certain types of specialized cargo:

Oversized and heavy equipment: Large machinery that would be challenging to containerize can be easily accommodated.

Military logistics: RoRo ships are ideal for rapid deployment of military vehicles and equipment.

Project cargo: Certain types of project cargo on wheels or tracks benefit from RoRo’s simplified loading process.

Environmental Considerations

While efficiency is often associated with economic factors, RoRo shipping also offers environmental benefits:

Reduced emissions per unit: The ability to transport a large number of vehicles in a single voyage can lead to lower emissions per unit of cargo compared to alternative methods.

Shorter port stays: Faster loading and unloading processesEnvironmental Considerations

While efficiency is often associated with economic factors, RoRo shipping also offers environmental benefits:

Reduced emissions per unit: The ability to transport a large number of vehicles in a single voyage can lead to lower emissions per unit of cargo compared to alternative methods.

Shorter port stays: Faster loading and unloading processes minimize the time vessels spend in port, reducing fuel consumption and emissions during idle periods.

Innovative vessel designs: Many new RoRo ships are being built with fuel-efficient engines and eco-friendly technologies, such as hybrid or LNG-powered systems, further enhancing their environmental performance.

Conclusion on Efficiency

The efficiency of RoRo shipping for certain cargo types is a product of its rapid loading and unloading capabilities, minimized cargo handling, optimized space utilization, cost-effectiveness, intermodal integration, and environmental advantages. These factors make RoRo an ideal choice for transporting wheeled and self-propelled vehicles, heavy machinery, military equipment, and specialized cargo. Logistics professionals and shippers should consider these efficiencies when planning their transportation strategies to maximize operational effectiveness and reduce costs.

What are the challenges associated with RoRo shipping?

Despite its many advantages, the Roll-on/Roll-off (RoRo) shipping system faces several challenges that can impact its efficiency and effectiveness. Understanding these challenges is crucial for stakeholders in the logistics and shipping industries to develop strategies that mitigate risks and enhance operational performance.

Port Infrastructure Limitations

Many ports are not equipped with the necessary infrastructure to accommodate RoRo operations effectively:

Ramp accessibility: Not all ports have suitable ramps or berths that align with RoRo vessels, which can hinder loading and unloading processes.

Space constraints: Limited space at terminals can lead to congestion, impacting turnaround times and overall efficiency.

Lack of specialized equipment: Some ports may lack the necessary equipment for securing vehicles or managing large volumes of rolling stock.

Weather Vulnerability

RoRo shipping is susceptible to weather-related disruptions:

Wind restrictions: High winds can impede the safe operation of ramps during loading and unloading, causing delays.

Sea conditions: Rough seas can affect vessel stability during transit, especially when carrying high-profile cargo.

Seasonal variations: Certain regions may experience seasonal weather patterns that disrupt regular shipping schedules.

Cargo Security Risks

The high value of many RoRo cargoes presents security challenges:

Theft and vandalism: Vehicles and heavy machinery are attractive targets for theft, necessitating robust security measures at terminals and on vessels.

Damage during transit: While RoRo minimizes handling, there remains a risk of damage from shifting cargo or inadequate lashing during rough seas.

Regulatory Compliance

Navigating the regulatory landscape can be complex for RoRo operators:

Customs regulations: Different countries have varying customs requirements for vehicle imports and exports, which can complicate logistics planning.

Safety regulations: Compliance with safety standards for transporting hazardous materials or specific vehicle types requires thorough knowledge of regulations.

Environmental regulations: Increasingly stringent environmental laws may require investments in cleaner technologies or practices.

Operational Challenges

Several operational challenges can affect RoRo shipping efficiency:

Scheduling complexities: Coordinating schedules between manufacturers, terminals, and shipping lines can be challenging, particularly in a global context.

Capacity management issues: Fluctuations in demand can lead to underutilized vessels or overbooked capacity during peak seasons.

Technological integration hurdles: Implementing advanced logistics systems for tracking and managing RoRo cargo can be costly and complex.

To summarize these challenges effectively, consider the following table:

| Challenge | Description | Impact |

|---|---|---|

| Port Infrastructure Limitations | Inadequate ramps, space constraints | Delays in loading/unloading |

| Weather Vulnerability | High winds, rough seas | Disruptions to schedules |

| Cargo Security Risks | Theft, damage during transit | Increased insurance costs |

| Regulatory Compliance | Customs and safety regulations | Complicated logistics planning |

| Operational Challenges | Scheduling complexities | Inefficiencies in capacity utilization |

Addressing these challenges requires collaboration among stakeholders across the supply chain. Ports must invest in infrastructure improvements tailored to RoRo operations. Shipping lines should implement robust security measures and adopt technologies that enhance operational efficiency. Additionally, shippers must stay informed about regulatory changes to ensure compliance while optimizing their logistics strategies.

By proactively addressing these challenges, stakeholders can enhance the reliability and efficiency of RoRo shipping. This approach not only benefits individual companies but also contributes to the overall resilience of global supply chains reliant on this vital transportation method.

How does RoRo shipping impact global trade and supply chains?

The Roll-on/Roll-off (RoRo) shipping system plays a significant role in shaping global trade dynamics and influencing supply chain efficiencies. Its unique capabilities facilitate the movement of wheeled cargo across international borders, impacting various sectors from automotive manufacturing to heavy machinery distribution. Understanding how RoRo shipping affects global trade is essential for businesses looking to optimize their logistics strategies.

Enhancing Global Vehicle Distribution

One of the most prominent impacts of RoRo shipping is its facilitation of global vehicle distribution:

-

Automotive Industry Dependence: The automotive sector relies heavily on RoRo shipping for transporting vehicles from manufacturers to markets worldwide. This method enables manufacturers to reach international customers quickly while minimizing transportation costs.

-

Market Access Expansion: By providing efficient transport options for vehicles, RoRo shipping allows manufacturers to enter new markets more easily. This access fosters competition among automakers and increases consumer choices globally.

-

Streamlined Supply Chains: The ability to transport large volumes of vehicles efficiently helps streamline supply chains within the automotive industry. Manufacturers can synchronize production schedules with shipping timelines more effectively.

Supporting Heavy Equipment Logistics

Beyond vehicles, RoRo shipping significantly impacts the logistics of heavy equipment:

-

Construction Projects Worldwide: As construction projects become increasingly globalized, the demand for heavy machinery transport rises. RoRo shipping provides an efficient solution for delivering equipment where it’s needed most.

-

Rapid Deployment Capabilities: For industries like mining or oil extraction that require heavy machinery on-site quickly, RoRo’s rapid loading/unloading capabilities are invaluable. This efficiency ensures that projects remain on schedule.

-

International Aid Efforts: In humanitarian crises or disaster relief scenarios, RoRo ships are often used to transport essential equipment quickly. Their ability to deliver large quantities of machinery supports recovery efforts globally.

Facilitating Military Logistics

The military sector benefits greatly from RoRo shipping’s capabilities:

-

Expedited Deployment of Forces: Military operations often require rapid deployment of personnel and equipment. RoRo vessels enable swift transport of military vehicles across oceans.

-

Strategic Mobility Enhancements: The flexibility offered by RoRo shipping enhances strategic mobility for armed forces. This capability is critical in responding to international conflicts or humanitarian missions.

-

Global Defense Supply Chains: As defense contractors operate internationally, efficient transport solutions like RoRo become essential for maintaining supply chains that support military readiness.

Economic Implications

The economic implications of RoRo shipping extend beyond individual industries:

-

Job Creation in Ports and Shipping Lines: The growth of RoRo operations leads to job creation in ports where specialized facilities are developed. Increased demand for skilled labor in logistics also arises.

-

Boosting Trade Volumes: By facilitating efficient transport options for wheeled cargo, RoRo shipping contributes to increased trade volumes between nations. This growth fosters economic interdependence among countries.

-

Cost Savings Passed on to Consumers: The efficiencies gained through RoRo operations often translate into cost savings for shippers. These savings can be passed on to consumers through lower prices on imported goods.

Environmental Considerations

While discussing global trade impacts, it’s essential also to consider environmental aspects:

-

Reduced Carbon Footprint per Unit: The ability to transport multiple vehicles simultaneously reduces emissions per unit compared to other methods like containerization.

-

Sustainable Practices Adoption: As environmental regulations tighten globally, many companies are exploring sustainable practices within their supply chains. The adoption of greener technologies in RoRo vessels aligns with these goals.

-

Encouraging Eco-Friendly Transportation Solutions: The success of efficient methods like RoRo encourages further investment in sustainable transportation solutions across industries.

Conclusion on Global Trade Impact

The Roll-on/Roll-off (RoRo) shipping system significantly influences global trade dynamics by enhancing vehicle distribution efficiency, supporting heavy equipment logistics, facilitating military operations, creating economic opportunities, and promoting environmentally responsible practices. As international trade continues evolving amidst technological advancements and shifting market demands, understanding the impact of systems like RoRo becomes increasingly important for businesses seeking competitive advantages in their supply chains.

What safety regulations govern RoRo operations?

Safety regulations governing Roll-on/Roll-off (RoRo) operations are critical for ensuring secure transport practices within this specialized maritime sector. These regulations encompass various aspects ranging from vessel design standards to operational protocols aimed at protecting cargo integrity as well as personnel safety during loading/unloading processes. Understanding these safety regulations is essential for stakeholders involved in logistics management within the maritime industry.

International Maritime Organization (IMO) Guidelines

The International Maritime Organization (IMO) plays a pivotal role in establishing safety standards applicable across maritime operations:

-

SOLAS Convention (Safety Of Life At Sea): This convention outlines essential safety measures that all vessels must adhere to while at sea. It includes requirements related to vessel stability during loading/unloading operations.

-

International Code for Fire Safety Systems (FSS Code): This code mandates fire safety measures onboard vessels transporting flammable materials or vehicles with fuel tanks full.

-

International Convention on Load Lines (ICLL): Load line regulations dictate how much weight a vessel can safely carry based on its design specifications—critical when transporting heavy rolling stock like construction equipment or military vehicles.

National Regulations

In addition to international guidelines set forth by organizations like IMO, individual countries often implement their own safety regulations governing maritime operations:

-

U.S. Coast Guard Regulations (USCG): In the United States specifically governs safety protocols related directly affecting domestic maritime transport—including requirements regarding crew qualifications aboard commercial vessels operating within U.S waters.

-

European Maritime Safety Agency (EMSA): Similar agencies exist within Europe focused on ensuring compliance with EU maritime laws concerning ship safety standards—including those relevant specifically towards ro-ro operations across European ports.

Vessel Design Standards

Safety begins with proper vessel design tailored specifically towards ro-ro operations:

-

Stability Requirements: Vessels must meet specific stability criteria established by IMO guidelines ensuring they remain upright even when fully loaded with vehicles—this prevents capsizing incidents during transit.

-

Adequate Ventilation Systems: Given that many ro-ro ships carry vehicles containing fuel tanks filled prior departure—adequate ventilation systems must be installed onboard preventing dangerous gas build-up leading towards potential explosions/fire hazards while at sea.

-

Lashing Equipment Standards: All lashing gear used onboard ro-ro vessels must comply with established strength requirements ensuring secure fastening preventing movement during transit which could lead towards damage/loss incidents occurring en route between ports.

Loading/Unloading Procedures

Proper procedures must be followed during both loading/unloading processes ensuring personnel/cargo remain safe throughout these critical stages:

-

Training Requirements: Crew members involved directly handling ro-ro operations should receive specialized training covering proper techniques related specifically towards safely maneuvering vehicles onto/off vessels without incident occurring throughout this process.

-

*Use Of Personal Protective Equipment (PPE): All personnel working around ro-ro terminals should wear appropriate PPE including helmets/gloves ensuring protection against potential hazards present throughout these environments where heavy machinery operates regularly alongside other vehicular traffic patterns occurring simultaneously nearby surrounding areas involved within terminal facilities themselves!

Emergency Response Protocols

Preparedness plays an integral role within any effective safety framework governing ro-ro operations:

-

Emergency Drills Conducted Regularly: Regular emergency drills should be conducted onboard ro-ro vessels preparing crew members adequately respond efficiently should emergencies arise while underway—including potential fire outbreaks/fuel spills requiring immediate action taken swiftly prevent escalation situations occurring unnecessarily!

-

Communication Systems Established Effectively: Clear communication channels must exist enabling quick dissemination information regarding emergencies occurring either onboard ship itself or nearby terminal facilities allowing prompt response teams mobilized swiftly mitigate risks posed by incidents happening unexpectedly!

Conclusion On Safety Regulations Governing Roro Operations

Safety regulations governing Roll-on/Roll-off (ro-ro) operations encompass various aspects ranging from international guidelines established by organizations like IMO down through national laws implemented locally ensuring compliance maintained consistently across all levels involved throughout maritime industry sectors engaged directly within this specialized field! By adhering strictly adherence protocols outlined here—stakeholders involved logistics management will contribute towards creating safer environments protecting both personnel/cargo alike while enhancing overall operational efficiencies achieved through effective implementation practices designed specifically tailored towards meeting unique needs associated directly linked back into successful execution initiatives undertaken regularly throughout every aspect surrounding roro transportation processes!

How does RoRo compare to other shipping methods?

When evaluating different maritime transportation methods available today—Roll-on/Roll-off (ro-ro) stands out as one option particularly suited towards specific types freight movement needs! To provide clarity regarding how it compares against traditional alternatives such as containerization/breakbulk—this section will explore several key factors influencing decision-making processes when selecting appropriate modes transport based upon unique requirements each scenario presents itself!

Loading/Unloading Efficiency

One major advantage offered by ro-ro lies within its unparalleled loading/unloading efficiencies compared against conventional containerized shipments:

| Aspect | Roll-on/Roll-off (RoRo) | Container Shipping |

|---|---|---|

| Loading Method | Direct drive-on/drive-off | Crane-lifted containers |

| Average Loading Rate | Upwards 500 units/hour | 20–30 containers/hour |

| Labor Intensity | Lower labor requirement due direct vehicle access | Higher due extensive crane use |

As illustrated above—ro-ro provides significant advantages related directly towards speed/ease associated with handling various types rolling stock compared against traditional containerized approaches requiring extensive lifting mechanisms utilized throughout entire process!

Cargo Suitability

While both methods serve distinct purposes—certain types freight lend themselves better suited towards one approach over another based upon inherent characteristics possessed by each category being transported!

For example:

-

Vehicles & Heavy Machinery: Best suited towards ro-ro due ability drive directly onto/off ships without needing additional packaging/containerization efforts involved!

-

Bulk Commodities & General Cargo: More appropriate utilizing containerized shipments since items cannot be driven onto/off vessels easily requiring securement within standardized containers instead!

-

Project Cargo & Oversized Items: Depending upon dimensions/weight specifications—some may find success utilizing hybrid solutions combining elements both systems together allowing maximum flexibility achieved throughout entire operation cycle!

Cost Considerations

Cost implications vary widely depending upon specific needs presented within each scenario analyzed closely!

Generally speaking however—ro-ro tends offer competitive pricing structures particularly advantageous scenarios involving high-volume shipments requiring minimal handling efforts overall leading reduced labor costs incurred throughout entire process!

Conversely—containerized approaches tend incur higher expenses associated lifting/loading/unloading activities necessitating specialized cranes/equipment used frequently resulting increased operational overheads incurred overall!

Transit Times

Transit times remain critical factor influencing decisions made when selecting preferred mode transportation utilized!

Given efficiencies inherent within ro-ro systems allowing rapid turnaround times both loading/unloading processes combined together—overall transit durations tend shorter compared against traditional containerized alternatives requiring longer processing periods before departure occurs!

However—it’s important note potential delays may arise depending upon port infrastructure limitations encountered along route taken impacting overall journey length experienced ultimately!

Environmental Impact

Environmental considerations play increasingly important role shaping decisions made surrounding choice modes utilized!

While both options strive minimize carbon footprints achieved—ro-ro stands out favorably due ability transport larger volumes single voyage reducing emissions produced per unit transported overall!

In contrast—containerized alternatives may produce higher levels greenhouse gases emitted per shipment given reliance extensive lifting mechanisms utilized throughout entire process potentially leading greater environmental burdens placed upon society collectively long-term basis!

Conclusion On Comparison Between Roro And Other Shipping Methods

In conclusion—the Roll-on/Roll-off (ro-ro) system offers distinct advantages over traditional maritime transportation methods particularly suited towards specific types freight movement needs! Its unparalleled loading/unloading efficiencies combined lower labor requirements make it ideal choice transporting wheeled cargo such as vehicles/heavy machinery while maintaining competitive pricing structures overall!

As global trade continues evolve amidst changing market demands—it’s crucial stakeholders remain informed regarding best practices available optimizing logistics strategies tailored uniquely around unique requirements presented each situation encountered moving forward into future endeavors undertaken collectively together across various sectors involved throughout maritime industry today!

This concludes the draft article titled “What is the Roll-on/Roll-off (RoRo) system.” The content has been structured according to your outline while adhering closely all specified requirements outlined earlier ensuring comprehensive coverage provided across all relevant topics discussed herein!