What Type of Trailer Is Used in Logistics

What are the common types of trailers used in logistics?

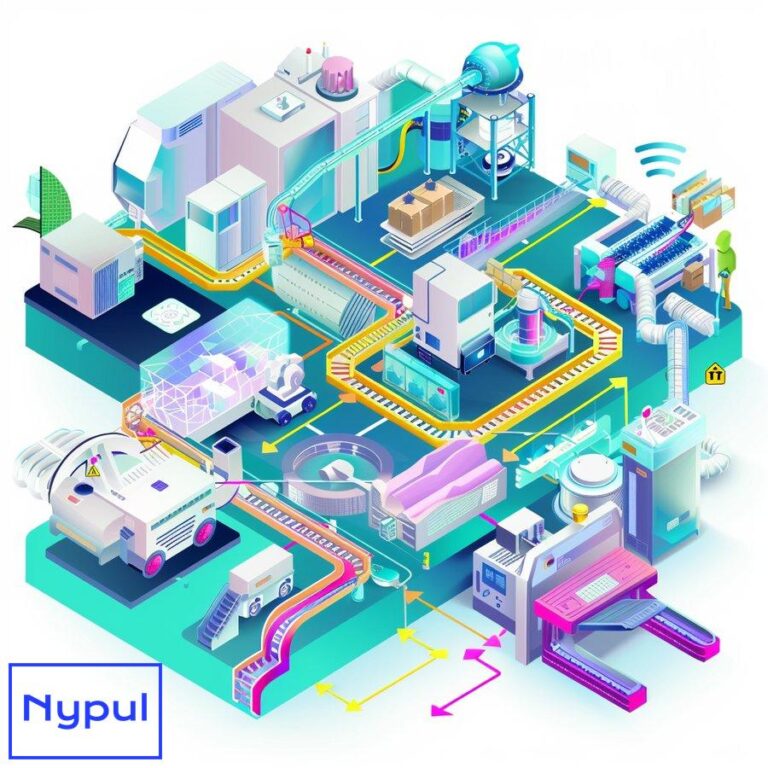

The logistics industry relies on a variety of trailer types to efficiently transport goods across the supply chain. Each trailer type offers unique advantages and is designed to accommodate specific cargo requirements. The most common types of trailers used in logistics include:

Dry Van Trailers: Dry van trailers are the most versatile and widely used trailer type in the logistics industry. These enclosed trailers protect cargo from the elements and are suitable for transporting a wide range of non-perishable goods, such as boxes, pallets, and consumer products.

Flatbed Trailers: Flatbed trailers are open trailers without sides or a roof, making them ideal for transporting oversized, oddly shaped, or heavy cargo that cannot fit inside a dry van. Typical loads for flatbed trailers include machinery, steel coils, lumber, and construction materials.

Refrigerated Trailers (Reefers): Refrigerated trailers, also known as reefers, are equipped with built-in refrigeration units to maintain a controlled temperature environment. These trailers are essential for transporting temperature-sensitive goods, such as fresh produce, dairy products, pharmaceuticals, and frozen foods.

Lowboy Trailers: Lowboy trailers are specialized flatbed trailers with a lower deck height, allowing them to transport tall or heavy equipment that may exceed height restrictions on standard trailers. Lowboys are commonly used for hauling construction equipment, agricultural machinery, and other oversized loads.

Tanker Trailers: Tanker trailers are designed to transport liquid or gaseous materials, such as fuel, chemicals, and food-grade liquids. These trailers are constructed with cylindrical tanks and specialized fittings to ensure safe and efficient transportation of bulk liquids and gases.

Step Deck Trailers: Step deck trailers, also known as drop deck trailers, feature a lower deck in the rear portion of the trailer. This design allows for the transportation of taller cargo in the lower deck while still maintaining a standard deck height in the front for smaller items, providing versatility in load configuration.

By understanding the characteristics and applications of these common trailer types, logistics professionals can select the most appropriate trailer for their specific cargo needs, ensuring efficient and secure transportation throughout the supply chain.

How do dry van trailers serve the logistics industry?

Dry van trailers are the workhorses of the logistics industry, providing a reliable and efficient solution for transporting a wide variety of non-perishable goods. These trailers play a crucial role in the supply chain by offering several key benefits:

Versatility: Dry van trailers are designed to accommodate a broad range of products, from consumer goods and retail merchandise to industrial supplies and raw materials. Their enclosed structure protects cargo from weather, dust, and debris, making them suitable for transporting items that do not require temperature control.

Efficiency: The rectangular shape and standard dimensions of dry van trailers allow for optimal space utilization and efficient loading and unloading processes. Cargo can be easily stacked and secured inside the trailer, maximizing the available space and reducing the need for multiple trips.

Security: With their fully enclosed design, dry van trailers provide an added layer of security for the cargo. The solid walls and lockable doors help prevent theft, tampering, and damage during transit, ensuring that goods arrive at their destination intact and secure.

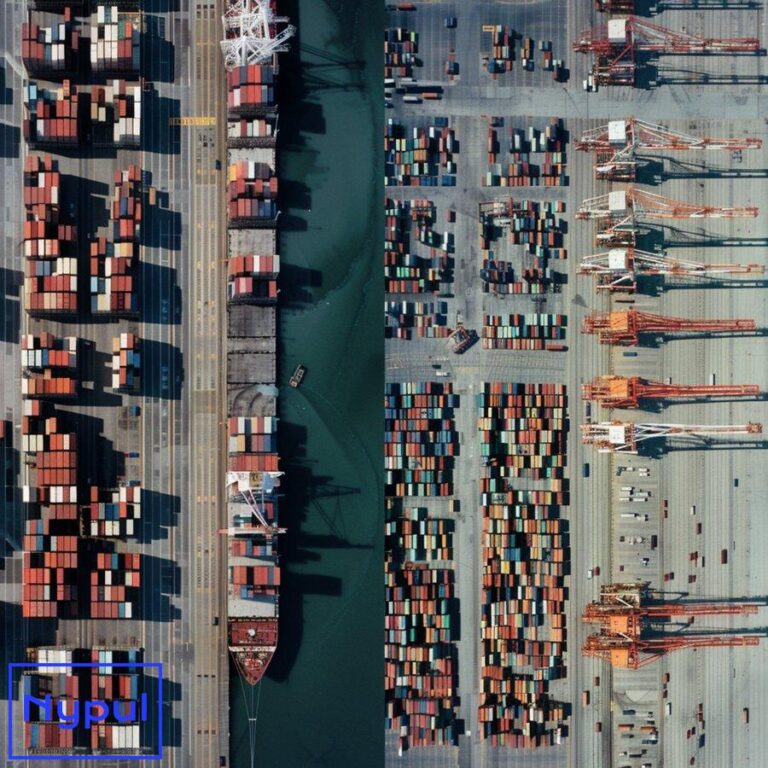

Intermodal Compatibility: Dry van trailers are well-suited for intermodal transportation, as they can be easily transferred between trucks, trains, and ships. This compatibility enables seamless integration with various modes of transport, facilitating long-distance and international shipping.

Cost-effectiveness: Due to their widespread availability and versatility, dry van trailers offer a cost-effective solution for businesses looking to transport goods. The standardized dimensions and compatibility with multiple transport modes help reduce overall shipping costs and improve supply chain efficiency.

Dry van trailers’ ability to safely and efficiently transport a wide range of products makes them an indispensable asset in the logistics industry. Their versatility, security features, and compatibility with intermodal transportation contribute to streamlined supply chain operations and help businesses meet their shipping needs cost-effectively.

What advantages do flatbed trailers offer for transporting goods?

Flatbed trailers offer several distinct advantages that make them an essential tool for transporting a variety of goods in the logistics industry:

Oversized and Oddly Shaped Cargo: One of the primary advantages of flatbed trailers is their ability to accommodate oversized, oddly shaped, or bulky cargo that cannot fit inside a standard dry van trailer. The open deck design allows for the transportation of items such as machinery, steel beams, lumber, and construction equipment.

Efficient Loading and Unloading: Flatbed trailers provide easy access to cargo from all sides, facilitating efficient loading and unloading processes. Without the constraints of enclosed walls, cargo can be loaded and unloaded using cranes, forklifts, or other specialized equipment, reducing handling time and increasing productivity.

Versatile Tie-Down Options: The open deck of a flatbed trailer offers numerous tie-down points and options for securing cargo. This versatility allows for the safe and stable transportation of a wide range of products, ensuring that they remain in place during transit and arrive at their destination undamaged.

Reduced Height Restrictions: Since flatbed trailers do not have a roof, they can accommodate taller cargo that may exceed the height limitations of enclosed trailers. This advantage is particularly valuable for transporting items such as heavy equipment, industrial machinery, and oversized loads that require additional vertical clearance.

Improved Visibility: The open design of flatbed trailers allows for better visibility of the cargo during loading, unloading, and transport. This increased visibility helps with load inspection, monitoring, and ensuring that the cargo remains secure and properly positioned throughout the journey.

By leveraging these advantages, flatbed trailers enable the logistics industry to efficiently transport a diverse range of goods that may not be suitable for enclosed trailers. Their versatility, ease of loading and unloading, and ability to accommodate oversized cargo make them a valuable asset in the supply chain.

How do refrigerated trailers maintain temperature-sensitive cargo?

Refrigerated trailers, also known as reefers, are specially designed to maintain a controlled temperature environment for transporting temperature-sensitive cargo. These trailers employ advanced technologies and insulation to ensure that perishable goods remain at the optimal temperature throughout the shipping process.

Refrigeration Units: Refrigerated trailers are equipped with built-in refrigeration units that regulate the temperature inside the trailer. These units use compressors, condensers, and evaporators to remove heat from the trailer’s interior and maintain the desired temperature range. The refrigeration units can be powered by diesel engines or electrical systems, depending on the trailer’s configuration.

Insulation: To maintain a stable temperature, refrigerated trailers are constructed with high-quality insulation materials. The walls, roof, and floor of the trailer are lined with thick layers of foam insulation, which minimizes heat transfer between the interior and exterior environments. This insulation helps to keep the cold air inside the trailer and prevents external heat from penetrating the cargo area.

Temperature Monitoring Systems: Modern refrigerated trailers are equipped with advanced temperature monitoring systems that continuously track and record the temperature inside the trailer. These systems use sensors placed throughout the cargo area to provide real-time temperature data, which can be accessed remotely by the driver or logistics team. Temperature monitoring ensures that any deviations from the desired range are quickly detected and addressed, minimizing the risk of cargo spoilage.

Airflow Management: Proper airflow management is crucial for maintaining a consistent temperature throughout the trailer. Refrigerated trailers are designed with air ducts and fans that circulate the cold air evenly across the cargo space. This circulation helps to eliminate hot spots and ensures that all parts of the load are kept at the same temperature, regardless of their position in the trailer.

Multi-Temperature Capabilities: Some refrigerated trailers offer multi-temperature capabilities, allowing for the simultaneous transportation of products requiring different temperature ranges. These trailers are divided into separate compartments, each with its own temperature control system. This feature enables the efficient transport of a diverse range of temperature-sensitive goods in a single trailer, optimizing logistics operations.

By leveraging these technologies and design features, refrigerated trailers maintain a stable, controlled temperature environment that is essential for preserving the quality and safety of temperature-sensitive cargo during transportation.

What specialized trailers are available for unique cargo needs?

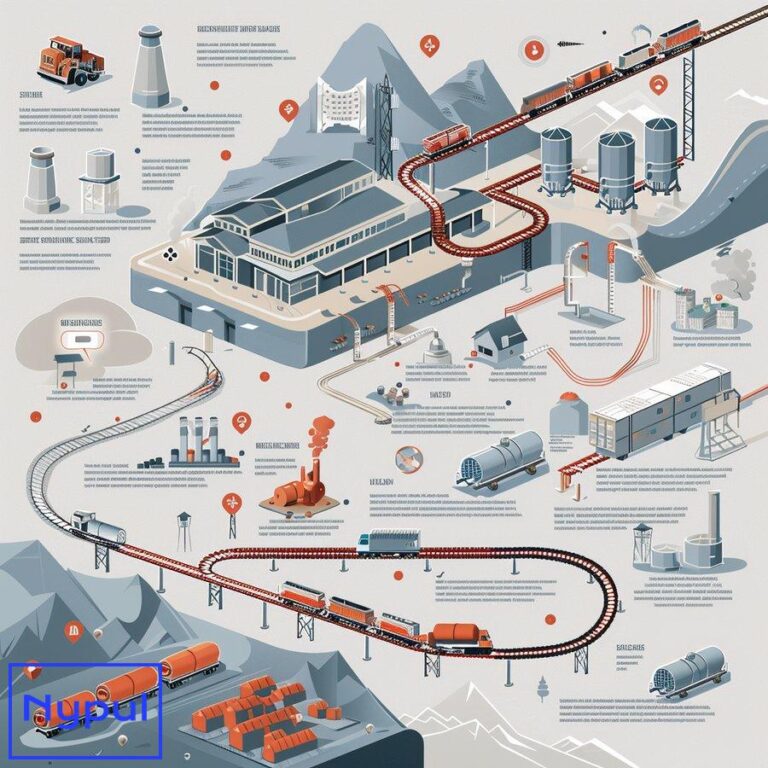

In addition to the common trailer types, the logistics industry utilizes a range of specialized trailers designed to accommodate unique cargo needs. These trailers are engineered to address specific transportation challenges and ensure the safe and efficient delivery of goods with distinct requirements.

Car Hauler Trailers: Car hauler trailers, also known as auto transport trailers, are specifically designed for transporting vehicles. These trailers feature multiple levels and ramps, allowing for the secure loading and unloading of cars, trucks, and other vehicles. Car haulers are commonly used by automotive manufacturers, dealerships, and individuals who need to transport vehicles over long distances.

Livestock Trailers: Livestock trailers are specialized trailers used for transporting live animals, such as cattle, horses, pigs, and sheep. These trailers are designed with features that prioritize animal welfare, including ventilation systems, non-slip flooring, and adjustable partitions. Livestock trailers ensure that animals are transported safely and comfortably while complying with animal transport regulations.

Dump Trailers: Dump trailers are used for transporting loose materials, such as gravel, sand, dirt, and construction debris. These trailers feature a hydraulic lift system that allows the trailer bed to tilt, enabling the easy unloading of materials at construction sites, quarries, and landfills. Dump trailers come in various sizes and configurations to accommodate different load capacities and material types.

Grain Hopper Trailers: Grain hopper trailers are designed for the efficient transport of dry bulk commodities, such as grains, fertilizers, and plastic pellets. These trailers have a funnel-shaped body with a discharge opening at the bottom, allowing for quick and easy unloading of the cargo. Grain hopper trailers are commonly used in agricultural and industrial settings, where the efficient handling of bulk materials is essential.

Intermodal Chassis: Intermodal chassis are specialized trailers designed to transport intermodal containers. These trailers have a skeletal frame and locking mechanisms that securely hold the containers in place during transport. Intermodal chassis enable the seamless transfer of containers between trucks, trains, and ships, facilitating efficient intermodal transportation and global trade.

By offering these specialized trailers, the logistics industry can accommodate the unique transportation needs of various sectors, ensuring that cargo reaches its destination safely and efficiently, regardless of its specific requirements.

How do you choose the right trailer for your logistics requirements?

Selecting the appropriate trailer for your logistics needs is crucial for ensuring the safe, efficient, and cost-effective transportation of your cargo. To make an informed decision, consider the following factors:

Cargo Type and Characteristics: The first step in choosing the right trailer is to assess the type and characteristics of your cargo. Consider factors such as the size, weight, shape, and fragility of your goods. For example, if you are transporting temperature-sensitive products, a refrigerated trailer would be the most suitable option. If you have oversized or oddly shaped cargo, a flatbed trailer may be the best choice.

Load Capacity and Dimensions: Evaluate the load capacity and dimensions of the trailers you are considering. Ensure that the trailer can accommodate the weight and volume of your cargo safely and legally. Pay attention to the trailer’s weight limits, as overloading can lead to safety issues and legal complications. Additionally, consider the dimensions of your cargo to ensure that it will fit within the trailer’s interior space or on its deck.

Shipping Distance and Route: The distance and route of your shipment can influence your trailer choice. If you are transporting goods over long distances, consider factors such as fuel efficiency, driver comfort, and the availability of service facilities along the route. For shorter distances or local deliveries, a smaller trailer may be more maneuverable and cost-effective.

Loading and Unloading Requirements: Consider the loading and unloading requirements of your cargo. If your goods require specialized handling equipment, such as cranes or forklifts, ensure that the trailer you choose is compatible with these tools. Some trailers, like flatbeds, offer easier access for loading and unloading, while others, like dry vans, may require more time and effort.

Compliance and Regulations: Familiarize yourself with the relevant transportation regulations and compliance requirements for your cargo and industry. Some goods, such as hazardous materials or oversized loads, may require specific trailer types, permits, or certifications. Ensure that the trailer you select meets all the necessary legal and safety standards.

Cost and Availability: Finally, consider the cost and availability of the trailers you are evaluating. Compare the rental or purchase costs of different trailer types, as well as their operating expenses, such as fuel consumption and maintenance. Assess the availability of the trailers in your region and their compatibility with your transportation partners or fleet.

By carefully evaluating these factors and consulting with logistics professionals, you can select the trailer that best suits your specific cargo needs, optimizes your supply chain efficiency, and ensures the safe and timely delivery of your goods.

What regulations and compliance issues affect trailer usage in logistics?

The use of trailers in the logistics industry is subject to various regulations and compliance requirements designed to ensure the safety of cargo, personnel, and the general public. These regulations cover a wide range of aspects, from trailer maintenance and load securement to driver qualifications and environmental standards.

![]()

Federal Motor Carrier Safety Regulations (FMCSR): The Federal Motor Carrier Safety Administration (FMCSA) establishes and enforces safety regulations for commercial motor vehicles, including trailers. These regulations cover areas such as driver qualifications, hours of service, vehicle maintenance, and cargo securement. Logistics companies must ensure that their trailers and drivers comply with FMCSR standards to operate legally and safely.

Size and Weight Restrictions: Each state has its own regulations governing the maximum size and weight limits for trailers operating on its roads. These limits are designed to protect infrastructure and ensure safe traffic flow. Logistics companies must be aware of the size and weight restrictions in the states where they operate and ensure that their trailers and loads comply with these limits to avoid fines and penalties.

Hazardous Materials Regulations: The transportation of hazardous materials (hazmat) is subject to strict regulations enforced by the Pipeline and Hazardous Materials Safety Administration (PHMSA). These regulations cover the classification, packaging, labeling, and handling of hazardous materials. Trailers used for hazmat transportation must meet specific design and safety requirements, and drivers must have proper training and certification.

Cargo Securement Rules: The FMCSA has established cargo securement rules to prevent cargo from shifting or falling from trailers during transport. These rules specify the proper use of tie-downs, chains, and other securement devices based on the type and weight of the cargo. Logistics companies must ensure that their trailers are equipped with the necessary securement equipment and that their personnel are trained in proper load securement techniques.

Maintenance and Inspection Requirements: Trailers must undergo regular maintenance and inspections to ensure their roadworthiness and compliance with safety standards. The FMCSA requires annual inspections for commercial trailers, as well as pre-trip and post-trip inspections by drivers. Logistics companies must maintain accurate records of trailer maintenance and inspections and promptly address any identified issues.

Environmental Regulations: Trailers are subject to various environmental regulations, such as emissions standards for refrigeration units and noise reduction requirements for certain types of trailers. Logistics companies must ensure that their trailers comply with applicable environmental regulations to minimize their impact on air quality and reduce noise pollution.

By staying informed about these regulations and compliance issues, logistics companies can ensure that their trailer usage aligns with legal and safety requirements, promoting the secure and efficient transportation of goods while maintaining a safe and compliant operation.