What Vessels Are Used for the Transportation of Rolling Cargo

Rolling cargo plays a crucial role in global trade, necessitating specialized vessels for its efficient transportation. This article explores the various types of ships used to transport rolling cargo, their unique features, and the factors that influence vessel selection for this purpose.

What is rolling cargo and why is it important in global trade?

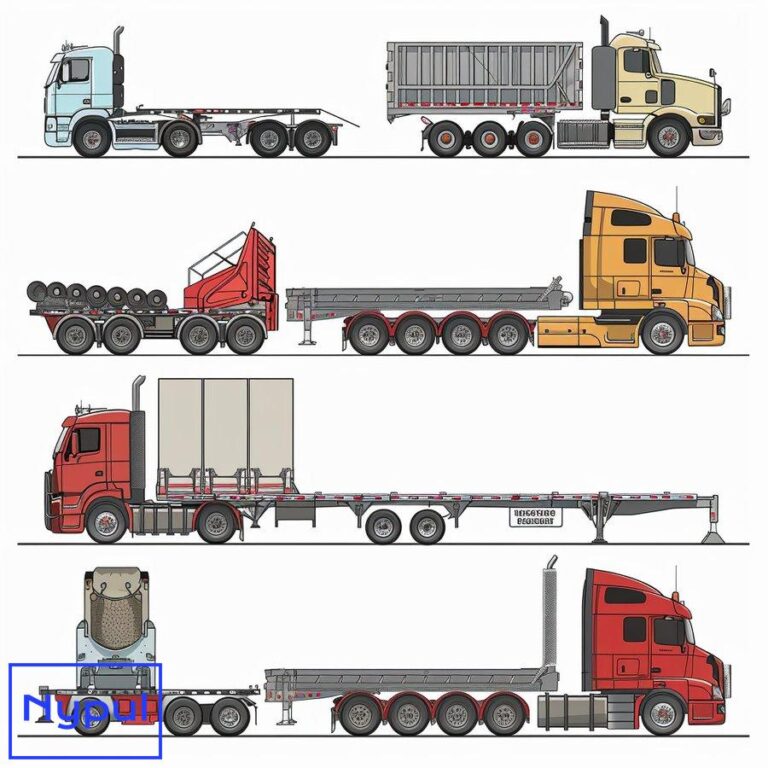

Rolling cargo, also known as ro-ro cargo, refers to wheeled vehicles and equipment that can be driven or rolled onto and off ships. This category includes a wide range of items such as cars, trucks, trailers, buses, construction equipment, and agricultural machinery. The significance of rolling cargo in global trade cannot be overstated, as it facilitates the movement of essential goods and vehicles across international borders.

Economic Impact

The transportation of rolling cargo contributes significantly to the global economy. The automotive industry, in particular, relies heavily on the efficient movement of vehicles from manufacturing plants to dealerships worldwide. In 2023, the global automotive market was valued at approximately $2.8 trillion, with a substantial portion of this value attributed to international trade facilitated by rolling cargo transportation.

Efficiency and Flexibility

Rolling cargo offers unique advantages in terms of efficiency and flexibility compared to other types of cargo:

Rapid Loading and Unloading: Vehicles can be driven directly onto and off ships, reducing port time and increasing overall efficiency.

Versatility: Rolling cargo vessels can accommodate a wide variety of wheeled goods, from passenger cars to heavy machinery.

Reduced Handling: The ability to roll cargo on and off ships minimizes the need for additional handling equipment, reducing the risk of damage and lowering overall costs.

Environmental Considerations

The transportation of rolling cargo also has environmental implications. While the efficiency of ro-ro vessels contributes to reduced fuel consumption per unit of cargo, the automotive industry’s reliance on these ships has led to increased scrutiny of their environmental impact. As a result, there is a growing focus on developing more sustainable rolling cargo transportation methods, including the use of alternative fuels and the implementation of energy-efficient technologies in vessel design.

Global Supply Chain Integration

Rolling cargo transportation plays a vital role in integrating global supply chains. Manufacturers can efficiently distribute their products to markets worldwide, enabling just-in-time delivery systems and reducing inventory costs. This integration has become increasingly important in the era of globalization, where companies rely on complex international networks for production and distribution.

Trade Facilitation

The ability to transport rolling cargo efficiently has facilitated trade agreements and economic cooperation between nations. Countries with strong automotive industries or those specializing in heavy machinery production benefit significantly from the availability of reliable rolling cargo transportation. This has led to the development of specialized ports and infrastructure to support the movement of wheeled goods, further enhancing global trade capabilities.

Understanding the importance of rolling cargo in global trade sets the stage for exploring the specialized vessels designed to transport these goods efficiently and safely across the world’s oceans.

How do Roll-on/Roll-off (RoRo) vessels work?

Roll-on/Roll-off (RoRo) vessels are specifically designed to transport wheeled cargo, allowing vehicles to be driven directly onto and off the ship. This unique design revolutionized the shipping industry by significantly reducing loading and unloading times compared to traditional cargo vessels. Let’s delve into the key aspects of how RoRo vessels operate.

Design and Structure

RoRo ships feature a distinctive design that sets them apart from other cargo vessels:

Ramps: The most prominent feature of RoRo vessels is their built-in ramps. These ramps can be located at the stern, bow, or side of the ship, allowing vehicles to be driven directly onto the vessel. Some ships have multiple ramps to facilitate faster loading and unloading.

Open Decks: RoRo ships have large, open decks that can accommodate various types of wheeled cargo. These decks are typically arranged in multiple levels, connected by internal ramps or elevators.

Watertight Doors: To ensure the safety and stability of the vessel, RoRo ships are equipped with watertight doors that can seal off different compartments in case of emergencies.

Loading Process

The loading process for RoRo vessels is straightforward and efficient:

-

Preparation: Before loading begins, the ship’s ramps are lowered and secured to the dock.

-

Vehicle Staging: Vehicles are staged in a designated area near the ship, organized based on their destination and loading order.

-

Driving On: Trained drivers or automated systems drive the vehicles onto the ship via the ramps.

-

Positioning: Once on board, vehicles are parked in predetermined locations on the various decks.

-

Securing: Each vehicle is securely lashed to the deck using specialized equipment to prevent movement during transit.

-

Sealing: After loading is complete, the ramps are raised, and all openings are sealed to ensure the vessel’s watertight integrity.

Cargo Handling Systems

RoRo vessels employ various systems to efficiently handle and secure cargo:

Lashing Systems: These include chains, straps, and tensioners used to secure vehicles to the deck, preventing movement during transit.

Deck Markings: Clear markings on the deck guide drivers and indicate designated parking areas for different types of vehicles.

Ventilation Systems: Proper ventilation is crucial to prevent the buildup of exhaust fumes and maintain air quality within the cargo holds.

Fire Suppression Systems: Given the nature of the cargo, RoRo vessels are equipped with advanced fire detection and suppression systems to ensure safety.

Navigation and Propulsion

RoRo vessels utilize advanced navigation and propulsion systems to ensure safe and efficient operation:

Bow Thrusters: These provide enhanced maneuverability, particularly useful when docking in tight spaces.

Stabilizers: To minimize rolling in rough seas, many RoRo ships are equipped with stabilizer systems.

Advanced Navigation Systems: GPS, radar, and other modern navigation technologies ensure accurate and safe voyages.

Fuel Efficiency: Many modern RoRo vessels incorporate fuel-efficient engines and design features to reduce operational costs and environmental impact.

Unloading Process

The unloading process essentially reverses the loading procedure:

-

Preparation: Upon arrival at the destination port, the ship’s ramps are lowered and secured.

-

Unlashing: Crew members remove the lashing equipment securing the vehicles.

-

Driving Off: Vehicles are driven off the ship, either by port workers or using automated systems.

-

Inspection: As vehicles exit the ship, they undergo inspection to ensure they have not been damaged during transit.

-

Customs Clearance: Depending on the port and destination, vehicles may need to clear customs before proceeding to their final destinations.

Efficiency and Turnaround Time

One of the key advantages of RoRo vessels is their rapid turnaround time in ports. The ability to drive cargo on and off the ship significantly reduces the time spent in port compared to traditional cargo vessels. This efficiency translates to cost savings for shipping companies and faster delivery times for customers.

| Aspect | RoRo Vessel | Traditional Cargo Vessel |

|---|---|---|

| Loading Method | Drive-on via ramps | Lifted by cranes |

| Loading Speed | High (vehicles driven on) | Lower (individual lifting) |

| Cargo Types | Wheeled vehicles, equipment | Containerized, bulk cargo |

| Port Infrastructure | Requires specialized ramps | Requires container cranes |

| Turnaround Time | Typically faster | Generally longer |

| Cargo Handling | Minimal (driven on/off) | More extensive (lifting, stacking) |

Understanding the operational principles of RoRo vessels provides insight into their efficiency and importance in the transportation of rolling cargo. These specialized ships have become an integral part of the global logistics network, facilitating the movement of vehicles and wheeled equipment across the world’s oceans with unparalleled speed and convenience.

What are the different types of RoRo ships?

Roll-on/Roll-off (RoRo) vessels come in various types, each designed to meet specific transportation needs and accommodate different types of rolling cargo. Understanding these different types of RoRo ships is crucial for shippers and logistics professionals to select the most appropriate vessel for their cargo requirements. Let’s explore the main categories of RoRo ships and their unique characteristics.

Pure Car Carriers (PCC)

Pure Car Carriers are specialized RoRo vessels designed primarily for transporting passenger vehicles:

Design: PCCs feature multiple decks with low clearance, optimized for stacking cars.

Capacity: These ships can typically carry between 4,000 to 8,000 cars.

Efficiency: PCCs are highly efficient for transporting large numbers of vehicles on long-distance routes.

Pure Car and Truck Carriers (PCTC)

PCTCs are an evolution of PCCs, designed to accommodate both cars and larger vehicles:

Versatility: These vessels can transport a mix of passenger cars, trucks, buses, and other larger vehicles.

Adjustable Decks: Many PCTCs feature adjustable decks that can be raised or lowered to accommodate vehicles of different heights.

Capacity: Modern PCTCs can carry up to 8,000 car equivalent units (CEUs).

Large Car and Truck Carriers (LCTC)

LCTCs represent the latest generation of car carriers, offering even greater capacity and flexibility:

Size: These are the largest RoRo vessels, with some capable of carrying over 8,000 CEUs.

High and Heavy Cargo: LCTCs are designed to handle a significant amount of high and heavy cargo, such as construction equipment and agricultural machinery.

Fuel Efficiency: Many LCTCs incorporate advanced propulsion systems and hull designs for improved fuel efficiency.

ConRo (Container Roll-on/Roll-off) Vessels

ConRo ships combine the features of container ships and RoRo vessels:

Dual Functionality: These vessels can carry both containerized cargo and rolling stock.

Design: ConRo ships typically have container storage on the upper decks and RoRo cargo on the lower decks.

Flexibility: This design offers flexibility in cargo mix, making ConRo vessels popular on routes with varied cargo demands.

RoPax (Roll-on/Roll-off Passenger) Vessels

RoPax ships are designed to carry both rolling cargo and passengers:

Passenger Accommodations: These vessels include cabins, restaurants, and other amenities for passengers.

Vehicle Capacity: RoPax ships can carry personal vehicles belonging to passengers as well as commercial rolling cargo.

Route Suitability: They are commonly used on short-sea routes and ferry services.

Deep Sea RoRo Vessels

These RoRo ships are designed for long-distance ocean voyages:

Endurance: Deep sea RoRo vessels have larger fuel capacities and are built to withstand harsh ocean conditions.

Cargo Mix: They can typically handle a diverse range of rolling cargo, from cars to heavy machinery.

Size: These ships are generally larger than short-sea RoRo vessels to accommodate more cargo for longer journeys.

Specialized RoRo Vessels

Some RoRo ships are built for specific types of cargo or routes:

Heavy Lift RoRo: Designed to handle exceptionally heavy or oversized cargo, such as large industrial equipment or wind turbine components.

Livestock Carriers: These RoRo vessels are specially equipped to transport live animals, featuring ventilation systems and feeding facilities.

Military RoRo Ships: Purpose-built for military logistics, these vessels can quickly deploy vehicles and equipment in various operational scenarios.

To provide a clear comparison of these different types of RoRo vessels, consider the following table:

| RoRo Vessel Type | Primary Cargo | Capacity (CEU) | Key Features |

|---|---|---|---|

| Pure Car Carrier (PCC) | Passenger cars | 4,000 – 8,000 | Low clearance decks, optimized for cars |

| Pure Car and Truck Carrier (PCTC) | Cars, trucks, buses | Up to 8,000 | Adjustable decks, versatile cargo mix |

| Large Car and Truck Carrier (LCTC) | Cars, trucks, heavy equipment | Over 8,000 | Largest capacity, high and heavy cargo capability |

| ConRo | Containers and rolling cargo | Varies | Dual functionality, flexible cargo mix |

| RoPax | Passengers and vehicles | Varies | Passenger amenities, suitable for short-sea routes |

| Deep Sea RoRo | Diverse rolling cargo | Varies | Long-distance capability, larger fuel capacity |

| Specialized RoRo | Specific cargo types (e.g., heavy lift, livestock) | Varies | Purpose-built features for specific cargo needs |

The diversity of RoRo vessel types reflects the varied needs of the global shipping industry. Each type of RoRo ship offers unique advantages, allowing shippers to choose the most appropriate vessel based on their specific cargo requirements, route characteristics, and operational needs. As the demand for efficient transportation of rolling cargo continues to grow, we can expect further innovations in RoRo vessel design and capabilities to meet evolving market demands.

What specialized features make RoRo vessels efficient for transporting rolling cargo?

RoRo vessels are equipped with a range of specialized features that make them highly efficient for transporting rolling cargo. These features are designed to maximize cargo capacity, ensure safe and secure transportation, and facilitate rapid loading and unloading processes. Let’s explore the key specialized features that contribute to the efficiency of RoRo vessels.

Ramp Systems

The ramp system is perhaps the most defining feature of RoRo vessels:

Stern Ramps: Located at the rear of the ship, stern ramps are the most common type. They allow for efficient loading and unloading, especially in ports with limited infrastructure.

Side Ramps: Some RoRo vessels are equipped with side ramps, which can be particularly useful in ports where stern loading is not possible or to facilitate simultaneous loading and unloading operations.

Quarter Ramps: These ramps are positioned at an angle between the stern and side of the ship, offering flexibility in port operations.

Bow Ramps: Less common but useful for certain operations, bow ramps allow for drive-through capability, which can be particularly efficient in some port configurations.

Adjustable Decks

Many modern RoRo vessels feature adjustable deck systems:

Hoistable Decks: These decks can be raised or lowered to accommodate vehicles of different heights, maximizing the use of vertical space within the ship.

Strengthened Decks: Certain areas of the deck are reinforced to handle heavier vehicles or equipment, providing flexibility in cargo placement.

Lashing Systems

Secure cargo stowage is critical for safe transportation:

Fixed Lashing Points: Decks are equipped with numerous fixed points for attaching lashing equipment.

Specialized Lashing Gear: RoRo vessels carry a variety of lashing equipment, including chains, straps, and tensioners, suitable for different types of vehicles and equipment.

Automated Lashing Systems: Some modern vessels incorporate automated or semi-automated lashing systems to improve efficiency and reduce labor requirements.

Ventilation Systems

Proper ventilation is crucial for the safety of both the cargo and the crew:

High-Capacity Fans: These ensure adequate air circulation throughout the cargo decks, preventing the buildup of exhaust fumes and maintaining air quality.

Monitoring Systems: Advanced sensors monitor air quality and can trigger additional ventilation or alarms if necessary.

Fire Safety Features

Given the nature of rolling cargo, fire safety is a top priority:

Advanced Fire Detection Systems: These include smoke, heat, and flame detectors strategically placed throughout the vessel.

Automatic Fire Suppression: Many RoRo ships are equipped with sprinkler systems or other automated fire suppression technologies.

Fire-Resistant Bulkheads: The ship’s internal structure is designed to contain and limit the spread of fire.

Cargo Management Systems

Efficient cargo handling is facilitated by advanced management systems:

Computerized Cargo Planning: Software helps optimize the loading plan, considering factors such as weight distribution, cargo type, and destination.

Real-Time Tracking: GPS-based systems allow for real-time tracking of individual vehicles or pieces of equipment on board.

Automated Guidance Systems: Some vessels use automated systems to guide vehicles to their designated parking spots, improving efficiency and reducing the risk of damage.

Propulsion and Maneuverability

RoRo vessels incorporate features to enhance their operational efficiency:

Bow Thrusters: These provide improved maneuverability, particularly useful during docking and undocking operations.

Fuel-Efficient Engines: Many modern RoRo ships use advanced propulsion systems designed for optimal fuel efficiency.

Dynamic Positioning Systems: These systems help maintain the ship’s position during loading and unloading operations, particularly in challenging weather conditions.

Specialized Lifting Equipment

While the primary method of loading is driving vehicles on and off, some RoRo vessels include additional equipment:

Internal Ramps and Lifts: These facilitate the movement of vehicles between decks.

Cargo Elevators: For vessels that handle a## How do alternative vessels handle rolling cargo transportation?

While RoRo vessels are the primary choice for transporting rolling cargo, there are alternative vessel types that can also accommodate wheeled goods. These alternatives may be used in specific situations or for certain types of cargo. Let’s explore some of the most common alternative vessels used for rolling cargo transportation.

Container Ships

While not specifically designed for rolling cargo, container ships can transport some types of wheeled goods:

Flat Racks: These are open-top containers with collapsible sides that can accommodate wheeled cargo.

Tweendecks: Some container ships have additional decks between the main decks, providing extra space for rolling cargo.

Lashing and Securing: Wheeled cargo on container ships is typically secured using chains, straps, and other lashing equipment.

Limitations: Container ships are not as efficient as RoRo vessels for rolling cargo due to the need for additional handling and the limited space available for vehicles.

Heavy Lift Ships

Heavy lift ships are designed to transport oversized and heavy cargo, including rolling stock:

Deck Space: These vessels have large, unobstructed deck space suitable for accommodating wheeled cargo.

Lifting Capacity: Heavy lift ships are equipped with powerful cranes capable of lifting extremely heavy loads.

Specialized Cargo: In addition to rolling cargo, heavy lift ships can transport other types of oversized equipment, such as industrial machinery and offshore structures.

Limitations: Heavy lift ships are not as efficient as RoRo vessels for standard rolling cargo due to the need for additional lifting equipment and the slower loading and unloading processes.

Multi-Purpose Vessels

Multi-purpose vessels are designed to handle a variety of cargo types, including rolling stock:

Versatility: These ships can transport a mix of containerized, bulk, and rolling cargo.

Deck Space: Multi-purpose vessels have flexible deck layouts that can be adapted to accommodate different cargo types.

Limitations: While multi-purpose vessels offer flexibility, they may not be as efficient as specialized RoRo ships for rolling cargo transportation.

Breakbulk Carriers

Breakbulk carriers are general cargo ships that can transport rolling stock:

Cargo Handling: Wheeled cargo is typically lifted onto the ship using cranes or other lifting equipment.

Lashing and Securing: Rolling cargo is secured using chains, straps, and other lashing equipment.

Limitations: Breakbulk carriers are not designed for rolling cargo transportation and may have limited deck space and cargo handling capabilities compared to RoRo vessels.

Combination Carriers

Combination carriers are a hybrid of RoRo and other vessel types, offering the ability to transport rolling cargo:

ConRo Ships: These vessels combine container and RoRo capabilities, allowing for the transportation of both containerized and wheeled cargo.

Ro-Ro/Lo-Lo Ships: These ships have both RoRo and lift-on/lift-off (Lo-Lo) capabilities, enabling them to handle a mix of rolling cargo and containerized cargo.

Limitations: While combination carriers provide flexibility, they may not be as efficient as specialized RoRo vessels for rolling cargo transportation.

While alternative vessels can accommodate rolling cargo to some extent, RoRo ships remain the most efficient and cost-effective choice for transporting wheeled vehicles and equipment. The specialized features and design of RoRo vessels make them the preferred option for shippers and logistics professionals who prioritize speed, flexibility, and cargo protection.

What factors should be considered when choosing a vessel for rolling cargo?

When selecting a vessel for transporting rolling cargo, several factors must be considered to ensure the most efficient and cost-effective solution. Shippers and logistics professionals must carefully evaluate these factors to make informed decisions that meet their specific cargo requirements and operational needs. Let’s explore the key factors to consider when choosing a vessel for rolling cargo transportation.

Cargo Type and Size

The type and size of the rolling cargo are crucial factors in vessel selection:

Vehicle Type: Whether the cargo consists of passenger cars, trucks, buses, or specialized equipment, the vessel must be able to accommodate the specific vehicle types.

Cargo Dimensions: The vessel’s deck height and clearance must be sufficient to accommodate the height and width of the cargo.

Cargo Weight: The vessel’s deck strength and overall carrying capacity must be able to support the weight of the rolling cargo.

Cargo Value: For high-value cargo, shippers may prioritize vessels with enhanced security features and cargo tracking capabilities.

Route and Distance

The characteristics of the shipping route and the distance of the voyage can influence vessel selection:

Port Infrastructure: The availability of suitable loading and unloading facilities at the origin and destination ports is essential. RoRo vessels require specialized ramps and infrastructure.

Water Depth: The vessel’s draft must be compatible with the water depth at the loading and unloading ports.

Weather Conditions: For long-distance voyages, the vessel’s seaworthiness and ability to withstand harsh weather conditions become more critical.

Transit Time: For time-sensitive cargo, shippers may prioritize vessels with faster transit times and efficient loading and unloading processes.

Frequency and Reliability: Regular, reliable service is essential for maintaining supply chain continuity.

Capacity and Flexibility

The vessel’s capacity and flexibility to accommodate changing cargo demands are important considerations:

Cargo Capacity: The vessel’s ability to carry the required volume of rolling cargo is essential. Shippers must consider both the number of vehicles and the mix of cargo types.

Deck Configuration: Adjustable decks and flexible cargo arrangements can enhance a vessel’s ability to accommodate different cargo mixes and sizes.

Scalability: As cargo volumes fluctuate, the ability to scale up or down by selecting larger or smaller vessels is beneficial.

Operational Efficiency

The vessel’s operational efficiency directly impacts the overall cost and timeliness of the shipping process:

Loading and Unloading Speed: Rapid loading and unloading processes minimize port time and increase efficiency.

Fuel Efficiency: Fuel-efficient vessels can reduce operational costs and environmental impact.

Reliability and Maintenance: Regular maintenance and a proven track record of reliability are essential for minimizing delays and disruptions.

Safety and Security

The safety and security of the cargo and crew are paramount considerations:

Safety Features: Vessels must comply with international safety regulations and have adequate fire suppression systems, ventilation, and cargo securing equipment.

Security Measures: For high-value cargo, shippers may prioritize vessels with enhanced security features, such as CCTV monitoring and restricted access areas.

Environmental Regulations: Compliance with environmental regulations, such as emission control and ballast water management, is increasingly important.

Cost and Pricing

The overall cost of the shipping service, including freight rates and ancillary fees, is a critical factor in vessel selection:

Freight Rates: Shippers must compare freight rates across different vessel types and shipping lines to find the most cost-effective option.

Ancillary Fees: Additional fees, such as port charges and cargo handling costs, can significantly impact the total shipping cost.

Cost-Benefit Analysis: Shippers must weigh the costs against the benefits of each vessel option, considering factors such as cargo protection, transit time, and reliability.

By carefully considering these factors, shippers and logistics professionals can make informed decisions when selecting a vessel for rolling cargo transportation. The choice of vessel ultimately depends on the specific requirements of the cargo, the shipping route, and the overall business objectives of the shipper.

How do loading and unloading systems differ among rolling cargo vessels?

The loading and unloading systems employed by rolling cargo vessels vary depending on the type of ship and the specific port infrastructure available. While RoRo vessels rely primarily on drive-on/drive-off methods, other vessel types may use alternative loading and unloading systems. Let’s explore the differences in loading and unloading systems among various rolling cargo vessels.

RoRo Vessels

RoRo ships are designed for efficient drive-on/drive-off loading and unloading:

Ramps: Stern, bow, or side ramps allow vehicles to be driven directly onto and off the vessel.

Cargo Decks: Vehicles are parked on multiple decks connected by internal ramps or elevators.

Lashing: Vehicles are secured to the deck using chains, straps, and tensioners to prevent movement during transit.

Cargo Planning: Computerized cargo planning systems optimize the loading sequence and vehicle placement.

Automated Systems: Some RoRo vessels incorporate automated guidance systems to assist drivers in parking vehicles on board.

ConRo Vessels

ConRo ships combine RoRo and container handling capabilities:

RoRo Decks: Lower decks are dedicated to rolling cargo, with drive-on/drive-off loading and unloading.

Container Handling: Upper decks are used for containerized cargo, which is typically lifted on and off using shore-based cranes.

Combination Loading: In some cases, rolling cargo may be loaded using a combination of drive-on/drive-off and crane lifting methods.

Heavy Lift Ships

Heavy lift vessels rely on crane lifting for loading and unloading rolling cargo:

Onboard Cranes: These ships are equipped with powerful cranes capable of lifting extremely heavy and oversized cargo.

Cargo Preparation: Rolling cargo is typically prepared for lifting by attaching specialized lifting gear, such as spreader bars or slings.

Lashing and Securing: Lifted cargo is secured to the deck using chains, straps, and other lashing equipment.

Multi-Purpose Vessels

Multi-purpose vessels can handle a variety of cargo types, including rolling stock:

Flexible Loading: These ships may employ a combination of drive-on/drive-off and crane lifting methods, depending on the cargo mix.

Cargo Handling Equipment: Multi-purpose vessels may carry their own cargo handling equipment, such as forklifts or cranes, to supplement port infrastructure.

Breakbulk Carriers

Breakbulk carriers rely on crane lifting for loading and unloading rolling cargo:

Shore-Based Cranes: Rolling cargo is lifted on and off the ship using shore-based cranes or mobile harbor cranes.

Cargo Preparation: As with heavy lift ships, rolling cargo is prepared for lifting using specialized gear.

Lashing and Securing: Lifted cargo is secured to the deck using chains, straps, and other lashing equipment.

Combination Carriers

Combination carriers, such as ConRo and Ro-Ro/Lo-Lo ships, employ a mix of loading and unloading systems:

RoRo Decks: Lower decks are dedicated to rolling cargo, with drive-on/drive-off loading and unloading.

Container Handling: Upper decks are used for containerized cargo, which is typically lifted on and off using shore-based cranes.

Combination Loading: In some cases, rolling cargo may be loaded using a combination of drive-on/drive-off and crane lifting methods.

The choice of loading and unloading system depends on the vessel type, port infrastructure, and cargo characteristics. RoRo vessels offer the most efficient drive-on/drive-off loading and unloading, while other vessel types rely more on crane lifting methods. Shippers must consider the available port facilities and the compatibility of the chosen vessel’s loading and unloading systems to ensure smooth and efficient cargo handling.

What safety measures are implemented on ships transporting rolling cargo?

Safety is of paramount importance when transporting rolling cargo by sea. RoRo vessels and other ships carrying wheeled vehicles and equipment must adhere to strict safety regulations and implement various measures to protect the cargo, crew, and the environment. Let’s explore the key safety measures implemented on ships transporting rolling cargo.

Fire Safety

Fire safety is a critical concern due to the presence of flammable materials and the potential for cargo damage:

Fire Detection Systems: RoRo vessels are equipped with advanced fire detection systems, including smoke, heat, and flame detectors.

Automatic Fire Suppression: Many ships have automatic sprinkler systems or other fire suppression technologies to quickly extinguish fires.

Fire-Resistant Bulkheads: The ship’s internal structure is designed with fire-resistant materials to contain and limit the spread of fire.

Crew Training: Crew members undergo extensive training in fire safety and emergency response procedures specific to rolling cargo vessels.

Ventilation Systems

Proper ventilation is essential to maintain air quality and prevent the buildup of exhaust fumes:

High-Capacity Fans: RoRo vessels have powerful fans that ensure adequate air circulation throughout the cargo decks.

Monitoring Systems: Advanced sensors monitor air quality and can trigger additional ventilation or alarms if necessary.

Cargo Securing

Secure cargo stowage is critical for safe transportation:

Lashing Equipment: Ships carry a variety of lashing equipment, including chains, straps, and tensioners, suitable for different types of vehicles and equipment.

Lashing Points: Decks are equipped with numerous fixed lashing points for attaching securing gear.

Cargo Planning: Computerized cargo planning systems optimize the loading sequence and vehicle placement to ensure proper weight distribution and stability.

Crew Training: Crew members are trained in proper cargo securing techniques and regularly inspect lashing equipment.

Stability and Ballast Systems

Maintaining the ship’s stability is essential for safe operations:

Ballast Water Management: Ballast water is used to maintain stability and can be adjusted based on cargo weight and distribution.

Stability Calculations: Detailed stability calculations are performed before and during the voyage to ensure the ship remains within safe limits.

Onboard Systems: Ships are equipped with various systems, such as trim and list indicators, to monitor and maintain stability.

Hazardous Cargo Management

Special precautions are taken when transporting hazardous materials:

Identification and Labeling: Hazardous cargo is clearly identified and labeled according to international regulations.

Segregation: Hazardous materials are segregated from other cargo and stored in designated areas with appropriate safety measures.

Crew Training: Crew members receive specialized training in handling and responding to incidents involving hazardous materials.

Emergency Response Plans: Ships have detailed emergency response plans in place to address potential incidents involving hazardous cargo.

Environmental Protection

Measures are taken to minimize the environmental impact of rolling cargo transportation:

Ballast Water Treatment: Ballast water is treated to remove or kill any invasive species before being discharged.

Emission Control: Many ships use low-sulfur fuels or have exhaust gas cleaning systems to reduce emissions.

Waste Management: Solid waste and sewage are properly stored and offloaded at designated port reception facilities.

Oil Spill Response: Ships have oil spill response equipment and procedures in place to quickly contain and clean up any spills.

By implementing these safety measures, ships transporting rolling cargo aim to protect the cargo, crew, and the environment while ensuring efficient and reliable transportation services. Compliance with international safety regulations and industry best practices is essential for maintaining a high level of safety in the rolling cargo shipping industry.