Whats the Difference Between Freight and Drayage

What is freight, and what are its main types?

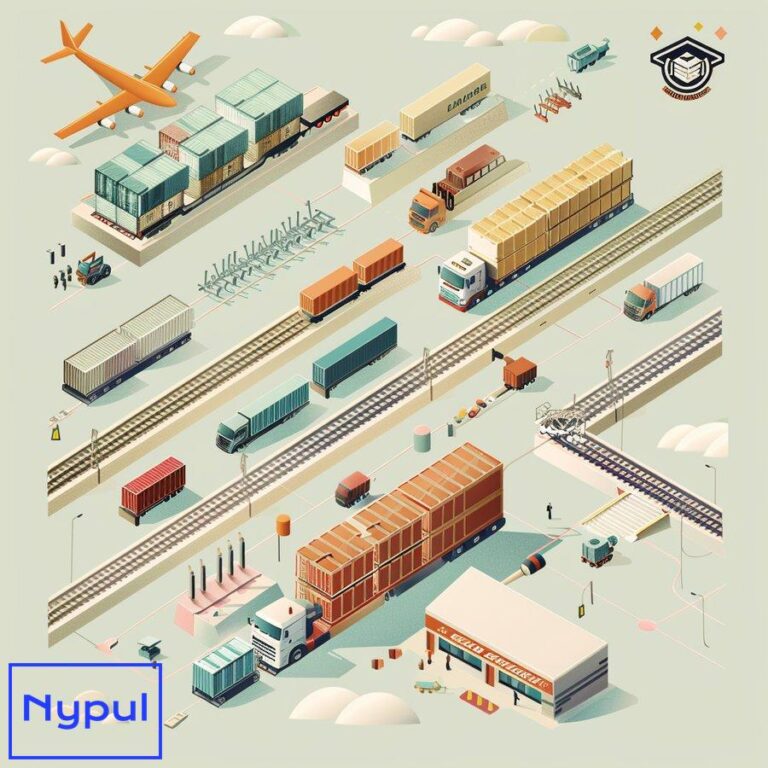

Freight refers to the transportation of goods in bulk, typically over long distances, by various modes such as trucks, trains, ships, or planes. It encompasses a wide range of cargo, from raw materials to finished products, and plays a vital role in facilitating trade and commerce on a local, national, and international scale.

Dry Freight

Dry freight includes goods that do not require special temperature control or handling during transportation. Examples include clothing, electronics, furniture, and non-perishable food items. These goods are typically transported in standard containers or trailers.

Refrigerated Freight

Also known as reefer freight, refrigerated freight involves the transportation of temperature-sensitive goods such as fresh produce, dairy products, pharmaceuticals, and chemicals. Specialized refrigerated containers or trailers maintain a controlled environment to prevent spoilage and ensure product integrity.

Hazardous Materials Freight

Hazardous materials (HAZMAT) freight includes goods that pose potential risks to health, safety, or the environment during transportation. Examples include flammable liquids, explosives, corrosive substances, and radioactive materials. HAZMAT freight requires special handling, packaging, and documentation to ensure compliance with strict regulations.

Less-than-Truckload (LTL) Freight

LTL freight involves the consolidation of smaller shipments from multiple customers into a single truckload. This cost-effective option is suitable for businesses that don’t have enough cargo to fill an entire truck. LTL carriers optimize routes and combine compatible shipments to maximize efficiency.

Full Truckload (FTL) Freight

FTL freight is a dedicated shipping method where a single customer’s goods occupy an entire truck. This option is ideal for large shipments or time-sensitive deliveries, as the truck travels directly from the origin to the destination without intermediate stops or cargo handling.

| Freight Type | Characteristics | Suitable For |

|---|---|---|

| Dry Freight | No special temperature control or handling required | Non-perishable goods, electronics, furniture |

| Refrigerated Freight | Temperature-controlled environment | Fresh produce, dairy, pharmaceuticals |

| Hazardous Materials Freight | Requires special handling and compliance with regulations | Flammable liquids, explosives, corrosive substances |

| Less-than-Truckload (LTL) Freight | Consolidation of smaller shipments from multiple customers | Businesses with shipments not large enough for a full truckload |

| Full Truckload (FTL) Freight | Dedicated shipping method for a single customer’s goods | Large shipments or time-sensitive deliveries |

How is drayage defined, and what is its role in intermodal transport?

Drayage is a specialized trucking service that involves the short-distance transportation of freight, typically within a limited geographical area such as a port, rail yard, or metropolitan region. It serves as a crucial link in the intermodal transportation chain, connecting different modes of transport and facilitating the smooth flow of goods.

In the context of intermodal transport, drayage plays a vital role in moving cargo between ports, rail terminals, and inland distribution centers. For example, when a container ship arrives at a port, drayage trucks are responsible for picking up the containers and transporting them to nearby warehouses or rail yards for further distribution.

First-Mile Drayage

First-mile drayage refers to the initial leg of the intermodal journey, where goods are transported from the shipper’s location to the nearest port or rail terminal. This stage involves the pickup of cargo from warehouses, factories, or storage facilities and its delivery to the point of embarkation.

Last-Mile Drayage

Last-mile drayage, also known as destination drayage, is the final stage of the intermodal transportation process. It involves the delivery of goods from the port or rail terminal to the consignee’s location, such as a distribution center, warehouse, or retail store. Last-mile drayage ensures that the cargo reaches its final destination efficiently.

Intra-Carrier Drayage

Intra-carrier drayage involves the transfer of cargo between two locations operated by the same carrier. This type of drayage is common when a carrier needs to reposition empty containers or move cargo between its own facilities to optimize operations and equipment utilization.

Inter-Carrier Drayage

Inter-carrier drayage refers to the transfer of cargo between two different carriers. This scenario arises when goods need to be moved from one carrier’s terminal to another’s, often to facilitate a change in the mode of transport or to accommodate the shipper’s or consignee’s preferences.

Drayage is essential for maintaining the efficiency and reliability of intermodal transport by ensuring seamless connections between different modes of transportation. It helps to minimize delays, reduce congestion at ports and terminals, and optimize the utilization of transportation assets.

What are the key differences between freight and drayage in terms of scope, transport types, and distance?

While both freight and drayage involve the transportation of goods, there are several key differences between the two in terms of scope, transport types, and distance covered.

Scope and Scale

Freight encompasses a broader range of transportation services, covering the movement of goods on a local, national, and international scale. It involves the shipping of large quantities of cargo, often in bulk, and can include various types of goods, from raw materials to finished products.

In contrast, drayage operates within a more limited scope, focusing on short-distance transportation within a specific geographical area, such as a port, rail yard, or metropolitan region. Drayage services are typically associated with the movement of containerized cargo, although they can also handle other types of freight.

Transport Types

Freight utilizes a wide range of transportation modes, including trucks, trains, ships, and planes. The choice of transport type depends on factors such as the nature of the goods, distance, time constraints, and cost considerations. Freight services can involve a single mode of transport or a combination of multiple modes, known as intermodal freight transport.

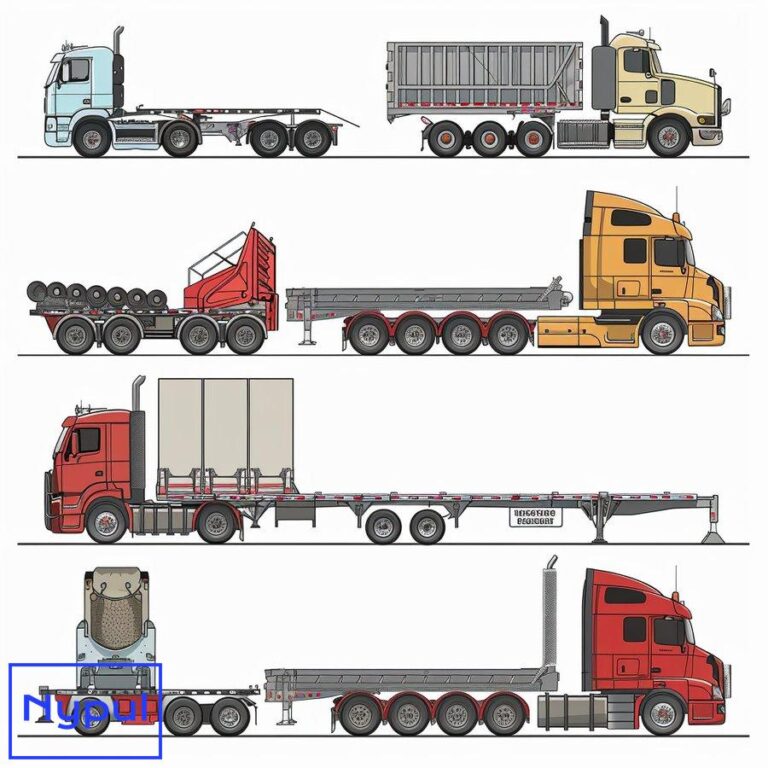

Drayage, on the other hand, primarily relies on trucking as the mode of transportation. Drayage trucks, which are specifically designed for short-distance hauling, are used to move cargo between ports, rail terminals, warehouses, and other local facilities. In some cases, drayage may also involve the use of specialized equipment, such as chassis or gensets, to accommodate specific cargo requirements.

Distance Covered

One of the most significant differences between freight and drayage lies in the distance covered during transportation. Freight services can involve long-distance shipping, spanning hundreds or even thousands of miles, across states, countries, or continents. Long-haul freight transportation is common for moving goods between major cities, distribution centers, or international trade routes.

Drayage, in comparison, focuses on short-distance transportation, typically within a radius of 50 to 100 miles from the origin. The primary purpose of drayage is to facilitate the movement of cargo between nearby locations, such as from a port to a local warehouse or from a rail terminal to a distribution center. Drayage trips are usually completed within a day, with drivers making multiple runs between facilities.

| Key Aspect | Freight | Drayage |

|---|---|---|

| Scope | Local, national, and international | Limited to specific geographical areas |

| Transport Types | Trucks, trains, ships, planes | Primarily trucking |

| Distance Covered | Long-distance, spanning hundreds or thousands of miles | Short-distance, typically within a 50-100 mile radius |

Understanding the differences between freight and drayage is crucial for businesses to make informed decisions when planning their transportation strategies. By leveraging the strengths of each service and optimizing their use based on specific requirements, companies can enhance their supply chain efficiency and effectively manage their shipping needs.

What are the various types of drayage services, and in what scenarios are they utilized?

Drayage services can be classified into several types, each catering to specific scenarios and requirements within the intermodal transportation chain. Understanding these different types of drayage helps businesses select the most appropriate service for their needs.

Port Drayage

Port drayage involves the transportation of cargo containers between a port and a nearby inland location, such as a warehouse or distribution center. This type of drayage is crucial for the efficient movement of goods from ships to the next stage of the supply chain. Port drayage trucks are equipped with specialized chassis to securely transport containers and must adhere to strict regulations and security measures.

Scenario: A container ship arrives at a seaport with imported goods. Port drayage trucks pick up the containers and transport them to a nearby warehouse for sorting and distribution.

Rail Drayage

Rail drayage refers to the transportation of cargo between a rail terminal and a nearby location, such as a warehouse or distribution center. This service facilitates the seamless transfer of goods between rail and road transport modes. Rail drayage trucks are designed to handle the unique requirements of loading and unloading containers from rail cars.

Scenario: A rail carrier delivers a shipment of automotive parts to a rail terminal. Rail drayage trucks pick up the containers and transport them to a nearby manufacturing facility for assembly.

Intermodal Drayage

Intermodal drayage involves the transportation of cargo containers between different modes of transport, such as ships, trains, and trucks. This type of drayage is essential for facilitating the smooth flow of goods across the intermodal transportation network. Intermodal drayage providers are well-versed in the specific requirements and regulations associated with each mode of transport.

Scenario: A shipper needs to transport goods from a factory to a distant distribution center. Intermodal drayage moves the cargo from the factory to a rail terminal, where it is loaded onto a train for long-distance transport. At the destination rail terminal, another drayage truck picks up the container and delivers it to the distribution center.

Shuttle Drayage

Shuttle drayage involves the transportation of cargo containers between two nearby locations, such as two warehouses or distribution centers within the same metropolitan area. This type of drayage helps optimize the utilization of containers and equipment by facilitating their quick repositioning.

Scenario: A retailer needs to transfer inventory from one distribution center to another to fulfill customer orders. Shuttle drayage trucks move the containers between the two facilities, ensuring a continuous supply of goods.

Expedited Drayage

Expedited drayage is a time-sensitive service that prioritizes the rapid transportation of cargo containers. This type of drayage is often used for urgent shipments or when there are tight deadlines to meet. Expedited drayage providers offer fast turnaround times and dedicated resources to ensure prompt delivery.

Scenario: A manufacturer urgently needs a shipment of raw materials to prevent a production line shutdown. Expedited drayage is used to quickly transport the container from the port to the manufacturing facility, minimizing downtime.

By understanding the different types of drayage services and the scenarios in which they are utilized, businesses can make informed decisions when selecting the most suitable drayage solution for their specific needs. This knowledge helps optimize supply chain efficiency, reduce costs, and ensure the timely delivery of goods.

How does drayage impact the overall supply chain efficiency?

Drayage plays a critical role in the overall efficiency of the supply chain, as it serves as a vital link between different modes of transportation and facilitates the smooth flow of goods. The impact of drayage on supply chain efficiency can be observed in several key areas.

Seamless Intermodal Connectivity

Drayage enables seamless connectivity between various modes of transport, such as ships, trains, and trucks. By providing efficient and reliable transportation services between ports, rail terminals, and inland locations, drayage ensures that cargo moves smoothly through the intermodal network. This seamless connectivity reduces delays, minimizes handling, and improves the overall speed and reliability of the supply chain.

Reduced Congestion and Improved Throughput

Efficient drayage operations help alleviate congestion at ports and terminals by quickly moving containers to inland locations. By promptly picking up and delivering containers, drayage services prevent the accumulation of cargo at these facilities, which can lead to bottlenecks and delays. This, in turn, improves the throughput of ports and terminals, allowing them to handle higher volumes of cargo more effectively.

Optimized Inventory Management

Drayage plays a crucial role in optimizing inventory management by ensuring the timely delivery of goods to warehouses and distribution centers. Reliable drayage services enable businesses to maintain lean inventories, reducing the need for excessive safety stock and minimizing storage costs. By delivering goods promptly, drayage helps businesses respond quickly to changes in demand and maintain a responsive and agile supply chain.

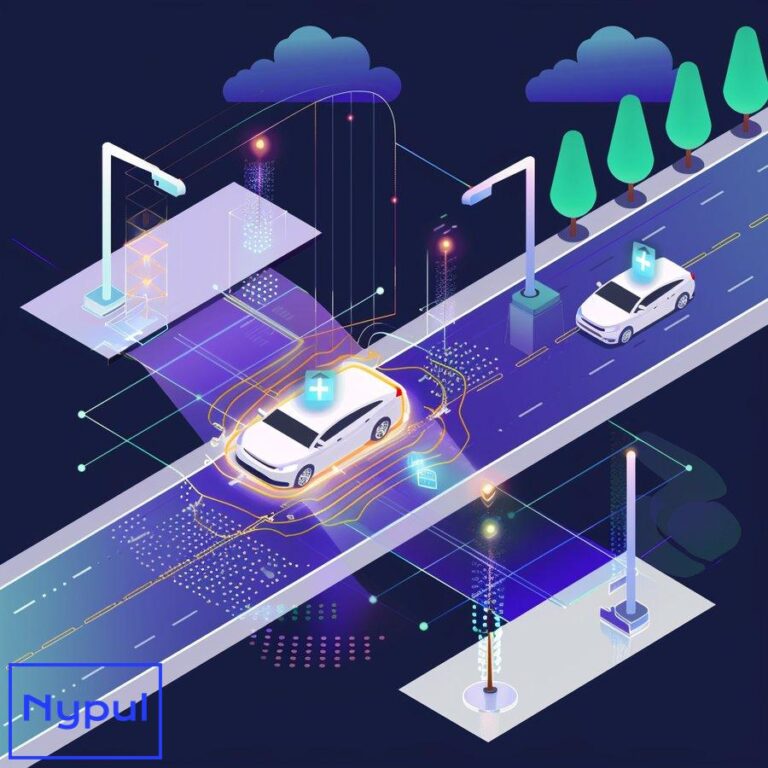

Enhanced Visibility and Tracking

Modern drayage providers often employ advanced technologies, such as GPS tracking and real-time monitoring systems, to provide enhanced visibility into the movement of cargo. This increased transparency allows businesses to track their shipments accurately, monitor progress, and proactively address any issues that may arise. Enhanced visibility improves supply chain efficiency by enabling better decision-making, facilitating communication between stakeholders, and reducing the risk of delays or lost cargo.

Flexibility and Scalability

Drayage services offer flexibility and scalability to businesses, allowing them to adapt to fluctuations in demand and changing market conditions. Drayage providers can quickly adjust their operations to accommodate peak seasons, sudden spikes in volume, or changes in shipping routes. This flexibility ensures that the supply chain remains responsive and efficient, even in the face of dynamic business environments.

Cost Optimization

Efficient drayage operations contribute to cost optimization in the supply chain by reducing transportation expenses and minimizing the risk of delays or disruptions. By leveraging the expertise and resources of drayage providers, businesses can avoid the need to invest in their own fleet of trucks and equipment. Additionally, drayage providers can optimize routes, consolidate shipments, and utilize backhaul opportunities to reduce empty miles and improve overall cost-efficiency.

| Impact Area | Key Benefits |

|---|---|

| Seamless Intermodal Connectivity | Reduces delays, improves speed and reliability |

| Reduced Congestion and Improved Throughput | Alleviates bottlenecks, increases port and terminal efficiency |

| Optimized Inventory Management | Enables lean inventories, reduces storage costs, improves responsiveness |

| Enhanced Visibility and Tracking | Facilitates better decision-making, reduces risk of delays or lost cargo |

| Flexibility and Scalability | Allows adaptation to fluctuations in demand and changing market conditions |

| Cost Optimization | Reduces transportation expenses, minimizes risk of delays or disruptions |

By understanding the impact of drayage on supply chain efficiency, businesses can make strategic decisions to optimize their transportation networks, streamline operations, and improve overall performance. Investing in reliable and efficient drayage services can lead to significant benefits in terms of cost savings, customer satisfaction, and competitive advantage.

What are the cost considerations when choosing between freight and drayage services?

When deciding between freight and drayage services, businesses must carefully evaluate the cost considerations to ensure they select the most cost-effective solution that meets their transportation needs. Several factors influence the costs associated with freight and drayage services.

Distance and Mode of Transport

The distance covered and the mode of transport significantly impact the cost of freight services. Long-distance shipping, especially when using multiple modes of transport, such as trucks, trains, and ships, can be more expensive than short-distance drayage. However, for shorter distances, drayage services may be more cost-effective, as they specialize in local transportation and can optimize routes and resources accordingly.

Volume and Frequency of Shipments

The volume and frequency of shipments play a crucial role in determining the cost of freight and drayage services. Freight services often offer economies of scale, where larger shipment volumes can lead to lower per-unit transportation costs. Businesses with consistent, high-volume shipping needs may benefit from negotiating favorable rates with freight carriers. On the other hand, drayage services may be more cost-effective for smaller, less frequent shipments, as they can consolidate loads and optimize equipment utilization.

Fuel Costs and Surcharges

Fuel costs and surcharges are important considerations when evaluating the cost of freight and drayage services. Fluctuations in fuel prices can significantly impact transportation costs, and carriers often pass these costs on to shippers through fuel surcharges. Drayage services, which typically involve shorter distances and less fuel consumption, may be less susceptible to fuel price volatility compared to long-distance freight services.

Equipment and Specialized Services

The type of equipment required and any specialized services needed can affect the cost of freight and drayage services. Freight services may involve the use of various equipment types, such as dry vans, flatbeds, or refrigerated trailers, each with different cost implications. Similarly, drayage services may require specialized equipment, such as chassis or gensets, to handle specific cargo requirements. Businesses should consider the cost of these specialized services when comparing freight and drayage options.

Accessorial Charges and Additional Fees

Accessorial charges and additional fees can significantly impact the total cost of freight and drayage services. These charges may include detention fees for delays at loading or unloading points, demurragefees for extended container storage, or handling charges for special cargo requirements. Drayage services may have lower accessorial charges due to their focus on short-distance transportation and faster turnaround times. However, businesses should carefully review the terms and conditions of both freight and drayage contracts to identify any potential additional costs.

Inventory Carrying Costs

Inventory carrying costs are an indirect but important consideration when choosing between freight and drayage services. Longer transit times associated with freight services may result in higher inventory carrying costs, as businesses need to maintain larger safety stocks to accommodate potential delays. Drayage services, with their shorter transit times and faster delivery, can help reduce inventory carrying costs by enabling more responsive and agile supply chain operations.

Technology and Visibility

The technology and visibility offered by freight and drayage providers can impact the overall cost and efficiency of transportation. Providers with advanced tracking systems, real-time monitoring, and electronic documentation can help businesses optimize their supply chain, reduce manual processes, and minimize the risk of errors or delays. While these technology solutions may come at an additional cost, they can ultimately lead to cost savings through improved efficiency and reduced disruptions.

| Cost Factor | Freight Considerations | Drayage Considerations |

|---|---|---|

| Distance and Mode of Transport | Long-distance, multi-modal transport can be more expensive | Short-distance, local transportation can be more cost-effective |

| Volume and Frequency of Shipments | Economies of scale for larger, consistent volumes | Cost-effective for smaller, less frequent shipments |

| Fuel Costs and Surcharges | More susceptible to fuel price volatility | Less impacted by fuel price fluctuations |

| Equipment and Specialized Services | Various equipment types and specialized services available | Specialized equipment and services for specific cargo requirements |

| Accessorial Charges and Additional Fees | Potential for higher accessorial charges and additional fees | Generally lower accessorial charges due to faster turnaround times |

| Inventory Carrying Costs | Longer transit times may result in higher inventory carrying costs | Shorter transit times and faster delivery can reduce inventory carrying costs |

| Technology and Visibility | Advanced tracking, monitoring, and documentation can optimize efficiency | Technology solutions can improve visibility and reduce disruptions |

When evaluating the cost considerations between freight and drayage services, businesses should take a holistic approach that considers both direct transportation costs and indirect costs such as inventory carrying costs and the impact of technology on efficiency. By carefully analyzing these factors and aligning them with their specific transportation needs and supply chain goals, businesses can make informed decisions that optimize cost-effectiveness and overall performance.